ECturn

2

Contents

1 Symbols and means of representation............................................................................................................3

2 Product liability ........................................................................................................................................................3

3 Safety ...........................................................................................................................................................................3

3.1 Intended use.......................................................................................................................................................................................................3

3.2 Safety instructions ...........................................................................................................................................................................................4

3.3 Safety-conscious working.............................................................................................................................................................................4

3.4 Inspection of the mounted system............................................................................................................................................................4

3.5 Additionally applicable documents ..........................................................................................................................................................4

4 Transportation and storage .................................................................................................................................5

5 Tools and aids ...........................................................................................................................................................5

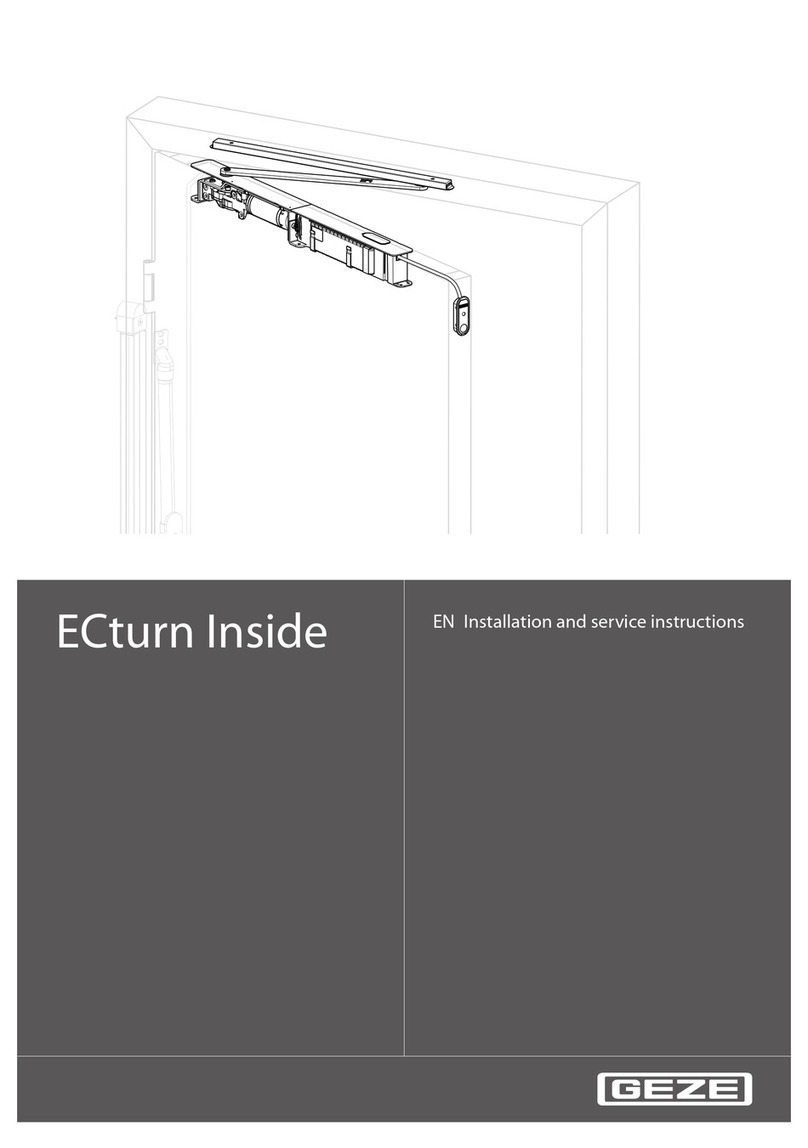

6 Product description ................................................................................................................................................5

6.1 System description and technical data ....................................................................................................................................................5

6.2 Basic structure and extension......................................................................................................................................................................6

7 Types of mounting, stops .....................................................................................................................................8

8 Mounting ...................................................................................................................................................................9

8.1 General information for mounting ............................................................................................................................................................9

8.2 Mounting dimensions for the types of mounting ............................................................................................................................ 10

8.3 Mounting the drive....................................................................................................................................................................................... 16

8.4 Mounting the guide rail .............................................................................................................................................................................. 16

8.5 Mounting the link arm................................................................................................................................................................................. 16

8.6 Door stop limiting ..........................................................................................................................................................................................17

8.7 Mounting and connecting the battery ..................................................................................................................................................17

8.8 Mounting the door transmission cable (optional) .............................................................................................................................18

8.9 Mounting the hood (optional)...................................................................................................................................................................19

8.10 Mounting the actuation sensors...............................................................................................................................................................19

8.11 Mounting the radio circuit board (optional) ........................................................................................................................................19

9 Electrical connection............................................................................................................................................19

9.1 Mains connection...........................................................................................................................................................................................19

10 Maintenance........................................................................................................................................................... 21

10.1 Dangers during mechanical service....................................................................................................................................................... 21

10.2 Maintenance work......................................................................................................................................................................................... 21

10.3 Electrical servicing ........................................................................................................................................................................................ 21

10.4 Electrical faults................................................................................................................................................................................................ 22

11 Disposal.................................................................................................................................................................... 22