2

Table of Contents

Contents Pa e

1. Introduction …………………………………………………… 3

2. Important Safety Instructions………………………………….. 3

3. Installation Safe uards ……………………………………….. 4

4. General Safe uards……………………………………………. 5

5. Operatin Conditions …………………………………………. 6

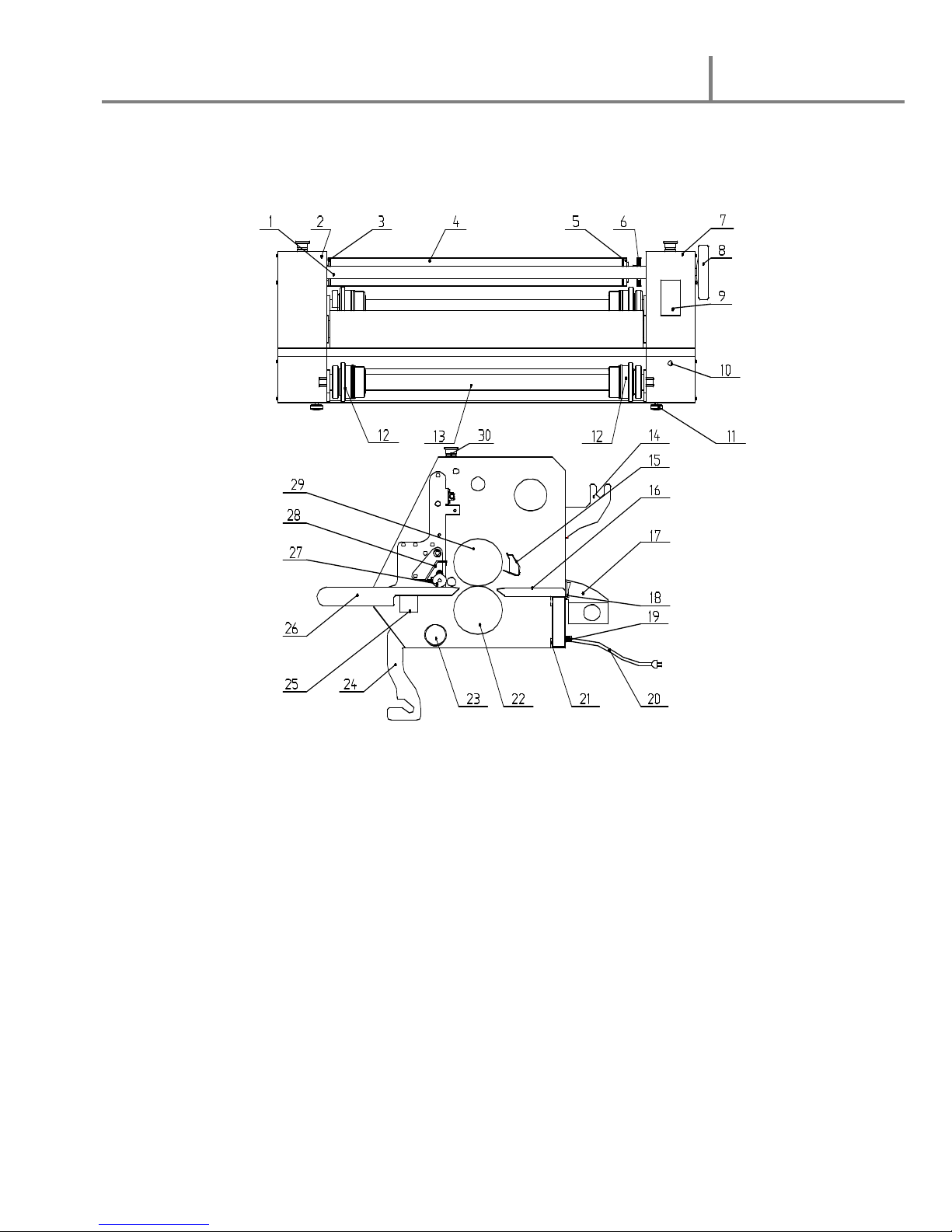

6. System Components ………………………………………….. 7

7. Control Panel …………………………………………………. 8

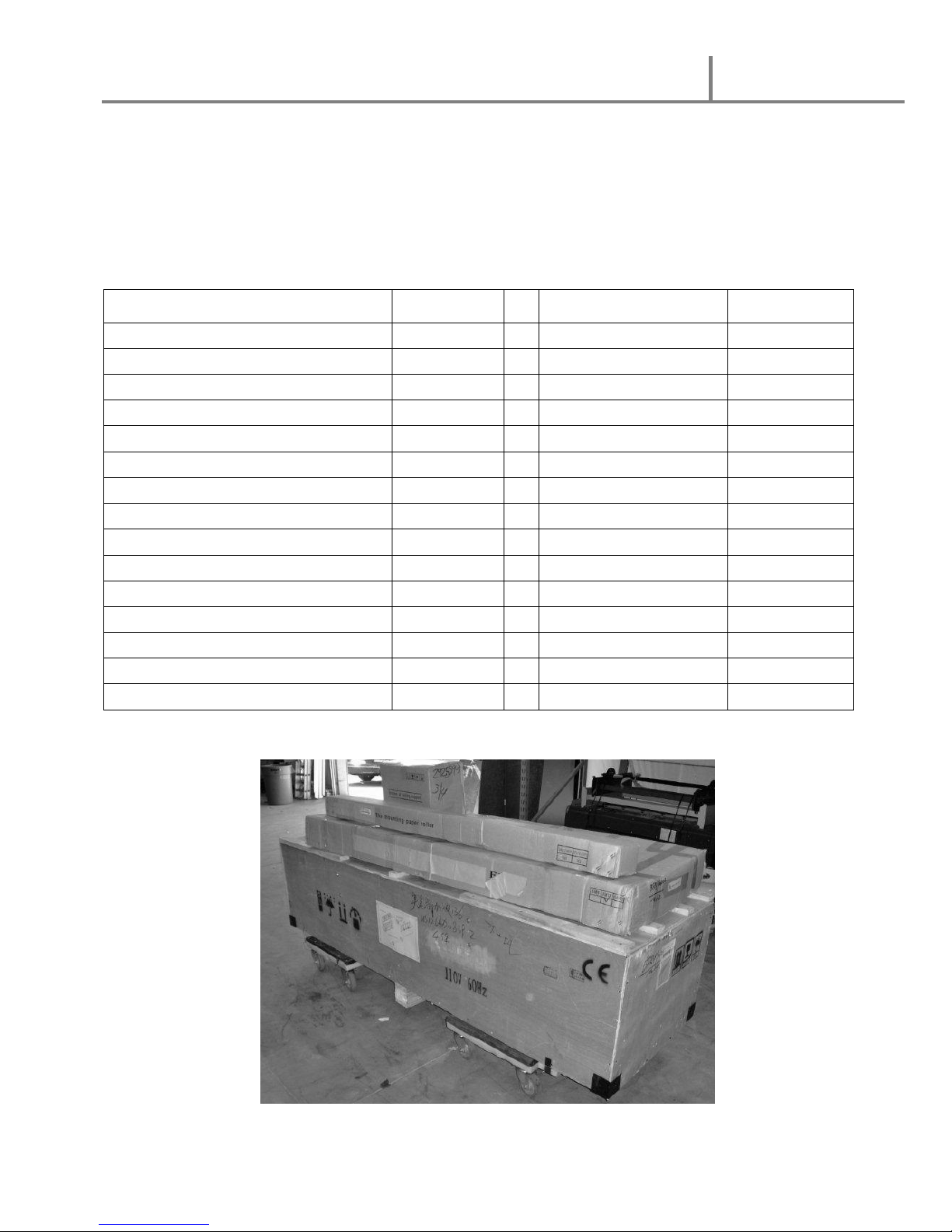

8. Packin List ………………………………………………… .. 9

9. Installation

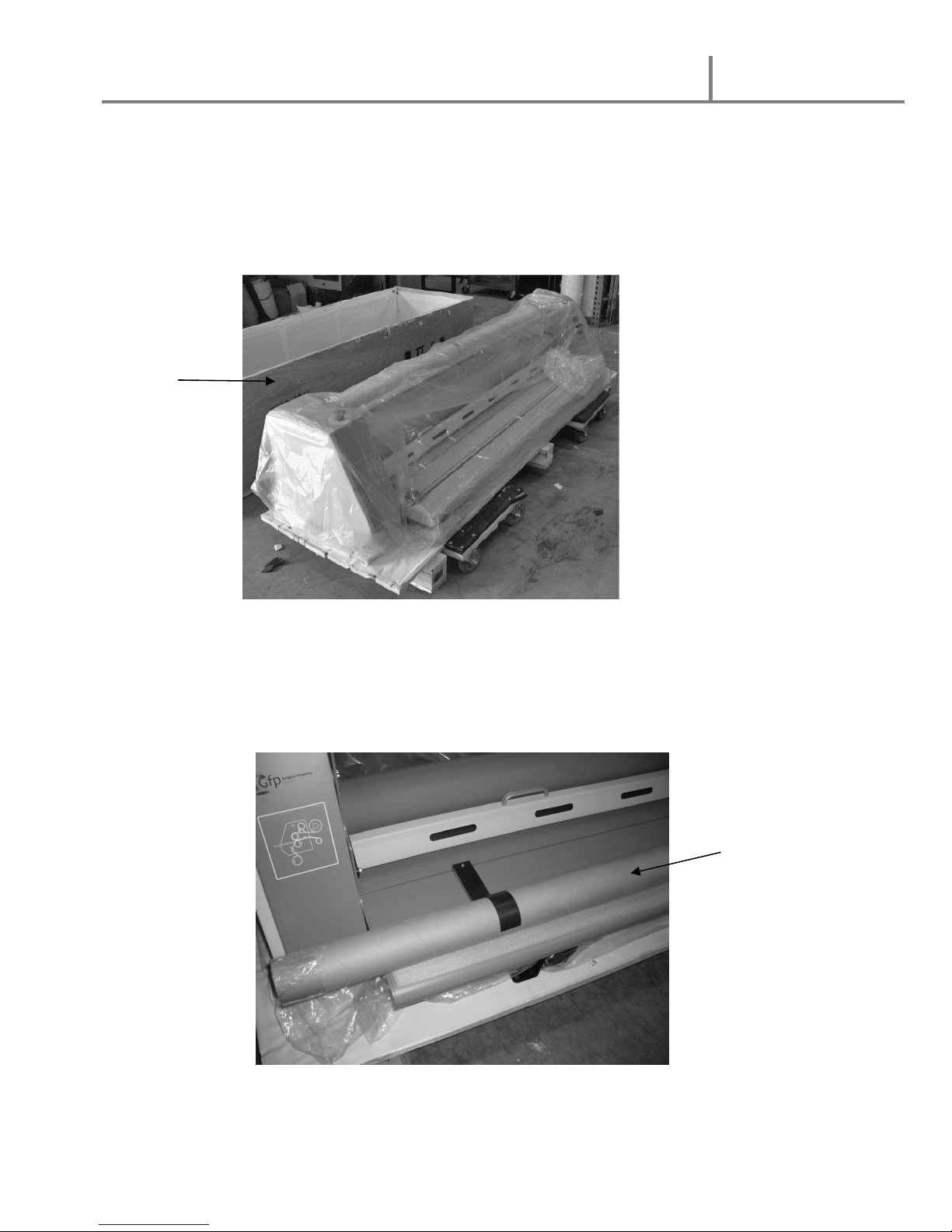

A. Uncrate the machine……………………………………. 10

B. Remove heat tube packa e……………………………... 10

C. Remove machine from Skid……………………………. 11

D. Assemble machine stand……………………………….. 12

E. Set Machine on stand…………………………………... 13

F. Attach supply support brackets………………………… 14

10. Installin heat tube

A. Insert heat tube…. .…………………………………….. 15

B. Connect electric wires..………………………………… 16

11. Installin Take up Reel ……………………………………….. 17

12. Additional installation items …………………………………. 18

13. Removin Press roller assembly……………………………… 18

14. Loadin film ………………………………………………….. 19

15. Threadin Film ……………………………………………….. 20

16. Operation ……………………………………………………... 21

17. Roller Gap………….. ………………………………………… 21

18. Roller Gap adjustment…………………………………………. 22

19. Optional Rewind ……………………………………………… 23

20. Troubleshootin ………………………………………………. 24

21. Specifications …………………………………………………. 25

22. Warranty ………………………………………………………. 26