Gfp 865DH-4

March 2021

2

Table of Contents

Contents Page

1. Introduction ……………………………………………………..

2. Important Safety Instructions…………………………………….

3. Installation Safeguards ………………………………………….

4. General Safeguards………………………………………………

5. Operating Conditions …………………………………………….

6. Electrical Requirements………………………………………….

7. Packing List………………………………………………………..

8. Installation

A. Uncrate the Machine……………………………………….

B. Remove Heat Tube Package…………………………………

C. Remove Machine from Skid……………………………….

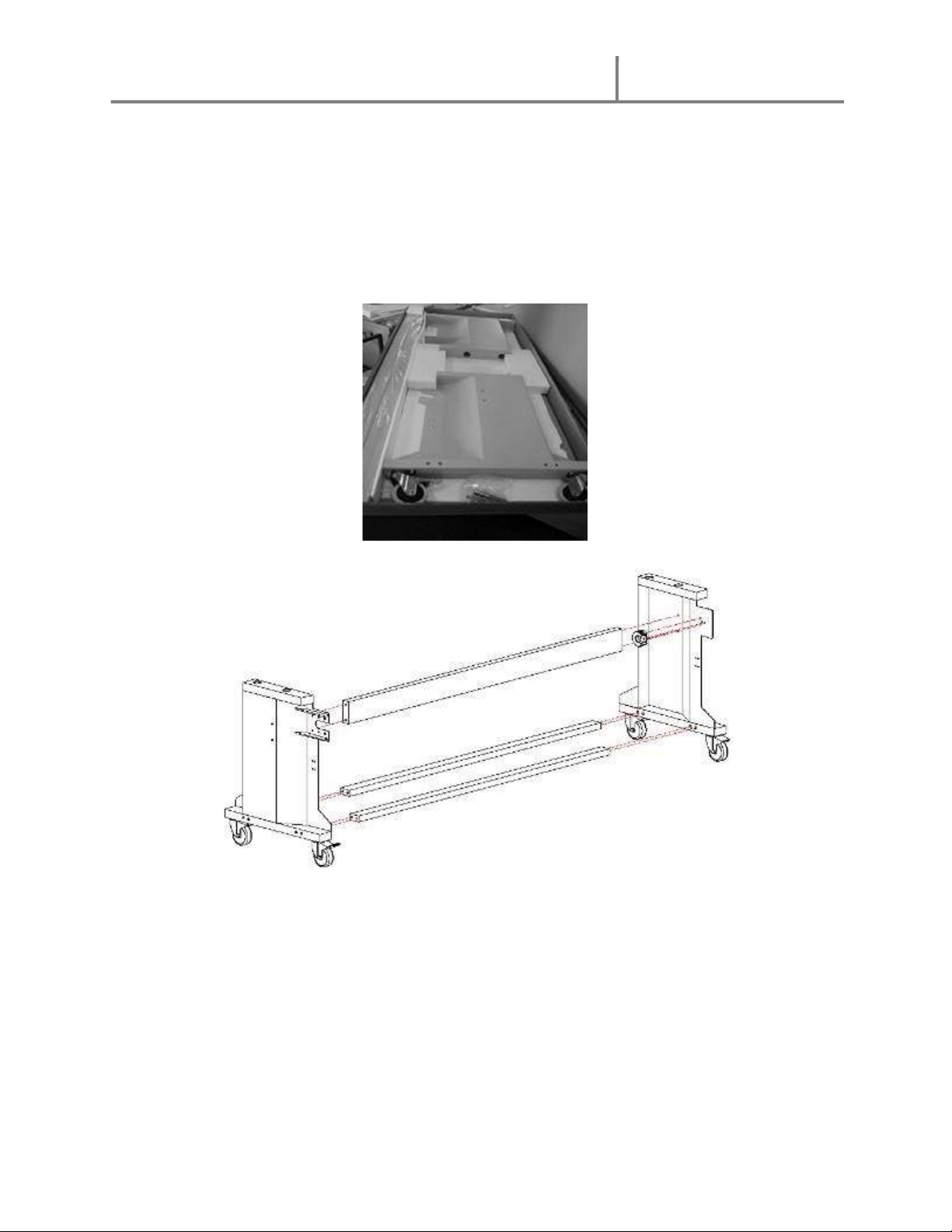

D. Assemble Machine Stand…………………………………..

E. Attach the Lower Supply Shaft Assembly

F. Set Machine on Stand…………………………………….…

G. Align machine to Stand…………………………………….

H. Install Front Media Unwind Shaft…………………………..

9. Installing the Heat Tubes

A. Inserting the Heat Tubes……………………………………….

B. Connecting the Electric Wires……………………………

10. Installing the Lower Rear Rewind ………………………………

11. Additional Installation Items …………………………………….

12. System Components………………..……………………………

13. Control Panel……………………………………………………..

14. Operation…. …………………………………………………….

15. Removing the Print Hold Down Assembly……………………….

16. Loading Film………………………………………………….…

17. Threading Film

A. Cold PSA Film…………………………………………….

B. Thermal Film Threading……………………………….…

C. Front Media Unwind…………………………………………..

18. Roller Pressure Adjustment..……………………………………..

19. Roller Gap Adjustment……………………………………………

20. Pull Roller Clutch Adjustment.……………………………………

21. Installing the Rear Rewind..………………………………….….

22. Troubleshooting

A. The Machine………………………………………….…….

B. Thermal Film Output…..…………………………….……

23. Specifications ……………………………………………………

24. Warranty …………………………………………………………

3

3

4

5

6

6

7

8

8

9

10

11

12

13

14

15

16

17

17

18

19

20

21

21

23

24

25

26

27

27

29

30

31

34