Gilson Economy 8in Sieve Shaker: SS-15

[Type here] [Type here] [Type here]

(H is for hours, M for minutes, and S for seconds.)

Toadjust the timer mode, press and hold both <UP>

and <DOWN> keys at the sametime until thedisplay

showsthemode.Oncethemodelettersaredisplayed,

press <UP> or <DOWN> to change modes. Press

<START/STOP> to accept new mode.

To set the run time, press either <UP> or <DOWN>.

Thefirstdigitontherighthandwillflashinhalf-second

intervals. Press either arrow key to adjust to the de-

sired value. To enter the displayed digit and move

to the next, press <START/STOP>. Once the last

digit on the left is entered, the timer is ready to start.

Press <START/STOP> to initiate the current run

program. Once running, pressing <START/STOP>

again will pause the timer with the current amount of

time remaining on screen. When allowed to time-

out, the timer beeps and displays DONE. Press any

key to continue. Setting and Mode values are saved

automatically.

Before performing maintenance or repairs on the sieve

shaker,ALWAYSreadandunderstandthesafety,operat-

ing, and maintenance instructions.

ALWAYS disconnect the SS-15 from its power before

performingmaintenance orrepair.TheSS-15'smotorhas

internal thermal protection which may cause it to restart

automatically.

Send back your unit's registration card. This card regis-

ters the serial number in Gilson's master file and assures

supply of proper parts when service is required. Provide

thisserialnumberwheneverorderingreplacementparts.

3.1

Cleaning the Unit:

3.1.1

Clean the unit AT LEAST once a year. It is de-

signedtogiveconsistentresults.Dirtcanaffecttest

results. An appropriate cleaning schedule for your

unit depends on the frequency of use, exposure to

dirt, and sample makeup.

3.1.2

Clean beneath the unit at least annually. Takecare

not to introduce cleaning agents into the timer or

the motor. If a thorough cleaning is required, the

motor and timermustfirstberemoved. See below.

3.1.3

To perform maintenance or repairs, or to inspect

the internal parts of the SS-15, place the unit on

either of its sides or on its back as appropriate.

Make sure to prop up the machine as necessary

to avoid damage to the power cord or platform.

3.2

Drive Belt:

3.2.1

Periodically check drive belt for wear, tension, and

alignment. A worn, loose, tight, or misaligned drive

beltcanaffecttheoperationofyourSS-15.Thebelt

should be snug: neither too tight nor too loose. A

snug fit assures longer life, less bearing wear, and

quieter operation than a belt which is too tight. A

loosebeltmaycause the unit to run tooslowlyorto

slip. The drive belt should deflect 1/64 of the value

of the space of the pulleys. The pulleys should be

aligned to avoid excessive edge wear on thebelt.

3.2.2

Toadjust or replace the belt, lay the unit on its left

side, making sure not to pinch the electrical cord.

Loosen the four Motor Mounting Bolts (#26) on the

topoftheoutercase(seePartsDiagram).Movethe

motor upordownto adjust tension inthedrivebelt.

Use a straight edge to maintain pulley alignment.

If you must adjust the belt past the end of the slots

to get proper snugness, replace the belt. NEVER

force or pry the belt over the pulley flanges.

3.3

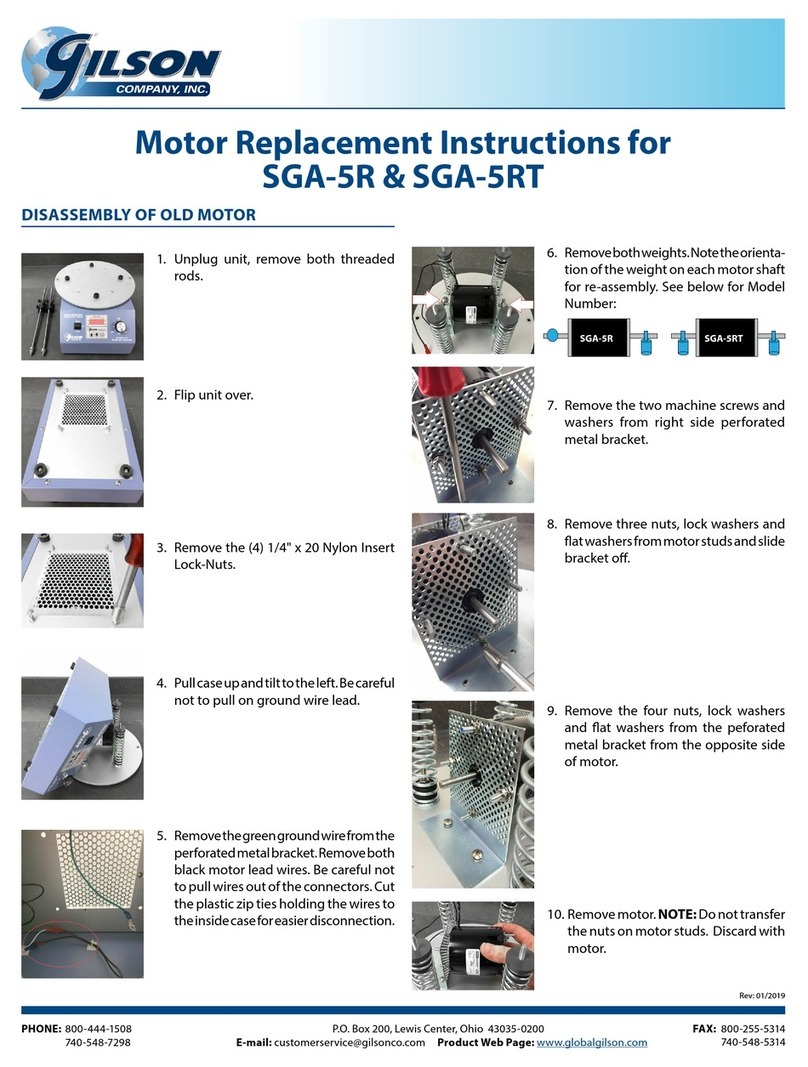

Motor:

3.3.1

Apply a few drops of oil to the motor and bearings

at least once a year.

3.3.2

Toremovethe motor,laythe uniton back or leftside

sothatit willfallaway from other internal parts when

the mounting bolts are removed. Remove the four

motor mounting bolts on top of the outer case. As

the motor loosens remove the drive belt. Remove

themotor terminal coverplate which is held with two

screwslocatedwherethepowerandtimercordsenter

the motor.

3.3.3

Disconnect the power and timer wire terminals,

notingwhereeachis attached,loosenthecordand

remove the wires from the motor terminal box. The

motor is now completely free. Remove motor belt

pulley by loosening the set screw.

3.3.4

Havethemotor cleaned oroverhauledbya trained

electric motor repair person. Replacement motors

are available from Gilson. To install the motor,

reversethestepsoftheproceduredescribedprevi-

ously. Make sure that both pulleys are aligned and

that the belt is properly tensioned.