Godex AG4000T User Manual Page 2of 42

1

Contents

1

Contents ....................................................................................................................................... 2

2

Introduction.................................................................................................................................. 4

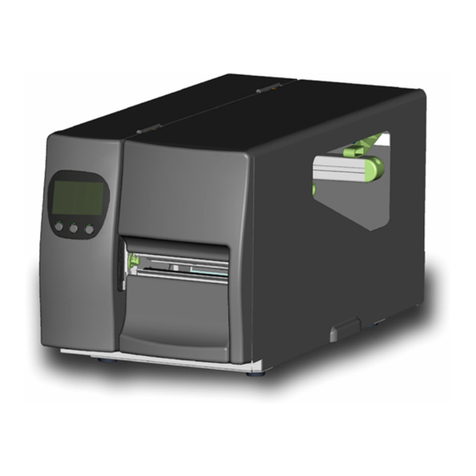

2.1 Overview................................................................................................................................ 4

2.2 Applicator Specifications Summarized............................................................................... 4

2.3 Dimensions AG4000T –400 mm............................................................................................ 5

2.4 Dimensions AG4000T –600 mm............................................................................................ 6

3

Basic Safety Precautions ............................................................................................................. 7

3.1 Coverage .............................................................................................................................. 7

3.2 Following the instructions in this operating manual ............................................................. 7

3.3 Possible device handlingrisks ............................................................................................... 7

3.4 Environmental conditions of the device operation ............................................................ 7

3.5 Occupational health and safety rules ................................................................................. 8

3.6 Safety instructions.................................................................................................................. 8

3.7 Never:..................................................................................................................................... 9

3.8 Applied harmonized standards and the safe use of electrical appliances..................... 9

3.9 The possible risks of electric shocks if working with the applicator.................................. 10

3.10 Configuring the pneumatic unit,safety ...................................................................... 10

4

Contents of delivery - what’s in thebox? ................................................................................. 11

4.1 Standard configuration with 250 mm effective stroke ..................................................... 11

4.2 Checking the box contents (AG-4000-400001) ................................................................ 11

4.2.1 Box 1: Printer + Accessories .......................................................................................... 11

4.2.2 Box 2: Applicator unit components............................................................................. 12

4.2.3 Box 3: Stand components ............................................................................................ 13

5

Assembling the system.............................................................................................................. 14

5.1 Required Tools ..................................................................................................................... 14

5.2 Assembling the stand .......................................................................................................... 14

5.3 Installing the internal rewinder and GPIO card in the printer .......................................... 17

5.4 Installing the label dispensing edge ................................................................................. 20

5.5 Assembling the applicator unit .......................................................................................... 22

6

Applicator unit adjustments. Fine tuning. ................................................................................ 24

6.1 Adjusting the applicator head distance from the dispensing edge .............................. 24

6.2 Adjusting the applicator head vertical resting position................................................... 25

6.3 Adjusting the support air angle and pressure................................................................... 26

7

Operating your AG4000T........................................................................................................... 27

7.1 Print & apply cycle: the basics ........................................................................................... 27

7.2 Printer configuration for applicatoruse ............................................................................. 27

7.2.1 Power on the system..................................................................................................... 27