6

Component: 1-24VDC Lithium Ion Battery Pack (15AH or 6.5AH) - #1

Location: Center of the upper deck. See figure 2.

Function: Supply 24-29VDC to the motor and/or accessories.

Connections: Connected by two spr ing loaded connectors at the r ear

of the battery pack and a push-button latch at the front of the battery pack.

Failure Signs: Batter ies dr ain quickly. Scooter r uns slowly or not at all.

Batteries will not charge, but charger is working properly. Beep Code #1 or #2.

Tests: Fully charge the batter y pack first and load test. Make sur e the contacts

are not corroded.

Expected Reading: 24-29VDC when fully charged.

Serviceable: Replace batter y pack as necessary.

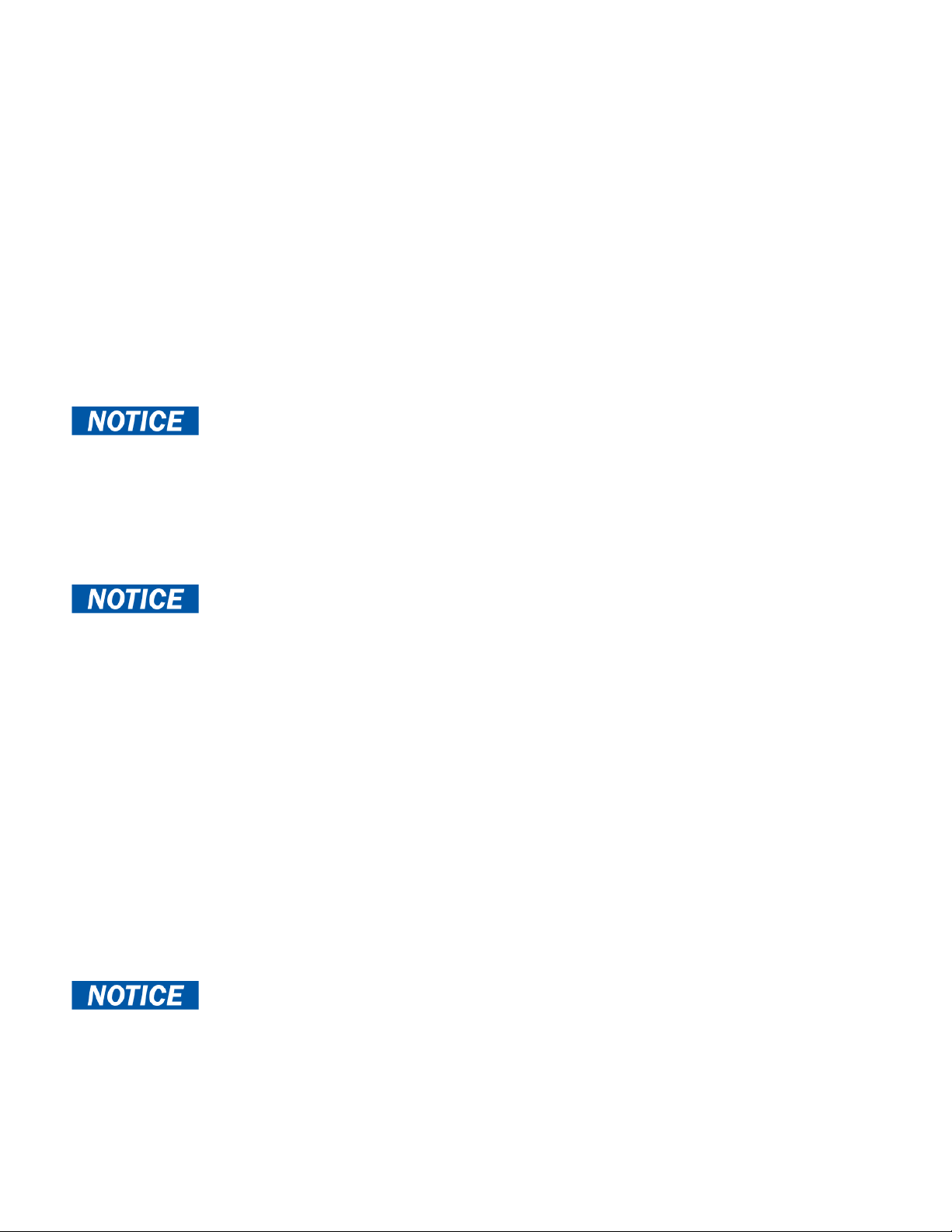

Component: Battery Harness - #2 Figure 2. Lithium Ion Battery Pack

Location: Inside the plastic upper/lower body halves.

Function: Connects the batter y (1) to the contr oller (4), and

the control board inside the scooter deck.

Provides short circuit protection through a 35-amp inline fuse,

located inside the controller cover.

Connections: Connected to the batter y (Bat -) and (Bat +),

controller (Bat -) and (Bat +), control board, and battery fuse.

Refer to the wiring diagram on page 11.

Failure Signs: Open fuse, cor r oded wir es, poor

connections, and poor spring tension can cause the battery

voltage (24-29 volts) not to be supplied to the entire electrical

system.

Make sure the fuse is good, and all connections are good.

Note: Battery pack will not charge if the inline fuse is blown.

Tests: Test the fuse for continuity. Test the har ness for

continuity. See figure 3. Refer to the wiring diagram on

page 11.

Expected Readings: Less than 10 ohms.

Serviceable: Replace the har ness as necessar y.

Replace inline fuse with exact type and rating. Refer to the

wiring diagram on page 11. Figure 3. Battery Harness

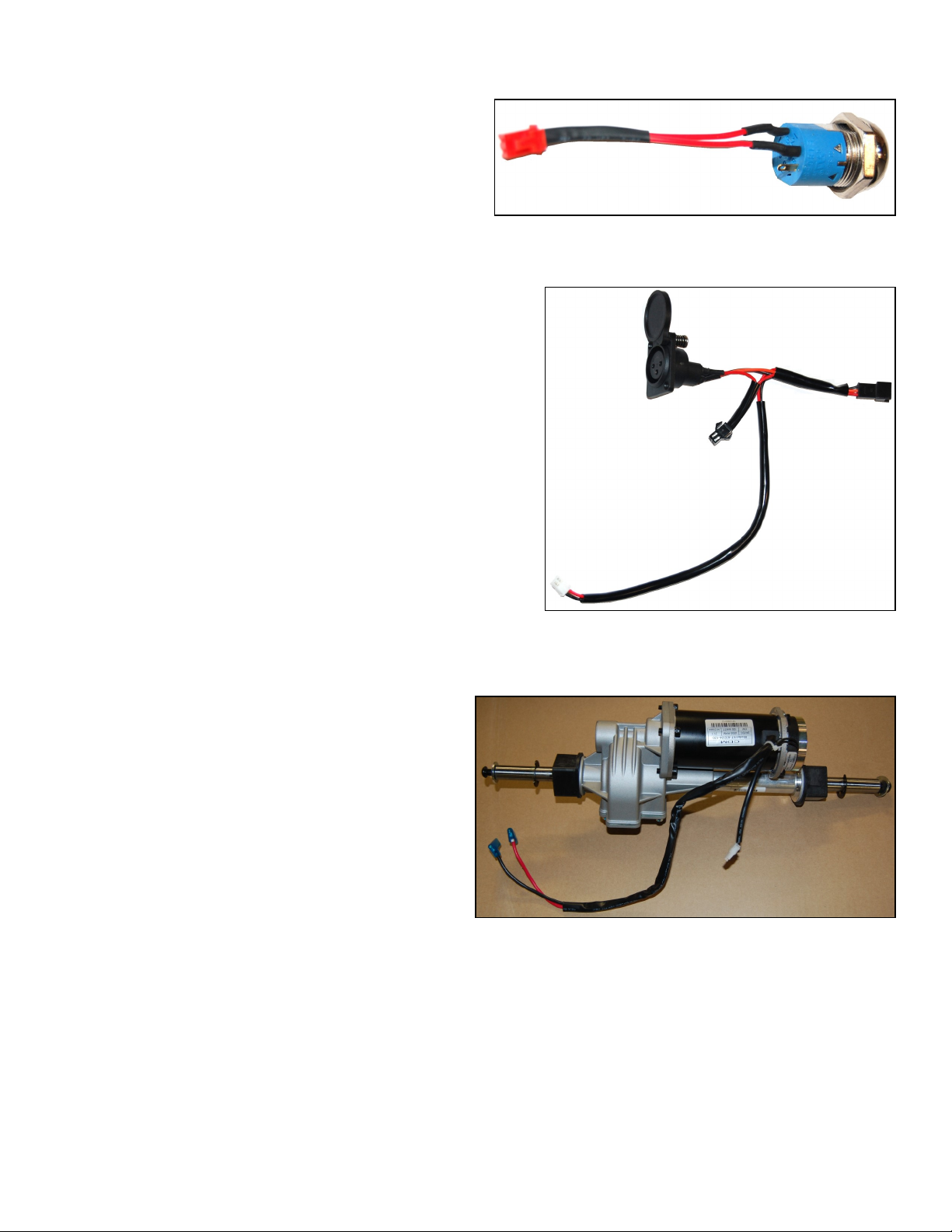

Component: Motor Harness - #3

Location: Rear of the scooter – Inside the plastic

upper/lower body halves. See figure 4. Refer to the

wiring diagram on page 11.

Function: Supplies 24-29 volts from the controller to

the motor.

Connections: Controller (M+) and (M-) and the motor.

See figure 4. Refer to the wir ing diagram on page 11.

Failure Signs: Scooter will not run. The motor is not

receiving the correct 24-29 volt battery voltage from the

controller.

Tests: Test har nesses for continuity. Check connectors.

Make sure the contacts are not corroded and are seated

properly.

Expected Readings: Continuity (less than 10 ohms). Figure 4. Motor Harness (hard wired into motor)

Serviceable: Replace as necessar y.