TAIYO ELECTRIC IND.CO.,LTD.

4TAIYO ELECTRIC IND.CO.,LTD.

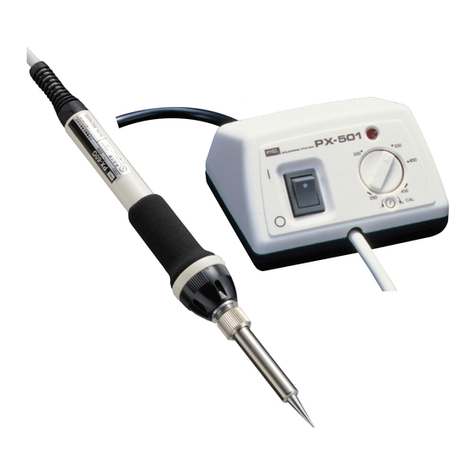

1. Exceptional heat recovery. (PAT.)

World-first tremendous heat recovery features

due to high-density 500W heater and its own

high-sensitivity sensor.

This next-generation high-wattage soldering

iron can be adapted to more purposes from a

conventional soldering iron.

2.

Grip is Light and Nimble

90% lighter than standard 500W sheet metal

irons. Will save your hands from repetitive

strain. The iron unit is designed to resist get-

ting too hot, greatly reducing the workload.

Can also be used to solder a power supply

substrate in addition to soldering of sheet

metal

3. Thick iron plating for lead-free soldering

All tips have a thick iron plating to slow ero-

sion caused by lead-free soldering.

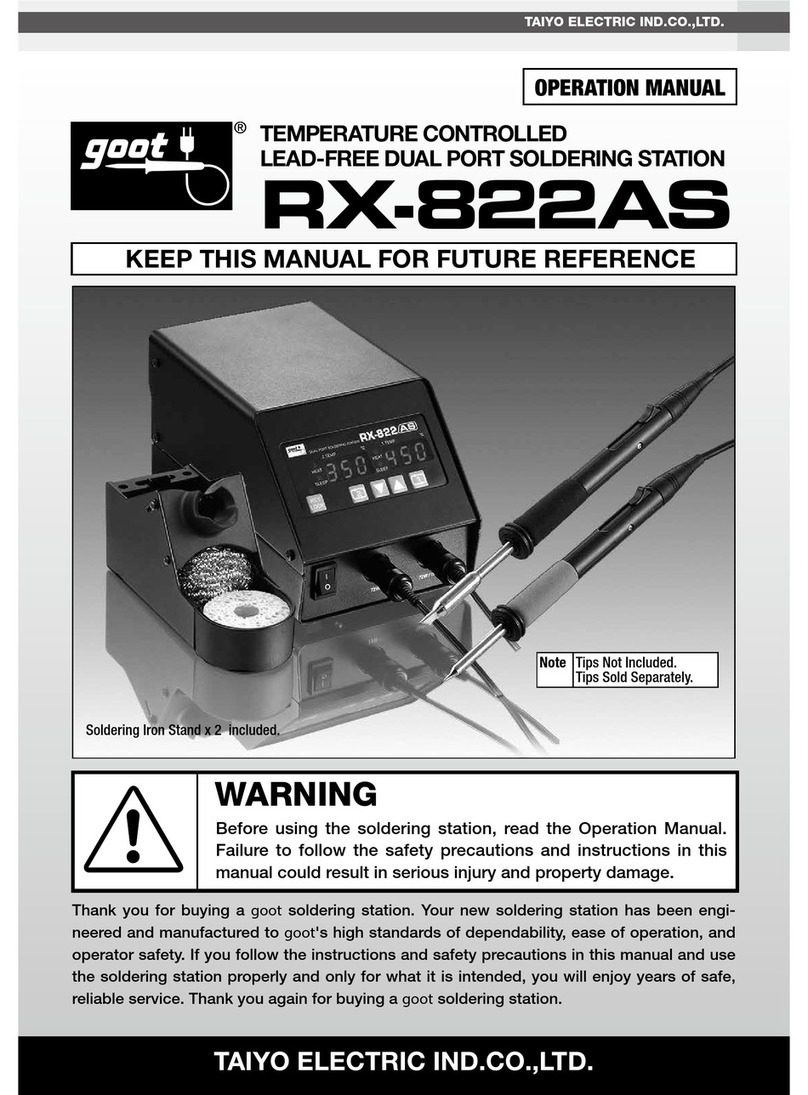

4. Key Lock function (PAT.)

Tamper-proof keypad lock using a password,

no tools or cards are needed.

5. Sleep function (PAT.)

The control unit automatically lowers the

temperature when inactive for a preset period

of time. This can also be done manually by

pressing and holding the ▼key for 1 second.

The sleep function can be used in conjunction

with the shutdown function.

6. Sleep function release (PAT.)

Sleep mode can be exited by touching touch-

ing the wet sponge with the tip to cause tem-

perature fluctuation.

Effective when sleep setting temperature is

greater than or equal to 100˚C

7. Alarm function (PAT.)

Prevents overheating of work.

When the soldering iron is left in contact with

the component being soldered past the time

set, this alarm sounds.

This function prevents inexperienced opera-

tors from overheating the component, helping

quality control.

8. Calibration function (PAT.)

The calibration function digitally offsets the

difference between the tip temperature and

the tip thermometer temperature.

9. Shutdown function

When the unit is not used for a preset time,

the unit enters shutdown mode automati-

cally, to prevent any unexpected accident.

Shutdown is released when turning the power

OFF and then ON again. Both the sleep func-

tion and the shutdown function can be used

together.

10. Multi-Voltage Inlet

Accepts a commercial power supply of

100V-240V. Inlet-type power cord is replace-

able. Can be used internationally.

2-1 Features of the RX-892AS

This machine is a heater-integrated lead-free soldering iron with realized heater output 500W

and temperature-controlled function. First in the world. Power comparable to large sheet metal

work, but from a small, lightweight iron unit.