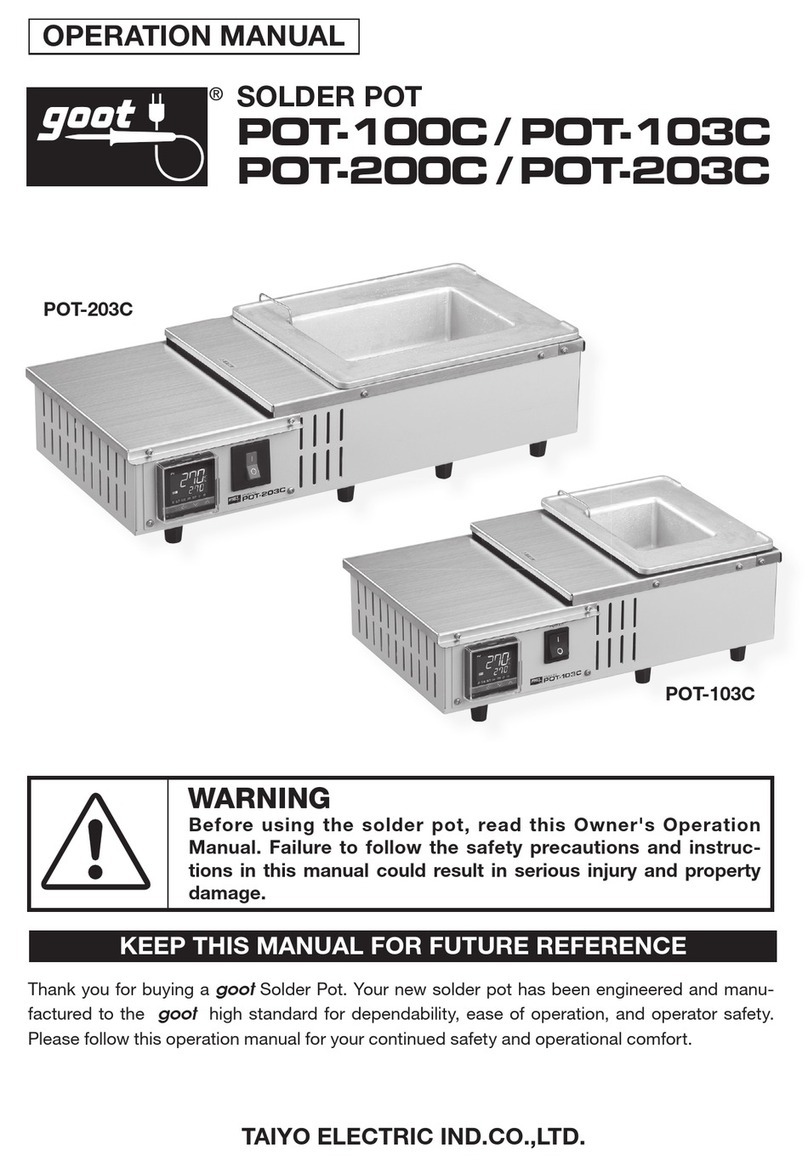

Thank you for buying a goot solder pot. Accurate PID temperature control, long life ceramic heater and solder bath material are

perfect for lead-free soldering.

KEEP THIS MANUAL FOR FUTURE REFERENCE

The safety signal words [WARNING] and [CAUTION] are defined below.

1. Table of Contents / Specifications

1. Table of Contents / Specifications...............................................................................................................................................1

2. Introduction.................................................................................................................................................................................1

2.1 Features ...............................................................................................................................................................................1

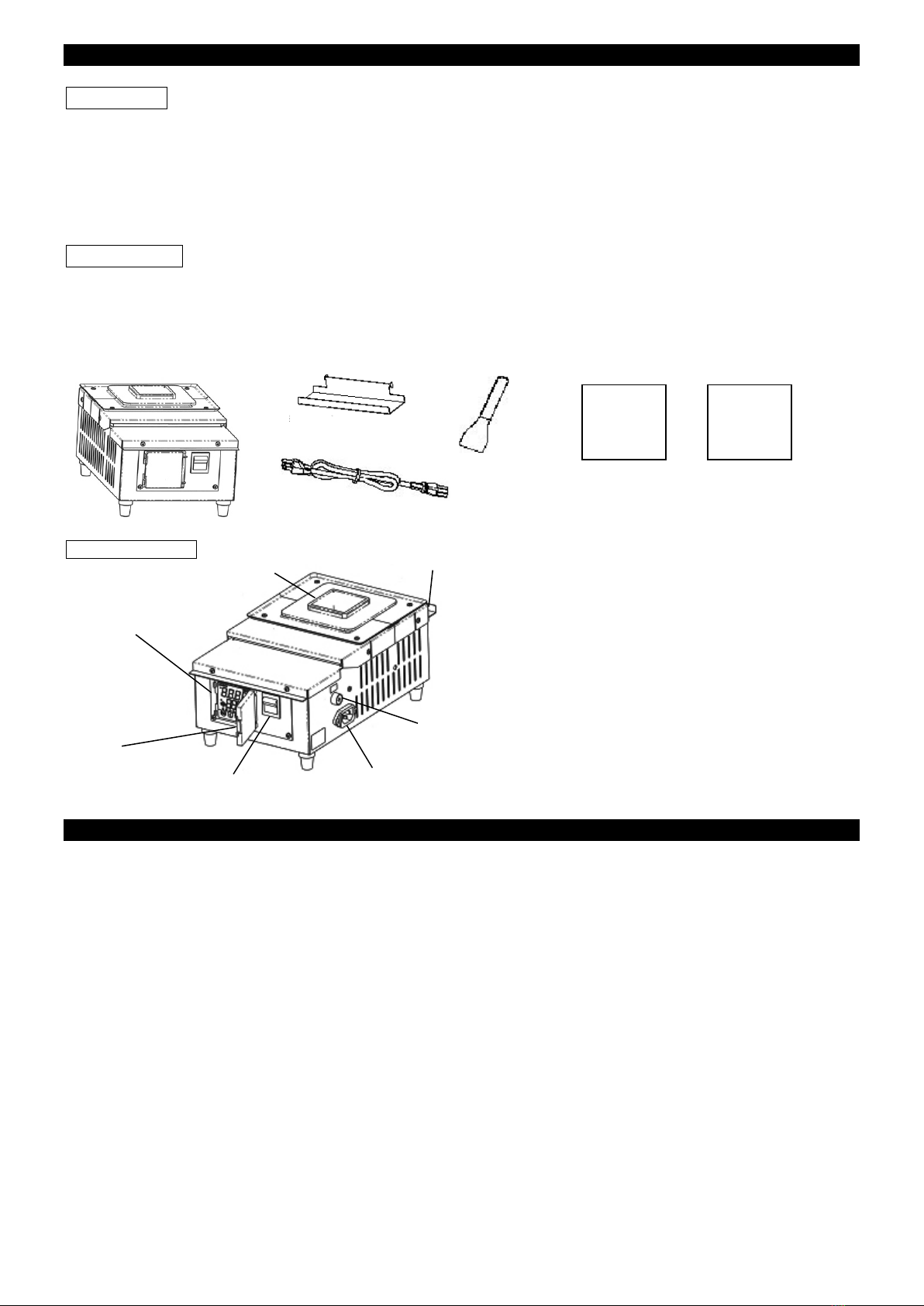

2.2 Unpacking.............................................................................................................................................................................1

3. Rules for Safe Operation ............................................................................................................................................................1

4. Operation Instructions.................................................................................................................................................................2

4.1 Set up...................................................................................................................................................................................2

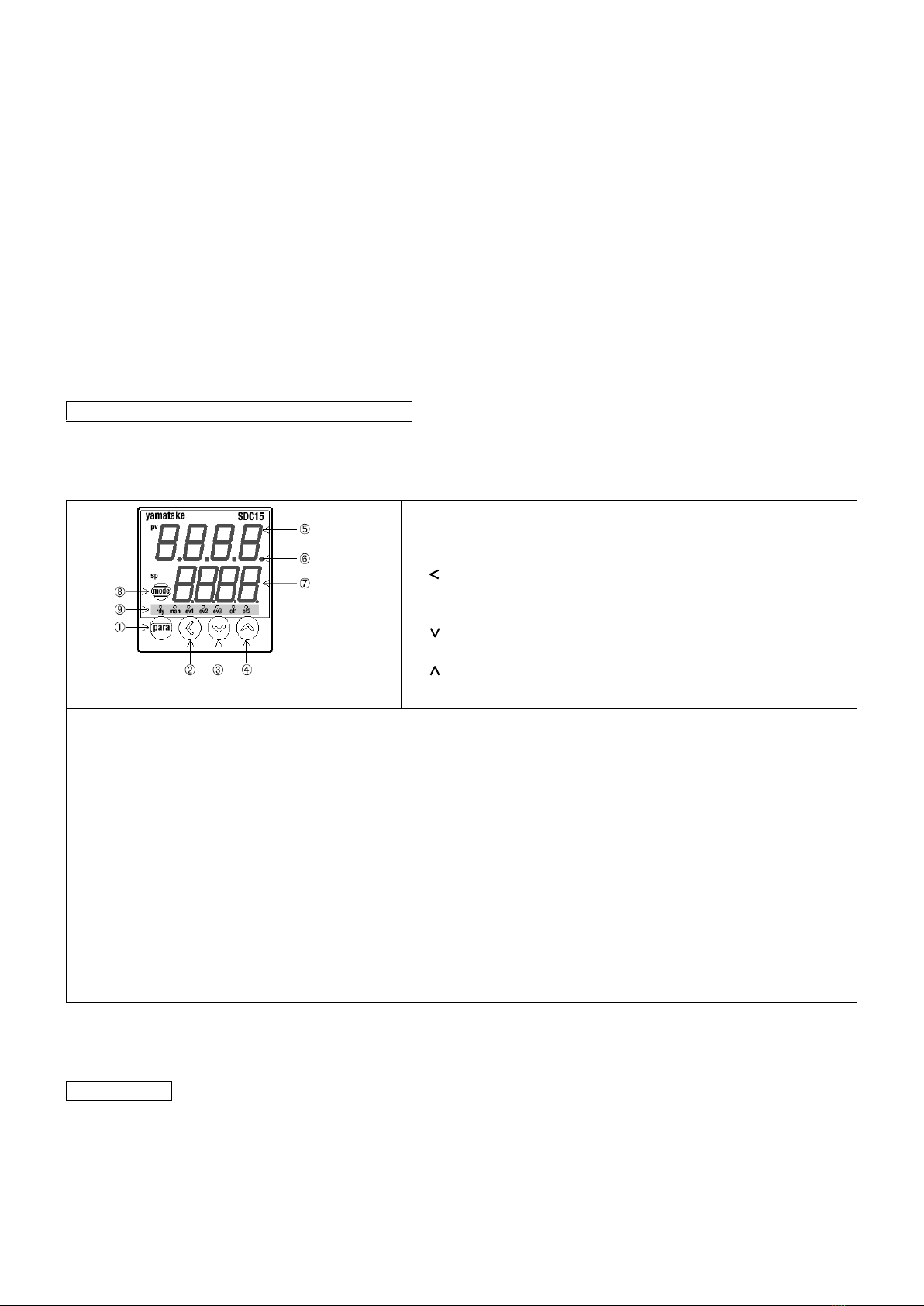

4.2 Name of Parts and Control Panel Functions.........................................................................................................................3

4.3 How to set.............................................................................................................................................................................3

5. Maintenance...............................................................................................................................................................................4

6. Troubleshooting..........................................................................................................................................................................1

7. Replacement Parts.....................................................................................................................................................................1

7.1 Replacement Parts...............................................................................................................................................................1

7.2 Replacement Procedures.....................................................................................................................................................1