TAIYO ELECTRIC

IND.CO.LTD.

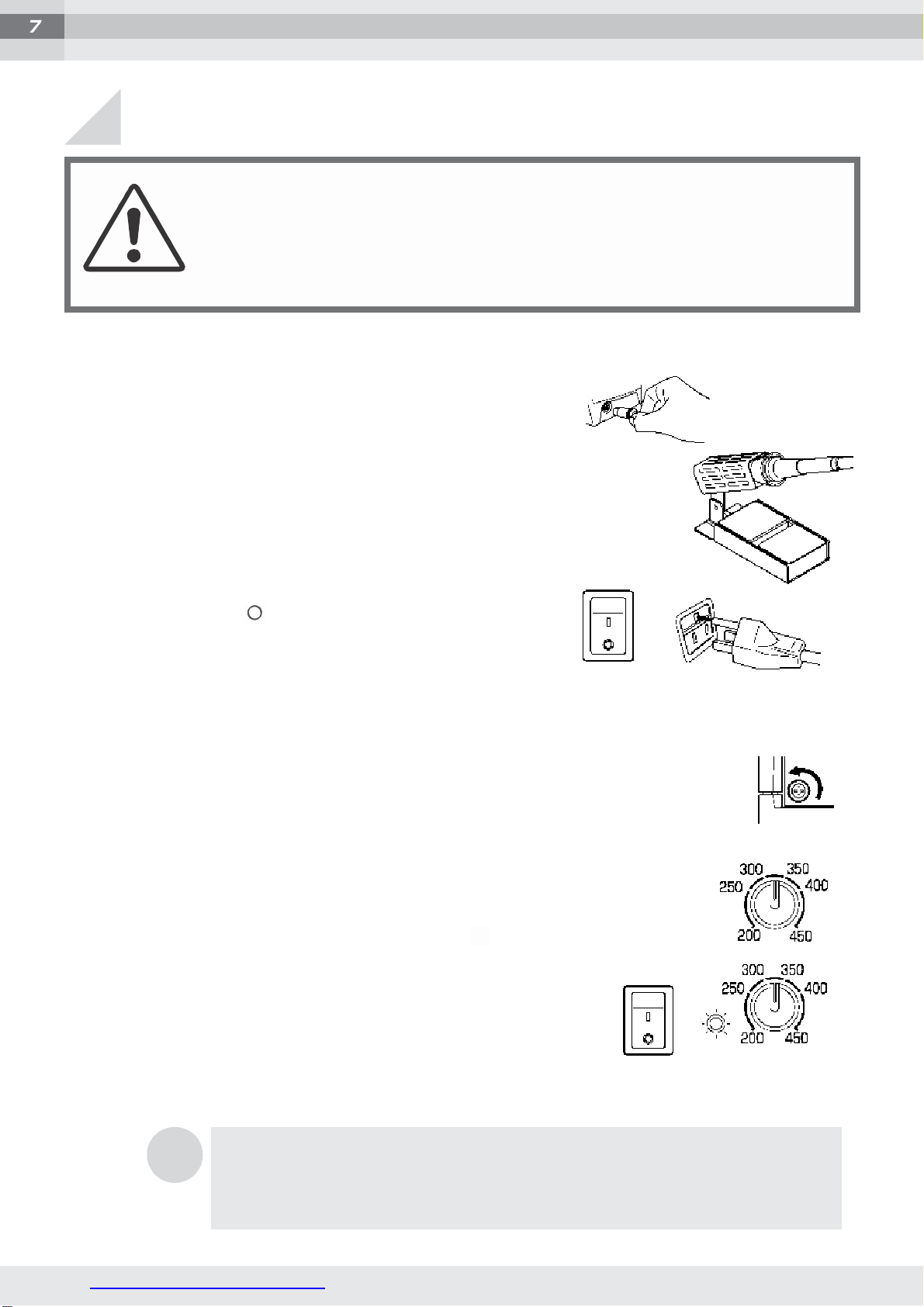

B. RX-711 series only

B-1. Set the temperature display changeover switch on the left side of

the front panel to the SET side. With the switch at this position, th

e

temperature

display

shows

t

he

set

temperature.

B-2. Set the power switch to ON (the I mark side).

The heater monitor lamp will light and the heater will

start to heat up. When turning the soldering station

power switch ON from OFF, “999” will be initially

displayedfor approximately 10 seconds.

B-3. Set the required temperature by using the

temper-

ature setting knob.

B-4. After doing the setting, when changing the switch to

t

h

e

MEAS side the digital display will show the measured

tempera-

ture. When the heater temperature reaches the set

temperature,

the monitor lamp will flash. This indicates that the soldering unit

is ready for use.

When turning the soldering station power ON again after

turnin

g

it OFF within one hour, the temperature displayedwill lower

to

“000” and then will displaymeasured

temperature.

CAUTION

Do not turn the temperature setting knob beyond 480°C. By

turning the temperature setting knob clockwise toward "MAX.",

the required temperature and tip temperature can be set

beyond 480°C. It may go up to approx. 510°C. Setting beyond

500°C could result in damage to your soldering station.

NOTE

1

NOTE

2

NOTE

3

There may be a difference of 2°C between the SET and MEAS temperature

display.

When the

soldering station

is

shipped

the

temperature calibration

is done with the

temperature display

set on the

SET side.

With the

temperature

display

set on the MEAS side

correction

of the tip

temperature

by

using

the

temperature setting knob is not

required.

When

the

temperature display

is set on

MEAS,

the

temperature displayed

will

fluctuate from

2 to 3

degrees

Celsius.

When the

temperature display

is set on MEAS if a heat load is placed for 10

seconds,

the

temperature display will not

change.

Example

While contacting

the tip on a wet

sponge,

the actual tip t

em

-

perature will drop for 10

seconds.

However the temperature shown on the

display will

be the

one before

the tip was

touched on

the sponge.

The actual temperature will be shown on the

display

10

seconds

later. The

temperature control circuit works

to

recover

the set

temperature when

the tip

is cooled

immediately

even thoughthe

display

of measured temperature is

not

changed.