5

2Introduction

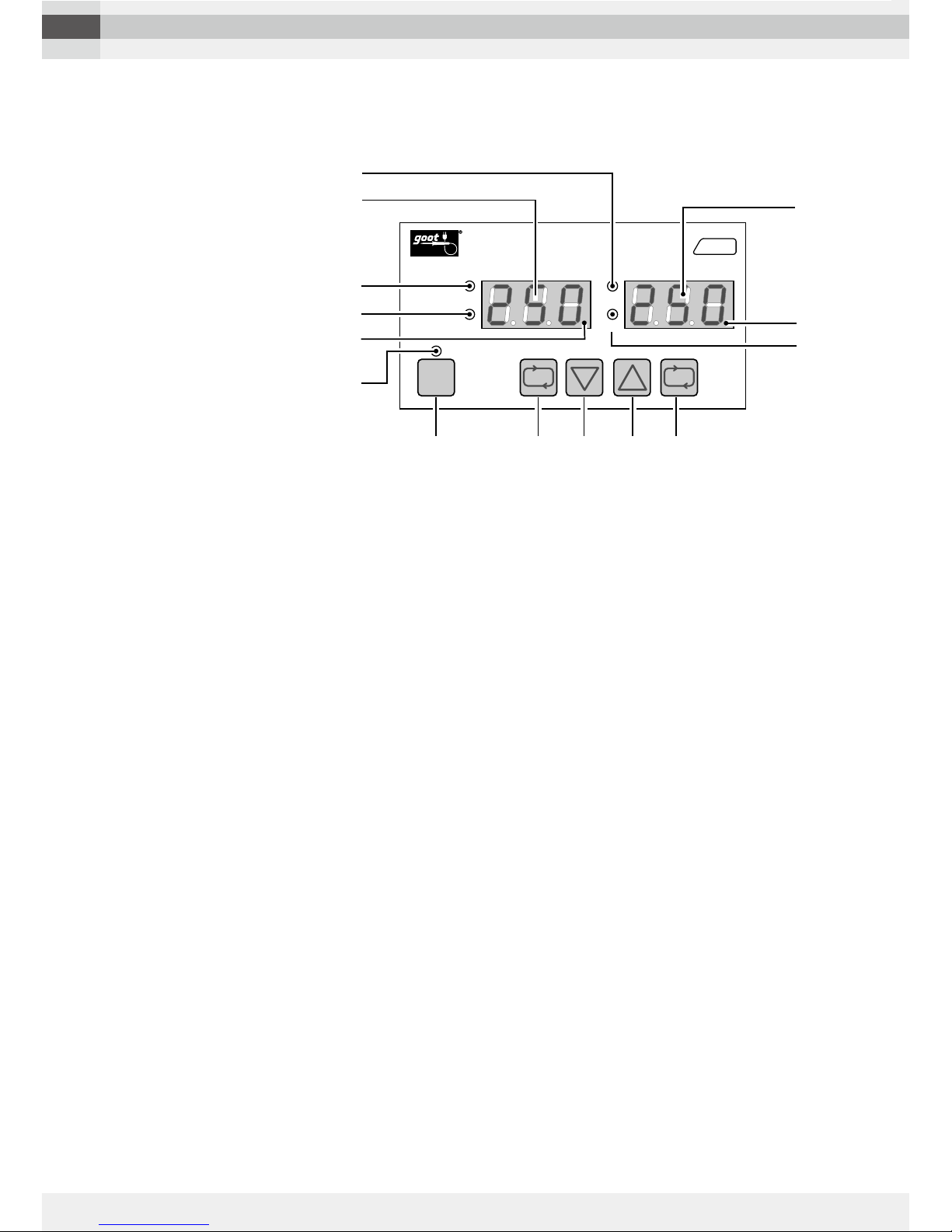

1. 2 soldering irons can be used

Can be prepared with 2 different tip types.

Therefore, you can do different types of

work at the same time.

2. 150W and 72W soldering irons can be used

simultaneously

Port [1] can be used for the 150W or 72W.

Port [2] can be used for 72W only. You can-

not use 150W in both parts.

3. The 2 soldering irons can be set to different

temperatures.

Port [1] and [2] can be set to different tem-

peratures. The set temperature and condi-

tion can be checked easily with the sepa-

rate temperature display.

4. Excellent heat recovery

Achieved by combining a compact-high-

output heater with a high-sensitivity-sensor.

It makes difficult work that requires high

heat capacity, easy.

5. New ergonomic design soldering unit (PAT.)

Provides comfortable handling, flexible sol-

dering unit cord and a shorter distance from

the grip to the tip.

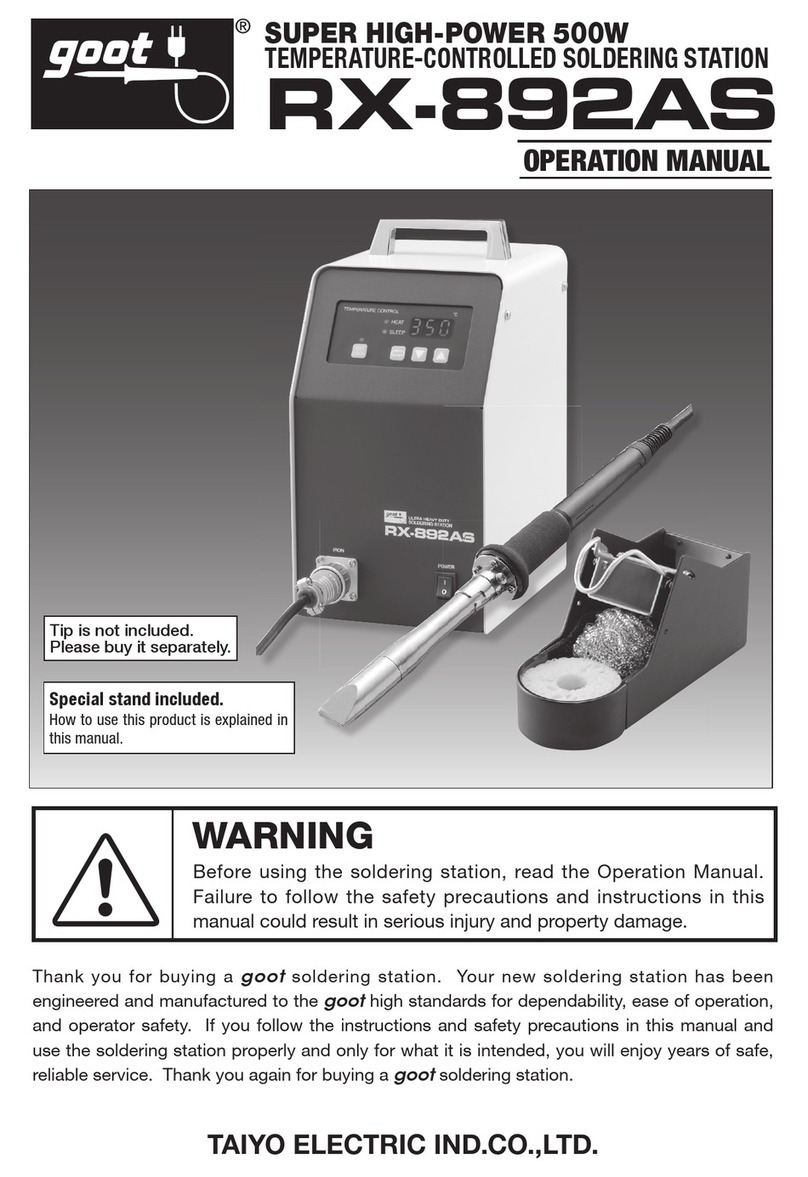

6. Fastest in its class

Reaches 350˚C (662˚F) in approx. 6 sec-

onds. (Equipped RX-80HRT series )

7. Easy to replace tip without using tools (PAT.)

Slide-change tip. No tools or heat resis-

tance pads needed.

8. Wide variety tip

9 tips for the RX-85HRT series and 7 tips

for the RX-85HSRT series are available. A

total of 43 tips with different shapes includ-

ing the tips for the RX-80HRT series are

available.

9.

Thick iron plating for lead-free soldering

All tips have a thick iron plating to slow ero-

sion caused by lead-free soldering.

10. Key Lock function (PAT.)

Tamper-proof keypad lock using a pass-

word. No tools or cards are needed.

11. Sleep function (PAT.)

The control unit automatically lowers the

temperature when inactive for a preset peri-

od of time, preventing overheating. Time

and temperature can be preset when inac-

tive. Can be used with the shut down func-

tion.

12. Sleep function release (PAT.)

Sleep mode can be exited by touching the

wet sponge to cause temperature fluctua-

tion.

13. Calibration function (PAT.)

The calibration function digitally offsets the

difference between the tip temperature and

the tip thermometer temperature.

14. Shutdown function

When the unit is not used for a preset time,

the unit enters shutdown mode automati-

cally, to prevent any unexpected accidents.

2-1 Features of the RX-822AS

The RX-822AS includes 2 soldering units per one control unit for lead-free soldering. The

tip is a long-life compact type with integrated heater.