Manual Conventions

2309908G

Contents

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . 2

ProMix Easy Models . . . . . . . . . . . . . . . . . . . . . . . . 3

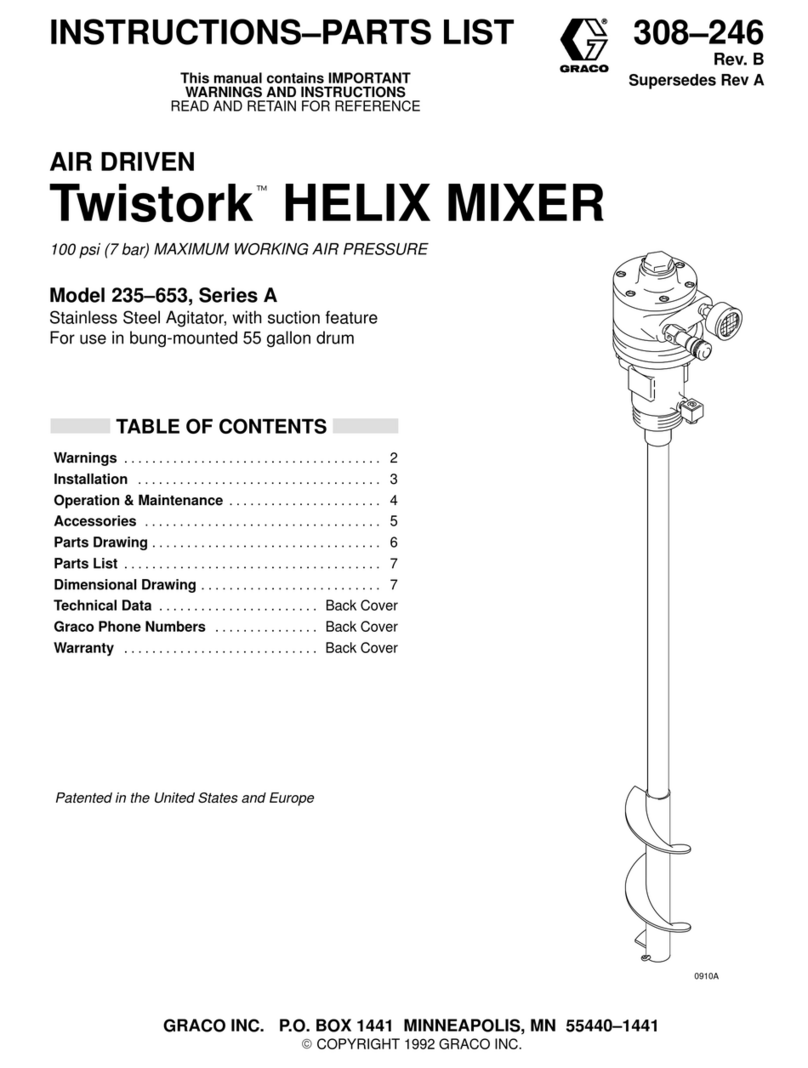

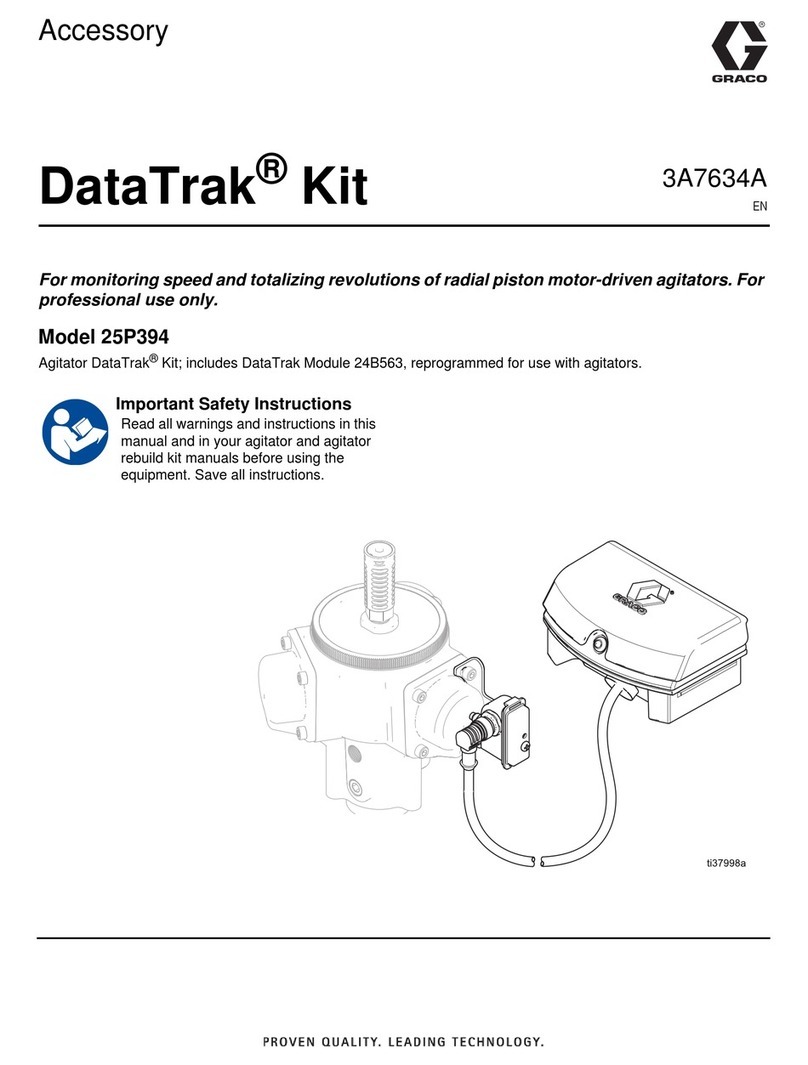

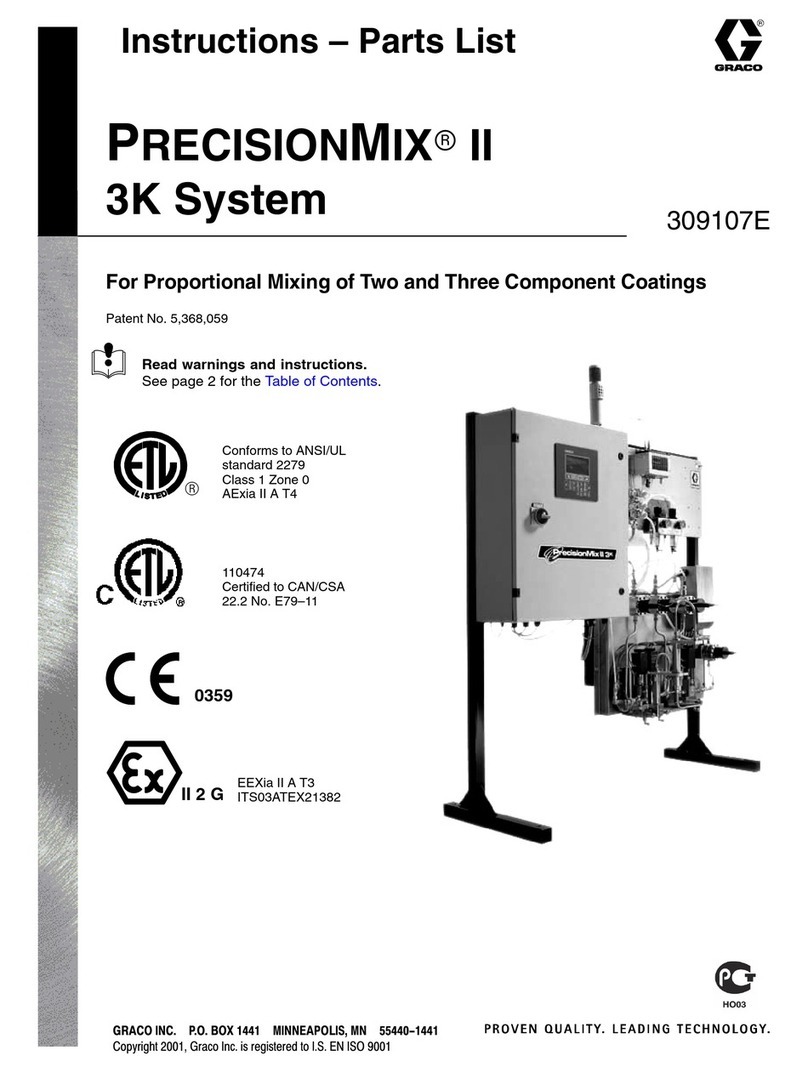

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

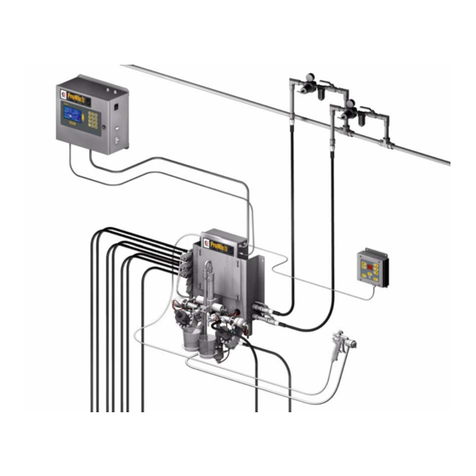

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Connection (non-IS units only) . . . . . . . . . 8

Air Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Solenoid Module . . . . . . . . . . . . . . . . . . . . . . . . 10

Fluid Controls . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 14

Fluid Manifold to Gun . . . . . . . . . . . . . . . . . . . . 14

Pump to Fluid Manifold . . . . . . . . . . . . . . . . . . . 15

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fluid Manifold Flushing . . . . . . . . . . . . . . . . . . . 16

Full System Flushing . . . . . . . . . . . . . . . . . . . . . 18

Priming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pump Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Batch Dispense or Ratio Check . . . . . . . . . . . . . . 25

Pot Life Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Recirculation Setting . . . . . . . . . . . . . . . . . . . . . . . 27

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Recalibrate Pump-based System . . . . . . . . . . . . . 29

Set Pump Calibration Value . . . . . . . . . . . . . . . . 29

Calibrate Pump Sensor . . . . . . . . . . . . . . . . . . . 29

Recalibrate Meter-based System . . . . . . . . . . . . . 30

Calibrate Meter . . . . . . . . . . . . . . . . . . . . . . . . . 30

Set Meter K-factor . . . . . . . . . . . . . . . . . . . . . . . 31

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . 34

2.5:1 Ratio UltraMix Pump . . . . . . . . . . . . . . . . . 34

24:1 Ratio HydraMix Pump . . . . . . . . . . . . . . . . 34

34:1 Ratio HydraMix Pump . . . . . . . . . . . . . . . . 35

47:1 Ratio HydraMix Pump . . . . . . . . . . . . . . . . 35

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Wall Mounting Diagram . . . . . . . . . . . . . . . . . . . . . 39

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 40

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 40

Manual Conventions

Note:

Warnings in the instruction sections (such as “Instal-

lation”) generally include a symbol indicating the hazard.

Follow the instructions and read the hazard section on

the general warning pages 5-6 for additional informa-

tion.

Example:

WARNING

WARNING: a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

CAUTION

CAUTION: a potentially hazardous situation which, if

not avoided, may result in property damage or destruc-

tion of equipment.

Additional helpful information.

WARNING

Your system must be grounded. Read warnings,

page 5 and follow instructions below.