2312775J

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

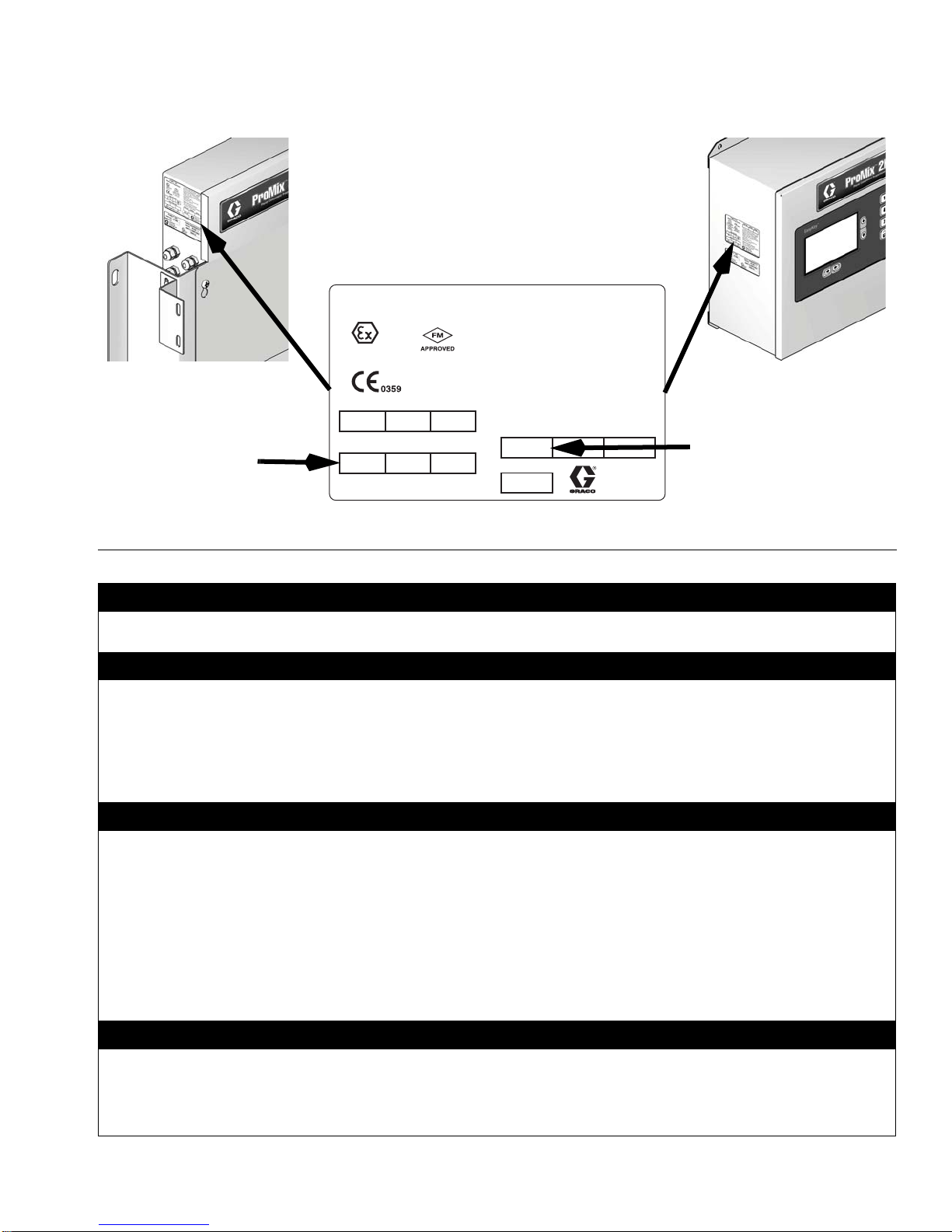

Equipment Approvals . . . . . . . . . . . . . . . . . . . . . . . 3

System Configuration and Part Numbers . . . . . . . 4

Configurator Key . . . . . . . . . . . . . . . . . . . . . . . . . 4

Standard Features . . . . . . . . . . . . . . . . . . . . . . . 6

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2KS Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 6

2KS Acid Compatible Accessories . . . . . . . . . . . 6

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Important Two-Component Material Information . 9

Isocyanate Conditions . . . . . . . . . . . . . . . . . . . . . 9

Material Self-ignition . . . . . . . . . . . . . . . . . . . . . . 9

Keep Components A and B Separate . . . . . . . . . 9

Moisture Sensitivity of Isocyanates . . . . . . . . . . 10

Changing Materials . . . . . . . . . . . . . . . . . . . . . . 10

Important Acid Catalyst Information . . . . . . . . . . 11

Acid Catalyst Conditions . . . . . . . . . . . . . . . . . . 11

Moisture Sensitivity of Acid Catalysts . . . . . . . . 11

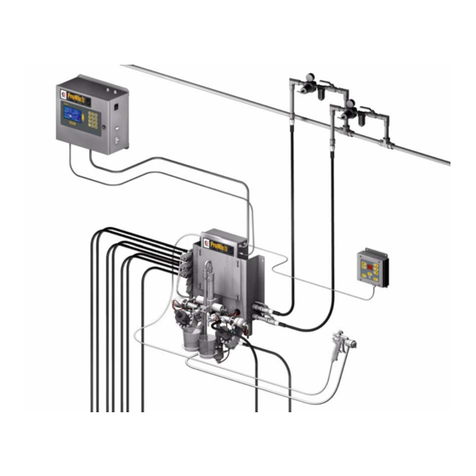

Component Identification and Definition . . . . . . 12

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Location Requirements . . . . . . . . . . . . . . . . . . . 14

Intrinsically Safe Installation Requirements . . . 14

Optional Cables . . . . . . . . . . . . . . . . . . . . . . . . 14

General Information . . . . . . . . . . . . . . . . . . . . . . . 16

Wall Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Air Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Air Connections . . . . . . . . . . . . . . . . . . . . . . . . . 17

Fluid Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fluid Connections . . . . . . . . . . . . . . . . . . . . . . . 18

Setup the Fluid Manifold for Dynamic Dosing . . 20

Solvent Meter Accessory . . . . . . . . . . . . . . . . . . 22

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Connect Main Power . . . . . . . . . . . . . . . . . . . . . 23

Connect EasyKey to Fluid Station Control . . . . 24

Connect Booth Control to Fluid Station Control . 24

Fluid Station Control Board Switch Settings . . . 25

Connect Color Change Module . . . . . . . . . . . . . 26

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Check Resistance . . . . . . . . . . . . . . . . . . . . . . . 29

Schematic Diagrams . . . . . . . . . . . . . . . . . . . . . . . 31

System Pneumatic Schematic . . . . . . . . . . . . . . 31

System Electrical Schematic . . . . . . . . . . . . . . . 32

Dimensions and Mounting Hole Layouts . . . . . . 34

Dynamic Dosing Restrictor Selection Graphs . . 36

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 44

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 44