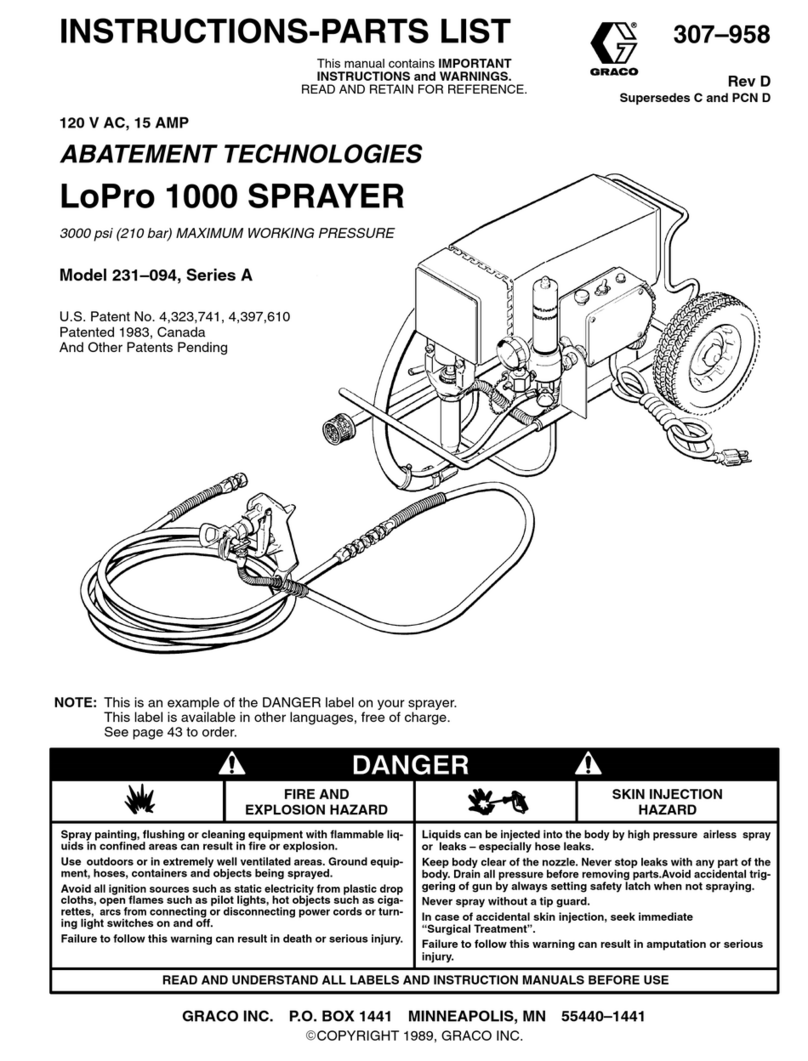

HIGH PRESSURE SPRAY CAN CAUSE

SERIOUS

INJURY

solvent and fluids could penetrate the skin, causing serious

Because of the high pressure and velocity of the spray, paint, injury. Operate equipment

only

after all instructions are clearly

understood.

OBSERVE ALL SAFETY WARNINGS

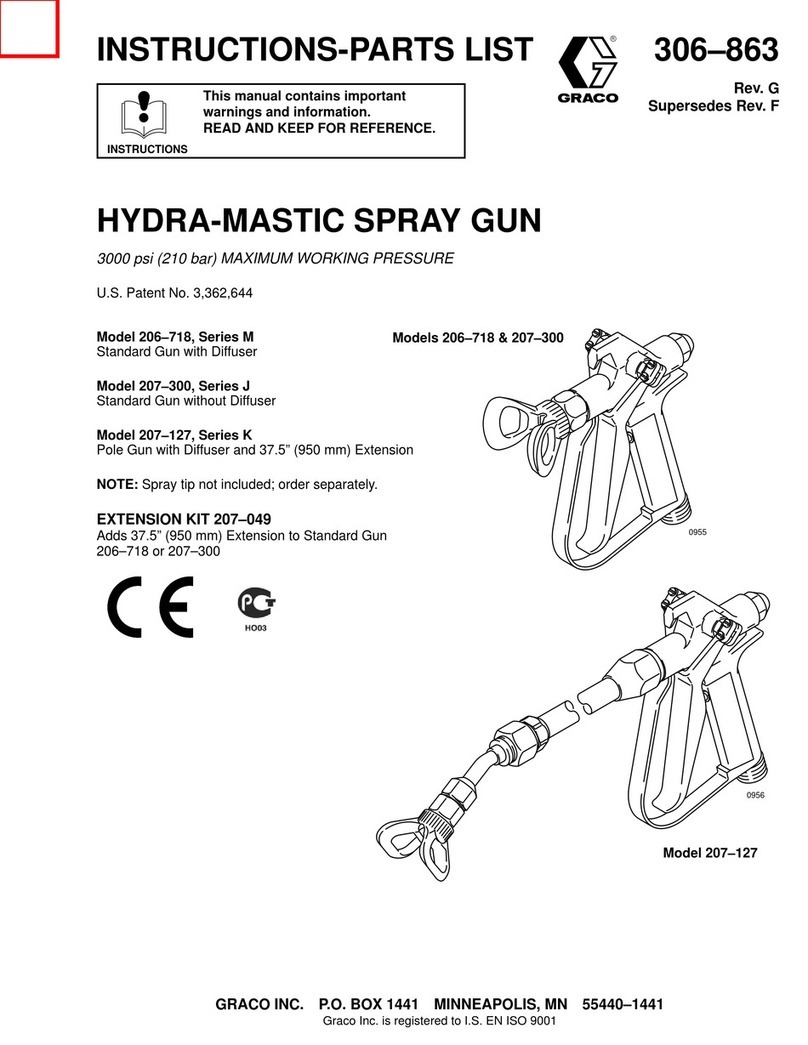

SPRAY GUN

NEVERpoint thegun ar yourself oranyone else.

The tip guard NEVER leave

a

pressurized unit unattended.

can provide additional protection against injection injuries.

Never put your hand, fingers or body directly over the spray

nozzle.

When spray gun is not actually spraying. always set gun

safety latch

in

closed, or

"SAFE"

position, making the trigger

Always have the tip guard in place while spraying. spray gun. Check diffuser operation by using the lowest

inoperative.

DO

NOT REMOVE

OR

MODIFY

any part of

Even after you shut off the electric motor, there is high possible spray pressure without a spray nozzle on gun. Trigger

pressure in the pump, hose and gun, until you release

it.

Always release pressure when you are done spraying and

gun into

a

waste container

-

fluid emitted should be diffused

into

an

irregular stream.

before servicing, cleaning, or removal of any parts. To release

pressure, shut off the unit, engage trigger safety

and

open

DO

NOTtry to"blow bacypaint: this is NOT an air spray unit.

drain valve. Have

a

container ready to catch draining material.

EMERGENCY MEDICAL CARE. DO

NOT

TREAT AS A

If

the spray appears to have penetrated the skin.

SEEK

SIMPLE CUT.

Be ready to tell the doctor exactly what fluid

was injected.

KEEP CLEAR OF MOVING PARTS

The electric motor has an overheating protection device which

aotomatically

restarts the motor when

it

cools.

So,

before

ex-

your fingers into any openings in shield.

amining or working on a motor which has stopped. shut off ALWAYS CHECK to be sure switch

is

OFF

and all lines are

the unit, relieve pressure and pull out the electrical plug. This clear

of

moving parts, before plugging in the power cord.

will avoid the hazard of the motor starting unexpectedly.

KEEP CLEAR of moving parts when unit is running; do not put

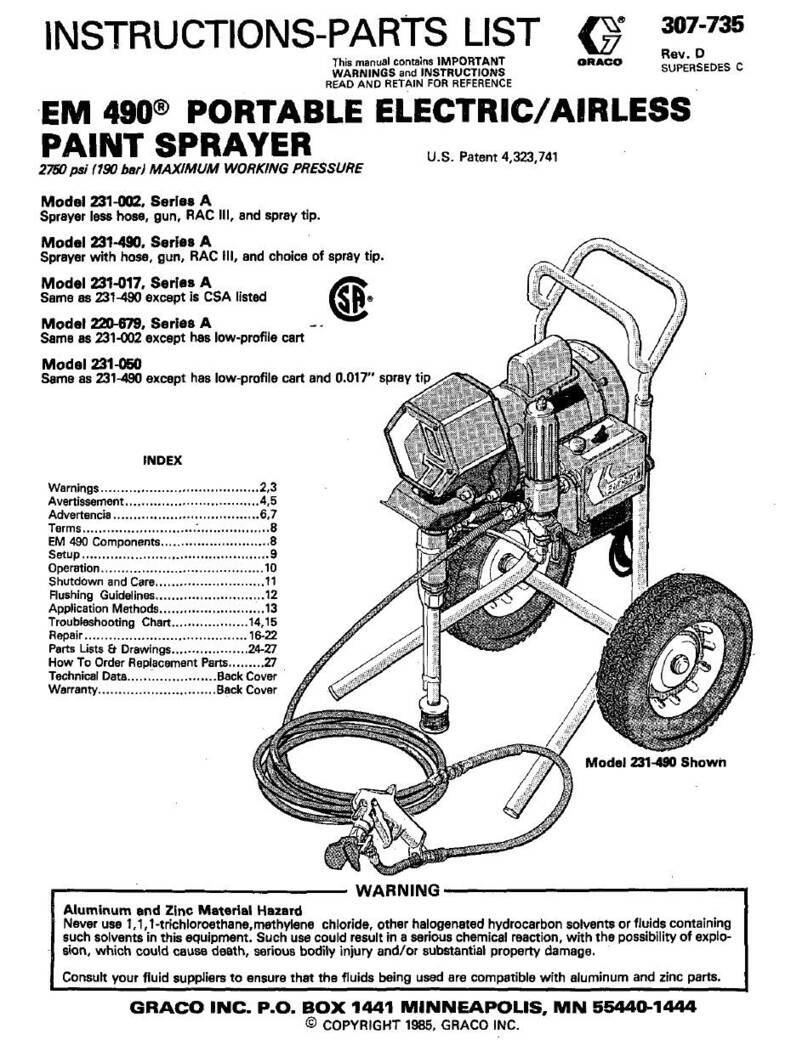

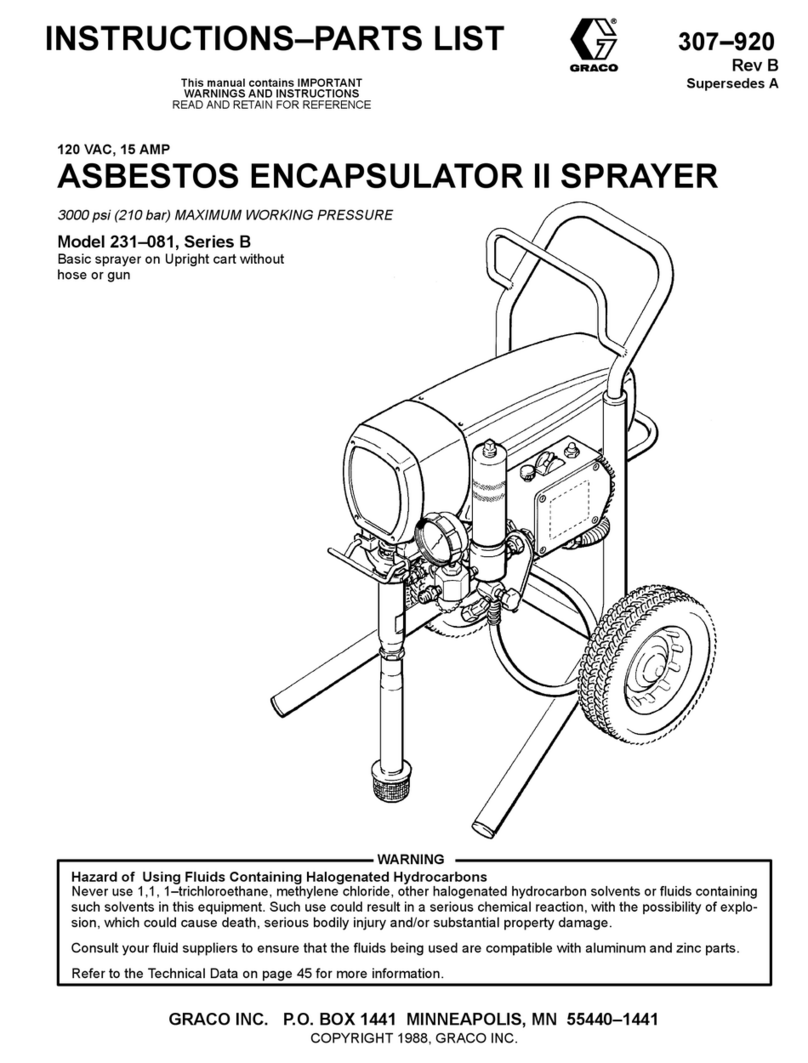

SYSTEM PRESSURE

Be sure that

all

accessory hoses, swivels, etc. used with this

unit can withstand

the

high pressure developed. This unit

Before each use, check entire hose for cuts, leaks, abrasion

or

bulging

of

cover or damage or movement of couplings. If any

develops fluid pressure up to 2700 PSI

1185

bar). of these conditions exist, replace the hose immediately. Never

use

rape or any

device

to attempt to mend the

hose.

DO NOT ABUSE HOSE:

Improper use

or

handling

of

hose

could result in hose failure and possible personal injury

or

property damage.

Do

not use chemicals

or

agents in the hose which are not

compatible with nylon tube

and

urethane cover

of

the hose.

cutting; also, do not expose to temperatures above

180"

F

Handle and route hose carefully to avoid kinking, abrasion,

NEVER ATTEMPT

TO

RECOUPLE THE

HOSE!

182"

C) or below

-40'

F

(-40"

C)

DO

not use hose to pull unit. Tighten all fluid connections securely before each use.

PREVENT STATIC SPARKING

The high velocity flow of material through equipment may grounded outlet that will accept the 3-prong plug.

Do

not

develop static electricity. Be sure that the equipment being

remove the third prong.

used, and the object being sprayed, are properly grounded to

explosion.

prevent static discharge and sparks, which could cause fire or The green wire of electric cord is connected to the unit chassis

and motor frame and the other

two

wires are connected to the

Use

only conductive or grounded fluid hoses for airless ap- switch motor for grounding continuity.

connections.

plications.

Be

sure that gun is grounded through hose Plug into an outlet

at

least

20

ft

16

mj from the area where you

arespraying. If you use an extension cord, it must have3 wires

Once each week, check electrical resistance of hose (when of

at

least

12

gauge 12.5

mm2)

and should not be over

100

ft

using multiple hose assemblies, check overall resistance).

(30.3

m) long.

exceed

29

megohms 1max.l for any coupled length or com-

Overall lend to end) resistance of unpressurized hose must not

Use

the lowest possible pressure when flushing equipment,

and maintain firm metal to metal contact between gun and

a

bination of hose lengths. If hose exceeds these limits, replace

it

immediately.

grounded metal waste container. This reduces the chance of

static sparking.

Never exceed 500 ft 1150 m) overall combined hose length. Follow the coating and solvent manufacturer's safety pre-

This unit has

a

3-prong grounding plug to protect you from cautions and warnings.

electric shock.

Be

sure to plug the unit into

a

properly

?EqA%*W

-"

ALWAYS unplug unit before removing shield for any reason.

IMPORTANT

United States Government safety standards have been adopted under Occupational Safety and Health Act. These standards

-

particularly the General Standards, Part

1910.

and the Construction Standards, Pan 1926

-

should be consulted in connection with

your use of airless spray equipment.

2

307-111