SAFETY PRECAUTIONS

IMPORTANT

READ

and

UNDERSTRND

United States Government safety standards have been adopted under the Occupational Safety and Health Act.

These standards

-

particularly the General Standards, Part 1910, and the Construction Standards, Part 1926

-

should be consulted in connection with your use of airless spray painting equipment.

HIGH PRESSURE SPRAY CAN CAUSE SERIOUS INJURY. Because of the high pressure and velocity of the

spray, paint, solvent and fluids could penetrate the skin causing serious injury. Operate equipment only after

all

instructions are clearly understood.

KEEP AWAY

FROM

SPRAY

NEVERpoint the

gun

at yourself oranyone else. The tip

guard can provide additional protection against in-

jection injuries. Never put your hand, fingers or body

directly over the spray tip.

Always have the tip guard

in

place while spraying.

Even after you shut off the pump, there is high pressure

triggering the spray gun.and by opening the drain valve.

in the pump, hose and gun until you release

it

by

always shut off the unit, trigger the spray gun, engage

So

before servicing, cleaning or removal'of any parts,

trigger safety, and open the drain valve to release

pressure. Leave drain valve

in

open position

during

all

service operations. Have

a

container ready to catch the

draining paint.

If the spray appears to have penetrated the skin,

SEEK

IMMEDIATE MEDICAL AlTENTION. DO NOT

TREAT AS A SIMPLE CUT.

Be ready to tell the doctor

exactly what fluid was injected.

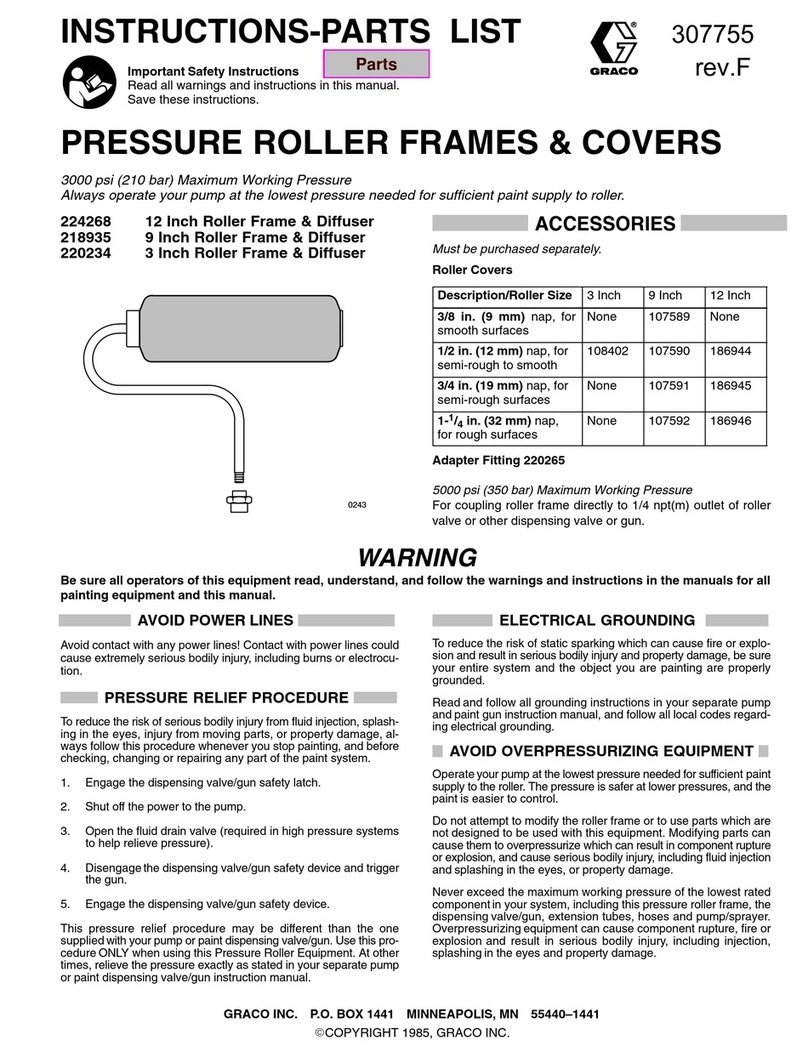

Don't exceed

5000

PSI

(350

bar1 working pressure to

gun. Be sure that all accessory items and system com-

ponents will withstand the pressures developed. NEVER

exceed the pressure rating of any component in system.

NEVER alter or modify equipment.

2

307-046

When spray gun is not actually spraying, always set gun

safety latch in closed, or "SAFE" position, making the

trigger inoperative.

Always remove tip from gun to clean

it.

Be very careful when removing spray

tip

or hose from

gun. A plugged line contains fluid under pressure. If the

tip or line is plugged, open drain valve, then loosen

tip

guard or hose coupling slightly and release pressure

slowly before removing completely.

inlet pressure to pump.

Don't exceed maximum recommended air or hydraulic

PREVENT STATIC SPARKING

The high velocity flow of material through the spray tip

may develop static electricity. Be sure your gun is

grounded. Use grounded paint hoses and be sure your

supply pump and the object you are painting are

grounded.

Always use the lowest pressure possible when flushing

and hold gun firmly against metal waste container.

..

: