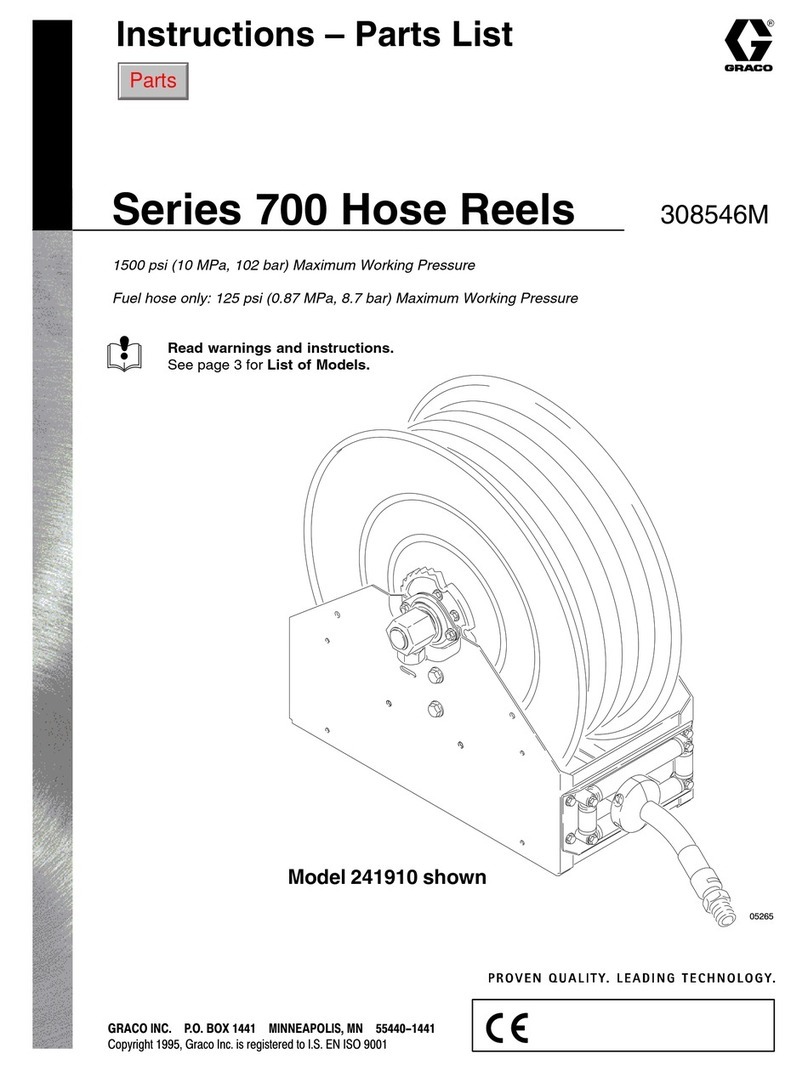

Installation

– T

ypical Installation

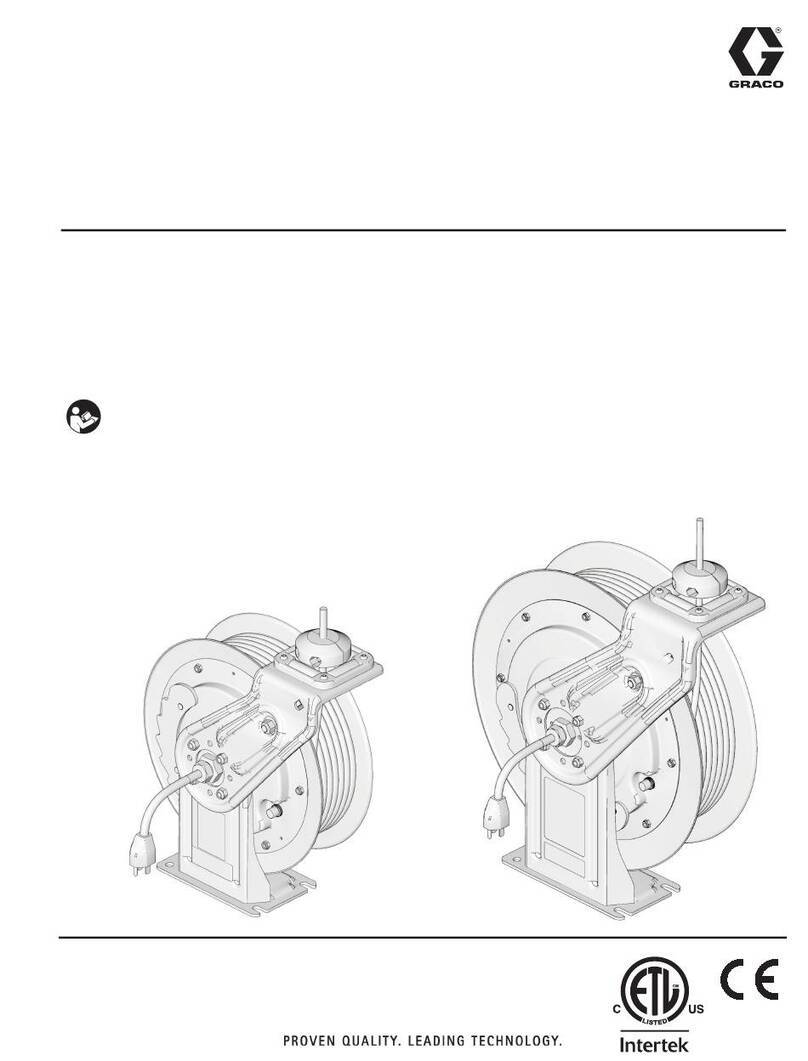

The

typical installations shown in Fig. 1 is only a guide

for selecting and installing a hose reel system. The

components and accessories shown are the minimum

requirements for all systems. However

, it is not an

actual system design. Contact your Graco

representative for assistance in designing a system to

suit your particular needs.

NOTE:

The air and fluid accessories required for your

pump must be properly sized to that pump. Refer to

your specific pump manual for selecting pump

accessories.

Three accessories are required in your system: a

ground wire (G), a bleed-type master air valve (E)

and a fluid drain valve (H). These accessories help

reduce the risk of serious injury

, including electric

shock and splashing in the eyes or on the skin.

The ground wire must be connected to the pump

grounding lug and to a true earth ground according

to your local code.

The bleed-type master air valve relieves air trapped

between this valve and the pump after the air is

shut of

f. T

rapped air can cause the pump to cycle

unexpectedly

. Locate the valve close to the pump.

The fluid drain valve assists in relieving fluid

pressure in the displacement pump, hose, and gun.

T

riggering the gun to relieve pressure may not be

sufficient.

WARNING

Air Line Accessories

Install

the following accessories in the order shown in

Fig. 1, using adapters as necessary:

D

Bleed-type Master Air V

alve (E):

locate

downstream from the air regulator and for easy

access from the pump.

D

Air Regulator (D):

controls pump speed and outlet

pressure by adjusting the air pressure to the pump.

Locate the regulator close to the pump but

upstream from the bleed-type master air valve.

D

Air Line Filter (C): removes harmful dirt and

moisture from the compressed air supply

.

Fluid Line Accessories

Install

the following accessories in the order shown in

Fig. 1, using adapters as necessary:

D

Fluid Drain V

alve (H):

install the drain valve

pointing down but so the handle points up when the

valve is opened.

DFluid Shutoff Valve (J):

shuts of

f fluid to the hose

reel.

D

Dispensing V

alve (N):

dispenses the fluid or air

.

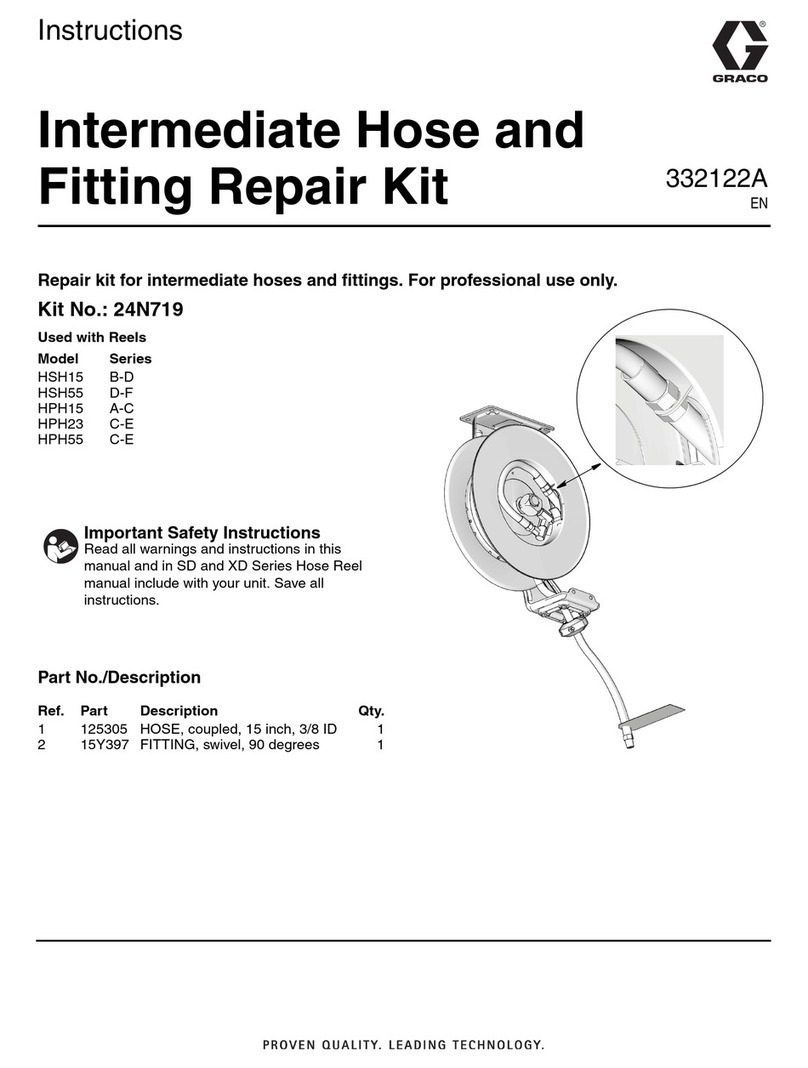

Required Hose Reel

Installation Accessories

Be

sure you have these accessories before starting

the installation. All of these accessories are shown on

pages 22 to 24.

D

Hose inlet kits (L)

D

Reel mounting bases, mounting brackets, and

mounting channels (P)

D

Dispense valves (N)

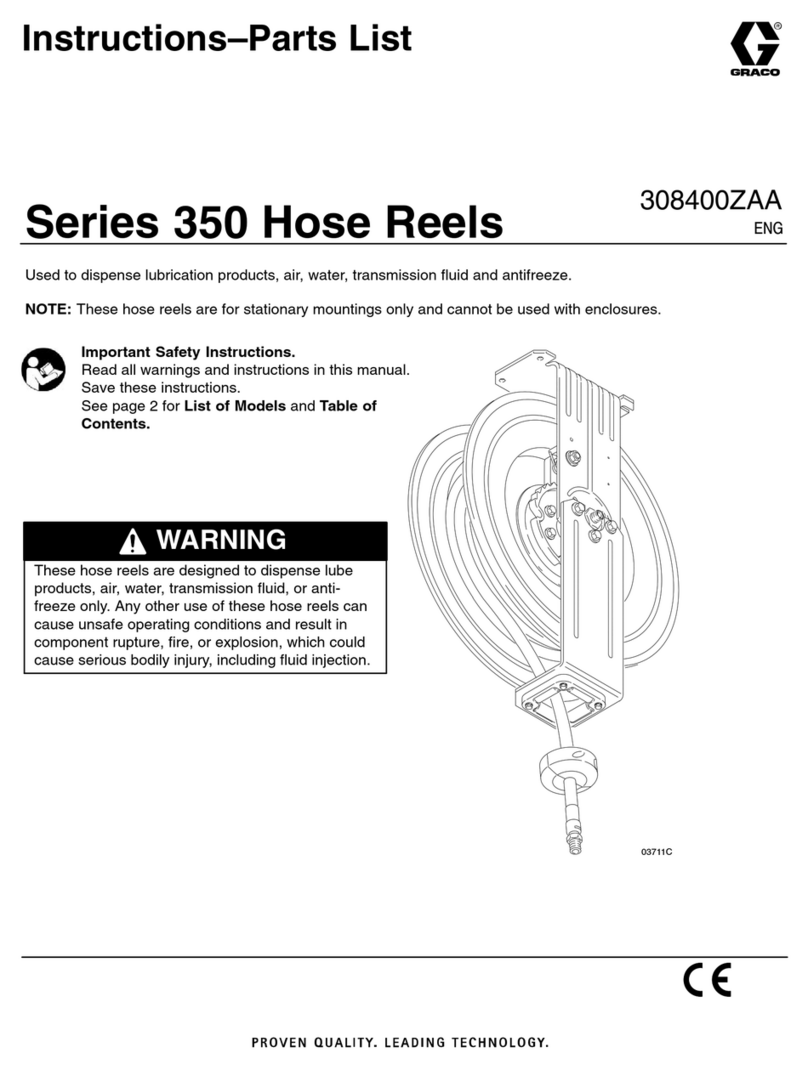

Mounting Restrictions

DFor

stationary mounting only; do not use in any

mobile installation.

DY

ou can

replace the roller support arm on Series

350 hose reels with an accessory-base-mounted

support.

D

Hose reel enclosures do not fit on these reels.

WARNING

T

o reduce the risk of injury when mounting a hose

reel overhead, always use a lift truck.