0244

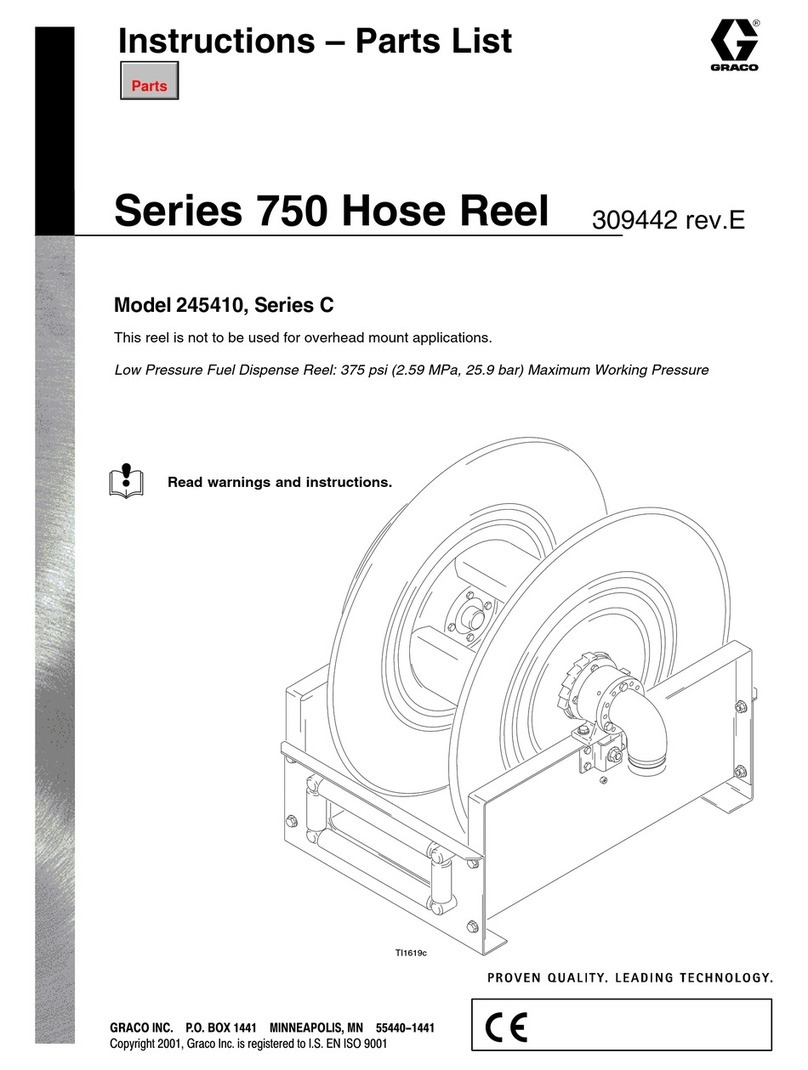

Fig 1

U–CUP PACKING (2)

Lips of packing must face dif-

fuser segments as shown

DIFFUSER

ASSEMBLY (1)

SETSCREW (5)

FRAME (4)

RETAINER

NUT (3)

Installing and Removing a Roller Cover (See Fig 1)

Installation: Hold the diffuser assembly and unscrew the retain-

er nut. Remove the diffuser assembly from the roller frame.

Slide the cover over the diffuser assembly, place the assembly

on the roller frame, and reinstall the nut. Do not to overtighten

the nut.

Removal: Hold the cover and unscrew the retainer nut. Slide the

cover and diffuser assembly off the roller frame, and press on

the end of the diffuser assembly to separate it from the cover.

Cleaning the Roller Diffuser (See Fig 1 and 2)

For water–base paint: Vigorously shake the diffuser in a bucket

of hot soapy water to remove wet paint.

For oil–base paint: Use a compatible solvent. Use a brass wire

brush to remove dried paint.

For further cleaning: Remove the roller cover. Remove the two

screws. Pull off the outside end cap. Disassemble all parts and

clean thoroughly in a compatible solvent.

To reassemble: Install the inside end cap onto the roller frame.

Slide all diffusers onto the roller frame. Twist and press the last

diffuser to snap the pieces together. Install the outside end cap

and the two screws. Holding the inside end cap, press on the

screws and rotate the diffusers to seat the screws. Tighten the

screws into the inside end cap; don’t overtighten.

0245

DIFFUSER SEGMENTS:

2 – 3 IN. MODEL

11 – 12 IN. MODEL

DIFFUSER

1c

1

a

INSIDE END CAP

SCREW

OUTSIDE END CAP

1b

Fig 2

PARTS LIST

Model 224268, 12 in. Frame & Diffuser

Model 218935, 9 in. Frame & Diffuser

Model 220234, 3 in. Frame & Diffuser

Includes items 1–5

REF

NO. PART NO. DESCRIPTION QTY

1 DIFFUSER ASSEMBLY

220233 3 in. model 1

218943 9 in. model 1

224377 12 in. model 1

1a 275643 END CAP, inside 1

1b 275645 END CAP, outside 1

1c 275673 DIFFUSER SEGMENT

3 in. model 2

9 in. model 8

12 in. model 11

2 108808 PACKING, U–CUP 1

3 183420 RETAINER NUT 1

4 ROLLER FRAME

220235 3 in. model 1

218582 9 in. model 1

224378 12 in. model 1

5 101983 SETSCREW 1

Wetted Parts Polyethylene, Acetal Homopolymer,

Plated Steel, Vitonr, Neoprene

SERVICE INFORMATION NOTE:

Added Model 224268, 12 in. Frame and Diffuser.

Ref No. 5 Setscrew 101983 was 108226.

GRACO WARRANTY AND DISCLAIMERS

WARRANTY

Graco warrants all equipment manufactured by it and bearing its name to be free from defects in material and workmanship on the date of sale by an authorized Graco distributor to the original

purchaser for use. As purchaser’s sole remedy for breach of this warranty, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment proven defective.

This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for, any malfunction, damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper mainte-

nance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility with Graco equipment

of structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materi-

als not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of the claim. If the claimed defect is verified, Graco will

repair or replace free of charge any defective parts. The equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in

material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor and transportation.

DISCLAIMERS AND LIMITATIONS

THE TERMS OF THIS WARRANTY CONSTITUTE PURCHASER’S SOLE AND EXCLUSIVE REMEDY AND ARE IN LIEU OF ANY OTHER WARRANTIES (EXPRESS OR IMPLIED), INCLUDING

WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE, AND OF ANY NON–CONTRACTUAL LIABILITIES, INCLUDING PRODUCT LIABILITIES,

BASED ON NEGLIGENCE OR STRICT LIABILITY. EVERY FORM OF LIABILITY FOR DIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES OR LOSS IS EXPRESSLY EXCLUDED AND DENIED.

IN NO CASE SHALL GRACO’S LIABILITY EXCEED THE AMOUNT OF THE PURCHASE PRICE. ANY ACTION FOR BREACH OF WARRANTY MUST BE BROUGHT WITHIN TWO (2) YEARS OF

THE DATE OF SALE.

EQUIPMENT NOT COVERED BY GRACO WARRANTY

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, WITH RESPECT TO ACCESSORIES,

EQUIPMENT, MATERIALS, OR COMPONENTS SOLD BUT NOT MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motor, switches, hose, etc.) are

subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these warranties.

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

PRINTED IN USA 307755F 6/1985 Rev. 6/2005