PHP A-4, 6, 8 & 9 Instruction Manual / General

1 General

1.1 Tender text

PHP for lossless storage of the expansion volume and for

pressure maintenance in closed heating, climate and cooling

systems. Designed and manufactured acc. to regulations of

EN 12828 and SWKI 93-1.

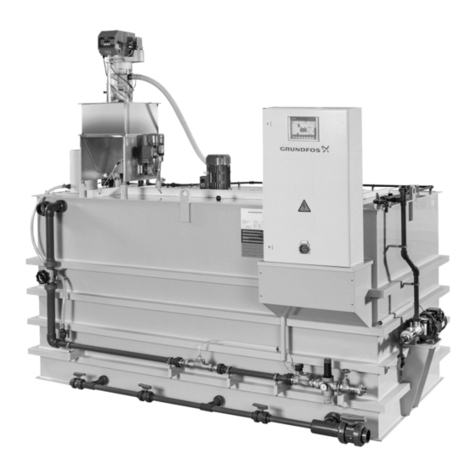

The PHP device is a nicely shaped, self-contained unit

with a pleasing design. It is designed for a modular

combination with external expansion vessels (max. 0.5 bar).

The connections for suction pipe and overflow pipe are

situated at the back of the device.

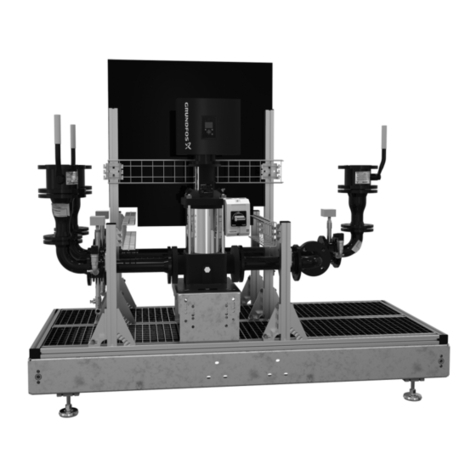

The control unit is built very compact with one resp.

two low-noise pressure maintenance pump(s) which are

executed as multistage centrifugal pump(s) with high

quality floating-ring type shaft seal. Also the PHP hydraulics

includes one resp. two continuously regulating, mechanically

set overflow valve of the expansion flow. High-precision

measuring of the plant pressure. Hydraulic connections and

necessary shut off devices for on-site piping are factory

provided on the left side of the control unit (possibility for

rebuilding to the right side of the control unit). Temperature

monitoring of the media streaming into the vessel.

Prepared connection point for mounting a makeup module

for a per litre accurate measuring. Combinable with an

option for water softening for standardized makeup water.

Prepared connection point for mounting a degassing module

for automatic and economic low pressure degassing, based

on the principle of pressure drop. The connection and the

necessary shut off device for the degassing pipe is situated

at the back of the control unit.

All operations are controlled by the microprocessor electronics.

The operator panel is situated ergonomically and contains an

illuminated 4-line text display. The handling is thought-out and

a lot of languages are supported. The measure and control

unit is executed in a closed electrical cabinet. Four potential-

free signalling contacts (fault, warning, makeup in operation,

device operation enabled).

For more signals two additional expansion modules

can be installed easily in prepared mounting positions.

Remote monitoring can be done also via PHP SMS module

or PHP bus module. External temperature monitoring

via an optional temperature sensor at the connection point

is prepared too.

Max. operation temperature of the plant: 110 °C

(with cooling vessel)

Max. temperature at the connection point: 70 °C

03