Installation Procedures

Page 2

Operating The Pump

Page 3

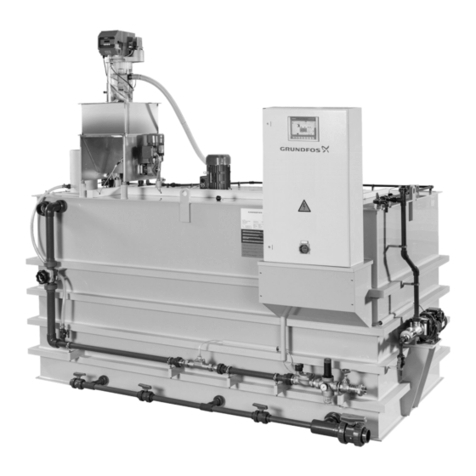

Installation

The pump must be installed so that persons cannot accidentally

come into contact with the hot surface of the motor.

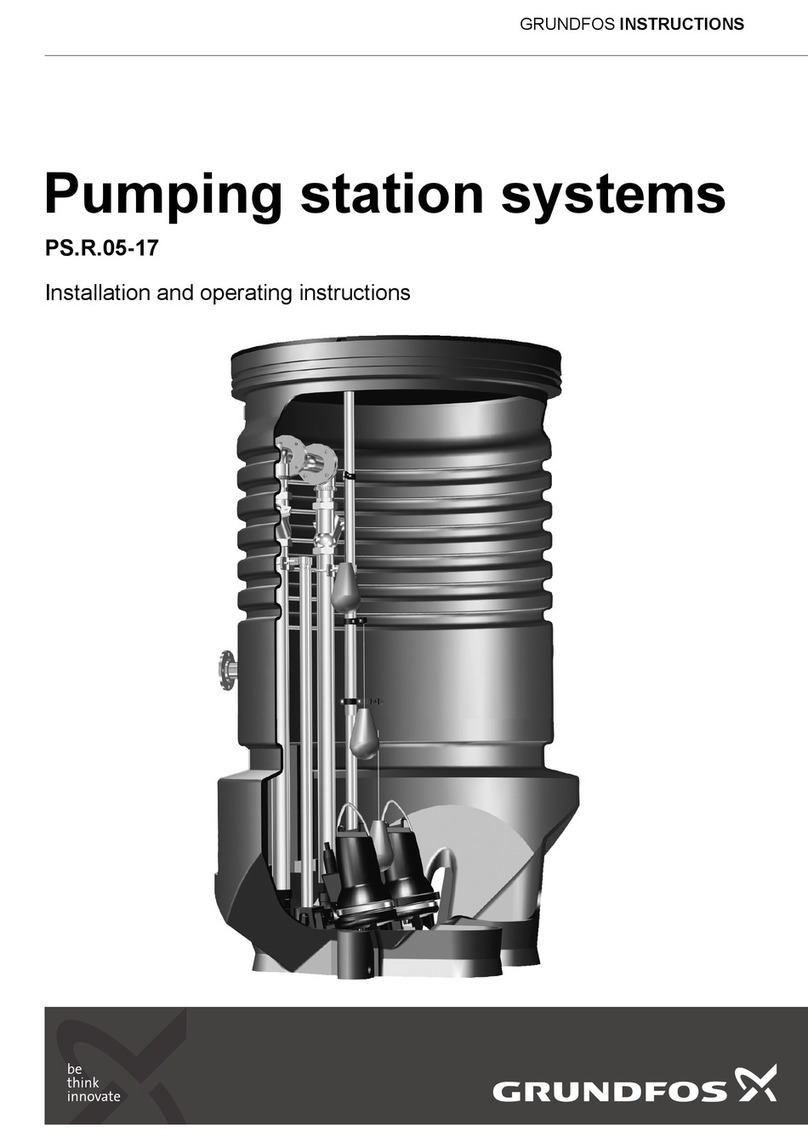

Pump Location

The pump is designed for tank mounting in vertical position. The

pump is positioned in a hole cut into the cover of the tank (upper

side) and is secured to the tank by four hexagon head screws

through the holes in the mounting flange. It is recommended to fit

a sealing gasket between the pump flange and tank.

NOTE: The pumps can only be mounted in vertical position.

The MTC 2 and 4 must have access to the tank from the drain

channel in the motor stool.

WARNING

MTC 2 AND 4

Figure 1

Pump mounting flange dimensions:

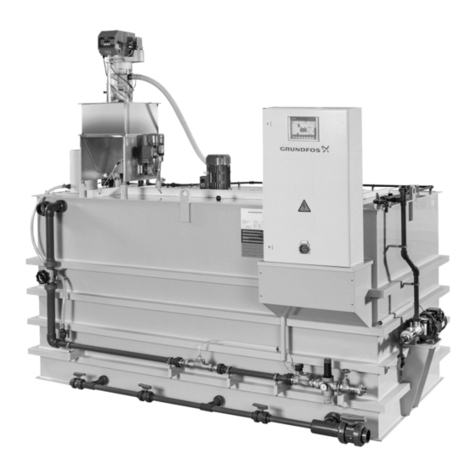

Suction Conditions

The bottom of the pump strainer must be at least 25 mm above the

bottom of the tank.

The pumps are designed to provide full performance down to a level

of A mm above the bottom of the strainer.

At a liquid level between A and B mm above the bottom of the

strainer, the built-in priming screw will protect the pump against dry

running.

Pump A B

Type

(mm/in) (mm/in)

MTC 2, 4 37/1.1 22/0.9

MTC 8, 12, 16 40/1.6 25/1.0

MTC 2 AND 4

MTC 8, 12 & 16

Electrical Connection

The electrical connection should be carried out in accordance with

local regulations.

The operating voltage and frequency are marked on the pump

nameplate. Please make sure that the motor is suitable for the

electricity supply on which it will be used.

The motor must be connected to a motor starter.

The terminal box, for motors up to and including 1.1 kW, can be

turned to four positions, in 90° steps, see Figure 4. Proceed as

follows:

1. Removed the four bolts

securing the motor to the

motor stool.

2. Turn the motor to the

required position.

3. Replace and tighten the

four bolts.

WARNING

Never make any connections in the pump terminal box unless

the electricity supply has been switched off.

If the pump is not connected to an electric installation, it must

be connected to an external mains switch.

Figure 2

Figure 3

The electric motor should be connected to the supply as shown in

the diagram inside the terminal box cover.

All other motors, from 1.5 kW and up, cannot be turned.

Start-up

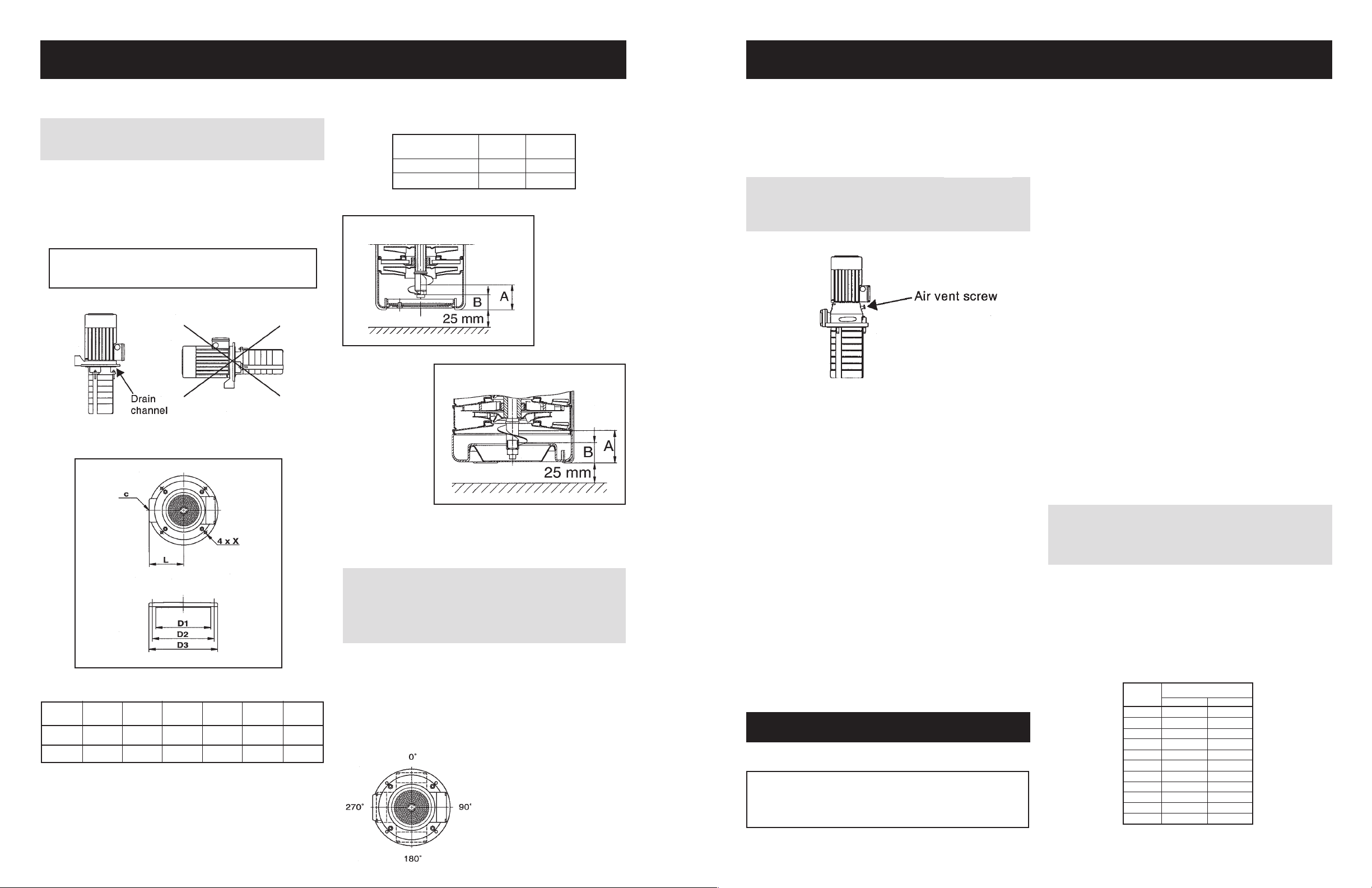

WARNING – MTC 8, 12 and 16

Pay attention to the direction of the vent hole and take care to

ensure that the escaping water does not cause injury to persons

or damage to the motor or other components. See Figure 5.

Figure 5

Before starting the pump, make sure:

• that all pipe connections are tight.

• that the pump body is partly filled with liquid (partly submerged).

• that the strainer is not blocked by impurities.

Start the pump as follows:

1. Close the isolating valve on the discharge side of the pump.

2. See the correct direction of rotation of the pump on the motor

fan cover. When seen from the top, the pump should rotate

counter-clockwise.

3. Start the pump and check the direction of rotation.

4. MTC 2 and 4:

Open the discharge isolating valve a little.

MTC 8, 12 and 16:

Loosen the air vent screw in the motor stool.

5. MTC 2 and 4:

Completely open the discharge isolating valve.

MTC 8, 12 and 16:

When a steady stream of liquid runs out of the vent hole,

tighten the air vent screw and completely open the isolating

valve.

The pump has now been vented and is ready for operation.

Operation and Maintenance

Note: The pump is not allowed to run against a closed

discharge valve for more than approximately five minutes as

this will cause an increase in temperature/formation of steam in

the pump which may cause damage to the pump.

Lubrication and Maintenance

Pumps installed in accordance with these instructions require very

little maintenance.

When a mechanical shaft seal is fitted, it is self-adjusting and has

wear-resistant seal rings which are lubricated and cooled by the

pumped liquid.

The pump bearings are also lubricated by the pumped liquid. The

motor ball bearings are grease packed and sealed for life. No

further lubrication is necessary.

Pumps from 4 kW and up have angular contact bearings.

Filter

Chip trays, filters, etc. should be cleaned at regular intervals to

ensure a correct flow of liquid.

Periodic Checks

At regular intervals, depending on the conditions and time of

operation, the following checks should be made:

• Check the quantity of liquid and operating pressure.

• Check that there are no leaks.

• Check that the motor is not overheating.

• Check the tripping of the motor starter.

• Check that all controls are operating satisfactorily.

If the above checks do not reveal any abnormal operating details,

no further checks are necessary.

Should any faults be found, check the symptons with the Fault

Finding Chart, page 4.

Service

WARNING

If a pump has been used for pumping liquids which are injurious

tohumanhealthorpoisonous,itwillbeclassifiedascontaminated.

Do not turn the pump upside down during service. Residual

liquids from the chambers may damage the motor.

A contaminated pump must not be sent to Grundfos for service until

Grundfos has received all necessary details about the pumped

liquid, etc. Otherwise, Grundfos can refuse to accept the pump for

servicing.

Possible costs of returning the pump are to be paid by the customer.

Sound Pressure Level

D1 D2 D3 L X

MTC

(mm/in) (mm/in) (mm/in) (mm/in)

C

(mm/in)

2, 4 140/5.51 160/6.30 180/7.09 121/4.76 3⁄4" NPT 7/0.28

8, 12, 16 180/7.09 210/8.27 200/7.87 100/3.94 1 1⁄4" NPT 9/0.35

Figure 4

Operating The Pump

Motor

(kW) 50 HZ 60 HZ

0.25 <70 <70

0.37 <70 <70

0.55 <70 <70

0.75 <70 <70

1.1 <70 <70

1.5 <70 71

2.2 <70 71

3.0 <70 71

4.0 73 71

5.5 73 78

7.5 73 78

LpA [dB(A)]