10 HANDICARE SIMPLICITY INSTALLATION MANUAL

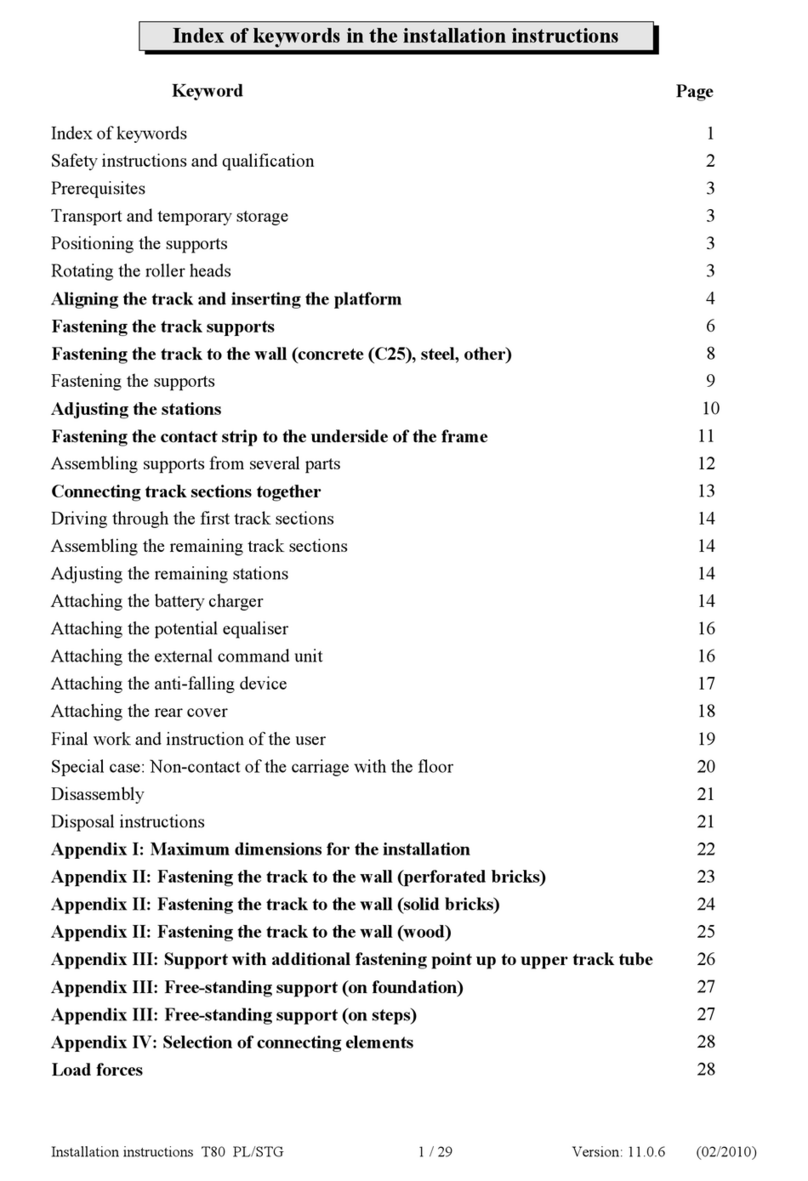

Figure 21

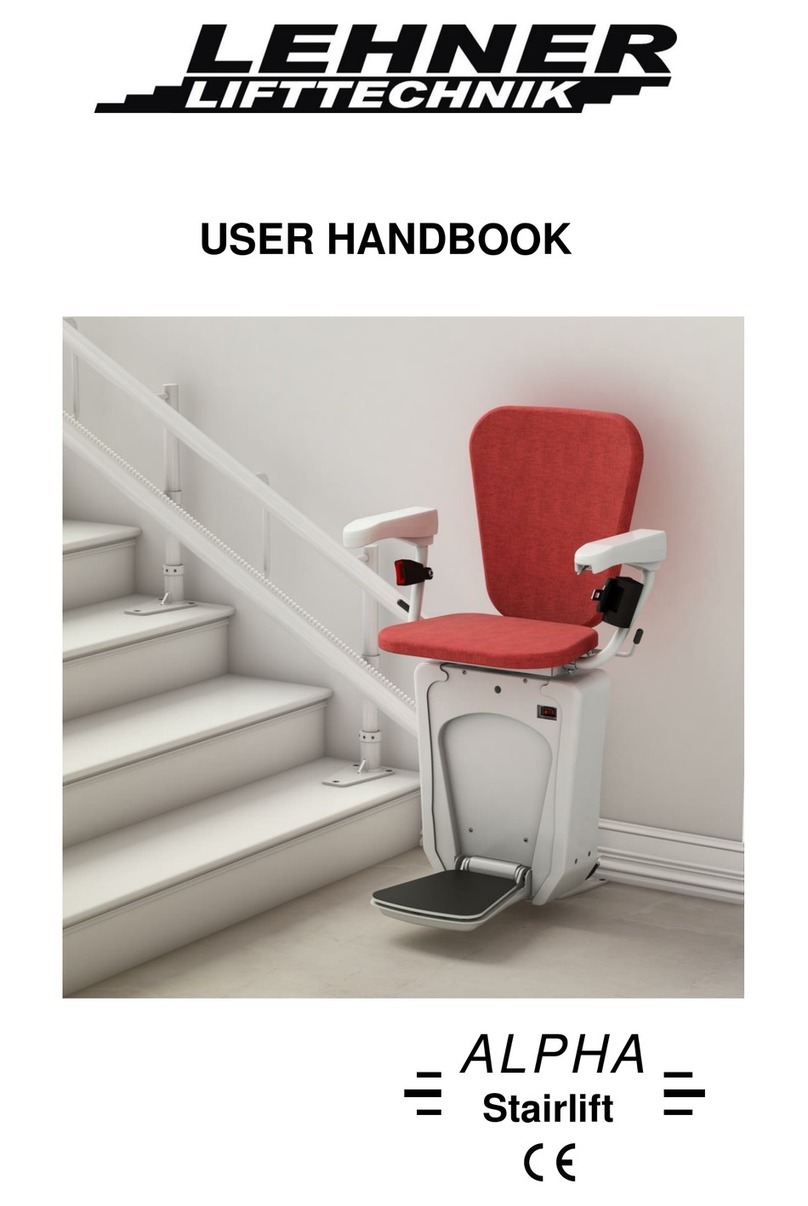

Figure 22

Loading the power pack

Loading the power pack

Items required: Tools required:

• Power pack • Loading toggle

• Fit Kit • Shorting links

End cap x 1

Green bag

Wood screws x 12

Final limit stops x 1

End stops x 1

Busbar pickup loading tool

(x 2 for Slide Track)

1 Carry the power pack box to the top of the

stairs.

2 Unpack the power pack from its box carefully.

3 Move the track away from the stringer slightly,

around 150mm, to give you more room to

work.

4 Remove the blanking plates from the side of

the power pack that will be facing the stairs

(Figure 22).

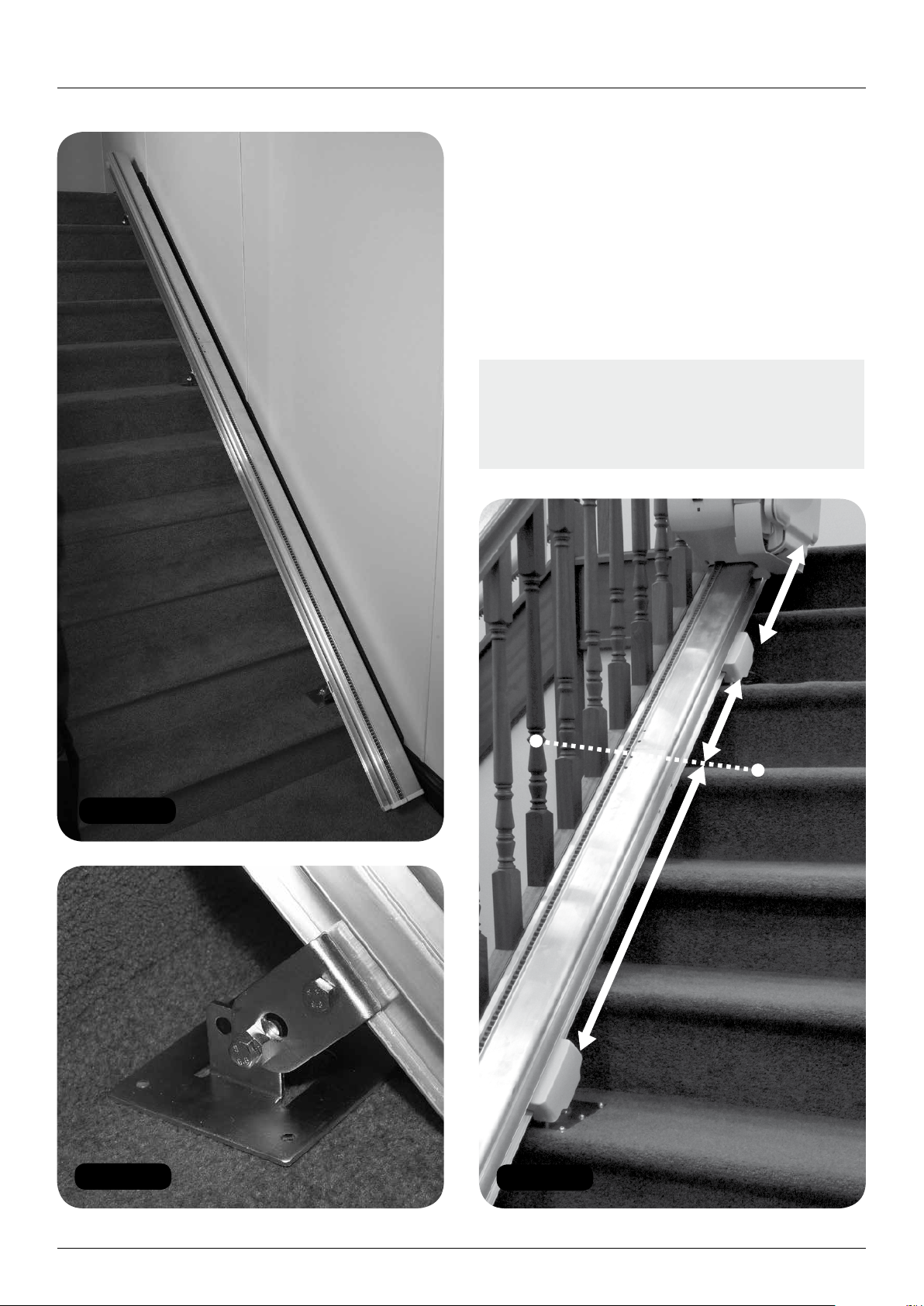

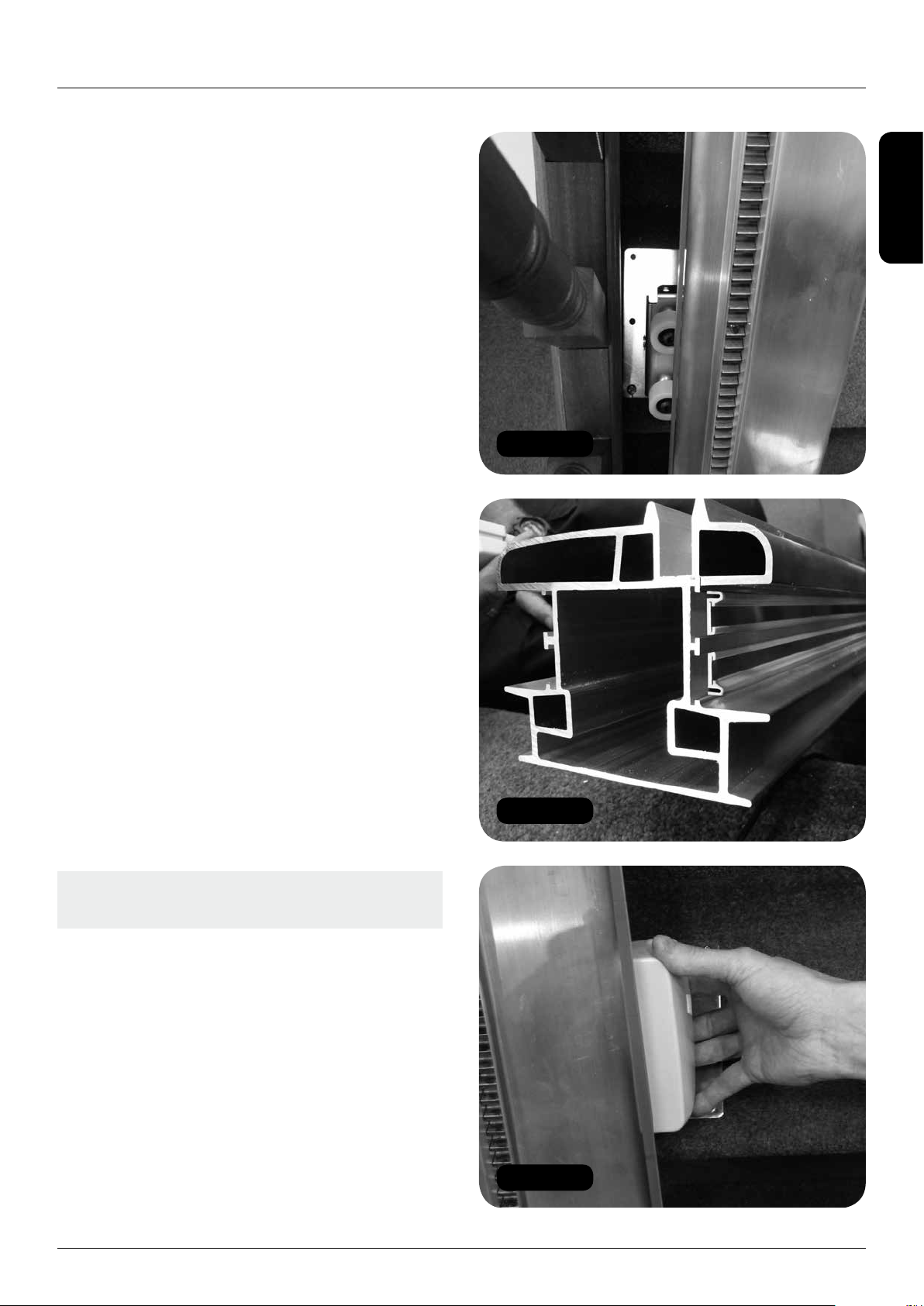

5 Connect the limit switch shorting links

(Figures 21 and 22).

6 Connect the driving links (or loading toggle)

(Figures 21 and 22).

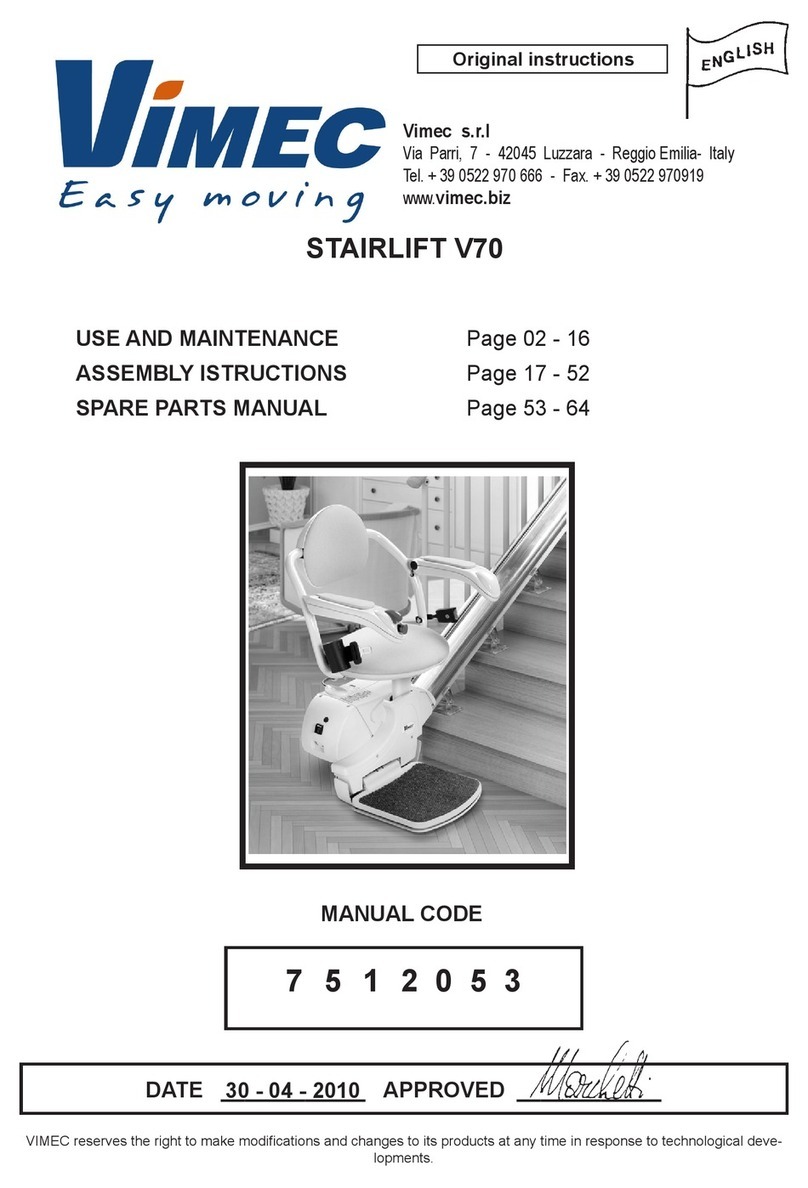

7 Ensure that the busbar pickup loading tool

is correctly positioned (Figure 23).

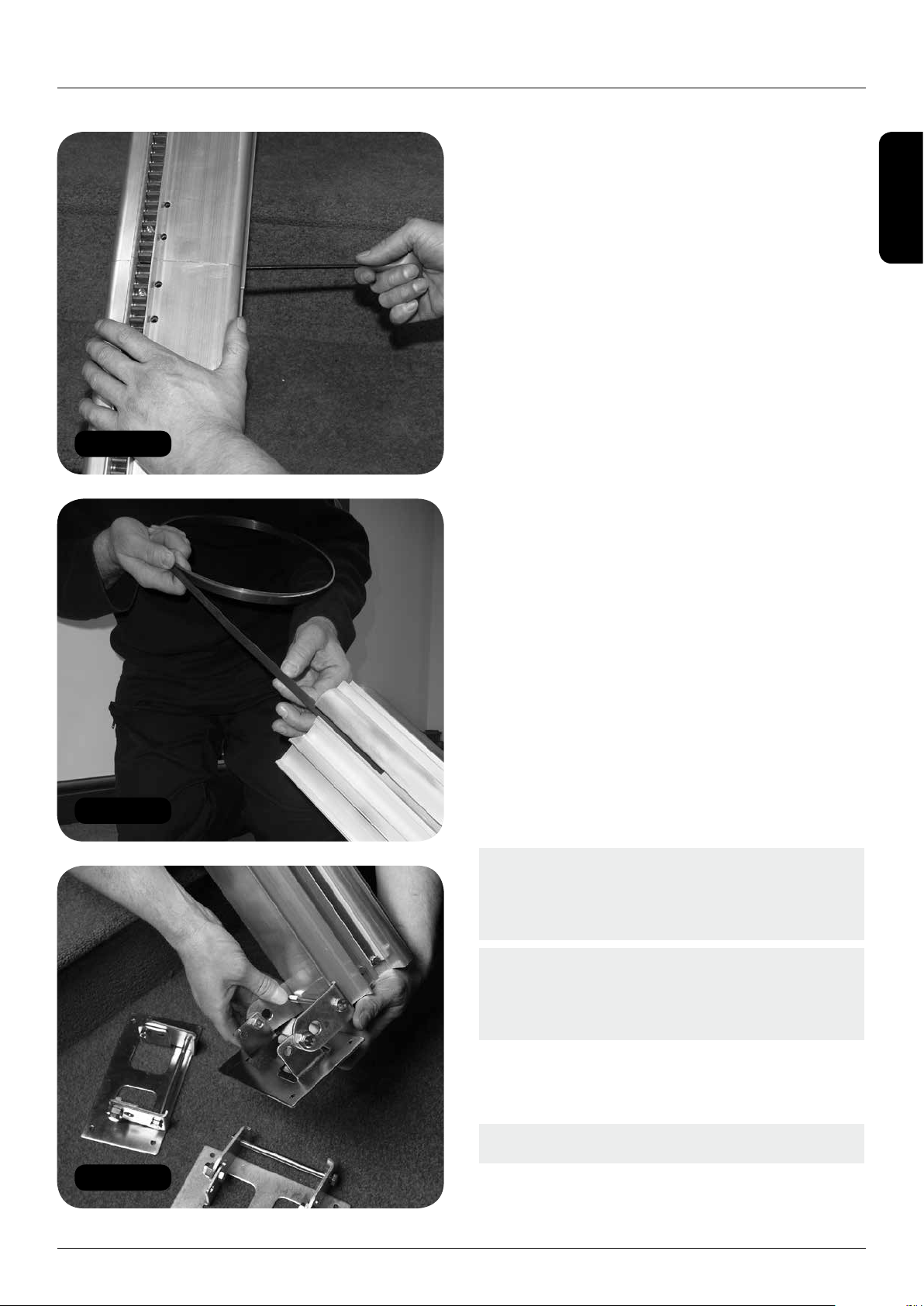

8 Carefully slide the power pack onto the track

until the drive pinion meets the beginning of

the rack (Figure 24).

9 Turn the power pack on from the main switch

on the lower safety edge (Figure 25).

10 Using the loading driving links or toggle

switch (Figure 26), drive the power pack

onto the track. The power pack should be

driven to a position approximately half way

between the top and middle foot.

11 Fit the top end stop and final limit stop to the

top of the track (Figure 27).

Note: The shorter (square ended stop) must

be fitted in the top channel – failure to do

this correctly could damage the lift.

12 Fit the top end cap to the track and tighten

the grub screws to secure it.

Note: The grub screws on the end cap should

not be over tightened. If the power supply

is being connected at the top of the stairs,

ensure that the power supply cable is fed

through the channel provided so that it exits

the track on the WALL side.

13 Now slide the top end stop and final limit

stop so that they sit against the positioning

extensions of the end cap and then tighten

the grub screws.