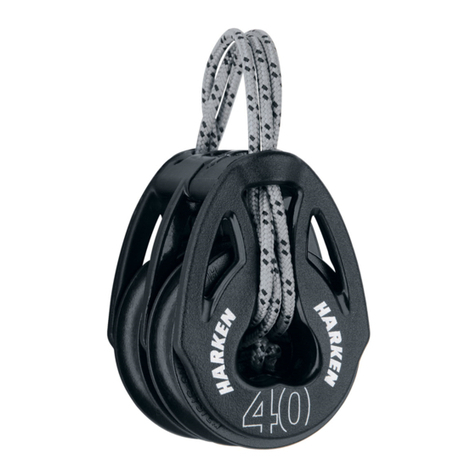

Harken 3299 User manual

Other Harken Marine Equipment manuals

Harken

Harken MKIII User manual

Harken

Harken 3386 User manual

Harken

Harken GT326S User manual

Harken

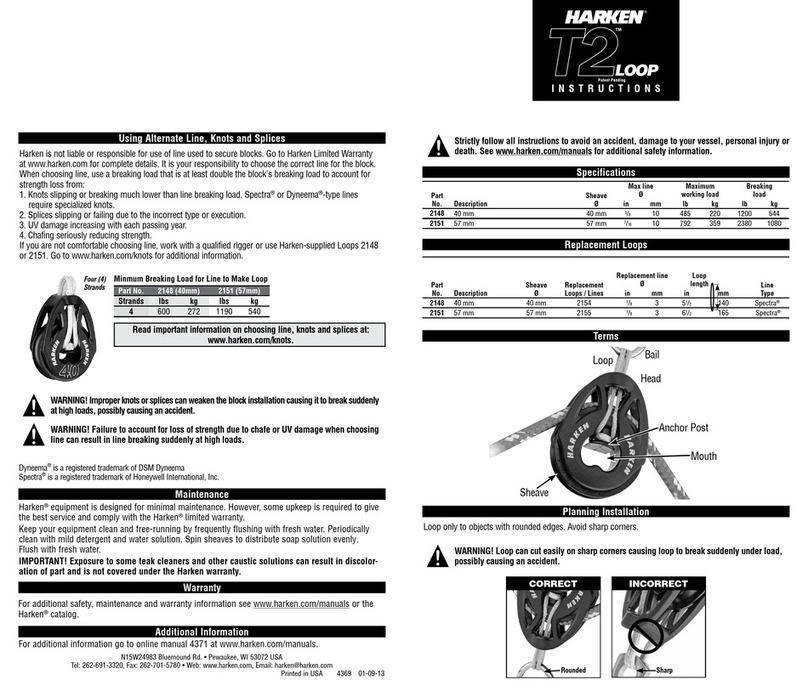

Harken T2 Loop 2148 User manual

Harken

Harken 3195 User manual

Harken

Harken 1635 User manual

Harken

Harken 1624 Assembly instructions

Harken

Harken R32 User manual

Harken

Harken 35.2 ST E Manual

Harken

Harken MKIV OCEAN Unit 3 User manual

Harken

Harken Carbo OneTouch User manual

Harken

Harken E2750HB User manual

Harken

Harken 7411.11 1/2.BLACK MKIV User manual

Harken

Harken 3299 User manual

Harken

Harken MKIV Unit 3 User manual

Harken

Harken T2 Loop 2148 User manual

Harken

Harken FlatWinder 250 Manual

Harken

Harken UNIT 2 MKIII User manual

Harken

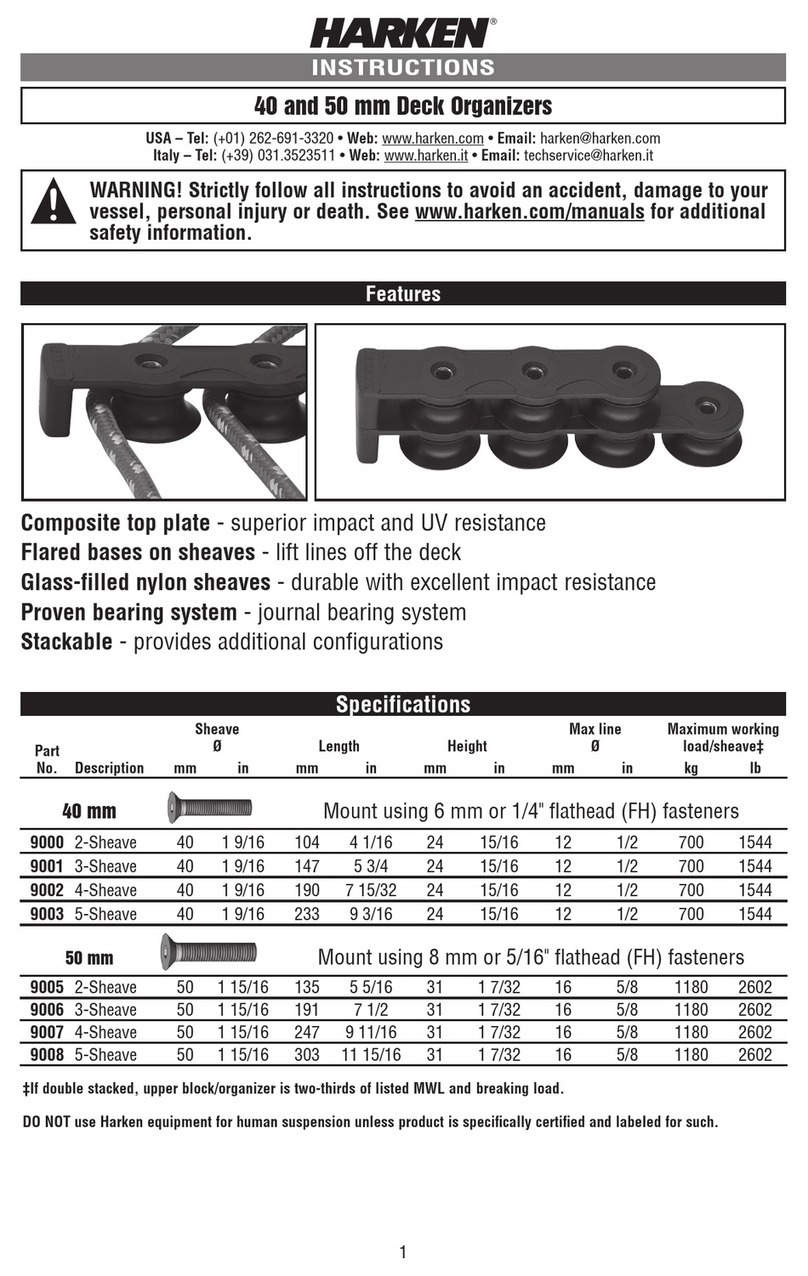

Harken 9000 User manual

Harken

Harken T2 Ratchamatic Block User manual

Popular Marine Equipment manuals by other brands

GUIDANCE MARINE

GUIDANCE MARINE 20- Series Installer's guide

Raymarine

Raymarine ST60 Tridata Owner's handbook

Sonic

Sonic 2024 Operation manual

Quicksilver

Quicksilver 88688A25 Installation, operation and maintenance instructions

Furuno

Furuno Navtex NX-700-A Operator's manual

olympia electronics

olympia electronics ΒS-532/WP quick start guide