harvst Sprout S6 Mini User manual

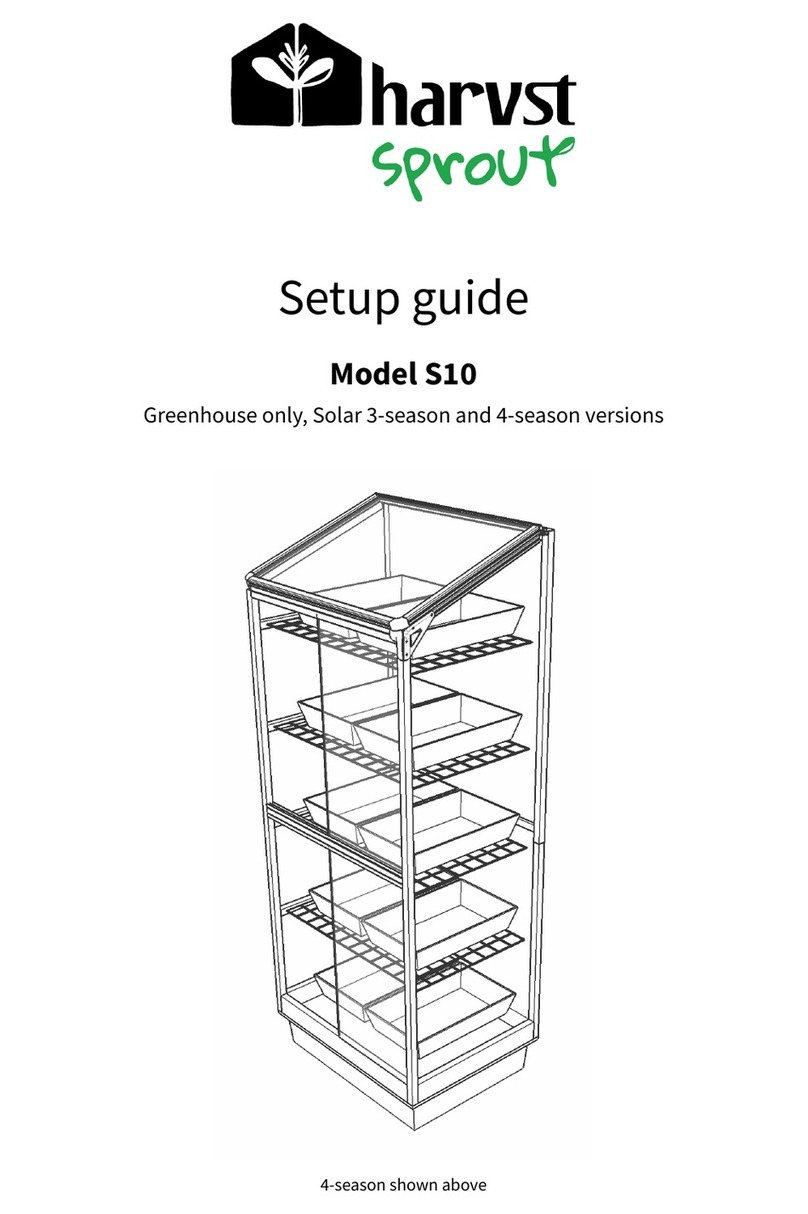

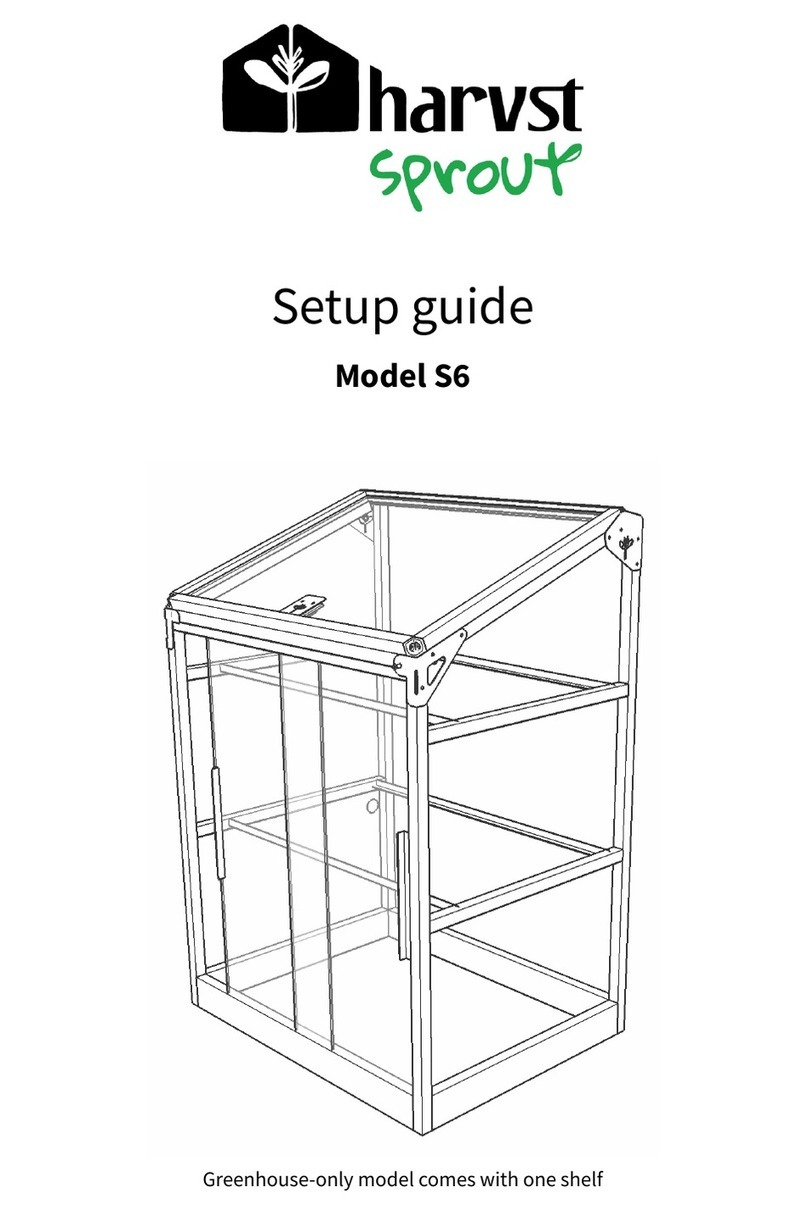

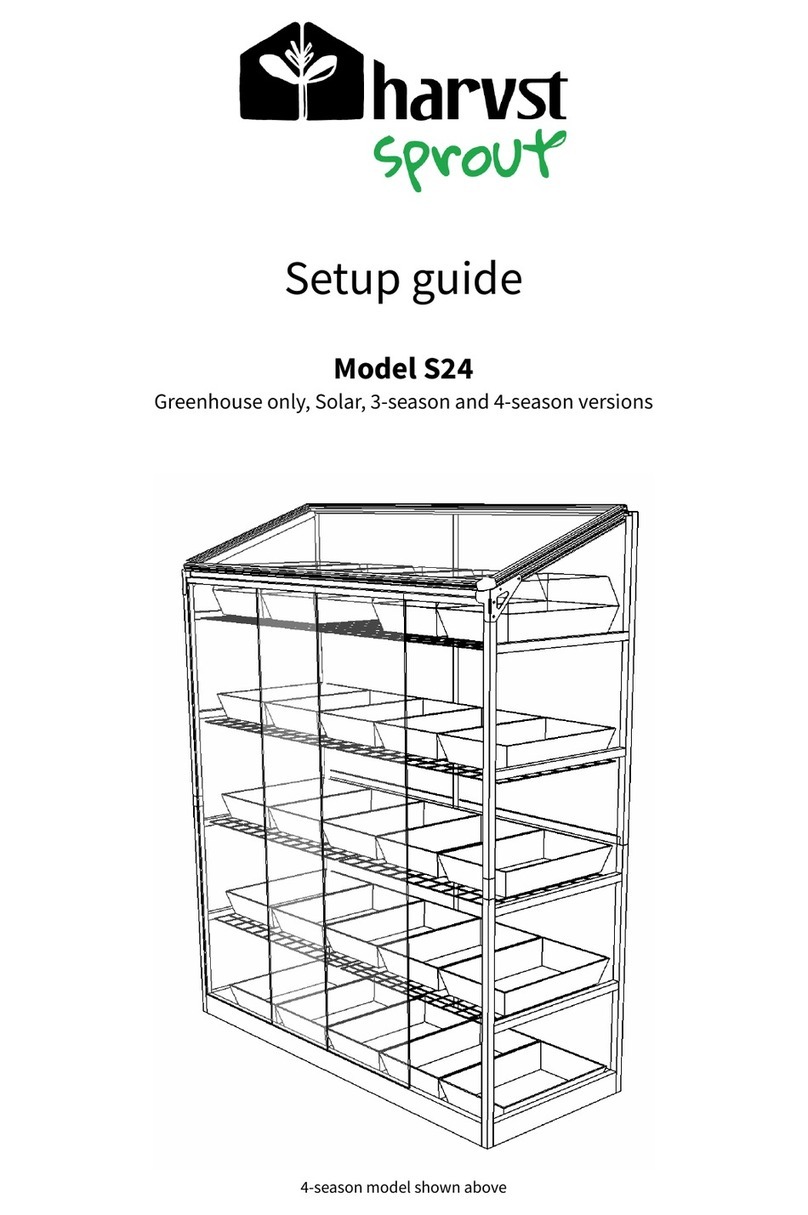

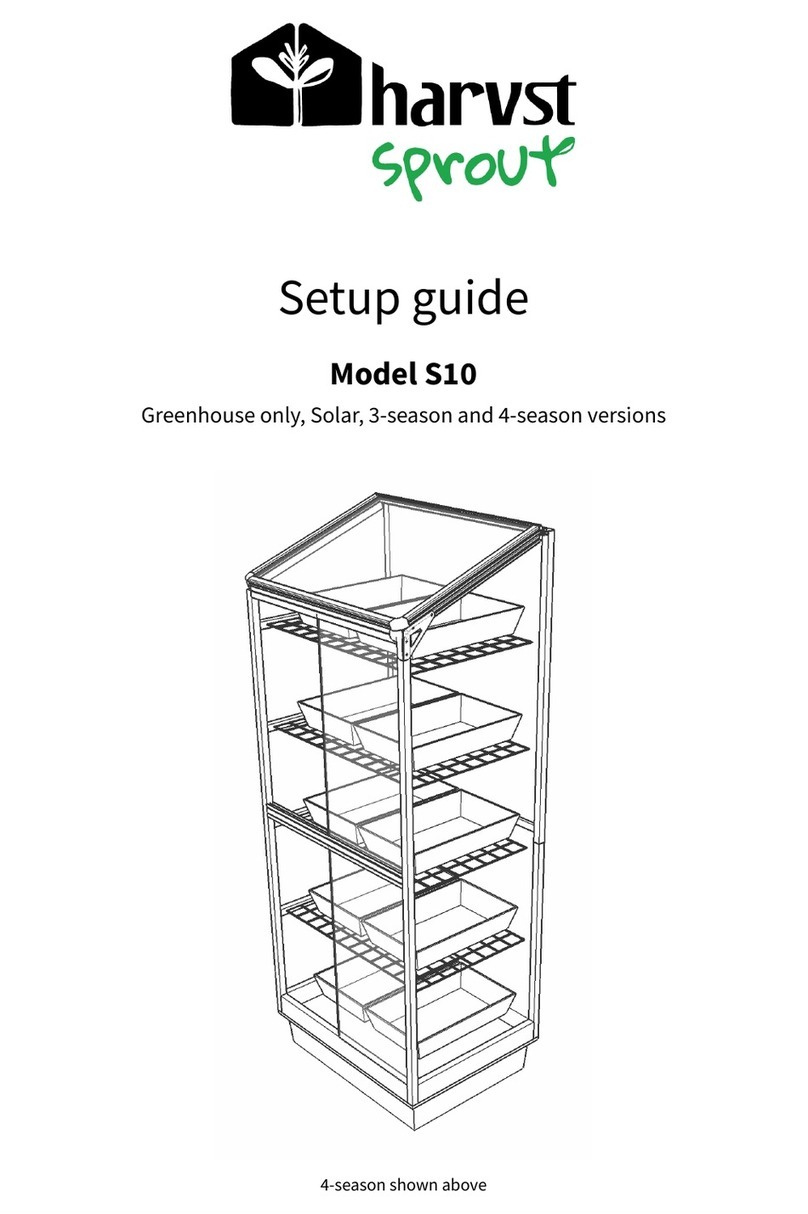

Setup guide

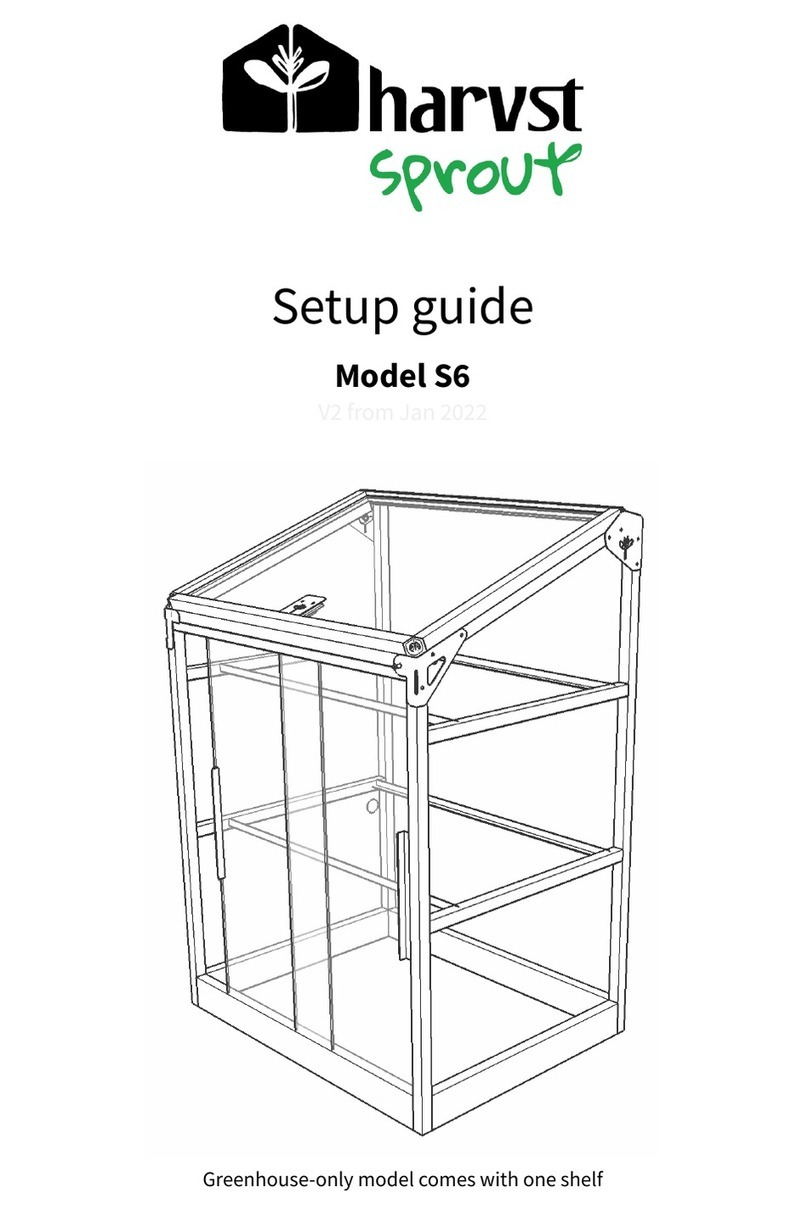

Model S6

Greenhouse only

V4 / From Feburary 2023

If you have a Smart Sprout please also use the smart setup guide whilst

assembling your S10

Thank you for buying a Harvst Sprout mini

greenhouse.

If you have any questions while setting up, send us an email

(help@harvst.co.uk) or check out our forums:

https://grow.harvst.co.uk

Important information

Sprout Mini Greenhouses are intended for outdoor use and should be

secured to a fence or wall with the provided fixings. Harvst accept no

liability for incorrectly used products.Exploded diagram

Tools provided

3mm allen key

8mm spanner

Pozidrive screwdriver

Tools required (not supplied)

Tape measure to identify parts

Secateurs for cutting pipe

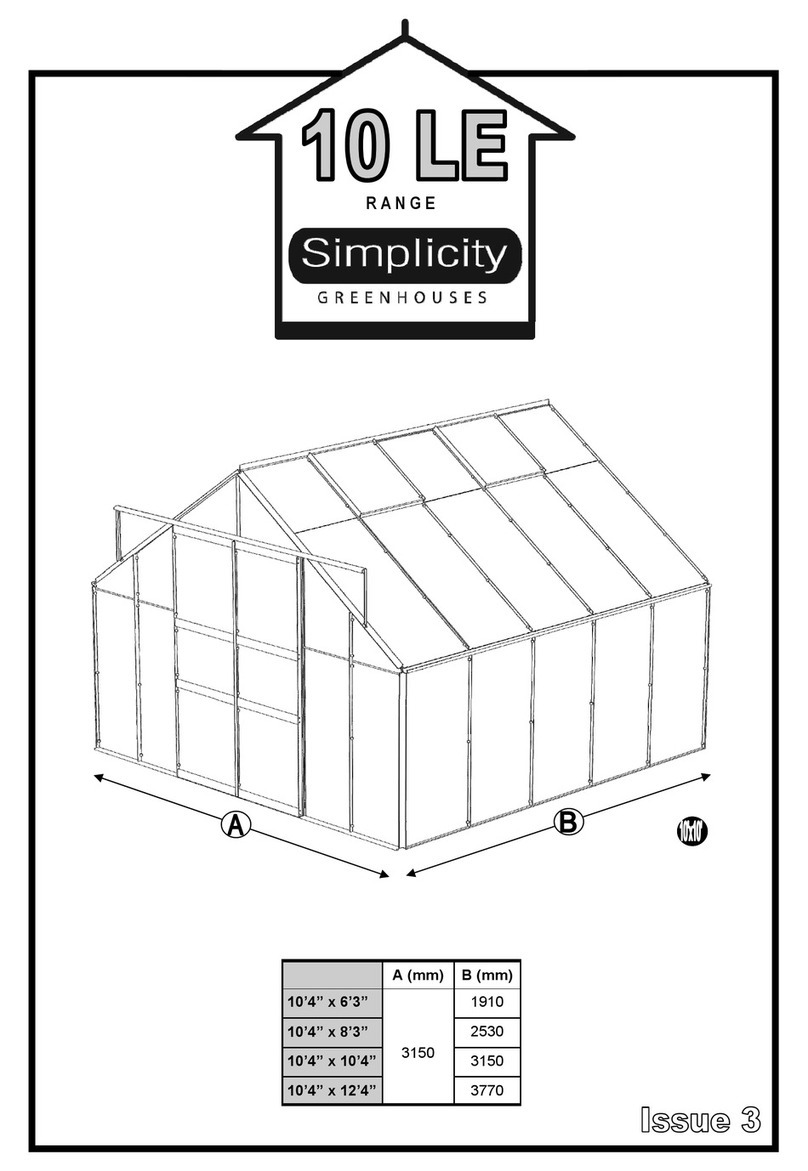

Parts list (aluminium pieces)

Weʼve fitted the front and rear uprights to the base parts for you, to save time and

help you get started. Weʼve also pre-fitted screws into bars, where required.

450mm x2

Lid sides, with corner cubes

600mm x1

Front crossbar

450mm x4

Side panel crossbar

2 pre installed screws per

piece

Front assembly x1

728mm uprights

600mm base

Rear assembly x1

910mm uprights

600mm base

600mm x1

Lid front

Door handles x2

610mm

Shelf supports x2

4 season kits will have a

LED shelf support bars

450mm x2

Side base parts with screws

1250mm two part lid hinge

x1

Side panel top assembly x2

One le and one right

Top mesh panel x1

Fixings and small parts

M5 x 8mm x12

M5 x 10mm x10

M5 x 16mm x2

M5 x 30mm x2

M5 Nyloc x6

M5 square nut x23

4.5 x 30 countersunk

head screws x2

4.5 x 30 dome head

screw x2

Blanking plug x10

M5 washer x2

Fixing bracket x2

10cm cable ties x20

Lid top plate x1

Adapter plate x1

4mm tubes for

shelving

90mm x2

190 x2

Roll of foil tape

3mm allen key

Screwdriver

8mm spanner

O-ring x2

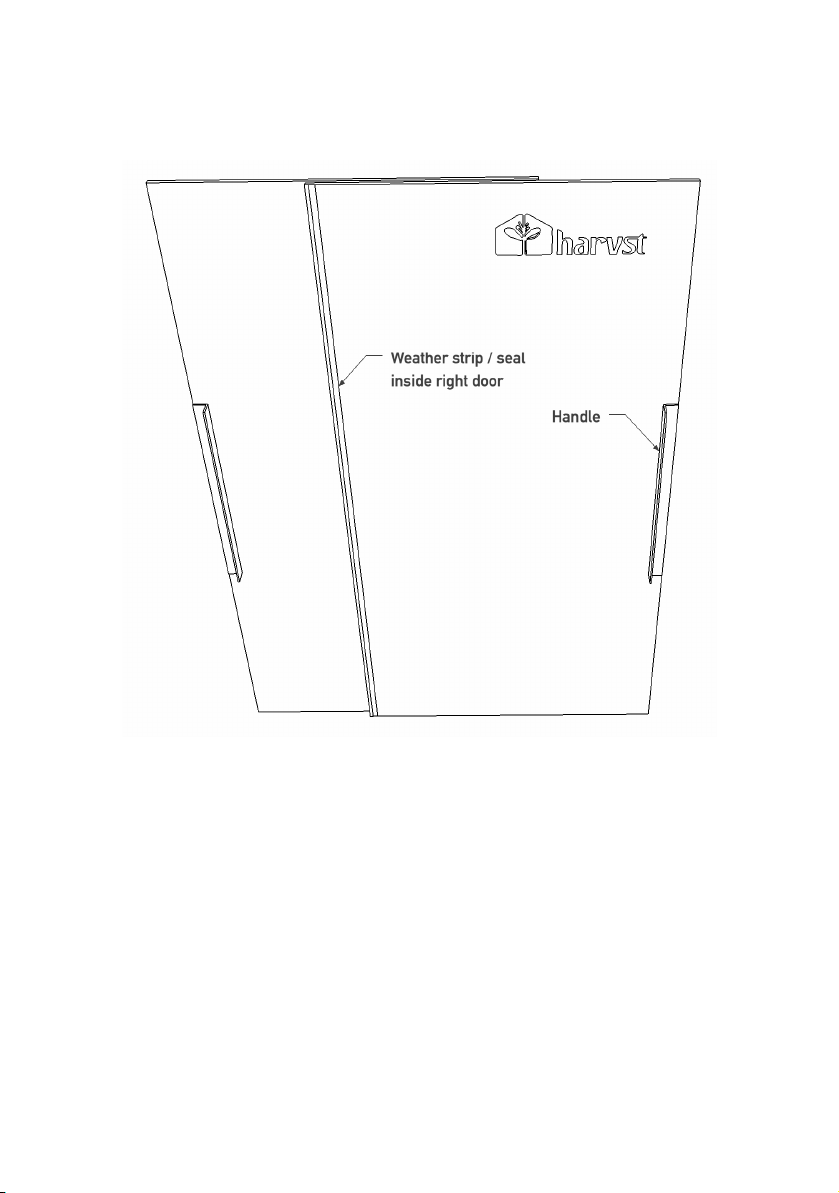

Panels

Black rear panel x1

Clear lid panel x1

Clear side panels x 8

Clear side top panel - le x1

Note: Holes for piping

Clear side top panel - right x1

Door pair x1

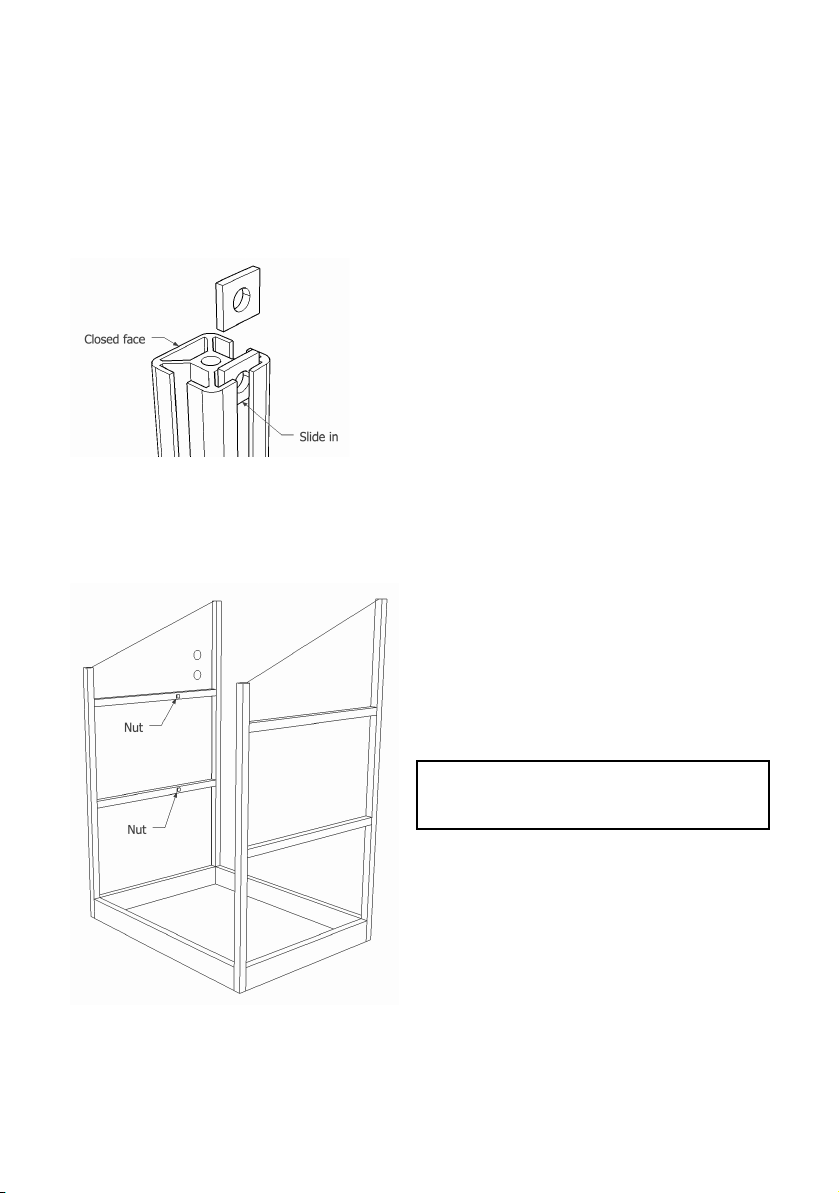

Introduction - slotting parts together

The greenhouse is based on parts that slot together using stainless steel screws, as shown in the

diagram below. These are self tapping screws which require a little bit of force to get them fully

seated.

Ensure that your screwdriver is

fully engaged with the screw

head when you tighten, so that

you donʼt round off the head of

the screw.

Note the orientation of each

piece in the description;

specifically the closed face.

Every care has been taken during manufacture to avoid sharp edges or burrs, however you

should still take care when handling metal parts.

WARNING DO NOT USE POWER TOOLS TO SCREW IN THE SCREWS. YOU MIGHT SNAP OFF

THE HEAD, WHICH IS NOT COVERED BY WARRANTY.

Step 1 - Seal the polycarbonate panels (optional)

Twin wall polycarbonate panels act like double glazing for your mini greenhouse, and to improve

the insulation characteristics, it is good to seal the ends of the channels using the provided foil

tape. It also helps prevent bugs from crawling into the plastic.

1. Peel back a couple of inches of the protective foil which covers both sides of the panels,

but donʼt take it all the way off yet.

2. Apply the tape to the end of the panel, covering the flutes.

3. Fold down the sides to seal the tape to the panels.

The white film is on the UV protected side which should face out when you place the panels

into the greenhouse.

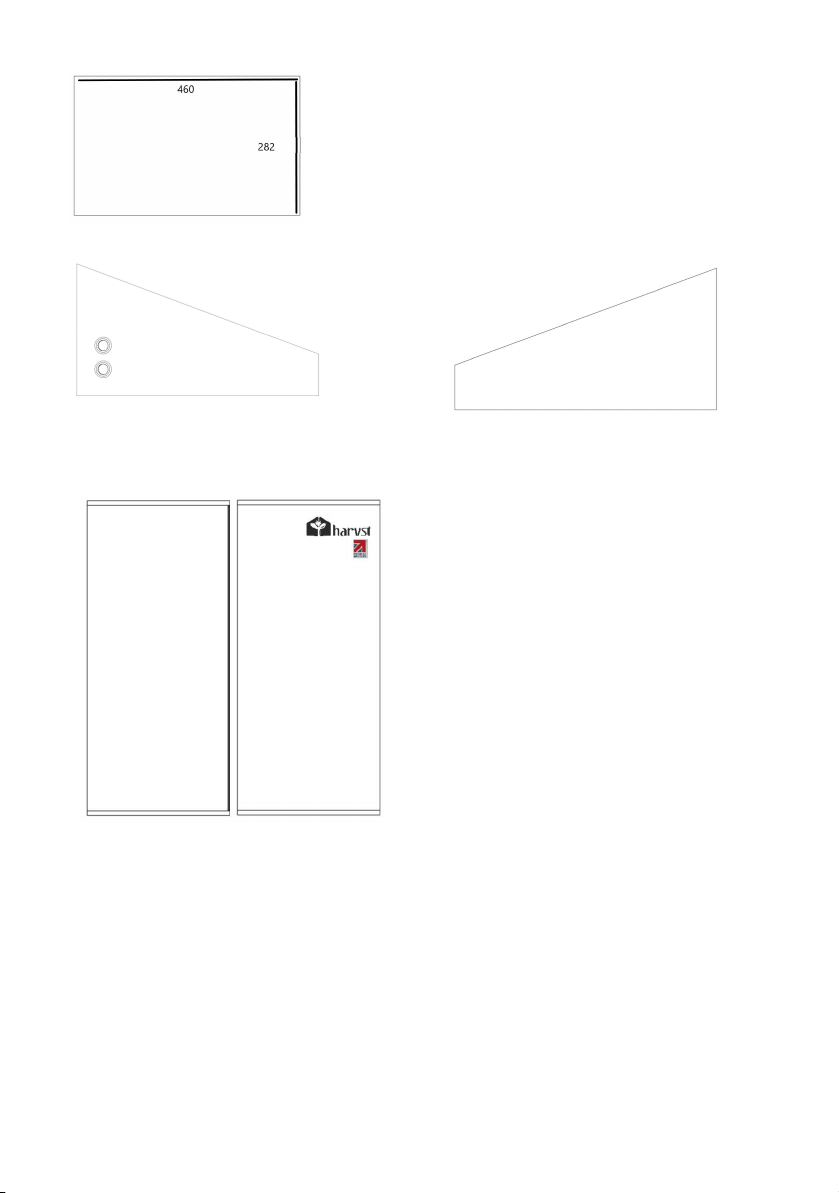

Step 2 - Fit the door handles

Do this step first to allow the adhesive tape to cure before fitting the doors at the end.

Parts

2 x door handle

1 x door pair

Fix the door handles to the doors as shown in the drawing

above, using the tape fixed to the handles.

Make sure you have peeled the protective film off the doors

first, that the surfaces are clean, dry and free from grease, and

that the UV treated side of the door panels (white film) faces

out.

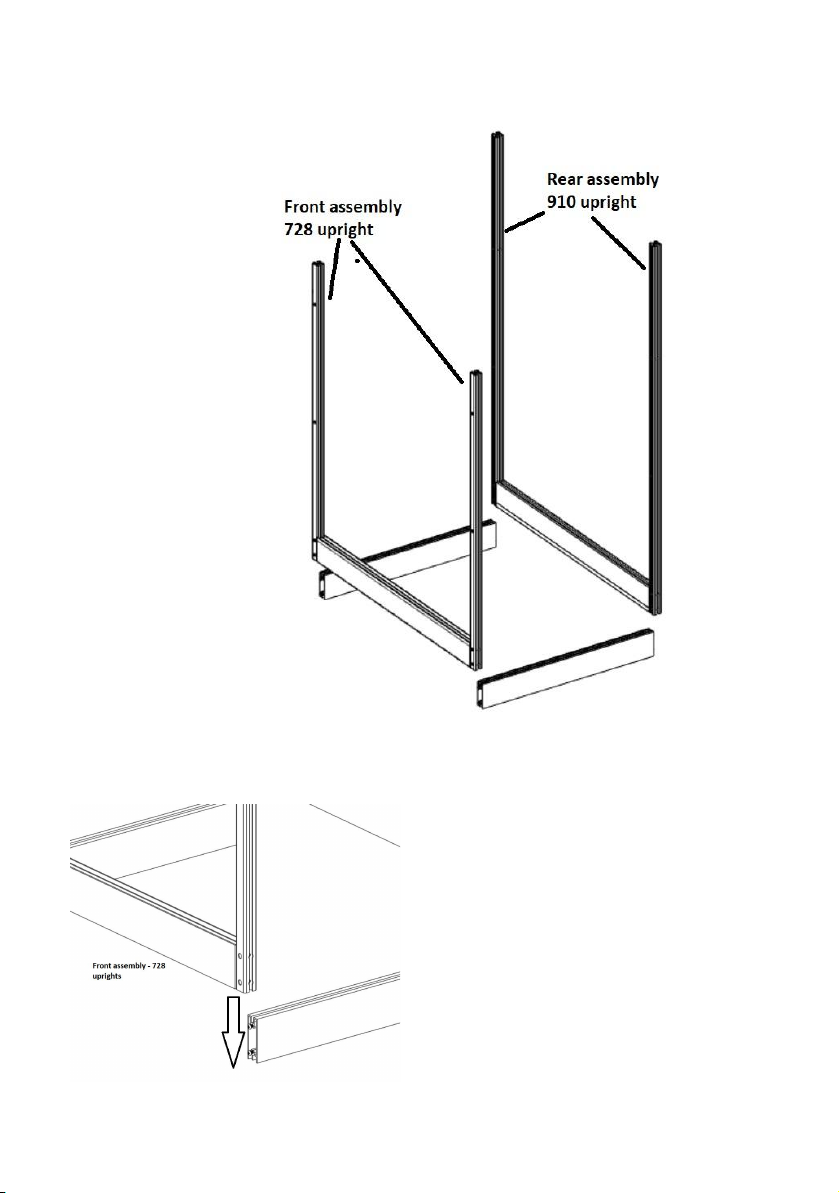

Step 3 - Assemble the base

Parts:

1 x front assembly

1 x rear assembly

2 x side base 45cm

This step is best done

on a flat surface where

you can easily access

the screws at the

bottom, such as a

table or workbench.

The closed faces on the

assembly uprights face

outside the

greenhouse.

Place the two side

bases with the single

channel facing up.

Slot the front assembly over the screws on the

side basees and tighten the screws.

Do the same for the rear assembly.

Step 4 - Insert square nuts into cross bars

Parts

2 x side cross bar 45cm

2 x M5 square nut

Insert one square nut into the inside channel of each

cross bar that will go on the le side of the

greenhouse.

The inside channel is the one opposite the closed

face.

These nuts are for irrigation parts which you may or

may not add in the future.

Step 5 - Insert the side panels and side cross bars

Parts:

4 x clear side panel

4 x side cross bar 45cm, two with nuts

Peel the protective plastic off both sides of two

side panels, remembering which side had the

white film.

The side with the white film should face

outside; it is the UV treated side.

Insert the bottom two clear side panels.

Slide a bar with square nut in the inside

channel over the le panel.

Slide a bar without a nut over the right panel.

Tighten the screws.

Finish inserting all the side panels and cross

bars in the same way.

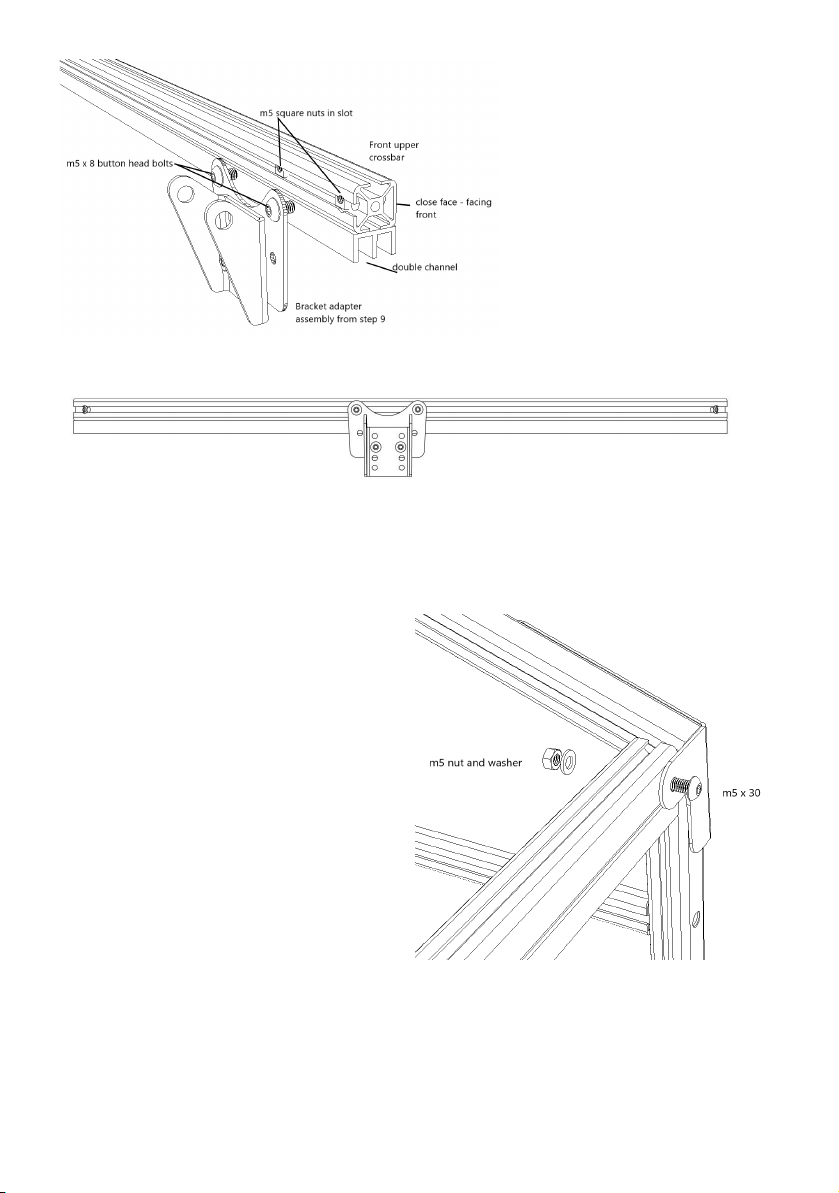

Step 6 - Fit the right side top assembly

Parts:

1 x Right side top assembly

3 x M5 * 8mm button head bolt

3 x M5 square nut

1 x M5 * 10mm button head bolt

Insert the 8mm bolts into the

assembly in positions marked 1,2,3,

and add the square nuts on the

inside, loosely.

Slide the assembly down over the

side panel, inserting the square

nuts into the outer channels on the

uprights.

Screw the 10mm bolt into the lower square nut which is already in the outside channel of the

assembly and tighten by hand. This will form part of the storm lock (see end of guide for more

info.) Ensure the second square nut in the channel is further up towards the rear of the

extrusion.

The front end goes down as far as it will go, and the rear end is flush with the top of the rear

upright (see drawing).

Tighten the bolts.

Step 7 - Fit the le side top assembly

Parts:

1 x Le side top assembly

3 x M5 * 8mm button head bolt

3 x M5 square nut

Repeat step 6 for the le hand side top assembly

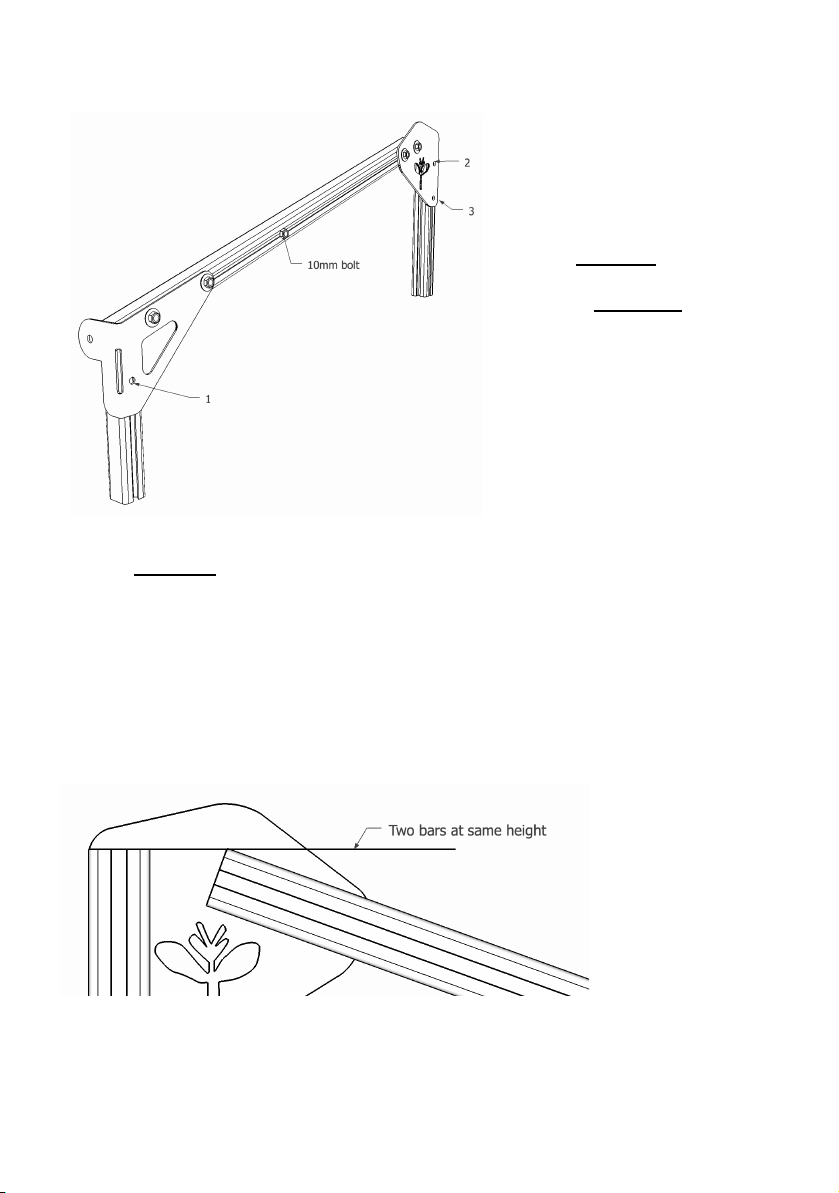

Step 8 - Fix lid lier bracket to adapter plate

This step is only relevant if you have purchased an automatic lid opener.

Parts in Lier Box :

1 x Piston Clip (end of box)

1 x Piston

1 x Arm

1 x Lier Bracket

The lid lier bracket is in the lid opener box.

Parts:

1 x lid lier bracket

1 x adapter plate

2 x M5 x 8mm button head

2 x M5 nyloc nut

Bolt the lier bracket to the adapter plate as

shown in the diagram to the right, with the

nyloc nuts on the inside of the bracket.

Step 9 - Fix bracket to front crossbar

Parts:

1 x front cross bar 60cm

1 x bracket assembly from step 8

2 x M5 x 8mm button head

2 x M5 square nuts

Slide two square nuts into the rear channel (the side opposite the closed face). Bolt the bracket

assembly in the exact centre of the bar.

Step 10 - Insert the front crossbar

Parts

2 x M5 x 30mm bolt

2 x M5 nyloc nut

2 x M5 washer

Use the M5 x 30 bolts to secure the front

crossbar to the rear of the side assembly

corner brackets.

Fix them in place with a washer and nyloc

nut on the rear.

Tighten so that the top door bar is secure.

Step 11 - Understand how the shelves fit

Refer to the drawing below to see the recommended position of the shelves.

Note: If you have a 4 seasons model please refer to your smart control guide for layout of

additional shelves

Parts:

2 x 90mm length 4mm pipe

2 x 190mm length 4mm pipe

A short section of 4mm tube pressed into the channel prevents the front shelf from sliding

forwards.

Use 190mm in front of the top shelf and 90mm length in your other shelf if applicable.

Step 12 - Fit the shelves

Parts:

Mesh shelves

2 x 610mm shelf support per shelf

4 x 10cm cable tie per shelf

Slide the square nuts for the 13mm water

pipe to the middle of the crossbars on the le

hand side of the frame, before you insert the

shelf supports.

Slot the shelf supports into the slots on the inside of the

side panel cross bars, inserting them at a diagonal and

then straightening up.

Place the mesh shelves onto the shelf supports and secure

with cable ties, one in each corner.

NOTE: The mesh shelf with a

slot cut out goes in the top

level to allow the lid lier

piston to operate. The front

shelf support goes in upside

down.

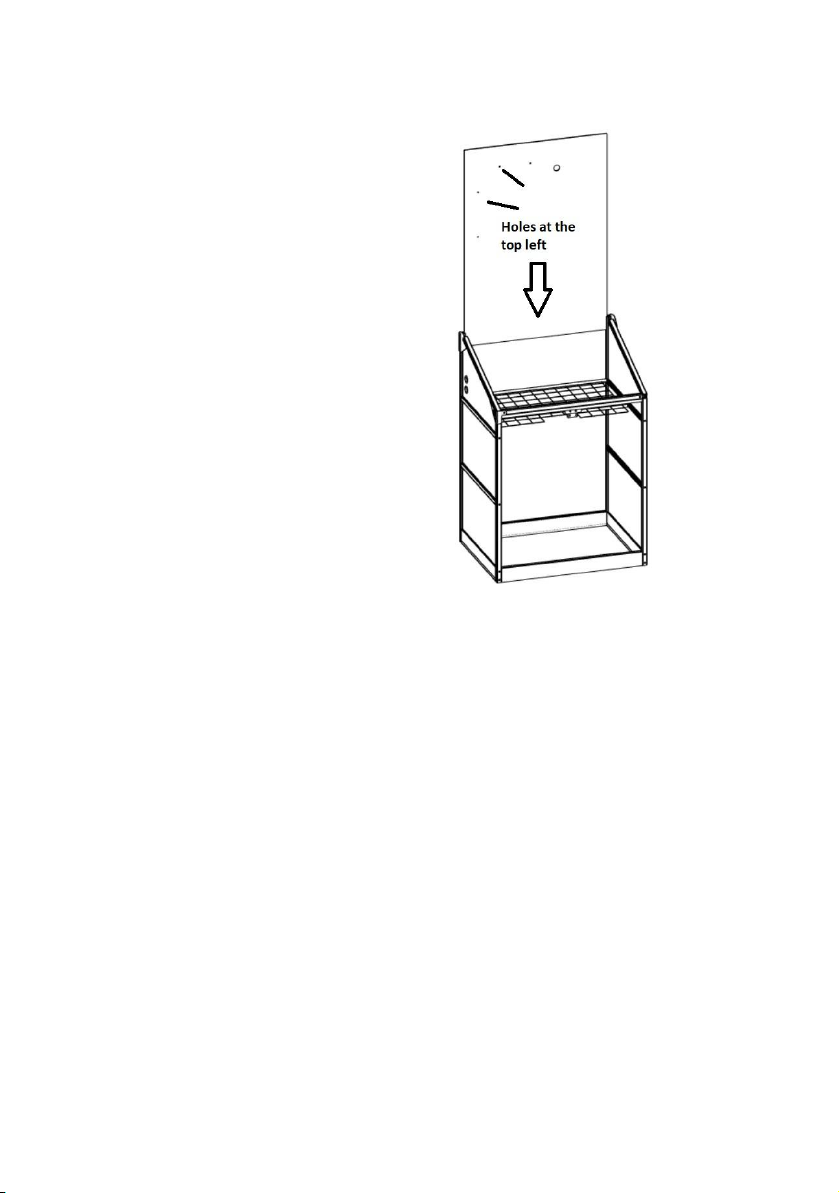

Step 13 - Install rear panel

Parts

1 x black rear panel

Drop the rear panel into the inner slots of the

rear uprights.

Ensure it goes fully into the lower base part -

itʼs a tight fit.

Note: Ensure the panel holes are in the top

le orientation when installing the panel

This step can be made easier by squeezing

the edges of the panels that will be in the

slots of the frame so that they are slightly

deformed.

Step 14 - Assemble the lid

Parts

1 x lid ridge

1 x lid bar rear

2 x lid side bars with corner caps

6 x M5 square nuts

2 x 30mm countersunk head screws

1 x 60cm lid front bar

1 x clear lid panel

a) Lay out the lid front bar onto a flat surface with the closed face facing downwards.

Attach the lid side bars with the corner piece to the lid front. The le and right lid side

bars are identified by L and R on their protective packaging.

Line up the corner piece with the open end of the lid front bar and use the countersunk

30mm screw to gently pull the corner piece into the end of the front bar

Repeat above steps for the le lid side

b) Peel back the film from the lid panel faces. The white side is outside facing. Slot the

clear lid panel into the internal area of the lid paying attention to the notches in the lid

panel corners as circled in the diagram below.

Insert 3 square nuts into the outside slot of the le/ right side bars.

c) Slide the ridge bar slotted face over the screws of the sidebar. Once positioned, tighten

the 2 screws in the side bars to fix the lid ridge in place.

Step 15 - Add lid props to lid

This is easiest done on a flat table or worktop.

Parts

2 x lid props

2 x m5 x 10 button head bolts

Note orientation of the lid prop

Secure the lid prop bracket. Measure 100mm from the rear of the lid sidebar to the centre of the

bolt and secure the bolt through the lid prop hole and into the square nut in the slot. Tighten

well.

Repeat for the other side, see diagram below.

Step 16 - Assemble lid lier

Parts

1 x lid lier piston

Insert the black lid lier piston into the lid lier, using the

instructions as supplied in the lier box.

Step 17 - Fit the lid lier to the lid

Parts:

2 x M5 x 16mm bolt

2 x M5 nyloc nut

1 x lid top plate

1 x lid lier

Locate the lid top plate in the orientation of the

diagram below on the exterior/ top of the lid. The

bottom lip of the plate below the harvst logo slots into

the gap between lid panel and the front lid bar for

support. The two holes on the lid top plate should

align with the holes on the lid panel.

Other manuals for Sprout S6 Mini

2

Table of contents

Other harvst Greenhouse Kit manuals

harvst

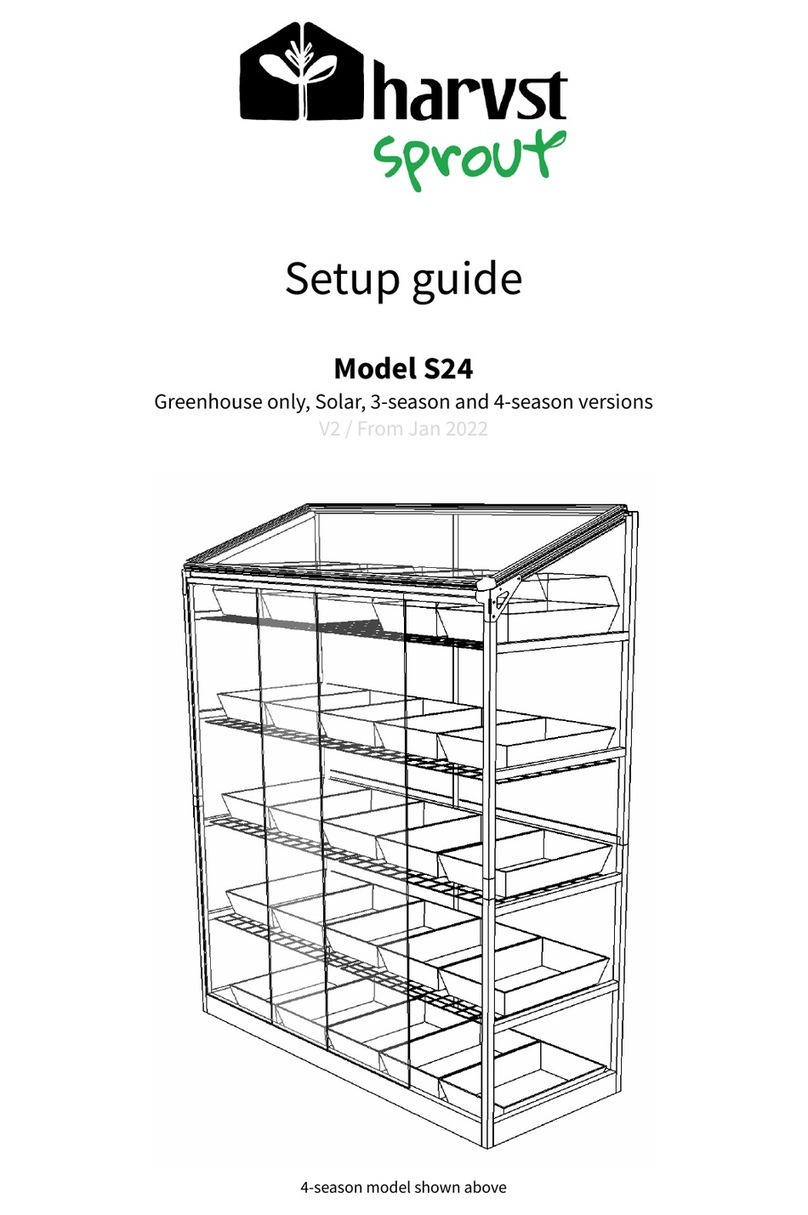

harvst S24 User manual

harvst

harvst S14 User manual

harvst

harvst Sprout S6 Mini User manual

harvst

harvst Terrace User manual

harvst

harvst Harvster User manual

harvst

harvst Terrace User manual

harvst

harvst Yard User manual

harvst

harvst Sprout S10 Mini User manual

harvst

harvst S14 User manual

harvst

harvst S14 User manual