HBK GEN7iB GEN Series User manual

English

User Manual

GEN series GEN7iB

Desktop and Rack Mount

Tethered Data Acquisition System

GEN7iB

2IMPRINT

IMPRINT

Document version 1.1 - June 2023

References made to the Perception software are for version 7.40 or higher

For HBK's Terms and Conditions visit www.hbm.com/terms

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

64293 Darmstadt

Germany

Tel: +49 6151 80 30

Fax: +49 6151 8039100

Email: [email protected]

www.hbm.com/highspeed

Copyright © 2023

All rights reserved. No part of the contents of this document may be reproduced or transmitted in

any form or by any means without the written permission of the publisher.

GEN7iB

LICENSE AGREEMENT AND WARRANTY 3

LICENSE AGREEMENT AND WARRANTY

LICENSE AGREEMENT and WARRANTY

For information about LICENSE AGREEMENT AND WARRANTY refer to:

www.hbm.com/terms.

Trademarks and patents

StatStream®is a registered trademark of HBK in the European Union and a trademark

in other countries.

StatStream® is patented in the US, Patent No. 7,868,886; patent pending in other

countries.

Legal statement

This product uses GNU General Public Licensed (GPL) software, the source code is

available at:

www.hbm.com/highspeed

For more information please refer to the following website:

www.gnu.org

LICENSE AGREEMENT AND WARRANTY

GEN7iB

4TABLE OF CONTENTS

TABLE OF CONTENTS

ToC - Overview

About this manual ......................................................13

1.1 Symbols used in this manual ........................................ 13

1.2 Manual conventions................................................ 14

2 Safety Messages ................................................15

2.1 Introduction....................................................... 15

2.2 Grounding ........................................................ 18

2.2.1 Mains power cord .................................................. 19

2.3 Instrument Symbols................................................ 20

2.4 Protection and isolation............................................. 21

2.4.1 Measurement categories............................................ 21

2.4.2 Basic insulation versus reinforced .................................... 23

2.4.3 Protection ........................................................ 25

2.4.4 Overvoltage/current protection....................................... 26

2.4.5 Isolation .......................................................... 26

2.5 Environment ...................................................... 27

2.6 Laser Safety....................................................... 28

2.7 Manual handling of loads ........................................... 29

2.8 International safety warnings ........................................ 30

2.9 Operation of electrical installations ................................... 46

3 Normative Documents and Declarations..............................47

3.1 Electrical ......................................................... 47

3.1.1 Electrostatic Discharge (ESD)........................................ 47

3.1.2 Electromagnetic Compatibility (EMC) ................................. 48

3.2 Environment ...................................................... 50

3.2.1 RoHS and WEEE - Waste Electrical and Electronic Equipment ............. 50

3.2.2 China RoHS ....................................................... 51

3.3 CE and UKCA Declaration of conformity ............................... 52

3.3.1 CE Declaration of conformity ........................................ 52

3.3.2 UKCA Declaration of conformity...................................... 52

3.4 FCC Class A Notice................................................. 53

4 Batteries .......................................................54

4.1 General........................................................... 54

4.2 Removal and replacement........................................... 55

4.3 Recharging ....................................................... 58

4.4 Disposal .......................................................... 59

GEN7iB 5

TABLE OF CONTENTS

TABLE OF CONTENTS

5 Mains Power ....................................................60

5.1 Power and frequency requirements ................................... 60

5.2 Connecting power.................................................. 61

5.3 Fuse requirements and protection .................................... 63

5.4 Fuse replacement .................................................. 64

6 Introduction.....................................................66

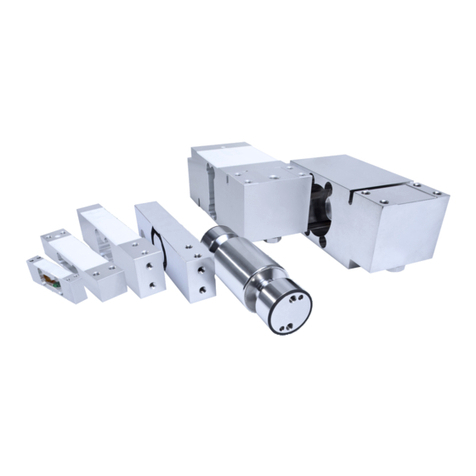

6.1 Introducing GEN7iB ................................................ 66

6.2 Mainframe overview................................................ 67

6.2.1 Mainframe feature comparison ...................................... 68

6.3 Hardware ......................................................... 69

6.3.1 PCI-e/CPCI backplane .............................................. 69

6.3.2 Input cards........................................................ 70

6.3.3 Master/Sync support ............................................... 70

6.3.4 Thermal protection ................................................. 70

6.4 Acquisition........................................................ 72

6.4.1 StatStream ....................................................... 73

6.5 Signal conditioning................................................. 74

6.6 Data storage ...................................................... 75

6.7 PC Section ........................................................ 76

6.8 Perception Software................................................ 77

6.8.1 Windows®logon password and remote desktop access.................. 77

6.9 Perception language settings ........................................ 78

7 Setting up the GEN7iB ............................................80

7.1 PC connections.................................................... 80

7.1.1 USB 3.0 and USB 2.0 ports .......................................... 82

7.1.2 Mini DisplayPorts .................................................. 82

7.1.3 Sound ............................................................ 82

7.1.4 Removable drive bay ............................................... 83

7.2 Removing and installing input cards .................................. 87

7.2.1 Removing cards ................................................... 87

7.2.2 Installing cards ..................................................88

7.3 Handle ........................................................... 90

7.3.1 Turning the handle ................................................. 91

7.4 Feet.............................................................. 92

7.4.1 To turn the feet out: ................................................ 92

7.4.2 To turn the feet in:.................................................. 92

7.5 Probe calibration................................................... 93

GEN7iB

6TABLE OF CONTENTS

TABLE OF CONTENTS

7.6 DC power output ................................................... 95

7.7 Digital Event/Timer/Counter ......................................... 97

7.7.1 Isolated event adapter ............................................. 101

7.7.2 Torque/RPM adapter .............................................. 102

7.7.3 eAxle setup ...................................................... 104

7.8 Accessing the CPU section ......................................... 105

7.9 Airlterreplacement .............................................. 110

8 Getting Started .................................................112

8.1 Front panel control ................................................ 112

8.2 Getting started ................................................... 114

9 Acquisition and Storage ..........................................115

9.1 Introduction...................................................... 115

9.1.1 The basic ideas behind Acquisition Modes in Perception V7 and V8 ...... 115

9.1.2 Terminology...................................................... 119

9.2 Acquistion Modes - User Interface ................................... 120

9.3 Setup for the Acquisition Modes .................................... 123

9.3.1 On start of acquisition ............................................. 123

9.3.2 Wait for trigger ................................................... 125

9.3.3 Waitfortriggertotriggermemoryrst ............................... 127

9.3.4 Onstartofacquisitionreducedrateandwaitfortriggertotriggermemoryrst

130

10 Digital Trigger Modes ............................................132

10.1 Introduction...................................................... 132

10.2 Understanding digital triggering ..................................... 133

10.2.1 Digital trigger detector ............................................. 133

10.2.2 Valid trigger conditions ............................................ 134

10.3 Trigger modes .................................................... 136

10.3.1 Basic trigger mode ................................................ 136

10.3.2 Dual trigger mode ................................................. 137

10.3.3 Triggerqualier ................................................... 138

10.4 Recorder and system trigger........................................ 139

10.5 Channel alarm .................................................... 140

11 Interface/Controller .............................................141

11.1 Introduction...................................................... 141

11.2 Communication and control ........................................ 142

11.2.1 Network protocols and ports........................................ 143

11.2.2 Using the 1 Gbit option connections ................................. 144

GEN7iB 7

TABLE OF CONTENTS

TABLE OF CONTENTS

11.3 Master/Sync connector ............................................ 145

11.3.1 Connecting the Master/Sync connector .............................. 149

11.3.2 Connecting multiple mainframes using the Master/Sync card ........... 150

11.3.3 Setting the Master/Sync operating modes ............................ 152

11.3.4 Synchronizing a Master/Sync setup to external time sources............ 154

11.4 I/O connector .................................................... 155

11.4.1 I/O connector input overvoltage protection ........................... 156

11.4.2 I/O connector functions and connector pinning........................ 157

11.4.3 External Start In/External Stop In.................................... 159

11.4.4 External Event In use with RT-FDB ................................... 161

11.5 Option - Removable Solid State Drive (SSD) ........................... 162

11.6 Option - Optical 1 Gbit Ethernet interface ............................. 164

11.7 Option - 10 Gbit Ethernet interface (SFP+ Module) ..................... 166

11.7.1 Installing a 1 Gbit SFP/10 Gbit SFP+ Module .......................... 173

11.7.2 Removing a 1 Gbit SFP/10 Gbit SFP+ Module ......................... 178

12 Input Cards ....................................................179

12.1 Available input cards .............................................. 179

12.2 GN310B (2 MS/s), GN311B (200kS/s) Power Analyzer input cards........ 182

12.2.1 Measuring voltages ............................................... 183

12.2.2 Connecting3-phaseArticialStarAdapter ............................ 187

12.2.3 Measuring currents ............................................... 189

12.2.4 Connecting HBM current transducers ................................ 193

12.2.5 Connecting LEM current transducers ................................ 194

12.2.6 Understanding the GN310B/GN311B category rating ................... 195

12.2.7 Understanding the GN310B/GN311B high voltage input ................ 197

12.2.8 GN310B/GN311B Isolation Voltage channel........................... 198

12.2.9 GN310B/GN311B Isolation Current channel ........................... 203

12.2.10 GN310B/GN311B type testing of the HV channels ..................... 204

12.3 Isolated 1kV input cards ........................................... 209

12.3.1 GN610B, Isolated 1kV 2MS/s input card with real-time formula database.. 209

12.3.2 GN611B, Isolated 1kV 200kS/s input card with real-time formula database 210

12.3.3 Using the GN610B/GN611B ........................................ 211

12.3.4 Understanding the GN610B/GN611B category rating ................... 215

12.3.5 Understanding the GN610B/GN611B input............................ 216

12.3.6 Using the High Precision Differential Probe ........................... 218

12.3.7 Measuring currents ............................................... 220

12.3.8 GN610B/GN611B Isolation and type testing........................... 221

12.3.9 GN610B/GN611B protection mechanisms ............................ 230

GEN7iB

8TABLE OF CONTENTS

TABLE OF CONTENTS

12.4 Isolated Basic/IEPE cards .......................................... 235

12.4.1 GN815, Isolated Basic/IEPE 2MS/s input card ......................... 235

12.4.2 GN816, Isolated Basic/IEPE 200kS/s input card ....................... 236

12.4.3 Using the GN815 and GN816 ....................................... 237

12.4.4 Understanding the GN815 and GN816 isolation........................ 239

12.4.5 Understanding the GN815 and GN816 input........................... 240

12.4.6 GN815 and GN816 Input overload protection .......................... 242

12.5 Basic high speed input card ........................................ 245

12.5.1 GN8101B/GN8102B/GN8103B, Basic 250, 100, 25 M/s input cards ....... 245

12.6 High resolution universal input card ................................. 246

12.6.1 GN840/GN1640 Universal 500 kS/s 8/16 channel input cards ........... 246

12.6.2 Basic mode and cabling............................................ 248

12.6.3 Bridge mode and cabling ........................................... 249

12.6.4 Basic sensor and cabling........................................... 253

12.6.5 Integrated Electronic Piezoelectric (IEPE) mode and cabling............. 254

12.6.6 Piezoelectric (Charge) mode and cabling ............................. 255

12.6.7 Resistive Temperature Detectors (RTD) mode and cabling. . . . . . . . . . . . . . . 256

12.6.8 Resistance mode ................................................. 257

12.6.9 Current loop mode and cabling...................................... 260

12.6.10 Thermocouple mode and cabling .................................... 261

12.6.11 DIN rail breakout .................................................. 262

12.6.12 Flexible wiring .................................................... 265

12.7 Opticalberisolatedinputcard ..................................... 266

12.7.1 GN1202B,Opticalberisolated100MS/sinputcard ................... 266

12.8 High resolution IEPE and Charge input cards .......................... 268

12.8.1 GN3210 IEPE and charge 250 kS/s input card ......................... 268

12.8.2 GN3211 basic 20 kS/s input card.................................... 270

13 Option Cards ...................................................272

13.1 Option Carrier Card (OCC) .......................................... 272

13.1.1 Option cards supported ............................................ 273

14 GEN series Synchronization Methods ...............................274

14.1 GEN series synchronization methods compared ....................... 274

14.1.1 Signal phase shift synchronization .................................. 274

14.1.2 Trigger synchronization ............................................ 276

14.1.3 Absolute time of day synchronization ................................ 277

14.1.4 Start/Stop synchronization ......................................... 279

14.1.5 Synchronizationspecicationoverview .............................. 280

GEN7iB 9

TABLE OF CONTENTS

TABLE OF CONTENTS

14.2 PTP ............................................................. 282

14.2.1 PTP(1) technology background ...................................... 282

14.2.2 PTP Protocol details............................................... 283

14.2.3 Best master clock algorithm (BMC) .................................. 284

14.2.4 PTP switch types ................................................. 286

14.2.5 Transparent clock switch synchronization ............................ 290

14.2.6 Common terms used in IEEE 1588 ................................... 294

14.2.7 PTP and Master/Sync ............................................. 295

14.3 GPS............................................................. 297

14.3.1 Installation....................................................... 297

14.3.2 Using the GPS antenna ............................................ 299

14.3.3 Setup comparison ................................................ 315

14.3.4 GPS antenna placement ........................................... 316

14.3.5 GPS antenna lightning protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 318

14.3.6 Trouble-shooting guide for G002B ................................... 318

14.4 IRIG............................................................. 319

14.4.1 System overview.................................................. 319

14.4.2 Installation....................................................... 322

14.4.3 Using the GMR1000 module ........................................ 323

14.4.4 Trouble-shooting guide for G001B ................................... 330

15 Understanding Inputs and Usage of Probes ..........................331

15.1 GEN series inputs ................................................. 331

15.1.1 Single-ended input ................................................ 332

15.1.2 Balanced differential input ......................................... 334

15.1.3 Isolated single-ended or Isolated unbalanced differential input........... 335

15.1.4 Isolated balanced differential input .................................. 337

15.2 GEN series voltage probe types ..................................... 339

15.2.1 Passive, single-ended voltage probes ................................ 340

15.2.2 Passive, single-ended isolated voltage probes ......................... 342

15.2.3 Passive, differential matched isolated voltage probes .................. 343

15.2.4 Active differential voltage probes.................................... 344

15.3 Probe bandwidth calibration ........................................ 345

15.3.1 1X Probes ....................................................... 345

15.3.2 10X Probes ...................................................... 347

15.3.3 Probes and differential measurements ............................... 348

15.4 Current shunt measurements ....................................... 349

A Real-time Formula Database Calculators ............................350

GEN7iB

10 TABLE OF CONTENTS

TABLE OF CONTENTS

A.1 Overview ........................................................ 350

B Maintenance ...................................................354

B.1 Preventive maintenance ........................................... 354

B.2 Preventive drive replacement ....................................... 355

B.2.1 Hard disk drive ................................................... 355

B.2.2 Solid State Drive (SSD)............................................. 355

B.3 Preventiveairlterreplacement ..................................... 356

B.4 Cleaning ......................................................... 357

B.5 Cleaning and disinfecting the touch screen ........................... 358

B.5.1 Cleaning the touch screen.......................................... 358

B.5.2 Disinfecting the touch screen ....................................... 358

B.5.3 US CDC-recommended disinfectant solutions safe for touch screen ...... 359

C Service Information .............................................361

C.1 General - Service Information ....................................... 361

C.2 Calibration/verication ............................................ 362

D Trouble-shooting ...............................................363

D.1 Boot setup ....................................................... 363

D.2 GHS Integrated system image restore................................ 367

D.2.1 Boot menu preparation ............................................ 367

D.2.2 Starting image restore ............................................. 369

D.2.3 Image restore phase 1 - Installing devices ............................ 372

D.2.4 Image restore phase 2 - Measuring video performance ................. 372

D.2.5 Image restore phase 3 - Windows 10 welcome......................... 373

D.2.6 Potential problems after restore..................................... 380

D.3 Touch screen calibration ........................................... 383

D.3.1 ELO touch screen ................................................. 384

D.4 Backing up the recovery partition.................................... 388

D.5 Recovery partition creation ........................................ 391

D.5.1 Using the Integrated System Recovery USB Disk....................... 391

D.5.2 Starting recovery partition creation .................................. 392

D.5.3 Starting recovery partition restore ................................... 393

D.6 GHS Integrated system BIOS update ................................. 396

D.7 Language settings in Windows...................................... 398

D.7.1 How to change the Windows®10 display language..................... 398

D.7.2 Installing a Language Pack in Windows 10............................ 401

D.8 Embedded Software upgrades ...................................... 410

D.8.1 Boot recovery switch .............................................. 410

GEN7iB 11

TABLE OF CONTENTS

TABLE OF CONTENTS

D.9 Unexpected mainframe shutdown ................................... 413

D.10 The Master/Sync connection does not synchronize .................... 414

D.11 Optical Network (SFP) ............................................. 415

D.12 Master/Syncconnectionvericationprocedure........................ 416

D.13 IRIG GMR1000 Trouble-shooting .................................... 418

D.14 GPS OTMC 100 Trouble-shooting .................................... 443

D.15 Diagnostics web page interface ..................................... 464

E Frequently Asked Questions ......................................465

E.1 Overview ........................................................ 465

F Rack Mount Instructions .........................................466

F.1 Mount GEN7iB in a 19-inch rack ..................................... 466

G PTP Synchronization ............................................468

G.1 Mainframe PTP connections........................................ 468

G.1.1 GEN7i ........................................................... 468

G.1.2 GEN7iA/GEN7iB .................................................. 469

G.1.3 GEN7tA/GEN7tB .................................................. 470

G.1.4 GEN2tB.......................................................... 471

G.1.5 GEN4tB.......................................................... 472

G.1.6 GEN3i ........................................................... 473

G.1.7 GEN3iA.......................................................... 474

G.1.8 GEN17tA/GEN17B ................................................ 475

G.2 Perception settings ............................................... 476

G.3 Synchronizing GEN series and QuantumX using PTP ................... 477

G.3.1 GEN3i with single QuantumX "B" version module....................... 477

G.3.2 GEN3i with single SomatXR "B" version module........................ 478

G.3.3 GEN3i with up to three QuantumX "B" version modules ................. 479

G.3.4 GEN3i with standard network switch and four or more of QuantumX "B" version

modules......................................................... 481

G.3.5 GEN3i with PTP network switch and four or more of QuantumX "B" version

modules......................................................... 483

G.3.6 GEN7tA/GEN7tB with multiple QuantumX "B" version modules ........... 485

G.3.7 GEN7tA/GEN7tB with single QuantumX "B"; version module ............. 486

G.3.8 Genesis using GPS-to-PTP bridge with Master/Sync Connected Systems.. 487

G.3.9 PTP Grandmasters ................................................ 488

G.3.10 HBK UL-0265 gigabit PTP switch .................................... 489

G.3.11 Siemens Scalance XR234-12M PTP switch ........................... 490

G.3.12 PTPcongurationerrors ........................................... 491

GEN7iB

12 TABLE OF CONTENTS

TABLE OF CONTENTS

H ApplicationSpecicUsage .......................................492

H.1 Calculatingmaximumbercablelength .............................. 492

H.2 Wake-on-LAN support (WOL)........................................ 494

H.2.1 Locating GEN3i, GEN3iA, GEN7i, GEN7iA and GEN7iB MAC/Physical address ..

496

H.2.2 Locating GEN3t, GEN7tA/GEN7tB and GEN17tA/GEN17tB MAC/Physical

address ......................................................... 498

H.3 eAxleconguration................................................ 500

H.4 Conguringanencoderwithdirectionandreset ....................... 502

H.4.1 From encoder to level converter ..................................... 502

H.4.2 From level converter to Digital I/O connector on the mainframe .......... 505

H.4.3 Activate Digital I/O channels with Perception.......................... 505

GEN7iB 13

ABOUT THIS MANUAL

ABOUT THIS MANUAL

1

1 About this manual

1.1 Symbols used in this manual

The following symbols are used throughout this manual to indicate warnings and

cautions.

DANGER

DANGER

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

WARNING

Indicates an electrical shock hazard which, if not avoided, could result in death or serious

injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could result in minor or

moderate injury; or alerts against unsafe practices; or alerts against actions which could

damage the product or result in a loss of data.

CAUTION

The ESD susceptibility symbol indicates that handling or use of an item may result in dam-

age from ESD if proper precautions are not taken.

Notice

The product or the environment may be damaged.

Impor

tant

Read the text to avoid errors with the usage of the GEN DAQ products.

Tip

The info icon indicates sections which provide additional information about the product.

This information is not essential for correct operation of the instrument, but provides

knowledge to make better use of the instrument.

GEN7iB

14 ABOUT THIS MANUAL

ABOUT THIS MANUAL

1

1.2 Manual conventions

When the wording “Click Start ...” is used, this refers to the Windows® Start button.

Compared to Windows®XP, Windows®Vista, Windows®7 and Windows®10, the Start

Menuhasundergonesomesignicantchanges.Thetaskbariconisnolongerlabeled

“Start” and is now simply the pearl icon (of the window-frame in an orb).

For clarity and convenience, these conventions are used throughout this manual:

●Menu names from the display appear in bold, blue lettering.

●Settings within a menu appear in bold, red lettering.

●Front panel controls and control names appear in bold, black lettering.

GEN7iB 15

SAFETY MESSAGES

SAFETY MESSAGES

2

2 Safety Messages

2.1 Introduction

Impor

tant

Read this section before using this product!

This instrument is mains powered and protective ground connections are required

(unlessotherwisespeciedforcertainparts).

This manual contains information and warnings that must be observed to keep the

instrument safe. The instrument should not be used when environmental conditions

exceedtheinstrument’sspecications(e.g.damp,highhumidity)oriftheunitisdam-

aged.

For the correct and safe use of this instrument, it is essential that both operating and

service personnel follow generally accepted safety procedures in addition to the safety

precautionsspeciedinthismanual.

Whenever it is likely that safety protection has been impaired, the instrument must be

madeinoperativeandsecuredagainstanyunintendedoperation.Qualiedmainte-

nance or repair personnel should be informed. Safety protection is likely to be impaired

if, for example, the instrument shows visible damage or fails to operate normally.

Appropriate use

This instrument and the connected transducers may be used only for measurement

and directly related control tasks. Any other use is not appropriate. To ensure safe

operation,theinstrumentmayonlybeusedasspeciedinthisusermanual.

●The covers protect the user from live parts and should only be removed by suitably

qualiedpersonnelformaintenanceandrepairpurposes.

●The instrument must not be operated with the covers removed.

●This instrument must not be used in life support roles.

●There are no user serviceable parts inside the instrument.

Itisalsoessentialtofollowtherespectivelegalandsafetyregulationsforspecic

applications during use. The same applies to the use of accessories. Additional safety

precautions must be taken in setups where malfunctions could cause major damage,

loss of data or even personal injury.

Some examples of precautions are: mechanical interlocking, error signaling, limit value

switches, etc.

GEN7iB

16 SAFETY MESSAGES

SAFETY MESSAGES

2

Maintenance and cleaning

The instrument is a maintenance-free product. However, please note the following

information about cleaning the housing:

●Before cleaning, disconnect the instrument completely.

●Clean the housing with a soft, slightly damp (not wet!) cloth. Never use solvents,

since these could damage the housing or the labeling on the front panel.

●When cleaning, ensure that no liquid gets into the housing or connections.

General dangers, failing to follow the safety instructions

This instrument is a state-of-the-art device and as such is fail-safe. Using this instru-

ment may be hazardous if it has been installed incorrectly and is operated by untrained

personnel. Any person assigned to install, maintain or repair the unit or to put the unit

intooperationmusthaverstreadandunderstoodtheusermanual,particularlythe

technical safety instructions.

Residual risks

This instrument’s scope of supply and performance covers only a small area of mea-

surement technology. In addition, equipment planners, installers and operators should

plan, implement and respond to the safety engineering considerations of measurement

technology in such a way as to minimize any residual risks. Prevailing regulations

must be complied with at all times. The residual risks of the measurement technology

must be referenced.

Conversionsandmodications

Neitherthedesignnorthesafetyfeaturesofthisinstrumentmaybemodiedwithout

ourexpresspriorwrittenagreement.Anymodicationshallexcludeallliabilityon

our part for any resultant damage. In particular, any repair or soldering work on cards

(replacement of components) is prohibited. When exchanging complete units, use only

originalpartsfromHBM.Theunitisdeliveredfromthefactorywithaxedhardware

and/orsoftwareconguration.Changesshouldonlybemadewithinthepossibilities

documented in this manual.

GEN7iB 17

SAFETY MESSAGES

SAFETY MESSAGES

2

Qualiedpersonnel

Peopleentrustedwiththeinstallation,tting,operationoftheinstrumentandputting

theunitintoservicemusthavetheappropriatequalications.Theinstrumentmayonly

beinstalledandusedbyqualiedpersonnel,instrictaccordancewiththespecica-

tions and the safety rules and regulations. This includes people who meet at least one

ofthethreefollowingqualicationlevels:

●Project personnel: Have a working knowledge of the safety concepts of automa-

tion and test and measurement technology.

●Automation plant or test and measurement operating personnel: Have been

instructed on how to handle the equipment and are familiar with the operation of

the cards and technologies described in this documentation.

●Commissioning engineers or service engineers: Have successfully completed the

training on how to repair the automation systems. They are also authorized to acti-

vate, to ground and to label circuits and equipment in accordance with engineering

safety standards. It is essential that the legal and safety requirements for the

product and any accessories are complied with during use.

GEN7iB

18 SAFETY MESSAGES

SAFETY MESSAGES

2

2.2 Grounding

The instrument must be used with a protective ground connection via the protective

ground conductor of the supply cable. The protective ground conductor is connected

to the instrument before the line and neutral connections are made when the supply

connectionismade.Ifthenalconnectiontothesupplyismadeelsewhere,ensure

that the ground connection is made before line and neutral connections are made.

WARNING

Any interruption of the ground connection, inside or outside the instrument, is likely to make

the instrument dangerous. Intentional interruption is prohibited.

For protection against electric shock, all external circuits or equipment need a safe

insulation. Therefore, peripheral equipment must not be connected to the system with

a power supply without the SELV (Separated Extra Low Voltage) rating unless explicitly

mentioned.

Signal connections to the instrument should be connected after the ground connection

is made and disconnected before the ground connection is removed, i.e. the supply

lead must be connected whenever signal leads are connected.

WARNING

For safety, it is essential that the protective ground connector of the instrument is used

whenever voltages greater than 33V RMS, 46.7V PEAK or 70V DC (IEC 61010-1:2010) are

connected. This is to prevent the instrument’s case becoming live in the event of a protec-

tive ground interruption, which could occur if the supply connector is accidentally discon-

nected from the instrument.

The primary purpose of protective grounding is to provide adequate protection against

electric shock that could cause death or injury to personnel while working on de-en-

ergized equipment. This is accomplished by grounding and bonding to limit the body

contact or exposure to voltages at the work-site to a safe value if the equipment were

to be accidentally energized from any source of hazardous energy. The greatest source

of hazardous energy in most cases is direct energizing of the equipment from a pow-

er-system or source.

WARNING

If connection to a protective ground is not possible for any reason, then please refer to the

international safety standard EN 50191:2000

GEN7iB 19

SAFETY MESSAGES

SAFETY MESSAGES

2

2.2.1 Mains power cord

DANGER

DANGER

Do not use the equipment with damaged cords and/or cables. Replace a damaged cord

and/or cable immediately.

GEN7iB

20 SAFETY MESSAGES

SAFETY MESSAGES

2

2.3 Instrument Symbols

A variety of symbols can be found in the system. Below is a list of symbols and their

meaning.

This symbol is used to denote the measurement ground connection.

This point is not a protective ground connection.

This symbol is used to denote a protective ground connection.

This symbol is used to denote a frame or chassis ground connection.

This point is not a protective ground connection.

Where caution is required, this symbol refers to the user manual for

further information.

This symbol warns that high voltages are present close to this symbol.

This symbol shows that the switch is a power switch. When pressed,

the instrument state toggles between the operating and power-off

mode. When the system is in power-off mode, all electronics are dis-

connected from the power, except for a small circuit used to detect the

switch state.

Table of contents

Other HBK Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Ambient Weather

Ambient Weather Fischer 1434B-22-B user manual

LogikaControl

LogikaControl HTR Installation and use manual

ADVANTEST

ADVANTEST R3267 series Operation manual

DPS Telecom

DPS Telecom NetGuardian 480 Techno Knowledge Paper

Keysight

Keysight N1911A Programming guide

PURE

PURE Avalon 300R Connect manual