HBK Z30A User manual

TOP Transfer Z30A / Z4A

ENGLISH DEUTSCH

Mounting Instructions

Montageanleitung

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-2001.0504

DVS: A02212 01 X00 01

05.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

TOP Transfer Z30A / Z4A

ENGLISH DEUTSCH

Mounting Instructions

TOP Transfer Z30A / Z4A

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 3................................................

2 Markings used 5....................................................

2.1 The marking used in this document 5..................................

2.2 The marking on the product 5.........................................

3 Scope of supply 6...................................................

4 Application notes 8.................................................

5 Structure and mode of operation 9....................................

5.1 TOP-Z30A 9........................................................

5.2 TOP-Z4A 10.........................................................

6 Conditions on site 11.................................................

6.1 Ambient temperature 11..............................................

6.2 Moisture and dampness 11............................................

6.3 Air pressure 11......................................................

6.4 Chemical effects 11..................................................

6.5 Load disturbance variables 11.........................................

6.6 Electromagnetic compatibility 11.......................................

7 Mechanical installation 12............................................

7.1 Important precautions during installation 12..............................

7.2 Installation aids for compressive loading 12..............................

7.2.1 Installation diagram for compressive loading 13..........................

7.3 Installation aids for tensile loading 13...................................

8 Electrical connection 21..............................................

8.1 Notes on cabling 21..................................................

8.2 Pin Assignment 21...................................................

8.3 TEDS transducer identification 23......................................

9 Technical data per VDI 2638 and ISO 376 24.............................

9.1 TOP-Z30A 24........................................................

9.2 TOP-Z4A 26.........................................................

10 Dimensions TOP Transfer 28..........................................

10.1 TOP-Z30A and accessories 28.........................................

10.2 TOP-Z4A and accessories 33..........................................

3

TOP Transfer Z30A / Z4A

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

Intended use

The force transducers of TOP Transfer types: TOP-Z30A and TOP-Z4A must be used for

force comparison measurements (force transfer). Use for any additional purpose shall be

deemed to be not as intended.

In the interests of safety, the transducer should only be operated as described in the

Mounting Instructions. It is also essential to observe the appropriate legal and safety

regulations for the application concerned during use. The same applies to the use of ac

cessories.

The transducer is not a safety element within the meaning of its use as intended. For safe

and trouble‐free operation, this transducer must not only be correctly transported, stored,

sited and installed but must also be carefully operated and maintained.

General dangers of failing to follow the safety instructions

The force transducers TOP-Z30A and TOP-Z4A are state‐of‐the‐art and failsafe. Trans

ducers can give rise to remaining dangers if they are inappropriately installed and oper

ated by untrained personnel.

Everyone involved with the installation, commissioning, maintenance or repair of a force

transducer must have read and understood the Mounting Instructions and in particular

the technical safety instructions.

Remaining dangers

The scope of supply and performance of the transducer covers only a small area of force

measurement technology. In addition, equipment planners, installers and operators

should plan, implement and respond to the safety engineering considerations of force

measurement technology in such a way as to minimize remaining dangers. Prevailing

regulations must be complied with at all times. There must be reference to the remaining

dangers associated with force measurement technology.

Unauthorized conversions and modifications are prohibited

The transducer must not be modified from the design or safety engineering point of view

except with our express agreement. Any modification shall exclude all liability on our part

for any damage resulting therefrom.

Qualified personnel

These transducers must only be installed by qualified personnel, strictly in accordance

with the specifications in conjunction with the safety requirements and regulations listed

below. It is also essential to observe the appropriate legal and safety regulations for the

application concerned. The same applies to the use of accessories.

TOP Transfer Z30A / Z4A

SAFETY INSTRUCTIONS

4

Qualified personnel means persons entrusted with the installation, assembly, commis

sioning and operation of the product, who possess the appropriate qualifications for their

function.

Conditions at the place of installation

Protect the transducer from moisture and dampness or weather such as rain, snow, etc.

Maintenance

The force transducers TOP-Z30A and TOP-Z4A are maintenance‐free.

Accident prevention

The prevailing accident prevention regulations must be taken into account, even though

the nominal force values in the destructive range are well in excess of the full scale value.

5

TOP Transfer Z30A / Z4A

MARKINGS USED

2 MARKINGS USED

2.1 The marking used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

WARNING This marking warns of a potentially dangerous situ

ation in which failure to comply with safety require

ments can result in death or serious physical injury.

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important

This marking draws your attention to important in

formation about the product or about handling the

product.

Tip

This marking indicates application tips or other

information that is useful to you.

Information

This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

uThis marking indicates an action in a procedure

2.2 The marking on the product

The CE mark enables the manufacturer to guarantee that the

product complies with the requirements of the relevant EU direc

tives (the Declaration of Conformity can be found at

https://www.hbm.com/HBMdoc

).

TOP Transfer Z30A / Z4A

SCOPE OF SUPPLY

6

3 SCOPE OF SUPPLY

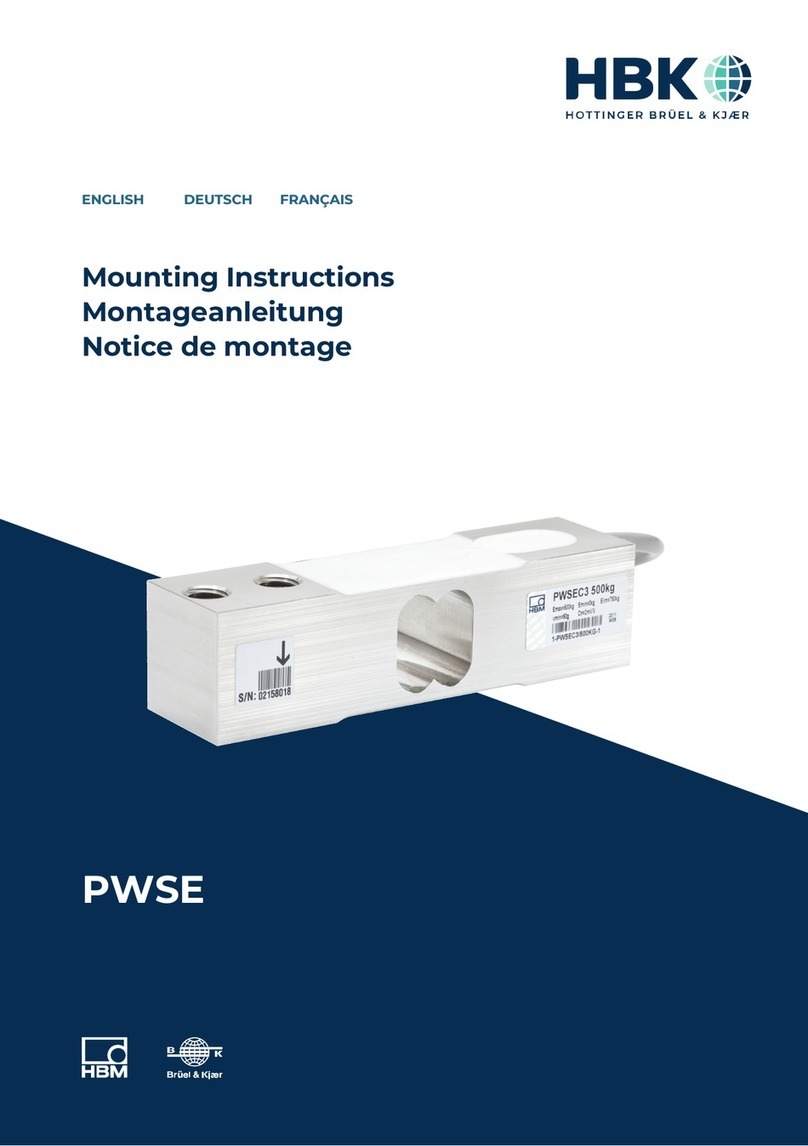

SForce transducer TOP-Z30A, TOP-Z4A

SOperating instructions TOP Transfer

The TOP Transfer force transducers are only available in conjunction with a DKD

calibration (not included in scope of supply)

SDKD calibration certificate to ISO 376 Order No. K-CAL-FD...

Accessories for TOP-Z30A

SKnuckle eyes ZGW/ZGOW

for 100 N to 1000 N: Order No. 1-U1R/200kg/ZGW

for 2 kN to 10 kN: Order No. 1-U2A/1t/ZGUW

SThrust piece to ISO 376

for 100 N to 1000 N: Order No. 1-EDO3/1kN

for 2 kN to 10 kN: Order No. 1-EDO4/50kN

SLoad button

for 100 N to 1000 N: Order No. 1-U1R/200kg/ZL

for 2 kN to 10 kN: Order No. 3-9202.0140

SZKM tensile force introduction part to ISO 376

for 2 kN to 10 kN: Order No. 1-Z30/10kN/ZKM

STransportation box

for 4 TOP-Z30A force transducer and accessories

Order No. 1-Z30/Box

Accessories for TOP-Z4A

SZKM tensile force introduction part to ISO 376

for 20 kN: Order No. 1-Z4/20kN/ZKM

50 kN: Order No. 1-Z4/50kN/ZKM

100 kN: Order No. 1-Z4/100kN/ZKM

200 kN: Order No. 1-Z4/200kN/ZKM

500 kN: Order No. 1-Z4/500kN/ZKM

7

TOP Transfer Z30A / Z4A

SCOPE OF SUPPLY

SKnuckle eyes ZGUW/ZGOW

for 20 kN: Order No. 1-Z4/20kN/ZGOW

1-Z4/20kN/ZGUW

50 kN: Order No. 1-U2A/2t/ZGOW

1-U2A/2t/ZGUW

100 kN: Order No. 1-Z4/100kN/ZGOW

1-Z4/100kN/ZGUW

200 kN: Order No. 1-U2A/10t/ZGOW

1-U2A/10t/ZGUW

500 kN: Order No. 1-Z4/500kN/ZGOW

1-Z4/500kN/ZGUW

SThrust piece EDO4 to ISO 376

20kN Order No. 1-EDO4/20kN

50kN Order No. 1-EDO4/50kN

100kN Order No. 1-EDO4/100kN

200kN Order No. 1-EDO4/200kN

500kN Order No. 1-EDO4/500kN

Cables/plugs

Description Order no.

Connection cable Kab 139A-6, 6m,with female cable

connector and free ends

1-KAB139A-6

Connector MS3106PEMV mounted on cable D-MS/MONT

15-pole D plug mounted on cable D-15D/MONT

TEDS ready mounted in 15-pole D plug for Z4A D-TEDS/MONT_DB

TOP Transfer Z30A / Z4A

APPLICATION NOTES

8

4 APPLICATION NOTES

Force transducer TOP Transfer

High precision force transducers in the type series TOP-Z30A and TOP-Z4A measure

compressive and tensile forces.

Because they measure static and quasi-static forces with extremely high accuracy and

reproducibility, they must be handled very carefully. Particular care must be taken when

transporting and installing the devices. Dropping or knocking the transducers may cause

permanent damage. It is recommended, as the TOP Transfer force transducers are peak

precision transducers for transfer measurements, that the ambient temperature is main

tained constant in the range of the nominal temperature.

Force transducers TOP-Z30A and TOP-Z4A with DKD certificate

The transducers are by default calibrated in the pressure direction. They can also be DKD

calibrated in the tensile direction on request. However, the transducer should be loaded

and used in one force direction only for high precision measurements.

The technical data lists the permissible limits for mechanical, thermal and electrical

stress. It is essential that these are taken into account when planning the measuring

set‐up, during installation and ultimately during operation.

To achieve optimum measurement results, the transducer must be connected to a highly

accurate amplifier (e.g. DMP40 from HBK).

9

TOP Transfer Z30A / Z4A

STRUCTURE AND MODE OF OPERATION

5 STRUCTURE AND MODE OF OPERATION

5.1 TOP-Z30A

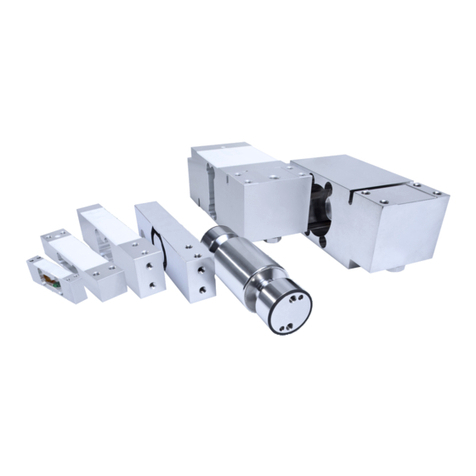

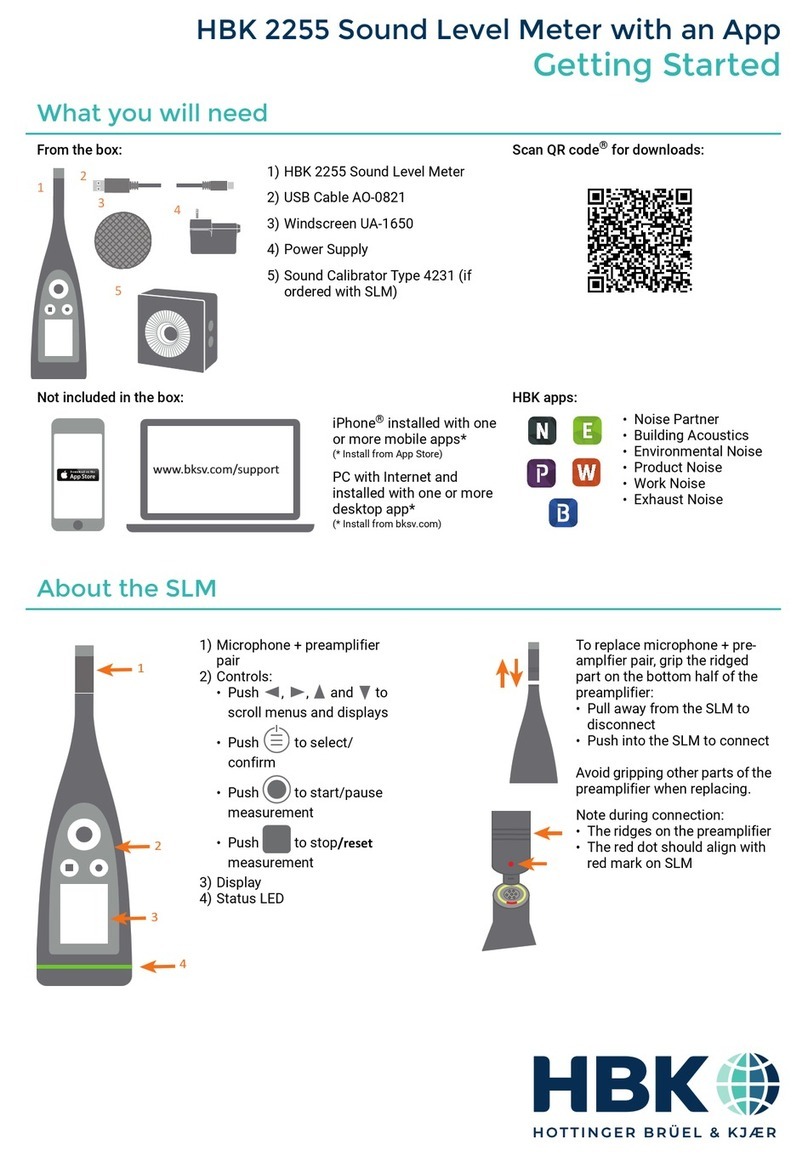

Fig. 5.1 TOP-Z30A (100 N...10 kN)

The measuring body consists of a measurement spring system with strain gages. The

internal threads located on both sides are used to apply tensile forces. Load buttons to

screw into the upper thread are available as accessories to apply the compressive

forces.

All nominal forces of the TOP-Z30A have the same size.

The electric connection is implemented with Binder connectors.

To reduce the bending moment during tensile measurements, caused by the cable in lat

eral cable outputs, an additional connector is located on the floor of the housing.

Every TOP-Z30A force transducer comes with TEDS (Transducer electronic Data sheet);

see chapter 8.3.

TOP Transfer Z30A / Z4A

STRUCTURE AND MODE OF OPERATION

10

5.2 TOP-Z4A

Fig. 5.2 TOP-Z4A (20 kN...500 kN)

The measuring body consists of a measurement spring system with strain gages.

The TOP-Z4A transducer has a convex threaded pin on top (also suitable for application

of compressive forces) and a threaded bore underneath for the application of tensile

forces.

The housing is protected on top and bottom by thin metal membranes.

11

TOP Transfer Z30A / Z4A

CONDITIONS ON SITE

6 CONDITIONS ON SITE

6.1 Ambient temperature

The temperature effects on the zero signal and on the sensitivity are compensated. To

obtain optimum measurement results, the nominal (rated) temperature range must be

observed. Temperature-related measurement errors can be caused by heating on one

side (e.g. radiant heat) or by cooling. A radiation shield and all-round thermal insulation

produces noticeable improvements, but must not be allowed to set up a force shunt.

6.2 Moisture and dampness

Avoid extreme moisture or a tropical climate if the values are outside the classified limits

(TOP-Z4A degree of protection IP67 as per DIN EN 60529, TOP-Z30A: IP50).

6.3 Air pressure

Air pressure changes do not affect the TOP-Z30A force transducer.

Air pressure changes act on the TOP-Z4A force transducer as a change in force. With

normal ambient pressure changes ±20mbar, this influence on the measurement signal is

negligibly small (air pressure changes of ±10 mbar only have an effect on the zero signal

of 6 N with 20 kN‐ and 50 kN‐transducers).

6.4 Chemical effects

The transducer housings are protected by a powder coating. They must not be exposed

to adverse ambient conditions (direct weather conditions, contact with corrosive media).

The un-coated force application areas on the TOP-Z4A are greased to protect them

against corrosion.

6.5 Load disturbance variables

Torsion, bending and lateral loads are disturbance variables and therefore to be avoided.

Remedies can, if necessary, be implemented with HBK installation aids (Chapter 7.2 and

7.3).

6.6 Electromagnetic compatibility

The transducers are tested for use in controlled electromagnetic environments to EN

61326:2002;Tab B.1.

TOP Transfer Z30A / Z4A

MECHANICAL INSTALLATION

12

7 MECHANICAL INSTALLATION

7.1 Important precautions during installation

SHandle the transducers carefully, mechanical loads on the housing membranes must

be avoided

SAlways use thermally insulated gloves when handling the transducers

SEnsure there is enough time available before measurement to allow the force trans

ducer to reach a stable temperature with regards to its components and environment.

Approx. 24 hours are recommended for precision measurements.

SConnect the force transducer to the excitation voltage approx. 1 hour before measure

ment

SWhen measuring compressive forces, make sure the support structure is rigid and

level

SThe force application surfaces and threads must be perfectly clean and fully bearing

SObserve the depths of engagement for the threaded rods or knuckle eyes, different

depths will affect the reproducibility

SDo not overload the transducer, only load up to the operating force

SThe forces must act on the transducer as accurately as possible in the direction of

measurement.

WARNING

Additional safeguards must be provided if there is a risk that overloading the transducer

may cause it to break, which could put people at risk.

Notice

Torsional and bending moments, eccentric loading and lateral forces may produce mea

surement errors and destroy the transducer if limit values are exceeded.

7.2 Installation aids for compressive loading

Thrust pieces to ISO 376 are available for the application of compressive forces.

Thrust pieces EDO3/1kN or EDO4/50kN (see page 32) and two load buttons (see page 31)

are available for the TOP-Z30A. The thrust piece (see page 38) can be positioned directly

on the convex threaded pin in the TOP-Z4A.

13

TOP Transfer Z30A / Z4A

MECHANICAL INSTALLATION

7.2.1 Installation diagram for compressive loading

F

Transducer

TOP-Z30A TOP-Z4A

F

Thrust piece

Load button

Type Load button

Order number

Thrust piece

Order number

TOP-Z30A / 100 N - 1000 N 1-U1R/200kg/ZL 1-EDO3/1kN

TOP-Z30A / 2 kN - 10 kN 3-9202.0140 1-EDO4/50kN

TOP-Z4A / 20 kN - 1-EDO4/20kN

TOP-Z4A / 50 kN - 1-EDO4/50kN

TOP-Z4A / 100 kN - 1-EDO4/100kN

TOP-Z4A / 200 kN - 1-EDO4/200kN

TOP-Z4A / 500 kN - 1-EDO4/500kN

7.3 Installation aids for tensile loading

Knuckle eyes and tensile force introduction parts (ZKM) to ISO 376 are available to install

the TOP-Z30A and TOP-Z4A. These installation aids prevent the application of torsional

moments and, where 2 knuckle eyes are used, bending moments, together with lateral

and oblique loads in the transducer. They are intended only for static tensile loading of

the transducer.

TOP Transfer Z30A / Z4A

MECHANICAL INSTALLATION

14

Installation of knuckle eyes

uScrew the knuckle eye thread into the transducer thread until the stop is reach and

then screw it one and a half turns back out.

Knuckle eyes ZGOW/ZGUW for TOP-Z4A

W

a

f

Knuckle eyes ZGW/ZGUW for TOP-Z30A

∅B

a

f

Type Knuckle eye top/bottom

Order number a f W B

TOP-Z30A/100N - 1000N 1-U1R/200kg/ZGW 147.5 170 12 8H7

TOP-Z30A/2kN - 10kN 1-U2A/1t/ZGUW 169 201 16 12H7

15

TOP Transfer Z30A / Z4A

MECHANICAL INSTALLATION

Type

Knuckle eye top/

bottom

Order number

Weigh

t (kg)

a f

W∅B

min max. min max.

TOP‐Z4A/

20kN

1-Z4/20kN/ZGOW

1-Z4/20kN/ZGUW 0.2 appr.

158

appr.

170

appr.

198

appr.

210 21 16H7

TOP‐Z4A/

50kN

1-U2A/2t/ZGOW

1-U2A/2t/ZGUW

0.8

0.4

appr.

190

appr.

199

appr.

245

appr.

254 25 20H7

TOP‐Z4A/

100kN

1-Z4/100kN/ZGOW

1-Z4/100kN/ZGUW 1.1 appr.

261

appr.

269

appr.

331

appr.

339 37 30H7

TOP‐Z4A/

200kN

1-U2A/10t/ ZGOW

1-U2A/10t/ZGUW

3.2

1.1

appr.

352

appr.

357

appr.

475

appr.

480 35 50 +0.001

-0.014

TOP‐Z4A/

500kN

1-Z4/500kN/ZGOW

1-Z4/500kN/ZGUW

1.,3

12.0

appr.

570

appr.

590

appr.

764

appr.

784 44 60 +0.003

-0.018

Information

With the TOP-Z30A, the nut on the base must be tightened before the upper nut; to do this,

hold the TOP-Z30A firmly with the spanner flats.

Notes on mounting with knuckle eyes

1. Shaft diameter

When using a sensor with knuckle eyes mounted on one or both sides, make sure that the

shaft is the right size.

You will find the diameters of the knuckle eyes and shafts and their recommended

tolerances in the table below.

Knuckle eyes TOP-Z30A

Knuckle eyes Nominal

diameter

Hole fitting

size

Recommended shaft

fitting size

1-U1R/200kg/ZGW 8 H7 g6

1-U2a/1t/ZGUW 12

Tab. 7.1 Recommended fitting sizes/tolerances for shaft and hole - Z30A

TOP Transfer Z30A / Z4A

MECHANICAL INSTALLATION

16

Knuckle eyes TOP-Z4A / Knuckle eyes with internal thread

Knuckle eyes Nominal

diameter

Hole fitting

size

Recommended shaft

fitting size

1-Z4/20kN/ZGOW 16

H7 g6

1-U2A/2T/ZGOW 20

1-U2A/100kN/ZGOW 30

1-U2A/10T/ZGOW 50 +0.002

-0.014 f6

1-Z4/500kN/ZGOW 60 +0.003

-0.018

Tab. 7.2 Recommended fitting sizes/tolerances for shaft and hole - Knuckle eyes with

internal thread

Knuckle eyes TOP-Z4A / Knuckle eyes with external thread

Knuckle eyes Nominal

diameter

Hole fitting

size

Recommended shaft

fitting size

1-Z4/20kN/ZGUW 16

H7 g6

1-U2A/2T/ZGUW 20

1-U2A/100kN/ZGUW 30

1-U2A/10T/ZGUW 50 +0,002

-0,014 f6

1-Z4/500kN/ZGUW 60 +0,003

-0,018

Tab. 7.3 Recommended fitting sizes/tolerances for shaft and hole - Knuckle eyes with

external thread

17

TOP Transfer Z30A / Z4A

MECHANICAL INSTALLATION

Customer's construction

Customer's shaft holder

Shaft

Play based on recommended fitting

size, see Tab. 7.1, Tab. 7.2 and

Tab. 7.3, page 15

Threaded connector for mounting

on force transducers

Fig. 7.1 Example diagram of installation with knuckle eye

CAUTION

If a shaft with an overly small diameter is used, the bearing of the knuckle eye will be

subjected to linear load. This subjects the inner bearing shell to excessive load, which can

lead to damage and, if forces are high, can cause the knuckle eye bearing to break.

Select the shaft as recommended in the mounting instructions.

2. Distance between knuckle eye and shaft bearing

The shaft support must allow for suitable play between the knuckle eye and the shaft

bearing.

TOP Transfer Z30A / Z4A

MECHANICAL INSTALLATION

18

CAUTION

If there is too much distance between the knuckle eye and the shaft bearing, this generates

bending moments in the shaft, causing it to deform.

This deformation puts strain on points of the edges of the inner bearing shell, which can

cause the knuckle eye or shaft to suffer damage or break.

Select the play as recommended in the mounting instructions.

To determine the play between the knuckle eye and the shaft bearing, you can apply the

following rule of thumb:

Shaft diameter Play between knuckle eye and bearing

≤30mm 1/10 of the nominal diameter

>30mm 1/20 of the nominal diameter

Tab. 7.4 Rule of thumb for determining play between knuckle eye and shaft bearing

Based on this, recommendations for the play between the knuckle eye and shaft bearing

are as follows:

TOP-Z30A

Knuckle eye Play between knuckle eye and shaft bearing

1-U1R/200kg/ZGW 0.8 mm

1-U2a/1t/ZGUW 1.2 mm

Tab. 7.5 Recommendations for play between knuckle eye and shaft bearing - Z30A

TOP-Z4A

Knuckle eye Play between knuckle eye and shaft bearing

1-Z4/20kN/ZOGW 1.6 mm

1-Z4/20kN/ZUGW

1-U2A/2T/ZGOW 2 mm

1-U2A/2T/ZGUW

1-Z4/100kN/ZOGW 3 mm

1-Z4/100kN/ZUGW

1-U2A/10T/ZGOW 2.5 mm

1-U2A/10T/ZGUW

Other manuals for Z30A

1

This manual suits for next models

3

Table of contents

Languages:

Other HBK Measuring Instrument manuals