HBK PWSE User manual

PWSE

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

Montageanleitung

Notice de montage

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-2002.3361

DVS: A03361 01 Y00 01

06.2023

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos

produits que sous une forme générale. Elles

n'impliquent aucune garantie de qualité ou de

durabilité.

PWSE

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

PWSE

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 3................................................

2 Markings used 6....................................................

2.1 The markings used in this document 6.................................

2.2 The marking used on the product 6....................................

3 Conditions on site 7.................................................

3.1 Protection against corrosion 7........................................

3.2 Deposits 7.........................................................

4 Mechanical installation 8............................................

4.1 Important precautions during installation 8..............................

4.2 Mounting 8........................................................

5 Electrical connection 10..............................................

5.1 Connection with six‐wire configuration 10................................

5.2 Connection with four‐wire configuration 10...............................

5.3 Shortening the cable 11...............................................

5.4 Cable extension 11...................................................

5.5 EMC protection 11...................................................

6 Specifications 12....................................................

7 Dimensions 14......................................................

3

PWSE

1 SAFETY INSTRUCTIONS

Proper use

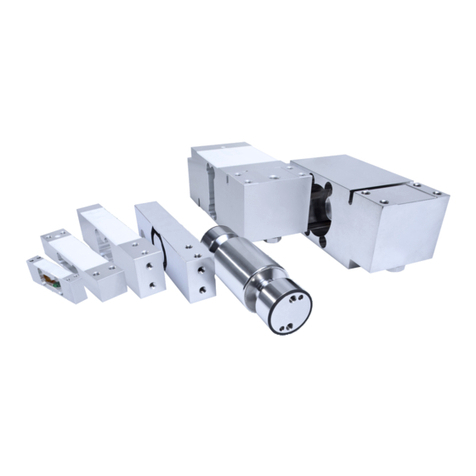

Load cells of the PWSE type series are designed for technical weighing applications

within the load limits detailed in the specifications. Any other use is not the designated

use.

The load cells may only be installed by qualified personnel in compliance with the spe

cifications and with the safety requirements and regulations of these mounting instruc

tions. It is also essential to observe the applicable legal and safety regulations for the

application concerned. The same applies to the use of accessories.

Load cells are not intended for use as safety components. Please also refer to the sec

tion: “Additional safety precautions". Proper and safe operation of the load cells requires

proper transportation, correct storage, siting and mounting, and careful operation.

Loading capacity limits

The data in the technical data sheet must be complied with when using the load cells. In

particular, the respective maximum loads specified must never be exceeded. The follow

ing limits set out in the specifications must not be exceeded, e.g.:

SLimit load

SLimit load at max. eccentricity

SLimit lateral loading

SBreaking loads

STemperature limits

SLimits of electrical loading capacity

Note that, when several load cells are installed in a scale, there is not always an even dis

tribution of load on the individual load cells.

Use as a machine element

The load cells can be used as machine elements. When used in this manner, it must be

noted that, to favor greater sensitivity, the load cell is not designed with the safety factors

usual in mechanical engineering. Please refer here to the section “Loading capacity lim

its" and to the specifications.

Accident prevention

The prevailing accident prevention regulations must be taken into account, even though

the maximum capacity values in the destructive range are well in excess of the full scale

value.

PWSE

4

Additional safety precautions

Load cells cannot (as passive transducers) implement any (safety‐relevant) cutoffs. This

requires additional components and constructive measures for which the installer and

operator of the plant is responsible.

In cases where a breakage or malfunction of the load cells would cause injury to persons

or damage to equipment, the user must take appropriate additional safety measures that

meet at least the requirements of applicable safety and accident prevention regulations

(e.g. automatic emergency shutdown, overload protection, catch straps or chains, or

other fall protection).

The layout of the electronics conditioning the measurement signal should be such that

measurement signal failure does not cause damage.

General dangers of failing to follow the safety instructions

Load cells are state‐of‐the‐art and reliable. Transducers can give rise to residual dangers

if they are incorrectly operated or inappropriately mounted, installed and operated by

untrained personnel. Everyone involved with siting, starting up, operating or repairing a

load cell must have read and understood the Mounting Instructions and in particular the

technical safety instructions. The load cells can be damaged or destroyed by non‐desig

nated use of the load cells or by non‐compliance with the mounting and operating instruc

tions, these safety instructions or any other applicable safety regulations (BG safety and

accident prevention regulations) when using the load cells. Load cells can break, particu

larly in the case of overloading. The breakage of a load cell can also cause damage to

property or injury to persons in the vicinity of the load cell.

If load cells are not used according to their designated use, or if the safety instructions or

specifications in the mounting and operating instructions are ignored, it is also possible

that the load cells may fail or malfunction, with the result that persons or property may be

affected (due to the loads acting on or being monitored by the load cells).

The scope of supply and performance of the transducer covers only a small area of

weighing technology, as measurements with (resistive) strain gauge sensors presuppose

the use of electronic signal processing. In addition, equipment planners, installers and

operators should plan, implement and respond to the safety engineering considerations

of the weighing technology in such a way as to minimize residual dangers. Pertinent

national and local regulations must be complied with.

Conversions and modifications

The transducer must not be modified from the design or safety engineering point of view

except with our express agreement. Any modification shall exclude all liability on our part

for any damage resulting therefrom.

Maintenance

The PWSE load cells are maintenance free.

5

PWSE

Selling on

If the load cell is sold on, these mounting instructions must be included with the load cell.

Environmental protection, disposal

In accordance with national and local environmental protection and material recovery and

recycling regulations, old transducers that can no longer be used must be disposed of

separately and not with normal household waste.

If you need more information about waste disposal, please contact your local authorities

or the dealer from whom you purchased the product.

Qualified personnel

Qualified personnel means persons entrusted with siting, mounting, starting up and oper

ating the product, who possess the appropriate qualifications for their function.

This includes people who meet at least one of the three following requirements:

SKnowledge of the safety concepts of automation technology is a requirement and as

project personnel, you must be familiar with these concepts.

SAs automation plant operating personnel, you have been instructed how to handle the

machinery. You are familiar with the operation of the equipment and technologies

described in this documentation.

SAs commissioning engineers or service engineers, you have successfully completed

the training to qualify you to repair the automation systems. You are also authorized

to activate, ground and label circuits and equipment in accordance with safety engin

eering standards.

PWSE

MARKINGS USED

6

2 MARKINGS USED

2.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

WARNING This marking warns of a potentially dangerous situ

ation in which failure to comply with safety require

ments can result in death or serious physical injury.

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important

This marking draws your attention to important in

formation about the product or about handling the

product.

Tip

This marking indicates application tips or other

information that is useful to you.

Information

This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

2.2 The marking used on the product

CE mark

The CE mark enables the manufacturer to guarantee that the product com

plies with the requirements of the relevant EC directives (the declaration of

conformity is available at http://www.hbm.com/HBMdoc).

7

PWSE

CONDITIONS ON SITE

3 CONDITIONS ON SITE

The PWSE series load cells reach the protection class IP67.

3.1 Protection against corrosion

The load cells must be protected against chemicals that could attack the transducer body

(stainless) steel or the cable.

Notice

Acids and all substances that release ions also attack stainless steels and their welded

seams.

Should there be any corrosion, this could cause the transducer to fail. In this case, appro

priate protective measures should be implemented.

3.2 Deposits

Dust, dirt and other foreign matter must not be allowed to accumulate sufficiently to

divert some of the measuring force onto the housing, thus invalidating the measured

value (force shunt).

PWSE

MECHANICAL INSTALLATION

8

4 MECHANICAL INSTALLATION

4.1 Important precautions during installation

SHandle the transducer with care.

SWelding currents must not be allowed to flow over the transducer. If there is a risk

that this might happen, you must use a suitable low‐ohm connection to electrically

bypass the transducer. HBM, for example, provides the highly flexible EEK ground

cable, which can be screwed on above and below the transducer.

SMake sure that the transducer cannot be overloaded.

WARNING

There is a danger of the transducer breaking if it is overloaded. This can cause danger for

the operating personnel of the system in which the transducer is installed.

Implement appropriate safety measures to avoid overloads or to protect against resulting

dangers.

Notice

Load cells are precision measuring elements and need to be handled carefully. Dropping or

knocking the transducer may cause permanent damage. Make sure that the transducer

cannot be overloaded, even while it is being mounted.

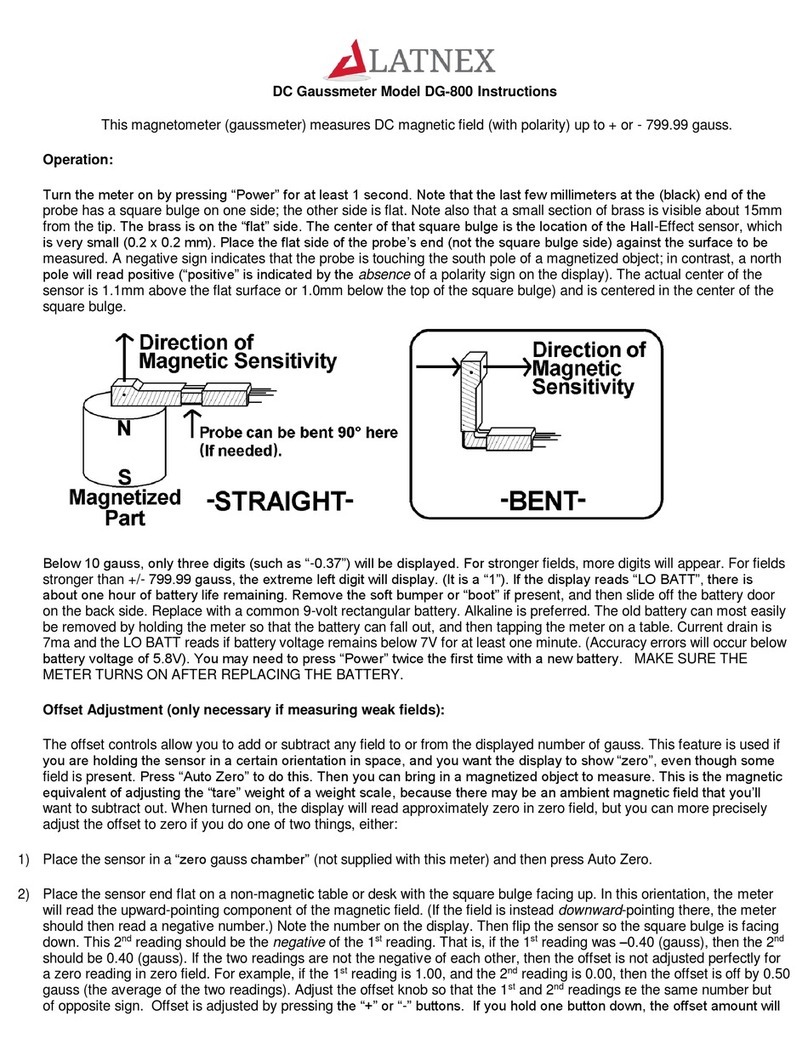

4.2 Mounting

Attach the load cells at the mounting holes and apply the load to the other end. The

screws and tightening torques to be used are given in the following table:

Maximum capacity Thread Min. property class Tightening torque1)

100 …300kg M10 10.9 66N⋅m

500 …750kg M12 10.9 115N⋅m

1) Recommendedvalue for the specified property class. Please comply with the screw manufacturer's

instructions with regard to screw dimensions.

9

PWSE

MECHANICAL INSTALLATION

= =

= =

Platformcenter

Load

application

Connection cable

Mounting

Spacing disc

Fig. 4.1 Load application and installation

Important

Load must not be applied to the side where the cable connection is located, as this would

cause a force shunt.

PWSE

ELECTRICAL CONNECTION

10

5 ELECTRICAL CONNECTION

The following can be connected for measurement signal conditioning:

SCarrier‐frequency amplifier

SDC amplifier

designed for strain gauge measurement systems.

The transducers are supplied in the standard version with a 3m cable and 6‐pin Pancon

connector in a six‐wire configuration.

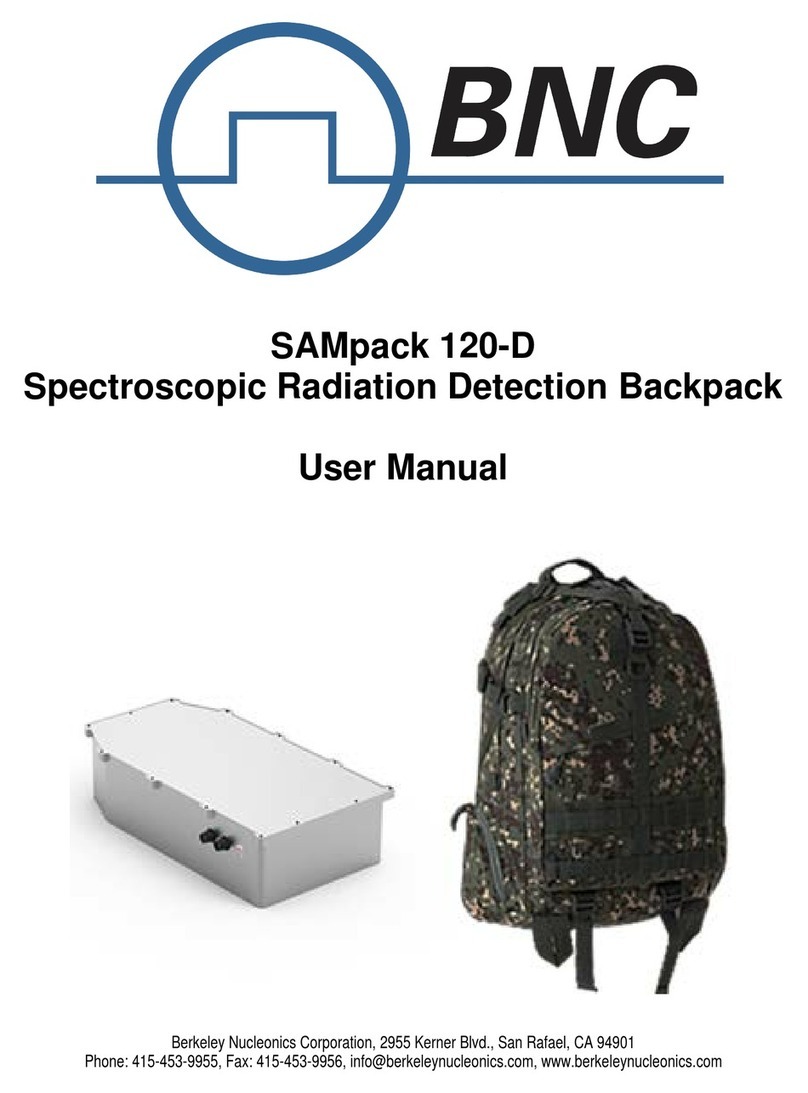

5.1 Connection with six‐wire configuration

Schematic diagram of a Pancon connector (CE100F26‐6), 6‐pin

blue marking

412356

Plug‐in contact 1 (white) = measurement signal (+)

Plug‐in contact 3 (black) = excitation voltage (-)

Plug‐in contact 6 (gray) = sense lead (-)

Plug‐in contact 4 (blue) = excitation voltage (+)

Plug‐in contact 5 (green) = sense lead (+)

Plug‐in contact 2 (red) = measurement signal (-)

Shield (yellow) = cable shield connected to

load cell body

Fig. 5.1 Connection with a 6‐wire cable (choice of lengths: 3m, 6m or 12m)

With this cable assignment, the output voltage at the measuring amplifier is positive

when the transducer is loaded (see Fig. 4.1).

5.2 Connection with four‐wire configuration

When transducers with a six‐wire configuration are connected to amplifiers with a

four‐wire configuration, the sense leads of the transducer must be connected to the cor

responding supply leads: Identification (+) with (+) and identification (-) with (-), see

Fig. 5.1. This measure also reduces the cable resistance of the excitation voltage leads.

Important

However, there will be a voltage loss on the supply leads due to the cable resistance that is

still present and not compensated for by the six‐wire configuration, even after connecting

the sense leads to the excitation voltage circuit. A large part of this loss can be eliminated

by a calibration, however, the temperature‐dependent part remains.

The TKcvalue given in the specifications for the transducer therefore does not apply for

the cable and transducer combination when connection is with four‐wire configuration, the

cable percentage must be added.

11

PWSE

ELECTRICAL CONNECTION

5.3 Shortening the cable

If the transducer is connected to an amplifier with a six‐wire configuration, the transducer

cable can be shortened as required, without adversely affecting the measurement accur

acy.

5.4 Cable extension

Only use shielded, low‐capacitance measurement cables for extension. Ensure that con

nection is perfect, with a low contact resistance.

The cable of a six‐wire transducer can be extended with a cable of the same type.

5.5 EMC protection

Electrical and magnetic fields often induce interference voltages in the measuring circuit.

To ensure reliable measurement, however, the transducer must be able to transmit signal

differences of a few μV to the analysis unit without interference.

Planning the shielding design

Due to the numerous application options and differing local constraints, we can only

provide you with general information on correct connection. The shielding design suitable

for your application must be planned locally by an appropriate specialist.

HBM load cells with shielded, round cables are EMC-tested in accordance with the

EU Directive and bear the CE mark. Voltage surges as per EN 61000-4-5 can give rise to

deviations from the load cell’s specified accuracy. These surges in plants are caused by

lightning strikes or switching operations in power circuits, for example, and disappear

again when interference is no longer active. This is particularly evident with cables over

30 m long or if the equipment is used outdoors. Customers should take additional pre

cautions in these cases.

Please note:

SConnect the connecting cable shield all over the surface of the shielding electronics

housing. When using several load cells, connect the shields all over the surface of the

junction box (combination of transducer signals, e.g. type VKK2 from HBM). From

there, connect the measurement cable for the electronics over the surface of the

junction box and the shielding electronics housing.

SThe shield of the connecting cable must not be used for discharging potential

differences within the system. You must therefore lay sufficiently dimensioned

potential equalization lines to compensate for possible potential differences.

SUse shielded low-capacitance measurement cables only (HBM cables fulfill these

conditions).

SDo not route measurement cables parallel to electric cables, especially power lines

and control circuits. If this is not possible, protect the measurement cable, for

example with steel conduits.

SAvoid stray fields from transformers, motors and contact switches.

PWSE

SPECIFICATIONS

12

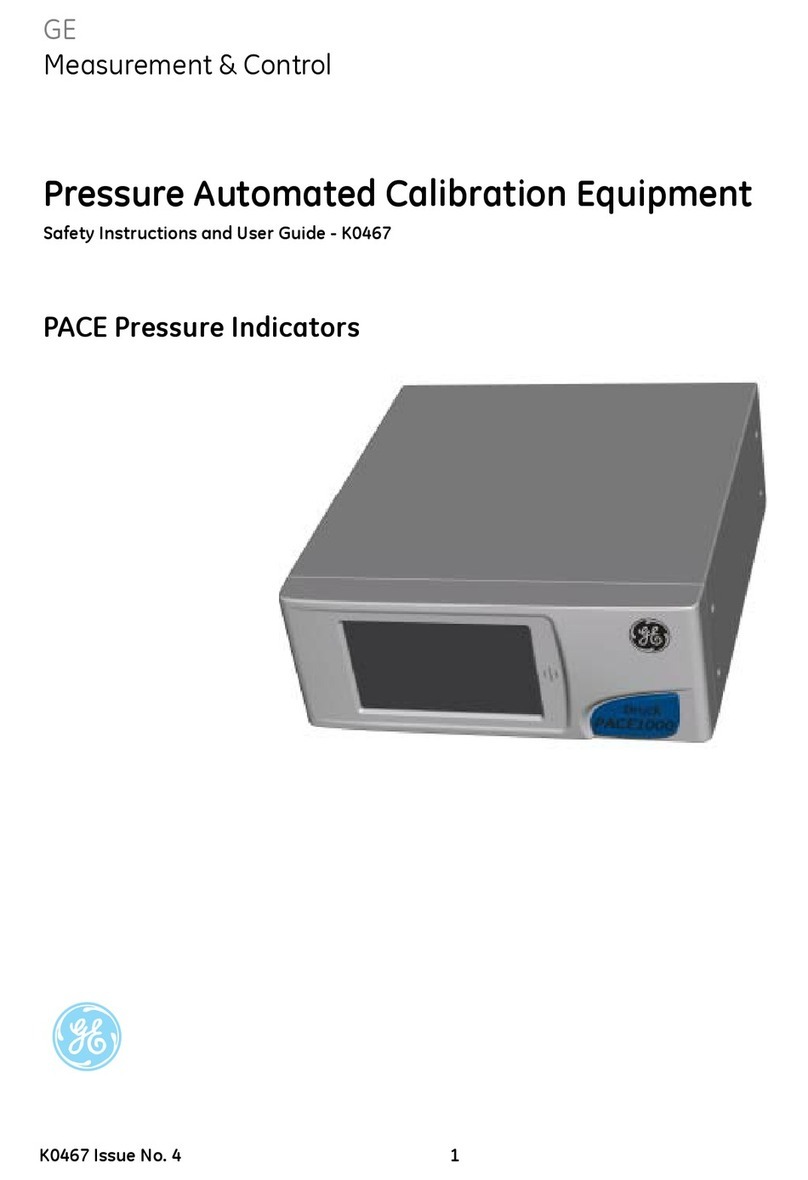

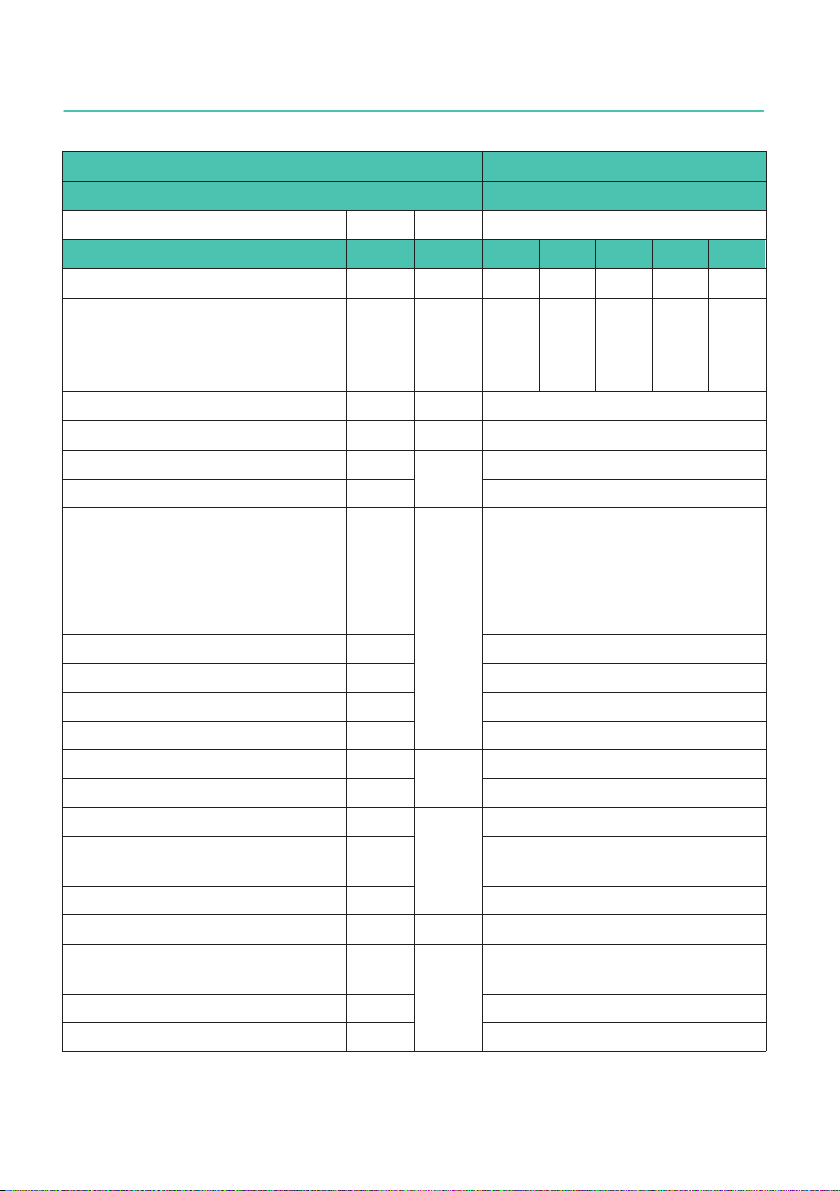

6 SPECIFICATIONS

Type PWSE

Accuracy class 1) C3MR

Number of scale intervals nLC 3000

Maximum capacity 1) (Emax)Emax kg 100 200 300 500 750

Minimum scale division (vmin)vmin g 10 20 50 50 100

Temperature coefficient of zero

signal per 10K 3) TK0

% of

Cn

±0.0140

±0.0140

±0.0093

±0.0140

±0.0093

Nominal platform dimensions mm 600 x 800

Maximum platform size mm 800 x 800

Nominal (rated) sensitivity (Cn)CnmV/V 2.0 ±0.2

Zero signal error ±0.1

Temperature coefficient of the

sensitivity per 10K 2) 3) in the

temperature range

+20 ... +40 °C

-10 ... +20 °C

TKC

% of

Cn

±0.0170

±0.0117

Relative reversibility error 2) 3) dhy ±0.0166

Linearity deviation 2) 3) dlin ±0.0166

Relative creep over 30min dcr ±0.0166

Off‐center load error 3) ±0.0166

Input resistance RLC Ω390 ±15

Output resistance R0359 ±10

Reference excitation voltage Uref

V

5

Nominal (rated) range of the

excitation voltage BU0 ... 12

Maximum excitation voltage 15

Insulation resistance at 100 VDC Ris GΩ > 2

Nominal (rated) temperature

range BT

°C

-10 ... +40

Operating temperature range Btu -10 ... +50

Storage temperature range Btl -25 ... +70

13

PWSE

SPECIFICATIONS

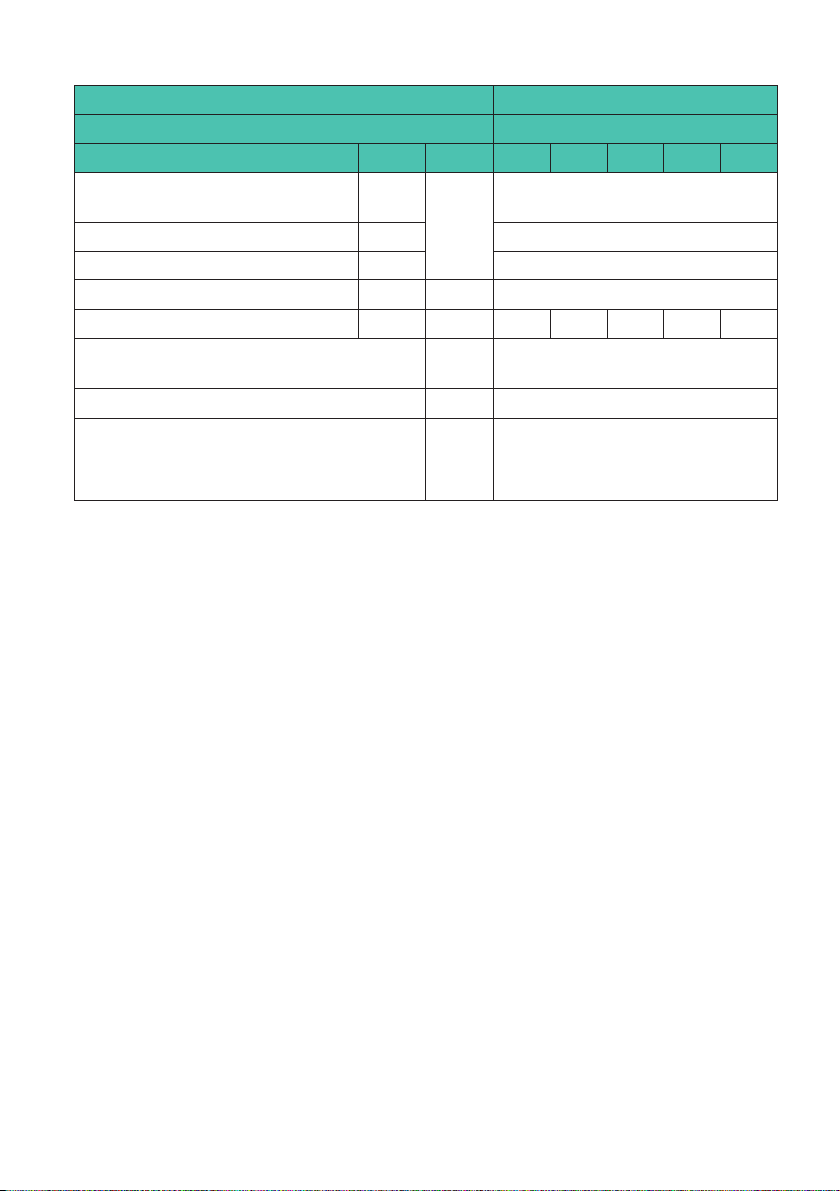

PWSEType

C3MRAccuracy class 1)

750500300200100kgEmax

Maximum capacity 1) (Emax)

Limit load at maximum 100mm

eccentricity EL% of

Emax

150

Limit lateral loading, static Elq 300

Breaking load Ed300

Nominal displacement 4) snom mm < 0.5

Weight, approx. Gkg 0.9 0.9 1.1 1.2 1.2

Degree of protection per DIN EN 60529

(IEC 529)

IP67

Cable length (standard) m 3

Material

Measuring body

Cable sheath

Stainless steel 1.4545

PVC

1) As per OIML R60, with PLC = 0.7.

2) The values for non‐linearity (dlin), relative reversibility error (dhy) and temperature coefficient of

sensitivity (TKC) are recommended values. The sum of these values is within the cumulative error limits

laid down by OIML R60.

3) As per OIML R76.

4) Loading with Emax and center of gravity in center of load cell.

PWSE

DIMENSIONS

14

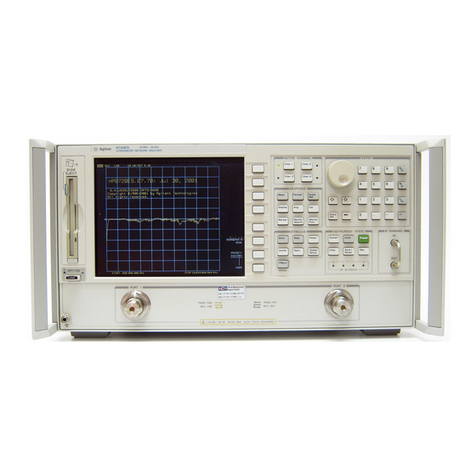

7 DIMENSIONS

Dimensions in mm (1 mm = 0.03937 inch)

H

38.1

G

T

W

7.8 22.4±0.1 79.3±0.1 22.4±0.1

139.7

Load direction / platform center

Maximum capacity H W G T

100 …200kg 30.2 30.5 M10 15

300kg 36.5 36.5 M10 19

500 …750kg 36.5 36.5 M12 19

PWSE

ENGLISH DEUTSCH FRANÇAIS

Montageanleitung

PWSE

INHALTSVERZEICHNIS

2

INHALTSVERZEICHNIS

1 Sicherheitshinweise 3...............................................

2 Verwendete Kennzeichnungen 6......................................

2.1 In dieser Anleitung verwendete Kennzeichnungen 6......................

2.2 Auf dem Gerät angebrachte Symbole 6.................................

3 Bedingungen am Einbauort 7.........................................

3.1 Korrosionsschutz 7.................................................

3.2 Ablagerungen 7.....................................................

4 Mechanischer Einbau 8..............................................

4.1 Wichtige Vorkehrungen beim Einbau 8.................................

4.2 Montage 8.........................................................

5 Elektrischer Anschluss 10............................................

5.1 Anschluss in Sechsleiter‐Technik 10....................................

5.2 Anschluss in Vierleiter‐Technik 10......................................

5.3 Kabelkürzung 11.....................................................

5.4 Kabelverlängerung 11................................................

5.5 EMV-Schutz 11......................................................

6 Technische Daten 13.................................................

7 Abmessungen 15....................................................

3

PWSE

SICHERHEITSHINWEISE

1 SICHERHEITSHINWEISE

Bestimmungsgemäße Verwendung

Die Wägezellen der Typenreihe PWSE sind für wägetechnische Anwendungen im

Rahmen der durch die technischen Daten spezifizierten Belastungsgrenzen konzipiert.

Jeder andere Gebrauch ist nicht bestimmungsgemäß.

Die Wägezellen dürfen nur von qualifiziertem Personal ausschließlich entsprechend der

technischen Daten unter Beachtung der Sicherheitsbestimmungen und Vorschriften

dieser Montageanleitung eingesetzt werden. Zusätzlich sind die für den jeweiligen

Anwendungsfall geltenden Rechts‐ und Sicherheitsvorschriften zu beachten. Sinngemäß

gilt dies auch bei Verwendung von Zubehör.

Die Wägezellen sind nicht zum Einsatz als Sicherheitsbauteile bestimmt. Bitte beachten

Sie hierzu den Abschnitt „Zusätzliche Sicherheitsvorkehrungen“. Der einwandfreie und

sichere Betrieb der Wägezellen setzt sachgemäßen Transport, fachgerechte Lagerung,

Aufstellung und Montage sowie sorgfältige Bedienung voraus.

Belastbarkeitsgrenzen

Beim Einsatz der Wägezellen sind die Angaben in den technischen Datenblättern unbe

dingt zu beachten. Insbesondere dürfen die jeweils angegebenen Maximalbelastungen

keinesfalls überschritten werden. Nicht überschritten werden dürfen z.B. die in den

technischen Datenblättern angegebenen Werte für

SGrenzlast

SGrenzlast bei max. Exzentrizität

SGrenzquerbelastung

SBruchlasten

STemperaturgrenzen

SGrenzen der elektrischen Belastbarkeit

Beachten Sie, dass beim Einbau mehrerer Wägezellen in eine Waage die Lastverteilung

auf die einzelnen Wägezellen nicht immer gleichmäßig ist.

Einsatz als Maschinenelemente

Die Wägezellen können als Maschinenelemente eingesetzt werden. Bei dieser

Verwendung ist zu beachten, dass die Wägezellen zu Gunsten einer hohen Messempfind

lichkeit nicht mit den im Maschinenbau üblichen Sicherheitsfaktoren konstruiert wurden.

Beachten Sie hierzu den Abschnitt „Belastbarkeitsgrenzen“ und die technischen Daten.

PWSE

SICHERHEITSHINWEISE

4

Unfallverhütung

Obwohl die angegebene Nennlast im Zerstörungsbereich ein Mehrfaches vom Messbe

reichsendwert beträgt, müssen die einschlägigen Unfallverhütungsvorschriften der

Berufsgenossenschaften berücksichtigt werden.

Zusätzliche Sicherheitsvorkehrungen

Die Wägezellen können (als passive Aufnehmer) keine (sicherheitsrelevanten)

Abschaltungen vornehmen. Dafür bedarf es weiterer Komponenten und konstruktiver

Vorkehrungen, für die der Errichter und Betreiber der Anlage Sorge zu tragen hat.

Wo bei Bruch oder Fehlfunktion der Wägezellen Menschen oder Sachen zu Schaden

kommen können, müssen vom Anwender geeignete zusätzliche Sicherheitsvorkehrungen

getroffen werden, die zumindest den Anforderungen der einschlägigen Unfallverhütungs

vorschriften genügen (z.B. automatische Notabschaltungen, Überlastsicherungen,

Fanglaschen oder ‐ketten oder andere Absturzsicherungen).

Die das Messsignal verarbeitende Elektronik ist so zu gestalten, dass bei Ausfall des

Messsignals keine Folgeschäden auftreten können.

Allgemeine Gefahren bei Nichtbeachten der Sicherheitshinweise

Die Wägezellen entsprechen dem Stand der Technik und sind betriebssicher. Von den

Aufnehmern können Gefahren ausgehen, wenn sie von ungeschultem Personal oder

unsachgemäß montiert, aufgestellt, eingesetzt und bedient werden. Jede Person, die mit

Aufstellung, Inbetriebnahme, Betrieb oder Reparatur einer Wägezelle beauftragt ist, muss

die Montageanleitung und insbesondere die sicherheitstechnischen Hinweise gelesen

und verstanden haben. Bei nicht bestimmungsgemäßem Gebrauch der Wägezellen, bei

Nichtbeachtung der Montage‐ und Bedienungsanleitung, dieser Sicherheitshinweise oder

sonstiger einschlägiger Sicherheitsvorschriften (Unfallverhütungsvorschriften der BG)

beim Umgang mit den Wägezellen, können die Wägezellen beschädigt oder zerstört

werden. Insbesondere bei Überlastungen kann es zum Bruch von Wägezellen kommen.

Durch den Bruch einer Wägezelle können darüber hinaus Sachen oder Personen in der

Umgebung der Wägezelle zu Schaden kommen.

Werden Wägezellen nicht ihrer Bestimmung gemäß eingesetzt oder werden die

Sicherheitshinweise oder die Vorgaben der Montage‐ oder Bedienungsanleitung außer

Acht gelassen, kann es ferner zum Ausfall oder zu Fehlfunktionen der Wägezellen kom

men, mit der Folge, dass (durch auf die Wägezellen einwirkende oder durch diese

überwachte Lasten) Menschen oder Sachen zu Schaden kommen können.

Der Leistungs‐ und Lieferumfang des Aufnehmers deckt nur einen Teilbereich der Wäge

technik ab, da Messungen mit (resistiven) DMS‐Sensoren eine elektronische Signalver

arbeitung voraussetzen. Sicherheitstechnische Belange der Wägetechnik sind zusätzlich

vom Anlagenplaner/Ausrüster/Betreiber so zu planen, zu realisieren und zu verantworten,

dass Restgefahren minimiert werden. Die jeweils existierenden nationalen und örtlichen

Vorschriften sind zu beachten.

Table of contents

Languages:

Other HBK Measuring Instrument manuals