HBK Z7A User manual

Z7A

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

Montageanleitung

Notice de montage

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-0101.0019

DVS: A01847 02 Y00 01

03.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos

produits que sous une forme générale. Elles

n'impliquent aucune garantie de qualité ou de

durabilité.

Z7A

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

Z7A

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 3................................................

2 Markings used 5....................................................

2.1 The markings used in this document 5.................................

2.2 Symbols on the product 5............................................

3 Notes on Mounting 6................................................

4 Load introduction 7.................................................

5 Connection 8.......................................................

5.1 Parallel connection 8................................................

5.2 Transducer connected in the four‐wire technique 9.......................

5.3 Cable extension 9...................................................

6 Specifications 10....................................................

7 Dimensions Z7A (in mm; 1 mm = 0.03937 inches) 12.....................

8 Accessories 13......................................................

3

Z7A

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

In cases where a breakage may cause injury to persons or damage to equipment, the

user must take appropriate safety measures (such as fall protection, overload protection,

etc.). Safe and trouble‐free operation of the load cells requires proper transportation,

correct storage, assembly and mounting as well as careful operation and maintenance.

It is essential to comply with the relevant accident prevention regulations. In particular

you should take into account the limit loads quoted in the specifications.

Use in accordance with the regulations

Z7A/... type load cells have been designed for weighing applications. Use for any addi

tional purpose shall be deemed to be not in accordance with the regulations.

To ensure safe operation, the load cells should only be used as described in the Mounting

Instructions. It is also essential to observe the appropriate legal and safety regulations

for the application concerned during use. The same applies to the use of accessories.

The Z7A/... load cells can be used as machine components (e.g. with tank weighing).

Please note in these cases that, in order to provide a high sensitivity, the load cells have

not been designed with the safety factors normally applied in machine design. The load

cell is not a safety element within the meaning of its use in accordance with the regula

tions. The measuring signal processing electronics has to be designed in such a way that

with a measuring signal failure no damages can occur.

General dangers due to non‐observance of the safety instructions

The Z7A/... load cells correspond to the state of the art and are fail‐safe. The load cells

can give rise to residual dangers if they are inappropriately installed and operated by un

trained personnel.

Everyone involved with the installation, commissioning, maintenance or repair of a load

cell must have read and understood the Mounting Instructions and in particular the tech

nical safety instructions.

Residual dangers

The scope of supply and performance of the load cells covers only a small part of weigh

ing technology. In addition, equipment planners, installers and operators should plan, im

plement and respond to the safety engineering considerations of weighing technology in

such a way as to minimize residual dangers. Prevailing regulations must be complied

with at all times. There must be reference to the residual dangers connected with weigh

ing technology.

Z7A

SAFETY INSTRUCTIONS

4

Environmental conditions

In the context of your application, please note that acids and all materials which release

(chlorine) ions will attack all grades of stainless steel and their welding seams. This may

result in corrosion which can lead to the failure of the load cell. In such cases the opera

tor must take appropriate safety measures.

Prohibition of own conversions and modifications

The load cells must not be modified from the design or safety engineering point of view

except with our express agreement. Any modification shall exclude all liability on our part

for any damage resulting therefrom.

Qualified personnel

These load cells are only to be installed by qualified personnel strictly in accordance with

the specifications and with the safety rules and regulations which follow. It is also essen

tial to observe the appropriate legal and safety regulations for the application concerned.

The same applies to the use of accessories.

Qualified personnel means persons entrusted with the installation, fitting, commissioning

and operation of the product who possess the appropriate qualifications for their func

tion.

Accident prevention

Although the specified maximum capacity in the destructive range is several times the

full scale value, the relevant accident prevention regulations from the trade associations

must be complied with. Take into consideration the values specified in particular in

chapter 4:

Slimit loads,

Smax. longitudinal forces,

Smax. transverse forces.

5

Z7A

MARKINGS USED

2 MARKINGS USED

2.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important

This marking draws your attention to important in

formation about the product or about handling the

product.

Tip

This marking indicates application tips or other

information that is useful to you.

Information

This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

2.2 Symbols on the product

CE mark

The CE mark enables the manufacturer to guarantee that the

product complies with the requirements of the relevant EC direc

tives (the declaration of conformity is available at

http://www.hbm.com/HBMdoc

).

Z7A

NOTES ON MOUNTING

6

3 NOTES ON MOUNTING

The following must be considered during the assembly of load cells:

SThe load cell must be handled with care.

SDo not overload the load cell, not even for a short time, for example, by impact forces

during mounting or unevenly distributed supporting forces.

SThe load cell seating must be horizontal, flat over the whole surface and, like the load

cell base, absolutely clean.

SThe fundament must be unyielding in relation to the expected loads.

SDust, dirt and other particles are not to accumulate such that they affect the load cell's

mobility and thus falsify the measured value.

SEvery load cell should be shunted by a stranded copper cable (approx. 16 mm2, e.g.

EEK... from HBM) during or immediately after installation to prevent any welding cur

rents from flowing through the load cell.

SIn load cells with an additional outer braided wire over the cable (item no. K-Z7A_ with

options 6R or 12R), this cable is only used for protection against increased mechani

cal stress (e.g. damage caused by gnawing rodents). To avoid accidental energiza

tion, the outer braided wire must be connected to potential equalization at least once.

This outer braid is not used to shield the load cell. The inner braid of the load cell ca

ble is used for shielding.

Notice

Never load the transducers against the indicated load direction (see arrow on the load

introduction side). This results in measuring errors and can damage the fixing bolts. With

the correct load direction and electrical connection, the output signal of the load cells is

positive.

The load cells are fixed at the mounting bores like a cantilever beam, the load is applied

at the other end. For the recommended screws and tightening torques refer to the table

below:

Max. capacity Thread Min. property

class

Tightening torque1)

Frict. coeff. μ= 0.125

0.5...2 t 2 x M12 10.9 115 Nm

5 t 2 x M20 10.9 560 Nm

10 t 2 x M24 10.9 970 Nm

1) Recommendedvalue for the stated property class. For screw dimensioning please refer to the

appropriate information given by the screw manufacturers.

7

Z7A

LOAD INTRODUCTION

4 LOAD INTRODUCTION

Loads should be introduced as closely as possible in the direction of measurement. Tor

sional moments, off‐center loads and transverse or lateral forces cause measurement

errors and may damage the load cell. These adverse influences must be avoided, e.g. by

using stay rods or guide rolls. These elements must not absorb any load or force compo

nents in the direction of measurement.

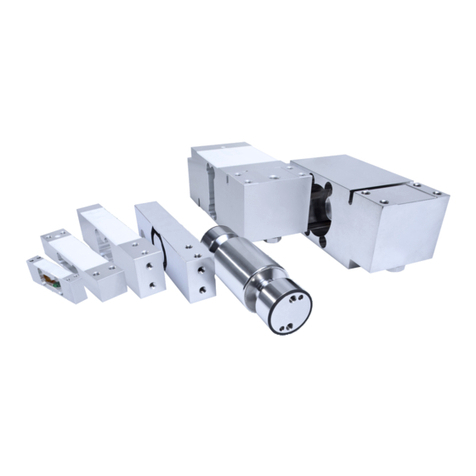

HBM offers different load‐introduction components suiting various mounting situations in

order to minimize the adverse effects due to load introduction:

SZEL Rubber‐metal bearing

SZPL Pendulum bearing

SEPO3R Thrust piece

SZL Load button insert

SZK Spherical cap

Z7A

CONNECTION

8

5 CONNECTION

Load cells with a strain gage measuring system can be connected to:

Scarrier‐frequency measuring amplifiers, or

SDC measuring amplifiers suitable for strain gage measuring systems.

The load cells are connected using the six‐wire circuit. The wiring assignment is shown in

the following diagram.

(white)

(black)

(grey)

Excitation (+)

(green)

(red)

(Wire strand)

Excitation (-)

Sense (-)

Signal (+)

(blue)

Sense (+)

Signal (-)

Shield,

connected to housing

Electric and magnetic fields often induce interference voltages in the measurement cir

cuit. Therefore:

Suse shielded, low‐capacitance measurement cables only (HBM cables fulfill these

conditions),

Sdo not route the measurement cables parallel to power lines and control circuits. If

this is not possible, protect the measurement cable with steel conduit for example.

Savoid stray fields from transformers, motors and contact switches.

5.1 Parallel connection

Load cells can be wired in parallel by joining the load cell cable core ends of the same

color. In this case, HBM provides junction boxes of the VKK... series. The output signal is

then the average of the individual output signals.

Important

Overloading of an individual load cell cannot then be detected from the output signal.

9

Z7A

CONNECTION

5.2 Transducer connected in the four‐wire technique

Upon connection to amplifiers using the four‐wire circuit, the cores bl (blue) and gn

(green) should be connected, as should bk (black) and gr (gray). The following deviations

occur in the case of cable of original length (6 m): Sensitivity -0.4 % and temperature co

efficient -0.02 %/10 K.

5.3 Cable extension

Extension cables must be shielded and of low capacitance. We recommend the use of

HBM cables, which satisfy these requirements.

HBM extension cables, 6 wires:

SKAB8/00‐2/2/2 (sold by the meter, order‐no. 4‐3301.0071 = grey or

4‐3301.0082 = blue)

SCABA1 (cable roll, order‐no. CABA1/20 = 20 m or CABA1/100 = 100 m in length)

With cable extensions it is important to ensure a good connection with minimum contact

resistance and good insulation.

When using the six‐wire circuit, the effects of resistance changes in the extension cable

are compensated. If you extend the cable using the four‐wire circuit, the sensitivity devi

ation can be eliminated by adjusting the amplifier. However, temperature effects can only

be compensated when operating with the six‐wire circuit.

Route the load cell connection cable so that any condensed water or dampness forming

on the cable can drip off. It must not be able to reach the load cell. In addition ensure that

no dampness can penetrate the open ends of the cable.

Load cell

Humidity

Connection cable

Z7A

SPECIFICATIONS

10

6 SPECIFICATIONS

Type Z7A

Accuracy class according to OIML R 60

Maximum number of load cell verification

intervals (nLC)

D1

1000

C3

3000

Max. capacity (Emax)t0.5; 1; 2; 5; 10 2; 5; 10

Min. load cell verificat. interval (vmin)% of

Emax

0.0357 0.0100

Sensivity (Cn)mV/V 2

Sensivity tolerance % ±0.1000 ±0.0500

Temperat. effect on sensivity (TKC)1) % of

Cn/10 K

±0.0350 ±0.0117

Temperat. effect on zero signal (TK0)±0.0500 ±0.0140

Hysteresis error (dhy)1)

% of Cn

±0.0500 ±0.0170

Non‐linearity (dlin)1) ±0.1000 ±0.0333

Creep (dcr) in 30 min. ±0.0735 ±0.0167

Input resistance (RLC)

Ω

350

Output resistance (RO) 356±0.2 356±0.12

Reference excitation volt. range (Uref)V0.5...12

Max. excitation voltage (BU)18

Nominal temperature range (BT)

°C [°F]

-10...+40 [+14...104]

Operating temperature range (Btu)-30...+70 [-22...158]

Storage temperature range (Btl)-50...+85 [-58...185]

Safe load limit (EL)% of

Emax

150

Breaking load (Ed)300

Max. capacity (Emax)t 0.5 1 2 5 10

Relative static lateral force

limit (Elq)2)

% of

Emax

100 50 25

(100)2) 15

(100)2) 18

(100)2)

Permissible dynamic load

(Fsrel) (vibration amplitude acc.

to DIN 50100)

70

11

Z7A

SPECIFICATIONS

Max. capacity (Emax)105210.5t

Nominal displacement (snom),

approx.

mm 0.25 0.30 0.35 0.45 0.70

Weight (G), approx. kg 2.3 5 8

Degree of protection,

acc. to IEC529

IP 67

Material

Measuring body

Cable gland

Cable sheath

Steel, galvanized nickel

Stainless steel3), VitonR

PVC

1) The data for linearity error (dlin) hyseresis (dhy) and temperature effect TKc) on sensitivity are typical

values. The sum of these data meets the requirements of OIML R60

2) The values indicated in parentheses refer to mounting conditions, with which the transducer foot is

prevented by stops from a movement. Here, major effects of errors have to be expected.

3) Acc. to EN 10088-1

Z7A

DIMENSIONS Z7A

12

7 DIMENSIONS Z7A (IN MM; 1 MM = 0.03937 INCHES)

øL

øM

NH

K2

D

A

B

Cable: 6 cores screened

5.4 - 6 m long

E

FG

K1

C

J

Max.

capac.

t

L+0.2 MH11 J B H N A D F G E C K1 K2 M1)

NVm

0.5; 1 30.2 17.5 13.4 47.6 11.1 11.9 203.2 101 98.3 63.5 19.1 36.5 10.6 29 135

230.2 17.5 13.4 47.6 11.1 11.9 203.2 102 98.3 63.5 19.1 36.5 10.6 29 135

541.3 25.5 22.5 70 22.2 15.9 235 118 123.7 66.5 20.6 47.6 16 46 660

10 51 32 27 82.6 19.1 20.7 279.4 140 139.7 82.6 25.4 60.3 21 51 1150

1) Tightening torque for screws with min. property class 10.9 (with friction coefficient μ = 0.16)

13

Z7A

ACCESSORIES

8 ACCESSORIES

ZEL Rubber‐metal bearing

R

B

ZEL

Z

a

X

Y

e

L

P

T

Max.

capac.

t

ZEL

Rubber-

metal

bearing

B L P R T X Y Z a e FR1)

N

smax2)

mm

mm

0.5...2 Z17/2t/

ZEL

76.3 180.9 70 100 9 120 60 10 112 +1.5

‐1.7 80 400 4.5

5Z17/5t/

ZEL

93 210.8 70 125 11 150 100 10 147+1.2

‐2.0 100 620 8

10 HLCB/

10t/ZEL

114.1 247.7 90 175 13 200 100 12 176 +1.8

‐2.0 130 810 9.5

1) FRRestoring force in N for s = 1 mm

2) smax Max. lateral displacement at max. capacity

Z7A

ACCESSORIES

14

Pendulum bearing ZPL

when the ZPL is

delivered two dust

protection rings

are also included

ZPL

max. deviation 35

M

D1

∅U

∅O

H

E

F1

T

∅C1

∅C

Max.

capac.

t

t

ZPL

Pendulum

bearing

C+0.

2

C1‐0.

1

D1E F1H M O T UD10

h9

FR1)

% of

load

smax2)

mm

0.5...2 Z17/2t/Z

PL

30.2 30 60 22 14 130

0.5

M10 46 8 30 2 7.5

5Z17/5t/Z

PL

41.3 41.1 73 26 16 169

0.5

M10 48 8 30 1.5 6.9

10 Z17/10t/Z

PL

51 50.8 82 32 21 196

0.5

M12 58 10 40 1.8 9.3

1) FRRestoring force in N for s = 1 mm

2) smax.Max. lateral displacement at max. capacity

15

Z7A

ACCESSORIES

EPO3R Thrust piece

Max.

capac.

(t)

EPO3R

Thrust piece

C-0.1 D E H3 H4 N O P Q

0.5...2 EPO3R/5t 37.8 21 16 58.7 74.7 12 89 70 9

5EPO3R/5t 37.8 21 16 81.1 79.1 12 89 70 9

10 EPO3R/20t 47.8 28 20 95.9 115.9 14 114 90 13

ZL Load button insert ZK Spherical cap

3

Spheric R1Spheric R2

Thread hole not

with capacities 2 t

Max.

capac.

(t)

ZL

Load but

ton insert

ZK

Spherical

cap

A C1-0.

1

C2C3C4C5F F1F2F3R1R2 U

0.5...2 Z17/2t/

ZL

Z17/2t/Z

K

17.5 30 15 13 28 29 10 12 27.5 4.5 60 38 25−0.05

−0.1

5Z17/5t/

ZL

Z17/5t/Z

K

25.5 41.1 23 21 39 40 12.3 16 31.5 4.5 60 57 25

−0.05

−0.1

10 Z17/10t/

ZL

Z17/10t/

ZK

32 50.8 28 25 47 50 15 21 39.5 5.5 160 70 25 −0.05

−0.1

Z7A

ACCESSORIES

16

Z7A

ENGLISH DEUTSCH FRANÇAIS

Montageanleitung

Z7A

INHALTSVERZEICHNIS

2

INHALTSVERZEICHNIS

1 Sicherheitshinweise 3...............................................

2 Verwendete Kennzeichnungen 5......................................

2.1 In dieser Anleitung verwendete Kennzeichnungen 5......................

2.2 Auf dem Gerät angebrachte Symbole 5.................................

3 Montagehinweise 6.................................................

4 Lasteinleitung 7....................................................

5 Anschließen 8......................................................

5.1 Parallelschaltung 8..................................................

5.2 Anschluss in Vierleiter‐Technik 9......................................

5.3 Kabelverlängerungen 9..............................................

6 Technische Daten 10.................................................

7 Abmessungen Z7A (mm) 12...........................................

8 Zubehör 13.........................................................

Table of contents

Languages:

Other HBK Measuring Instrument manuals