HBK Z6R User manual

Z6R, Z6R-P

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

Montageanleitung

Notice de montage

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-0201.0017-1

DVS: A04514 04 Y00 00

07.2023

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos

produits que sous une forme générale. Elles

n'impliquent aucune garantie de qualité ou de

durabilité.

Z6R, Z6R-P

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

Z6R, Z6R-P

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 3................................................

2 Markings used 5....................................................

2.1 The markings used in this document 5.................................

2.2 Symbols on the device 5.............................................

3 Conditions on site 6.................................................

4 Mechanical installation 7............................................

4.1 Important precautions during installation 7..............................

4.2 Mounting and load application 7.......................................

5 Electrical connection 9..............................................

5.1 Cable assignment six-wire configuration 9..............................

5.2 Plug connection in a six-wire configuration 9............................

5.3 Cable assignment four-wire configuration 10.............................

5.4 Shortening the cable 11...............................................

5.5 Cable extension 11...................................................

5.6 Parallel connection 11................................................

5.7 EMC protection 11...................................................

6 Waste disposal, environmental protection 13............................

7 Specifications 14....................................................

8 Dimensions 16......................................................

9 Accessories 18......................................................

9.1 Oscillating loading foot PCX 18.........................................

9.2 Oscillating loading foot ZKP 19.........................................

9.3 Knuckle eye ZGWR 20................................................

9.4 Cone, conical pan ZK 21...............................................

9.5 Pendulum bearing ZPL 22.............................................

9.6 Rubber-metal bearing ZEL 23..........................................

9.7 Mounting base / mounting kit 24.......................................

3

Z6R, Z6R-P

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

Appropriate use

Transducers of the Z6R/Z6R-P type series are designed solely for technical weighing

applications within the application limits detailed in the specifications. Any other use is

not appropriate.

Any person instructed to carry out installation, commissioning or operation of the trans

ducer must have read and understood the Operating Manual and in particular the techni

cal safety instructions.

In the interests of safety, the transducer should only be operated by qualified personnel

and as described in the Operating Manual. It is also essential to comply with the legal and

safety requirements for the application concerned during use. The same applies to the

use of accessories.

The transducer is not intended for use as a safety component. Please also refer to the

section: "Additional safety precautions". Proper and safe operation requires proper trans

portation, correct storage, siting and mounting, and careful operation.

Operating conditions

SPlease observe the permissible maximum values stated in the specifications for:

-Limit load

-Limit lateral loading

-Breaking loads

-Temperature limits

-Limits of electrical loading capacity

SNote, that when several transducers are installed in a scale, there is not always an

even distribution of load on the individual transducers.

SThe transducers can be used as machine elements. When used in this manner, it must

be noted that, to favor greater sensitivity, the transducer is not designed with the

safety factors usual in mechanical engineering.

SThe transducer must not be modified from the design or safety engineering point of

view except with our express agreement.

SThe transducer is maintenance-free.

SIn accordance with national and local environmental protection and material recovery

and recycling regulations, old transducers that can no longer be used must be dis

posed of separately and not with normal household garbage, see Chapter 6, Page 13.

Z6R, Z6R-P

SAFETY INSTRUCTIONS

4

Explosion protection version option

SComply with the relevant code of practice during installation.

SComply with the installation conditions cited in the Certificate of Conformity and/or

the Type Certificate.

Qualified personnel

Qualified persons means persons entrusted with the installation, fitting, commissioning

and operation of the product who possess the appropriate qualifications for their func

tion.

This includes people who meet at least one of the three following requirements:

SKnowledge of the safety concepts of measurement and automation technology is a

requirement and as project personnel, they must be familiar with these concepts.

SAs measurement or automation plant operating personnel, they have been instructed

how to handle the machinery. They are familiar with the operation of the equipment

and technologies described in this documentation.

SAs commissioning engineers or service engineers, they have successfully completed

the training to qualify them to repair the automation systems. They are also autho

rized to activate, ground and label circuits and equipment in accordance with safety

engineering standards.

Additional safety precautions

Additional safety precautions to meet the requirements of the relevant national and local

accident prevention regulations must be taken in plants where malfunctions could cause

major damage, loss of data or even personal injury.

The scope of supply and performance of the transducer covers only a small area of mea

surement technology. Before starting up the transducer in a system, a project planning

and risk analysis must first be implemented, taking into account all the safety aspects of

measurement and automation technology so that residual risks are minimized. This par

ticularly concerns personal and machine protection. The transducers function passively

and cannot implement any (safety-relevant) cutoffs. In the event of a fault, the relevant

precautions must establish safe operating conditions.

General dangers of failing to follow the safety instructions

The transducer corresponds to the state of the art and is failsafe. The transducer may

give rise to residual dangers if it is inappropriately installed or operated.

5

Z6R, Z6R-P

MARKINGS USED

2 MARKINGS USED

2.1 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

WARNING This marking warns of a potentially dangerous situ

ation in which failure to comply with safety require

ments can result in death or serious physical injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important This marking draws your attention to important in

formation about the product or about handling the

product.

Tip This marking indicates application tips or other

information that is useful to you.

Information This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

2.2 Symbols on the device

CE certification

The CE mark enables the manufacturer to guarantee that the

product complies with the requirements of the relevant EU direc

tives (the Declaration of Conformity can be found on the HBK

website www.hbm.com or www.hbkworld.com).

Z6R, Z6R-P

CONDITIONS ON SITE

6

3 CONDITIONS ON SITE

Series Z6R/Z6R-P load cells are hermetically encapsulated and are therefore not at all

sensitive to the influence of moisture and humidity. Nevertheless, the load cells must be

protected against constant humidity and moisture.

Protection against corrosion

The load cell must be protected against chemicals that could attack the transducer body

steel, or the cable.

Notice

Acids and all substances that release ions also attack stainless steels and their welded

seams.

Should there be any corrosion, this could cause the transducer to fail. If this is the case,

you must provide appropriate means of protection.

Deposits

Dust, dirt and other foreign matter must not be allowed to accumulate sufficiently to

divert some of the measuring force onto the housing, thus invalidating the measured

value (force shunt).

7

Z6R, Z6R-P

MECHANICAL INSTALLATION

4 MECHANICAL INSTALLATION

4.1 Important precautions during installation

SHandle the transducer with care.

SWelding currents must not be allowed to flow over the transducer. If there is a risk

that this might happen, you must provide a suitable low-ohm connection to electrically

bypass the transducer. HBK, for example, provides the highly flexible EEK ground

cable, which can be screwed on above and below the transducer.

SMake sure that the transducer cannot be overloaded.

WARNING

There is a danger of the transducer breaking if it is overloaded. This can cause danger for

the operating personnel of the system in which the transducer is installed.

Implement appropriate safety measures to avoid overloads or to protect against the

resulting dangers.

Notice

Load cells are precision measuring elements and need to be handled carefully. Dropping or

knocking the transducer may cause permanent damage. Make sure that the transducer

cannot be overloaded, including while it is being mounted.

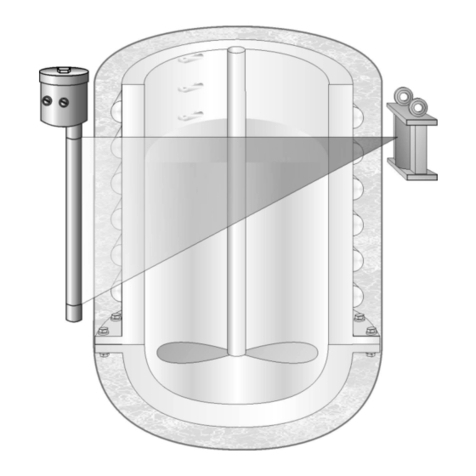

4.2 Mounting and load application

Attach the load cells at the mounting holes and apply load to the other end. The screws

and tightening torques to be used are given in the following table:

Maximum

capacities

Thread Min. property class Tightening torque 1))

20 … 200 kg M8 10.9 34 N⋅m

1) Recommendedvalue for the specified property class. Please comply with the screw manufacturer's

instructions with regard to screw dimensions.

Important

Load must not be applied to the side where the cable connection is located, as this would

cause a force shunt.

Z6R, Z6R-P

MECHANICAL INSTALLATION

8

The load must act as accurately as possible in the direction of measurement. Torsional

moments, eccentric loads and lateral or side forces cause measurement errors and can

permanently damage the load cell. Catch such interference effects, e.g. using lateral stay

bars or guide rollers, but ensure that these elements do not absorb any load or force

components in the direction of measurement (force shunt which will in turn lead to mea

surement errors).

To minimize error effects from load application, HBK offers different load application

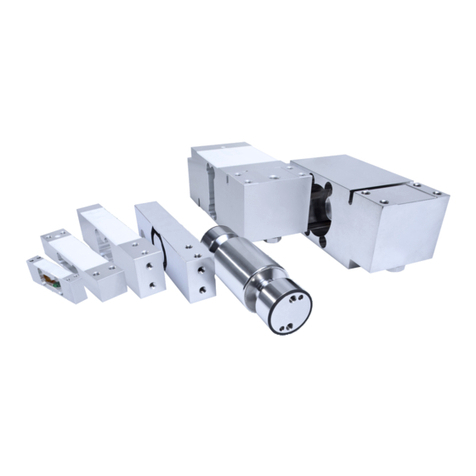

elements, according to the mounting conditions:

SPendulum bearing ZPL (1-Z6/200kg/ZPL) (for nominal rated loads 20 kg … 200 kg)

SKnuckle eyes ZGWR (1-Z6/200kg/ZGWR) (for nominal rated loads 20 kg … 200 kg)

SRubber-metal bearing ZEL (1-Z6/200kg/ZEL) (for nominal rated loads 20 kg … 200 kg)

SCone/conical pan ZK (1-Z6/200kg/ZK) (for nominal rated loads 20 kg … 200 kg)

SOscillating loading foot PCX (1-Z6/PCX/500kgSet) (for nominal rated loads

20 kg … 200 kg)

SOscillating loading foot ZKP (1-Z6/ZKP/200kg) (for nominal rated loads

20 kg … 200 kg)

SMounting plate / Mounting set ZPU (1-Z6/ZPU/200kg) (for nominal rated loads

20 kg … 200 kg)

9

Z6R, Z6R-P

ELECTRICAL CONNECTION

5 ELECTRICAL CONNECTION

The following can be connected for measurement signal conditioning:

Scarrier-frequency amplifiers

SDC amplifiers

designed for strain gauge measurement systems.

The load cells are delivered with a six-wire configuration.

5.1 Cable assignment six-wire configuration

white

black

gray

Excitation voltage (+) Plug in contact 7

green

red

Shielding/drain wire, connected to housing

Excitation voltage (-) Plug in contact 6

Sense lead (-) Plug in contact 5

Measurement signal (+) Plug in contact 1

blue

Sense lead (+) Plug in contact 3

Measurement signal (-) Plug in contact 8

Fig. 5.1 Pin assignment

With this connector pin assignment, the output voltage at the measuring amplifier is posi

tive when the transducer is loaded.

5.2 Plug connection in a six-wire configuration

Pin assignment for Z6R-P (Z6R load cell with M12x1 male connector)

Plug-in contact 1 = measurement signal (+)

Plug-in contact 2 = not assigned

Plug-in contact 3 = sense lead (+)

Plug-in contact 4 = not assigned

Plug-in contact 5 = sense lead (-)

Plug-in contact 6 = excitation voltage (-)

Plug-in contact 7 = excitation voltage (+)

Plug-in contact 8 = measurement signal (-)

Z6R, Z6R-P

ELECTRICAL CONNECTION

10

Matching couplings (jack + cable) from HBK:

Pin assignment for 1-KAB168 Pin assignment for 1-KAB175 Plug in

contact

Wire

color

Connection Wire

color

Connection

White Measurement signal (+) White Measurement signal (+) 1

Red Measurement signal (-) Red Measurement signal (-) 8

Blue Excitation voltage (+) Blue Excitation voltage (+) 7

Pink Excitation voltage (-) Black Excitation voltage (-) 6

Green Sense lead (+) Green Sense lead (+) 3

Gray Sense lead (-) Gray Sense lead (-) 5

Yellow Not in use -

Brown Not in use -

Couplings

Coupling with male connector M12 F, 8-pin, TPU IP67,

cable sheath PUR, 5 m long

1-KAB168-5

Coupling with male connector M12 F, 8-pin, TPU IP67,

cable sheath PUR, 20 m long

1-KAB168-20

Coupling with male connector M12 F, 8-pin, stainless steel,

IP68/69, Hygienic design, 3 m long

1-KAB175-3-1

Coupling with male connector M12 F, 8-pin, stainless steel,

IP68/69, Hygienic design, 6 m long

1-KAB175-6-1

Coupling with male connector M12 F, 8-pin, stainless steel,

IP68/69, Hygienic design, 12 m long

1-KAB175-12-1

5.3 Cable assignment four-wire configuration

When transducers in a six-wire configuration are connected to amplifiers in a four-wire

configuration, the sense leads of the transducer must be connected to the corresponding

excitation voltage leads: Marking (+) with (+) and marking (-) with (-), see Fig. 5.1. This

measure also reduces the cable resistance of the excitation voltage leads. However,

there will be a voltage loss on the supply leads due to the cable resistance that is still

present and not compensated for by the six-wire configuration. A large part of this loss

can be eliminated by a calibration, however, the temperature-dependent part remains.

11

Z6R, Z6R-P

ELECTRICAL CONNECTION

Important

The TCsvalue given in the specifications for the transducer therefore does not apply for

the cable and transducer combination when connection is in a four-wire configuration,

where the cable percentage must be added.

The following deviations occur in the case of an uncut cable (3 m):

SSensitivity approx. -0.2%

STCSapprox. -0.01% per 10 K.

5.4 Shortening the cable

If the transducer is connected to an amplifier in a six-wire configuration, the transducer

cable can be shortened as required, without adversely affecting the measurement accu

racy.

5.5 Cable extension

Only use shielded, low-capacitance measurement cables for extending. Ensure that con

nection is perfect, with a low contact resistance. The cable of a six-wire transducer can

be extended with a cable of the same type.

Cable types recommended by HBK:

SKAB7.5/00‐2/2/2 (by the meter, Order No. 4‐3301.0071 for gray or 4‐3301.0082 for

blue version)

SCABA1 (cable roll, Order No. CABA1/20 = 20 m or CABA1/100 = 100m long)

5.6 Parallel connection

Only load cells with an aligned output (nominal (rated) sensitivity and output resistance)

are suitable for parallel connection. The load cells can be wired in parallel by joining the

load cell cable core ends of the same color. For this purpose, type VKK junction boxes,

also for explosion protection, are available in the HBK product line. The output signal is

then the average of the individual output signals.

Important

Overloading in an individual load cell cannot then be detected from the output signal after

load cells have been connected in parallel.

5.7 EMC protection

Electrical and magnetic fields often induce interference voltages in the measuring circuit.

To ensure reliable measurement, however, the transducer must be able to transmit signal

differences of a few μV to the analysis unit without interference.

Z6R, Z6R-P

ELECTRICAL CONNECTION

12

Planning the shielding design

Due to the numerous application options and differing local constraints, we can only

provide you with general information on correct connection. The shielding design suitable

for your application must be planned locally by an appropriate specialist.

HBM load cells with shielded, round cables are EMC-tested in accordance with the

EU Directive and bear the CE mark. Voltage surges as per EN 61000-4-5 can give rise to

deviations from the load cell’s specified accuracy. These surges in plants are caused by

lightning strikes or switching operations in power circuits, for example, and disappear

again when interference is no longer active. This is particularly evident with cables over

30 m long or if the equipment is used outdoors. Customers should take additional pre

cautions in these cases.

Please note:

SConnect the connecting cable shield all over the surface of the shielding electronics

housing. When using several load cells, connect the shields all over the surface of the

junction box (combination of transducer signals, e.g. type VKK2 from HBM). From

there, connect the measurement cable for the electronics over the surface of the

junction box and the shielding electronics housing.

SThe shield of the connecting cable must not be used for discharging potential

differences within the system. You must therefore lay sufficiently dimensioned

potential equalization lines to compensate for possible potential differences.

SUse shielded low-capacitance measurement cables only (HBM cables fulfill these

conditions).

SDo not route measurement cables parallel to electric cables, especially power lines

and control circuits. If this is not possible, protect the measurement cable, for

example with steel conduits.

SAvoid stray fields from transformers, motors and contact switches.

Important

Potential equalization is specified for applications in potentially explosive atmospheres.

13

Z6R, Z6R-P

WASTE DISPOSAL, ENVIRONMENTAL PROTECTION

6 WASTE DISPOSAL, ENVIRONMENTAL PROTECTION

The correct disposal of old equipment prevents ecological damage and health hazards.

As waste disposal regulations may differ from country to country, we ask that you con

tact your supplier to determine what type of disposal or recycling is legally applicable in

your country.

Packaging

The original HBK packaging is made from recyclable material and can be sent for recy

cling. Store the packaging for at least the duration of the warranty.

For ecological reasons, empty packaging should not be returned to us.

Z6R, Z6R-P

SPECIFICATIONS

14

7 SPECIFICATIONS

Type Z6R, Z6R-P

Accuracy class C3

Number of load cell verification

intervals

nLC 3000

Nominal (rated) load Emax kg 20; 50; 100; 200

Nominal (rated) sensitivity Cn2

Sensitivity tolerance % ±0.05

Input resistance RLC

Ω

350 …480

Output resistance R0356 ±0.12

355 ±0.12 (Z6R-P)

Reference excitation voltage Uref

V

5

Nominal (rated) range of the excita

tion voltage

BU0.5 …12

Insulation resistance at 100 VDC Ris GΩ > 5

Nominal temperature range BT

°C

-10 …+40

Operating temperature range Btu -30 …+70

Storage temperature range Btl -50 …+85

Limit load EL% of

Emax

150

Breaking load Ed≥300

Cable length, six-wire configuration m 3

Degree of protection per DIN EN60529 (IEC529) Z6R: IP68 (test conditions 2 m

water column / 1,000 h);

Z6R-P: up to IP68/IP69K

Material

Measuring body

Housing

Cable inlet gland

Cable sheath

Stainless steel 1)

Stainless steel 1)

Stainless steel / Viton®

PVC

optional TPE or PUR

1) As per EN 10088-1.

15

Z6R, Z6R-P

SPECIFICATIONS

Maximum capacity kg 20 50 100 200

Relative permissible vibrational

stress Fsrel % of Emax 70

Nominal (rated) displacement,

approx. snom mm 0.3

Weight, approx. Gkg 0.6

Z6R, Z6R-P

DIMENSIONS

16

8 DIMENSIONS

Z6R/20kg 0200kg

Dimensions (in mm; 1 mm = 0.03937 inches)

Load application

Metal cover

Cable, 6-wire shielded; shield on enclosure

Mounting

123

48

42

18 82 10

21

27

8.2 8.2

20

20

Ø40Ø33

10.8

Ø27

17

Z6R, Z6R-P

DIMENSIONS

Z6R-P/20kg0200kg

Load application

Metal cover

Mounting

123

48

42

18 82 10

21

27

8.2 8.2

20

20

Ø40

Ø33

Ø16

Ø27

M12x1

25

Connector plug

Dimensions in mm (1 mm = 0.03937 inches)

8.2

Z6R, Z6R-P

ACCESSORIES

18

9 ACCESSORIES

9.1 Oscillating loading foot PCX

1-Z6/PCX/500kgSet,Emax = 20 kg … 200 kg

Dimensions (in mm; 1 mm = 0.03937 inches)

1 set comprising 4 pieces Z6/PCX/500kg

AF = Across Flats

AF13

AF17

AF17

This manual suits for next models

1

Table of contents

Languages:

Other HBK Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Brookfield

Brookfield CAP 2000+L operating instructions

Interacoustics

Interacoustics AA222 Instructions for use

OEM

OEM TUF-2000F user manual

BERTHOLD TECHNOLOGIES

BERTHOLD TECHNOLOGIES Uni-Probe LB 490 user manual

Eddyfi Technologies

Eddyfi Technologies M2M MANTIS Technical documentation

Grunbeck

Grunbeck GENO-control Operation manual