HBK C5 User manual

C5

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

Montageanleitung

Notice de montage

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-0111.0019

DVS: A05804 01 YC0 00

01.2022

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos

produits que sous une forme générale. Elles

n'impliquent aucune garantie de qualité ou de

durabilité.

保留变更的权利。

所有信息是对我品的般性描。在性能或者

耐性方它并提保证。

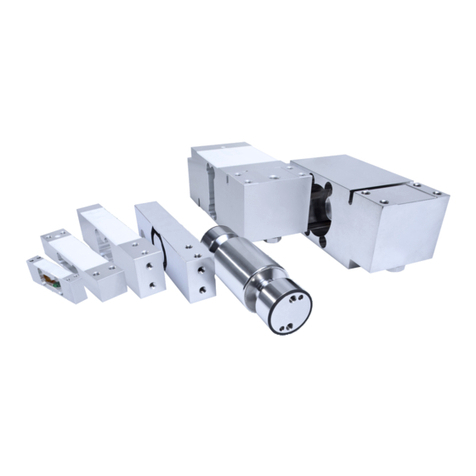

C5

ENGLISH DEUTSCH FRANÇAIS

Mounting Instructions

C5

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety Instructions 3................................................

2 Markings used 6....................................................

2.1 Markings used in this document 6.....................................

3 Scope of supply and equipment variants 7.............................

3.1 Scope of supply 7..................................................

3.2 Accessories (not included in the scope of supply) 7......................

3.3 Equipment variants 7................................................

4 General application instructions 9....................................

5 Structure and mode of operation 10....................................

5.1 Force transducer operation 10.........................................

5.2 Strain gage housing 10...............................................

6 Conditions on site 11.................................................

6.1 Ambient temperature 11..............................................

6.2 Moisture and corrosion protection 11...................................

6.3 Deposits 11.........................................................

7 Mechanical installation 12............................................

7.1 Important precautions during installation 12..............................

7.2 General installation guidelines 12.......................................

7.3 Using the C5 with a thrust piece 14.....................................

8 Electrical connection 15..............................................

8.1 Shortening or extending the cable 16....................................

8.2 4-wire connection 16.................................................

8.3 EMC protection 17...................................................

9 TEDS chips transducer identification 18................................

10 Dimensions 19......................................................

11 Mounting dimensions of connection variants 20.........................

12 Specifications 22....................................................

13 Versions and ordering numbers 24.....................................

3

C5

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

Intended use

Force transducers in the C5 series are designed solely for measuring static and dynamic

compressive forces within the load limits stated in the specifications. Any other use is

not the intended use. To ensure safe operation, it is essential to comply with the

regulations in the mounting instructions, the safety requirements listed below, and the

data specified in the supplied technical data sheets. It is also essential to observe the

applicable legal and safety regulations for the relevant application.

Force transducers are not intended for use as safety components. Please also refer to

the “Additional safety precautions” section. Proper and safe operation of force

transducers requires proper transportation, correct storage, setup and mounting, and

careful operation.

Load-carrying capacity limits

The information in the technical data sheets must be observed when using the force

transducers. The respective specified maximum loads in particular must never be

exceeded. The values specified in the technical data sheets must not be exceeded:

SForce limits

SLateral force limits

SMaximum eccentricity

SBreaking forces

SPermissible dynamic loads

STemperature limits

SElectrical load limits

Please note that when several force transducers are interconnected, the load/force

distribution is not always uniform.

Use as machine elements

Force transducers can be used as machine elements. When used in this manner, note

that to favor greater sensitivity, force transducers were not designed with the safety

factors usual in mechanical engineering. Please refer here to the "Load-carrying capacity

limits" section and to the specifications.

Accident prevention

The prevailing accident prevention regulations must be taken into account, even though

the nominal (rated) force values in the destructive range are well in excess of the full

scale value.

C5

SAFETY INSTRUCTIONS

4

Additional safety precautions

The force transducers (as passive transducers) cannot execute (safety) shutdowns. This

requires additional components and design measures, for which the installer and

operator of the plant is responsible.

Wherever,in the event of breakage or malfunction of the force transducers, people or

property may be injured, the user must take suitable additional safety precautions which

at least comply with the relevant accident prevention regulations (e.g. automatic

emergency stop, overload protection, catch straps or chains, or other fall protection

devices).

The electronics that processes the measurement signal should be designed so that

failure of the measurement signal cannot lead to secondary failures.

General dangers of failing to follow the safety instructions

Force transducers are state-of-the-art and failsafe. The transducers can be dangerous if

they are mounted, set up or operated improperly, or by untrained personnel. Every person

involved in setting up, starting up, operating or repairing a force transducer must have

read and understood the mounting instructions and in particular the technical safety

instructions. The force transducers can be damaged or destroyed by non-designated use

of the force transducer or by non-compliance with the mounting manual, these safety

instructions or other applicable safety regulations (safety and accident prevention

regulations of the Employers' Liability Insurance Association) when using the force trans

ducers. A force transducer can break, particularly if it is overloaded. The breakage of a

force transducer can cause damage to property or injury to persons in the vicinity of the

force transducer.

If force transducers are not used in accordance with their intended purpose, or if the

safety instructions or the specifications in the mounting instructions are disregarded, the

force transducers may also fail or malfunction, with the result that (due to loads acting on

or monitored by the force transducers) people or property may be injured.

The scope of supply and performance of the transducer covers only a small area of force

measurement technology, as measurements with (resistive) strain gage sensors

presuppose the use of electronic signal processing. Equipment planners, installers and

operators should always plan, implement and respond to the safety engineering

considerations of force measurement technology in such a way as to minimize residual

dangers. Pertinent national and local regulations must be complied with.

Conversions and modifications

The design or safety engineering of the transducer must not be modified without our

express permission. Any modification shall exclude all liability on our part for any

resulting damage.

5

C5

SAFETY INSTRUCTIONS

Maintenance

The force transducers of the C5 series are maintenance free. We recommend having the

force transducer calibrated at regular intervals.

Disposal

In accordance with national and local environmental protection and material recovery and

recycling regulations, old transducers that can no longer be used must be disposed of

separately and not with normal household garbage.

If you require more information about disposal, please contact your local authorities or

the dealer from whom you purchased the product.

Qualified personnel

Qualified personnel means persons entrusted with installing, mounting, starting up and

operating the product who possess the appropriate qualifications for their work.

This includes people who meet at least one of these three requirements:

SAs project personnel, you know and are familiar with the safety concepts of

automation technology.

SAs automation plant operating personnel, you have been instructed how to handle the

machinery. You are familiar with the operation of the equipment and technologies

described in this documentation.

SAs a commissioning or service engineer, you have successfully completed training on

the repair of automation plants. Moreover, you are authorized to start up, ground and

label circuits and equipment in accordance with safety engineering standards.

During use, compliance with the legal and safety requirements for the relevant

application is also essential. The same applies to the use of accessories.

The force transducer may only be used by qualified personnel exclusively in accordance

with the technical data in conjunction with the safety rules and regulations.

C5

MARKINGS USED

6

2 MARKINGS USED

2.1 Markings used in this document

Important instructions for your safety are highlighted. It is essential to follow these

instructions to prevent accidents and damage to property.

Icon Meaning

WARNING This marking warns of a potentially dangerous situa

tion in which failure to comply with safety require

ments could result in death or serious physical injury.

CAUTION This marking warns of a potentially dangerous situa

tion in which failure to comply with safety require

ments could result in slight or moderate physical

injury.

Notice This marking draws your attention to a situation in

which failure to comply with safety requirements

could lead to property damage.

Important This marking draws your attention to important

information about the product or about handling the

product.

Tip This marking indicates tips for use or other

information that is useful to you.

Information This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections of the manual,

diagrams, or external documents and files.

uThis symbol indicates an action step.

7

C5

SCOPE OF SUPPLY AND EQUIPMENT VARIANTS

3 SCOPE OF SUPPLY AND EQUIPMENT VARIANTS

3.1 Scope of supply

SC5 force transducer

SC5 mounting instructions

STest report

3.2 Accessories (not included in the scope of supply)

Connection cable/ground cable Ordering number

Configurable connection cable for connecting the force

transducer to the bridge amplifier

K-CAB-F

Connection cable KAB157-3; IP67 (with bayonet locking); 3 m

long, TPE outer sheath; 6 x 0.25mm²; free ends, shielded, outside

diameter 6.5 mm

1-KAB157-3

Connection cable KAB158-3; IP54 (with screw lock); 3 m long,

TPE outer sheath; 6 x 0.25mm²; free ends, shielded, outside

diameter 6.5 mm

1-KAB158-3

Loose cable socket (bayonet connection) 3-3312.0382

Loose cable socket (screw connection) 3-3312.0354

Ground cable, 400 mm long 1-EEK4

Ground cable, 600 mm long 1-EEK6

Ground cable, 800 mm long 1-EEK8

3.3 Equipment variants

The C5 force transducer always comes supplied with a thrust piece.

The force transducer is available in different versions. The following options are

available:

1. Nominal (rated) force

You can purchase force transducers with nominal (rated) forces between 5 MN and

20 MN. The nominal (rated) force is the force at which the sensor provides the rated out

put specified on the type plate as the output signal.

2. Number of measuring bridges

You can purchase the force transducer with a single bridge (SB), in which case the C5

comes supplied with one measuring bridge. The double-bridge version (DB) is optionally

available. The C5 then comes supplied with two electrically isolated bridge circuits.

C5

SCOPE OF SUPPLY AND EQUIPMENT VARIANTS

8

3. Bending moment bridges

You can purchase the force transducer with or without bending moment bridges (NB). If

you select the bending moment bridges option, the C5 comes with two electrically

isolated bending moment bridges.

The bending moments are recorded at 90 degrees to each other. Please note that no

characteristic value is specified for the bending moment bridges in the test report or in

the optional calibration certificate.

4. Transducer identification

You can purchase the force transducer with transducer identification (“TEDS”). TEDS

(Transducer Electronic Data Sheet) makes it possible to store the transducer data

(characteristic values) in a chip which can be read out by a connected measuring device.

With the double bridge version, or if you have selected optional bending moment bridges,

each measuring bridge is assigned its own TEDS. See also section 9, page 18.

5. Plug protection

On request, we can fit plug protection, consisting of a strong square tube, so that the plug

is protected against mechanical damage.

6. Plug version

The standard version of the force transducer is delivered with a bayonet connector. A

threaded connector can be supplied instead, if required. It is also possible to obtain the

force transducer with a fixed cable.

9

C5

GENERAL APPLICATION INSTRUCTIONS

4 GENERAL APPLICATION INSTRUCTIONS

Force transducers are suitable for measuring compressive forces. They provide highly

accurate static and dynamic force measurements and must therefore be handled very

carefully. Particular care must be taken when transporting and installing the devices.

Dropping or knocking the transducer may cause permanent damage.

The permissible limits for mechanical, thermal and electrical stress are listed in sec

tion 12 “Specifications”, page 22. It is essential to take these limits into account when

planning the measuring setup, during installation and, ultimately, during operation.

C5

STRUCTURE AND MODE OF OPERATION

10

5 STRUCTURE AND MODE OF OPERATION

5.1 Force transducer operation

The measuring body is a steel spring element to which strain gages are applied. The

strain gages for each measuring circuit are installed so that four extend and four shorten

when a force acts on the transducer. Each strain gage changes its ohmic resistance in

proportion to its change in length and so misaligns the Wheatstone bridge. If bridge

excitation voltage is present, the circuit produces an output signal proportional to the

change in resistance and therefore also proportional to the applied force. The SGs are

arranged such that parasitic forces or torques and temperature effects are compensated

as much as possible.

If the bending moment bridges option is selected, the force transducer is equipped with

two additional measuring bridges. These measuring bridges are installed in such a way

that force acting in the measuring direction is largely compensated, but acting bending

moments (such as due to eccentric force action) lead to an output signal.

5.2 Strain gage housing

To protect the strain gages, the column-type force transducers have a housing which is

screwed to the force transducer and protects the strain gages from external influences.

The housing must not be removed or damaged.

11

C5

CONDITIONS ON SITE

6 CONDITIONS ON SITE

Protect the transducer from weather conditions such as rain, snow, ice, and salt water.

6.1 Ambient temperature

The effects of temperature on the zero signal and rated output are compensated. To

obtain optimum measurement results, comply with the nominal (rated) temperature

range. The strain gages are designed and arranged to ensure a high insensitivity to

temperature gradients. Despite this, temperatures that are constant and, ideally, change

slowly have a favorable effect on accuracy. A radiation shield and thermal insulation on

all sides provide noticeable improvements,but must not form a force shunt.

6.2 Moisture and corrosion protection

Regardless of the choice of electrical connection, the sensors achieve IP 54 protection

according to DIN EN 60529 (splash-proof).

We recommend protecting the sensor from long-term exposure to moisture and weather

conditions.

6.3 Deposits

Dust, dirt and other foreign matter must not be allowed to accumulate to such an extent

that some of the measuring force is diverted, invalidating the measured value (force

shunt).

C5

MECHANICAL INSTALLATION

12

7 MECHANICAL INSTALLATION

7.1 Important precautions during installation

SHandle the transducer with care.

SNote the requirements for the force application parts stated in the following sections

of this manual.

SWelding currents must not be allowed to flow over the transducer. If there is a risk

that this might happen, you must use a suitable low-ohm connection to electrically

bypass the transducer. HBM provides the highly flexible EEK ground cable for this

purpose, for example, that is screwed on above and below the transducer.

SMake sure that the transducer cannot be overloaded.

WARNING

There is a danger of the transducer breaking if it is overloaded. This could endanger the

operating personnel of the equipment in which the transducer is installed.

Implement appropriate safety measures to avoid a force overshoot or to protect against

resulting dangers. The maximum possible mechanical stresses, especially the breaking

force,are noted in the specifications.

During installation and operation of the transducer, observe the maximum parasitic forces

- lateral forces, bending moments and torques, see technical data - and the maximum

permissible load capacity of the force application parts being used.

7.2 General installation guidelines

The forces to be measured must act on the transducer as accurately as possible in the

direction of measurement. Eccentric loads,resulting bending moments and lateral forces

can lead to measurement errors and destroy the transducer if the limit values are

exceeded.

Customers' constructional elements must meet the following conditions..

SThey must be sufficiently rigid so that they do not bend even under load

SThey must have sufficient hardness (40 HRC minimum)

SThey must be free of paint or other coatings

SThe upper and lower load application points must be parallel to each other

13

C5

MECHANICAL INSTALLATION

Fex Fnom

Fq

Mb

Fnom Force in direction of measurement

Fex Force parallel to direction of measurement, but outside center of

force transducer

MbBending moment

FqForce perpendicular to direction of measurement

The C5 is a high-quality reference transducer. It is advisable to always have the sensor

calibrated with the attachments with which it is planned to use the sensor.

You can place the C5 directly on a suitable substructure. The force transducer measures

static and dynamic compressive forces, and can be used at full oscillation width (peak-to-

peak).

Load is applied via the spherical load button on top of the force transducer. We

recommend using the supplied thrust piece to guarantee ideal force application. The

thrust piece has a suitable surface finish, and is placed on the crowned load button.

If you want to do without a thrust piece, please note that the surface of the structural

component that applies the force to the convex load application part must be ground and

have a minimum hardness of 40 HRC.

C5

MECHANICAL INSTALLATION

14

The substructure must be capable of absorbing the force to be measured. Remember

that the rigidity of the overall system depends on the stiffness of the force application

part and the substructure. Please also note that the substructure must ensure that force

is always applied to the transducer vertically, meaning there must be no inclination, even

under full load.

7.3 Using the C5 with a thrust piece

Thrust pieces prevent torsional moments being applied, can adjust slight misalignments,

and make sure that the compressive forces are applied centrally.

The transducer has a load button with a crowned load application surface. The thrust

piece is simply placed onto the load button and the sensor is placed on a surface that is

sufficiently hard and flat.

The C5 force transducer comes supplied with a suitable thrust piece as standard. All

thrust pieces offered by HBK comply with the recommendations of ISO 376.

15

C5

ELECTRICAL CONNECTION

8 ELECTRICAL CONNECTION

Signal conditioners designed for strain gage measuring systems can be used for

conditioning measurement signals. Both carrier frequency-and DC amplifiers can be

connected.

C5 force transducers are delivered in a six-wire configuration and are available with the

following electrical connections:

SBayonet connector: plug-compatible with the MIL-C-26482 series 1 connection

(PT02E10-6P); IP54 (standard version)

SThreaded connector: plug-compatible with the MIL-C-26482 series 1 connection

(PC02E10-6P); IP54

SCable connection: With fixed 6-wire cable; IP54

wh (white)

bk (black)

rd (red)

bu (blue)

gn (green)

gy (gray)

Shield

Measurement signal (+)

Excitation voltage (+)

Sense lead (-)

Sense lead (+)

Excitation voltage (-)

Measurement signal (-)

Cable shield,

connected to housing

B

D

C

A

F

E

Device plug pin assignment Cable assignment

AF

B

C

E

D

Fig. 8.1 6-wire connection

C5

ELECTRICAL CONNECTION

16

Threaded connector Bayonet connector

Fig. 8.2 Pin assignment for HBM cables

With this cable assignment, the output voltage on the amplifier is positive in the pressure

direction when the transducer is loaded.

The cable shield is connected to the transducer housing. This produces a Faraday cage

which covers the sensor, the cable and – provided it is correctly wired – the connector to

the signal conditioner, therefore ensuring optimum reliability even in the critical EMC

environment.

Only use plugs that meet EMC guidelines. The shielding must be fitted flat all over the

surface. With other connection techniques, an EMC-proof shield must be provided in the

stranded wire area and this shielding should also be connected extensively (also see

HBM Greenline Information).

8.1 Shortening or extending the cable

We cannot recommend extending the connection cable. HBK offers cables in various

lengths (also with fitted plug for sensor and amplifier).

8.2 4-wire connection

If you connect 6-wire transducers to 4-wire amplifiers, you must connect the transducer

sense leads to the corresponding excitation voltage leads: Marking (+) with (+) and

marking (-) with (-), see Fig. 8.1. This measure reduces the cable resistance of the

excitation voltage leads, among other effects. If you use an amplifier with a 4-wire

configuration, the output signal and temperature dependence of the output signal (TCS)

depend on the length of the cable and the temperature. If you use the 4-wire

configuration described above, this will result in slightly higher measurement errors. An

amplifier system using the 6-wire configuration can perfectly compensate for these

effects.

If you are using the sensor with a 4-wire configuration, it is essential to consider this in

the calibration.

17

C5

ELECTRICAL CONNECTION

8.3 EMC protection

Electrical and magnetic fields can often induce interference voltages in the measuring

circuit. Therefore please note the following:

SUse only shielded, low-capacitance measurement cables (HBM cables fulfill both

conditions).

SDo not route the measurement cables parallel to power lines and control circuits. If

this cannot be avoided, protect the measurement cable with steel conduits, for

example.

SAvoid stray fields from transformers, motors and contact switches.

SConnect all the devices in the measurement chain to the same protective conductor.

SAlways fit the cable shield all over the surface of the connector housing.

C5

TEDS CHIPS TRANSDUCER IDENTIFICATION

18

9 TEDS CHIPS TRANSDUCER IDENTIFICATION

A TEDS (Transducer Electronic Data Sheet) chip allows you to store the rated outputs of a

sensor in a chip in accordance with IEEE 1451.4. The C5 can be delivered with TEDS chip,

which is then fitted in the transducer housing, connected and supplied with data by HBK

before delivery.

The force transducer is always delivered with a test record.

If the sensor is ordered from HBK without additional calibration, the results of the test

report will be stored in the TEDS chip. If an additional DAkkS calibration is ordered, the

results of the calibration will be stored in the TEDS chip.

The chip content can be edited and modified with suitable hardware and software. This

can be achieved with HBK’s Quantum Assistant or DAQ software, for instance. Please pay

attention to the operating manuals of these products.

Information

Please note that no characteristic values are stored for any bending moment bridges that

may be ordered.

This manual suits for next models

4

Table of contents

Languages:

Other HBK Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Netafim

Netafim M Series Installation, operation and maintenance guide

Extech Instruments

Extech Instruments MA3110 user manual

ThermoWorks

ThermoWorks PTR operating instructions

netvox

netvox R718E user manual

ICM Controls

ICM Controls ICM493-60A Installation, operation & application guide

Bosch

Bosch Professional GLM 50-27 CG Original instructions

GHM

GHM GREISINGER GIA 20 EB Mounting and operating manual

TDE Instruments

TDE Instruments Digalox DPM72-MPPV-USB instruction manual

Tektronix

Tektronix WVR7000 Series Quick start user manual

Vishay

Vishay P3 instruction manual

HP

HP 8690B Operating and service manual

Powerfix

Powerfix Z22855 Operation and safety notes