HBK HBM Bruel & Kjaer CANHEAD User manual

CANHEAD

ENGLISH DEUTSCH

Operating Manual

Bedienungsanleitung

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-0102.0010

DVS: A01185 13 X00 00

12.2021

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

CANHEAD

ENGLISH DEUTSCH

Operating Manual

CANHEAD

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 4................................................

2 Markings used 7....................................................

2.1 The marking used in this document 7..................................

2.2 The markings used on the product 8...................................

3 Table of types 9....................................................

4 Field of application 10................................................

5 Bus configuration 12.................................................

5.1 Bus configuration with MGCplus 12.....................................

5.2 Device Net specifications 13...........................................

6 Configuration 14....................................................

6.1 Base module (CB1014/CB1015) 15.....................................

6.1.1 Shunt resistor 17.....................................................

6.2 Base module CB1016 20..............................................

6.3 Base module CB1010 20..............................................

6.4 Amplifier module 21..................................................

6.4.1 Removing and installing the amplifier module 22..........................

6.5 Forms of assembly 22................................................

6.5.1 Degree of protection of CANHEAD modules 24...........................

7 Connection 25.......................................................

7.1 Connecting the modules CB1014/CH1015 25............................

7.1.1 Pin assignment CB1014/1015 30.......................................

7.2 Connecting the module CB1016 31.....................................

7.2.1 Pin assignment CB1016 31............................................

7.3 Connecting the module CB1010 31.....................................

7.3.1 Pin assignment CB1010 32............................................

7.3.2 CANHEAD with TEDS (CB1010) 32......................................

7.4 Connecting CANHEAD to MGCplus 33...................................

8 Connecting to MGCplus 36............................................

8.1 How many modules are possible at what cable length? 36..................

9 Configuring with MGCplus 37..........................................

9.1 Configuration through the MGCplus Assistant software 37.................

3

CANHEAD

TABLE OF CONTENTS

10 CANHEAD enhancements 45..........................................

10.1 Enhanced data rate (with MGCplus only) 45..............................

10.2 Enhanced filters 47...................................................

10.3 Synchronous mode (ML801B) 49.......................................

CANHEAD

SAFETY INSTRUCTIONS

4

1 SAFETY INSTRUCTIONS

Appropriate use

A CANHEAD module with connected sensors or transducers is to be used exclusively for

measurement tasks and related control tasks .Use for any purpose other than the above

shall be deemed to be inappropriate.

In the interests of safety, the device should only be operated as described in the Operat

ing Manual. It is also essential to observe the appropriate legal and safety regulations for

the application concerned during use. The same applies to the use of accessories.

Each time, before starting up the equipment, you must first run a project planning and risk

analysis that takes into account all the safety aspects of automation technology. This

particularly concerns personal and machine protection.

Additional safety precautions must be taken in plants where malfunctions could cause

major damage, loss of data or even personal injury. In the event of a fault, these precau

tions establish safe operating conditions.

This can be done, for example, by mechanical interlocking, error signaling, limit value

switches, etc.

Conditions on site

SProtect the device from direct contact with water.

SProtect the CANHEAD system from humidity or effects of the weather such as rain,

snow, etc. The equipment complies with protection class IP20 per DIN EN 60 529.

Connection threads in the housing need to be locked during operation.

SDo not expose the instrument to direct sunlight.

SObserve the maximum permissible ambient temperatures given in the specifications.

SThe permissible relative humidity at 31 ºC is 80 % (non condensing); linear reduction

down to 50 % at 40 ºC.

SThe devices are classed as overvoltage category II, pollution grade 2 equipment.

SPlace the device so that it can easily be disconnected from the mains at any time.

SThe CANHEAD system can be safely operated up to a height of 2000 m

General dangers of failing to follow the safety instructions

The device is a state of the art unit and as such is reliable. The module may give rise to

dangers if it is inappropriately installed and operated by untrained personnel.

Any person instructed to carry out installation, starting up, maintenance or repair of the

module must have read and understood the Operating Manual and in particular the

technical safety instructions.

5

CANHEAD

SAFETY INSTRUCTIONS

Maintenance and cleaning

The CANHEAD system is maintenance‐free.

SBefore cleaning, disconnect the equipment completely.

SClean the housing with a soft, slightly damp (not wet!) cloth. Never use solvents, since

these could damage the labelling on the front panel and the display.

SWhen cleaning, ensure that no liquid gets into the equipment or connections.

Residual dangers

The scope of supply and performance of the CANHEAD system only covers a small area

of measurement technology. In addition, equipment planners, installers and operators

should plan, implement and respond to the safety engineering considerations of

measurement technology in such a way as to minimize remaining dangers. On-site

regulations must be complied with at all times. There must be reference to the remaining

dangers connected with measurement technology.

Safety rules

The supply connection, as well as the signal and sense leads, must be installed in such a

way that electromagnetic interference does not adversely affect device functionality

(HBM recommendation: ”Greenline shielding design”, downloadable from the Internet at

http://www.hbm.com/Greenline).

Automation equipment and devices must be covered over in such a way that adequate

protection or locking against unintentional actuation is provided (such as access checks,

password protection, etc.).

When devices are working in a network, these networks must be designed in such a way

that malfunctions in individual nodes can be detected and shut down.

Safety precautions must be taken both in terms of hardware and software, so that a line

break or other interruptions to signal transmission, such as via the bus interfaces, do not

cause undefined states or loss of data in the automation device.

Conversions and modifications

The device must not be modified from the design or safety engineering point of view

except with our express agreement. Any modification shall exclude all liability on our part

for any damage resulting therefrom.

In particular, any repair or soldering work on motherboards is prohibited. When exchang

ing complete modules, use only original parts from HBM.

The product is delivered from the factory with a fixed hardware and software configura

tion. Changes can only be made within the possibilities documented in the manuals.

CANHEAD

SAFETY INSTRUCTIONS

6

Qualified personnel

Qualified persons means persons entrusted with the installation, fitting, commissioning

and operation of the product who possess the appropriate qualifications for their func

tion.

This device is only to be installed and used by qualified personnel, strictly in accordance

with the specifications and the safety rules and regulations.

This includes people who meet at least one of the three following requirements:

SKnowledge of the safety concepts of automation technology is a requirement and as

project personnel, you must be familiar with these concepts.

SAs automation plant operating personnel, you have been instructed how to handle the

machinery and are familiar with the operation of the equipment and technologies

described in this documentation.

SAs commissioning engineers or service engineers, you have successfully completed

the training to qualify you to repair the automation systems. You are also authorized

to activate, to ground and label circuits and equipment in accordance with safety engi

neering standards.

Maintenance and repair work on an open device with the power on must only be carried

out by trained personnel who are aware of the dangers involved.

It is also essential to comply with the legal and safety requirements for the application

concerned during use. The same applies to the use of accessories.

7

CANHEAD

MARKINGS USED

2 MARKINGS USED

2.1 The marking used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

WARNING This marking warns of a potentially dangerous situ

ation in which failure to comply with safety require

ments can result in death or serious physical injury.

CAUTION This marking warns of a potentially dangerous

situation in which failure to comply with safety

requirements can result in slight or moderate physical

injury.

NOTICE This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important

This marking draws your attention to important in

formation about the product or about handling the

product.

Tip

This marking indicates application tips or other

information that is useful to you.

Information

This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

CANHEAD

MARKINGS USED

8

2.2 The markings used on the product

CE mark

The CE mark enables the manufacturer to guarantee that the

product complies with the requirements of the relevant EC direc

tives (the declaration of conformity is available at

http://www.hbm.com/HBMdoc

).

Statutory marking requirements for waste disposal

National and local regulations regarding the protection of the

environment and recycling of raw materials require old equip

ment to be separated from regular domestic waste for disposal.

For more detailed information on disposal, please contact the

local authorities or the dealer from whom you purchased the

product.

9

CANHEAD

TABLE OF TYPES

3 TABLE OF TYPES

SAmplifier module 1‐CA1030

SBase modules:

Completion

resistor

(W)

Quarter bridge

/ 3‐wire

Quarter bridge

4‐wire

Quarter bridge

4‐wire

Half and full

bridges, DC volt

age sources

Terminal connector RJ45 connector

- - - - CB1010

120 CB1014‐120 CB1015‐120 CB1016‐120 -

350 CB1014‐350 CB1015‐350 CB1016‐350 -

Scope of supply

SBase or amplifier module

SMounting instructions

SWith CB1014 and CB1015: 11 cable bushings each Ø5.2 mm and 7.5 mm

Accessories (not included in scope of supply)

SConnection cable (2 m) 1‐KAB267‐2

(Devicenet cable, with integral connectors for setting up a CAN line)

SCAN termination resistor 1‐CANHEAD‐TERM

SMale and female connectors M12 1‐CANHEAD‐M12

ST‐connector 1‐CANHEAD‐M12‐T

SMounting set 1‐CANHEAD‐MOUNT

SCable by the meter 4‐3301.0180

(Thin Media cable)

SAdapter cable 1‐KAB417

Associated MGCplus components (MGCplus required):

S1‐ML74B

S1‐AP74

SSystem CD ”MGC with ML74 documentation”

CANHEAD

FIELD OF APPLICATION

10

4 FIELD OF APPLICATION

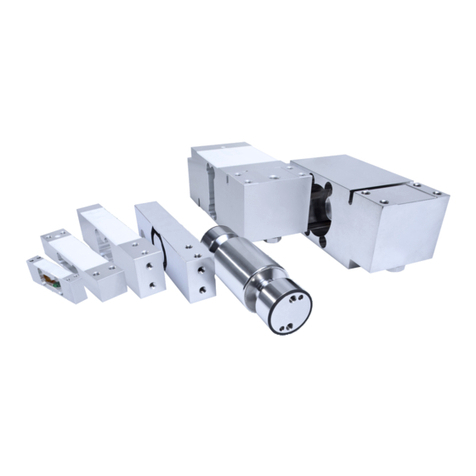

The CANHEAD system is 10‐channel measurement electronics for quarter‐bridge,

half‐bridge, and full‐bridge strain gages, DC voltage sources and strain gage‐based trans

ducers.

The special feature of HBM's CANHEAD concept is the separate assembly of the base

module and the plug‐in amplifier module.

SBase module

Sfor wiring the SG or transducer connection cables

Base modules for SG‐quarterbridges (CB1014, CB1015) are available for all the standard

SG resistance values (120, 350, 700, 1000 Ω).

SAmplifier module

SFor implementing highly‐sensitive and precise measurements

So when installing the strain gages ‐ for example, in experimental stress analysis ‐ the

base module (with all the wiring) is connected to the strain gages first. This allows the

the amplifier module to be used for other measuring tests until its ultimate involvement.

It is also possible to remove the amplifier module without the intelligent base module

losing the measuring point specific data that has been saved.

Amplifier

module

Amplifier

module

Amplifier

module

Base

module

CAN bus and power supply

CANHEAD amplifier modules for single

strain gages or transducers

MGCplus

ML74B amplifier /

AP74 connection

board

Ethernet

up to

12 CANHEADs

per bus line

max. 250 m in 250 kBaud mode; max. 100 m in 500 kBaud mode (details see data sheet)

10 channels per module; with CB1014/15, one

additional channel for temperature compensation

Base

module

Base

module

Fig. 4.1 Block diagram of the overall system with MGCplus

11

CANHEAD

FIELD OF APPLICATION

Notice

Avoid electrostatic discharge! Ensure that any person or object is electrostatically dis

charged by touching a grounded object, before touching the CANHEAD module during mea

surement. Non‐observance may result in invalid measured values being supplied for up to

200 ms.

CANHEAD

BUS CONFIGURATION

12

5 BUS CONFIGURATION

With a bus system, intelligent measurement electronics are interconnected or connected

to the central evaluator and server / PC by a data line.

A CAN bus with a fixed baud rate has been chosen for the transfer of data generated in

the base module and in the amplifier module. This gives the optimum ratio between man

agement data, parameterization data and process data (measured values) with at the

same time faster data transfer rates and greater bus lengths.

The bus allows cyclic and acyclic data to be transferred. This ensures that the synchro

nized AD converter operating in parallel can process in real time. A HBM specific CAN

protocol is used for data transport of up to 12 CANHEADs in one bus line.

5.1 Bus configuration with MGCplus

The master here is the ML74B communications module, to read the data into an MGCplus

system. In conjunction with catman measurement software, this provides a tried and

tested plug‐and‐play solution.

MGCplus

ML74B / AP741))

Termination

resistor

CAN bus linear structure with trunk and drop lines

10

channels

10 channels

max. 12 CANHEAD modules

T‐conn.

no termination

resistor required

10

channels

10

channels

Fig. 5.1 Connection to MGCplus

1) The AP74 connection board in the MGCplus provides an built‐in termination resistor.

The T‐connector 1‐CANHEAD‐M12‐T is used if a drop line is to be established.

Notice

It is preferable to install CAN bus as a line bus. Only use the T‐connector on the input side.

13

CANHEAD

BUS CONFIGURATION

Maximum configuration

per ML74B max. 12 CANHEADs, corresponding to 120 measuring points

Per

MGCplus system 250 e.g. 500 measuring points1)

1) The maximum number of 256 channels per MGCplus system must not be exceeded. The number of

channels may be distributed among several ML74B. The maximum number of channels per CP42 and

CP52 is 256, with up to 512 channels possible if a CP52 is combined with an NT040 power supply.

5.2 Device Net specifications

More detailed specifications for Device Net (bus topology, drop lines, etc.), can be found

on the Internet site www.odva.org →Devicenet →Planning and Installation Manual

Notice

The maximum CAN bus line length must not exceed 250 m at the 250^kBaud setting and

100 m at the 500^kBaud setting, see also technical Datasheet.

A drop line must be no longer than 15 m (but if possible, drop lines should be avoided).

TR TR

Power

Supply

TR

trunk line drop lines

device or node

terminating resistor

Fig. 5.2 Line bus and drop lines (example from the DeviceNet Manual)

CANHEAD

CONFIGURATION

14

6 CONFIGURATION

Each CANHEAD base module has 10 measurement channels. When strain gage bridges

are connected, bridge excitation occurs at a carrier frequency of 600 Hz. Thermoelectric

voltage at the contact points and dc voltage drift are therefore irrelevant. 0.5, 1.0 and 2.5

volts are available as bridge excitation voltages.

CANHEADs designed for 10 channels each have an A/D‐converter (24 bits) per channel,

so that all measurement data recording is time‐synchronized.

The soldered fuse on the right next to the amplifier module is there to protect the device.

If none of the LEDs come on (see Page 34), check this fuse for conductivity (de‐ener

gized).

If the fuse is faulty, the CANHEAD device must be sent to HBM Darmstadt.

The two LEDs correspond to the status LEDs on the back of the CANHEAD (see Fig. 7.7,

Page 34).

Locking the lid

The lid covering the base module housing is lockable; this provides mechanical protec

tion and conforms with EMC requirements.

*) Unlocking the lid:

turn in the opposite direction

Locking the lid *)

Locking the lid *)

Fig. 6.1 Locking and opening the base module

15

CANHEAD

CONFIGURATION

6.1 Base module (CB1014/CB1015)

Shielding plate

Pin assignment

Base modul 2 Sgs per terminal block

Amplifier module

Additional channel for

temperature

compensation

Fig. 6.2 Base module (CB1014) with amplifier module (CA1030)

The number and arrangement of the connection terminals gives the base modules

CB1014 (three‐wire circuit) and CB1015 (four‐wire circuit) a different appearance (see

Chapter 7).for 10 strain gage channels in a quarter bridge circuit

The pin assignment (three‐wire or four‐wire circuit) is depicted in the lid of the base mod

ule (see Fig. 6.2 and Section 7.1.1).

There is an eleventh measurement channel for temperature compensation using a com

pensating strain gage or Pt100.

Notice

When the lid of the CANHEAD is open, you can see a coding resistor on the left next to the

amplifier module. The coding resistor indicates the version of the base module (120 W, 350

W), it does not have an electrical function!

CANHEAD

CONFIGURATION

16

Coding

resistor

Fuse

Amplifier module LED Red

LED Green

Jumper ext.

/

int.

shunt

Shunt1)

1) see chapter 6.1.1

A base module is available for each strain gage nominal resistance value (120, 350 Ω).

All the measuring point specific data is stored in the base module (e.g. CAN bus ID, cali

bration values, user data).

Each module can be identified through an ID that is unique throughout the world. This ID

is permanently stored in the base module.

17

CANHEAD

CONFIGURATION

Strain gage connection

CAN bus connection

Fig. 6.3 Base module (CB1014) for strain gage and CAN bus connection

6.1.1 Shunt resistor

A shunt resistor (1 mV/V) is incorporated in all the CANHEAD base modules for single

strain gages in a quarter bridge circuit (CB1014, CB1015 and CB1016). Use a jumper set

ting to decide whether this internal shunt resistor or an external one, for example a preci

sion resistor with certification, is to be used.

By using the following formula

Sthe requisite shunt for a required misalignment can be determined, or

Sthe misalignment for a given shunt can be determined

Misalignment by means of an internal shunt resistor

v = misalignment V0/Vsin [V/V]

Re= value of the supplementary resistor

CANHEAD

CONFIGURATION

18

Rs= value of the shunt resistor

Given: Re, RsWanted: v

R' = (Re* Rs) / (Re+ Rs) Example: Re= 350 Ω, Rs= 87325 Ω

v = -0.5 * (Re- R') / (Re+ R') v = -0.001 V/V = 1.000 mV/V

Given: Re, v Wanted: Rs

R' = Re* ( ( 0.5 + v ) / ( 0.5 - v) ) Example: Rs= 350 Ω, v = 1.000 mV/V

Rs = 1 / ( 1/R' - 1/Re)R

s= 87325 Ω= 87.325 kΩ

Measurement errors caused by the effect of the cable resistor in the unregulated

three‐wire circuit (CB1014) can be corrected by proper use of the shunt calibration.

Loss of sensitivity = Re/ (Re+ Rcab) Correction by the shunt

calibration in conjunction with

the CANHEAD correction

function (see Chapter 9.1).

Offset error = 1/2 (Rcab / Re) Correction by the CANHEAD

zeroing function

Notice

To enable the CANHEAD correction function to determine the proper correction factor, the

value of the actual shunt resistor being used must be entered in the CANHEAD (the value

of the internal shunt resistor is entered at the factory). See Chapter 9.1, ”Configuration with

the MGCplus Assistant”

This manual suits for next models

4

Table of contents

Languages:

Other HBK Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

GANN

GANN Hydromette RTU 600 operating manual

MARTINDALE

MARTINDALE FD500 instructions

Elesa

Elesa MPI-R10 operating instructions

Endress+Hauser

Endress+Hauser Proline Prowirl R 200 operating instructions

Associated Research

Associated Research MEG CHEK 2100 owner's manual

Britpart

Britpart DA4512 instruction manual