HBK PAD4001A User manual

PAD4001A, PAD4003A

ENGLISH DEUTSCH FRANÇAIS

Operating Manual

Bedienungsanleitung

Manuel d'emploi

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

Mat.: 7-1001.4238

DVS: A04238 01 Y00 01

11.2021

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

Änderungen vorbehalten.

Alle Angaben beschreiben unsere Produkte in allge

meiner Form. Sie stellen keine Beschaffenheits- oder

Haltbarkeitsgarantie dar.

Sous réserve de modifications.

Les caractéristiques indiquées ne décrivent nos

produits que sous une forme générale. Elles

n'impliquent aucune garantie de qualité ou de

durabilité.

PAD4001A, PAD4003A

ENGLISH DEUTSCH FRANÇAIS

Operating Manual

PAD4001A, PAD4003A

TABLE OF CONTENTS

2

TABLE OF CONTENTS

1 Safety instructions 3................................................

2 Markings used 6....................................................

2.1 Symbols on the device 6.............................................

2.2 The markings used in this document 6.................................

3 Structure and mode of operation 7....................................

3.1 Structure of the electronics 7.........................................

3.2 Signal conditioning 8................................................

3.3 Adaptive interference suppression 9...................................

3.4 Inputs and outputs 9................................................

3.4.1 Trigger function 10...................................................

3.4.2 Filling and dosing 10.................................................

3.4.3 Limit value function 10................................................

3.4.4 Extreme value functions 10............................................

4 Conditions on site 11.................................................

5 Mechanical installation 12............................................

5.1 Important precautions during installation 12..............................

5.2 Dimensions 12......................................................

6 Electrical connection 13..............................................

6.1 Cable laying 13......................................................

6.2 Pin assignment 13...................................................

6.3 Supply voltage 15....................................................

7 Interfaces 17........................................................

7.1 RS‐485 4‐wire interfaces (UART) 17.....................................

7.2 CANopen interface 18................................................

8 Operation via software 20.............................................

9 Environmental protection 20..........................................

3

PAD4001A, PAD4003A

SAFETY INSTRUCTIONS

1 SAFETY INSTRUCTIONS

Appropriate use

PAD digital transducer electronics are to be used exclusively for measurement tasks and

directly related control tasks within the application limits detailed in the specifications.

Any other use is not appropriate.

Any person instructed to carry out installation, commissioning or operation of the device

must have read and understood the Operating Manual and in particular the technical

safety instructions.

In the interests of safety, the device should only be operated by qualified personnel and

as described in the Operating Manual. It is also essential to comply with the legal and

safety requirements for the application concerned during use. The same applies to the

use of accessories.

PAD is not intended for use as a safety component. Please also refer to the "Additional

safety precautions" section. Proper and safe operation requires proper transportation,

correct storage, siting and mounting, and careful operation.

Operating conditions

SPlease observe the allowed maximum values stated in the specifications for:

-Max. supply voltage

-Max. voltage for inputs and outputs

-Max current of outputs

-Temperature limits

SMake sure that the max. current for plugs and sockets is adhered to in bus mode.

SThe device must not be modified from the design or safety engineering point of view

except with our express agreement. In particular, any repair or soldering work on

motherboards (exchanging components) is prohibited.

SThe device is delivered from the factory with a fixed hardware and software configura

tion. Changes can only be made within the possibilities listed in the corresponding

documentation.

SThe device is maintenance free.

SPlease note the following points when cleaning the housing:

-Disconnect the device from all current and voltage supplies before cleaning it.

-Clean the housing with a soft, slightly damp cloth. Never use solvent, as this could

damage the label or the housing.

-When cleaning, ensure that no liquid gets into the device or connections.

SIn accordance with national and local environmental protection and material recovery

and recycling regulations, old equipment that can no longer be used must be disposed

of separately and not with normal household garbage, see Chapter9 on page20.

PAD4001A, PAD4003A

SAFETY INSTRUCTIONS

4

Qualified personnel

Qualified persons means persons entrusted with the installation, fitting, commissioning

and operation of the product who possess the appropriate qualifications for their func

tion.

This includes people who meet at least one of the three following requirements:

SKnowledge of the safety concepts of measurement and automation technology is a

requirement and as project personnel, they must be familiar with these concepts.

SAs measurement or automation plant operating personnel, they been instructed how

to handle the machinery. They are familiar with the operation of the equipment and

technologies described in this documentation.

SAs commissioning engineers or service engineers, they have successfully completed

the training to qualify them to repair the automation systems. They are also author

ized to activate, ground and label circuits and equipment in accordance with safety

engineering standards.

Working safely

SThe device must not be directly connected to the power supply system. The supply

voltage must be between 12 and 30VDC.

SError messages should only be acknowledged once the cause of the error is removed

and no further danger exists.

SAutomation equipment and devices must be designed in such a way that adequate

protection or locking against unintentional actuation is provided (e.g. access checks,

password protection, etc.).

SFor those devices operating in networks, safety precautions must be taken both in

terms of hardware and software, so that a line break or other interruptions to signal

transmission do not cause undefined states or loss of data in the automation device.

SAfter making settings and carrying out activities that are password-protected, ensure

that any controls that may be connected remain in a safe condition until the switching

performance of the device has been tested.

Additional safety precautions

Additional safety precautions to meet the requirements of the relevant national and local

accident prevention regulations must be taken in plants where malfunctions could cause

major damage, loss of data or even personal injury.

The scope of supply and performance of the device covers only a small area of measure

ment technology. Before starting up the device in a system, a project planning and risk

analysis must first be implemented, taking into account all the safety aspects of meas

urement and automation technology so that residual risks are minimized. This particu

larly concerns personal and machine protection. In the event of a fault, the relevant pre

cautions must establish safe operating conditions.

5

PAD4001A, PAD4003A

SAFETY INSTRUCTIONS

General dangers of failing to follow the safety instructions

The device is state of the art and failsafe. The device may give rise to residual dangers if

it is inappropriately installed or operated.

PAD4001A, PAD4003A

MARKINGS USED

6

2 MARKINGS USED

2.1 Symbols on the device

CE mark

The CE mark enables the manufacturer to guarantee that the

product complies with the requirements of the relevant EC dir

ectives (the Declaration of Conformity can be found on the HBM

website (www.hbm.com) under HBMdoc).

Statutory waste disposal mark

In accordance with national and local environmental protection

and material recovery and recycling regulations, old devices that

can no longer be used must be disposed of separately and not

with normal household garbage. Also see Chapter9 on page20.

2.2 The markings used in this document

Important instructions for your safety are specifically identified. It is essential to follow

these instructions in order to prevent accidents and damage to property.

Symbol Significance

NOTICE This marking draws your attention to a situation in

which failure to comply with safety requirements can

lead to damage to property.

Important

This marking draws your attention to important in

formation about the product or about handling the

product.

Tip

This marking indicates application tips or other

information that is useful to you.

Information

This marking draws your attention to information

about the product or about handling the product.

Emphasis

See …

Italics are used to emphasize and highlight text and

identify references to sections, diagrams, or external

documents and files.

uThis marking indicates an action in a procedure

7

PAD4001A, PAD4003A

STRUCTURE AND MODE OF OPERATION

3 STRUCTURE AND MODE OF OPERATION

PAD digital transducer electronics are part of the family of electronics developed by HBM

for static and dynamic weighing processes. They record the measurement signals of

connected sensors with strain gages. The transducer electronics digitally condition the

signals and deliver a fully-filtered, scaled and digitized output signal for direct connection

to bus systems or PCs via the RS‐485 interface or CANopen. The electronics can be

quickly and easily matched to a particular system by various parameters, and they work

with an internal data rate of up to 1200 measurements per second.

The inbuilt digital inputs and outputs allow event-driven weight determination, e.g. for

checkweigher applications or dosing controls. The digital outputs can be configured by

software command, and can be used to control coarse flow and fine flow in dosing

valves, for example.

The PanelX software is available as a free download from the HBM website for setting all

the parameters in full, for realizing dynamic measurement signals, and for frequency ana

lysis of the dynamic system: http://www.hbm.com/software

.

Information

This part of the operating manual describes the hardware and the functions of the elec

tronics. The communication commands and detailed configuration instructions for various

applications are included in the online documentation of the PanelX program.

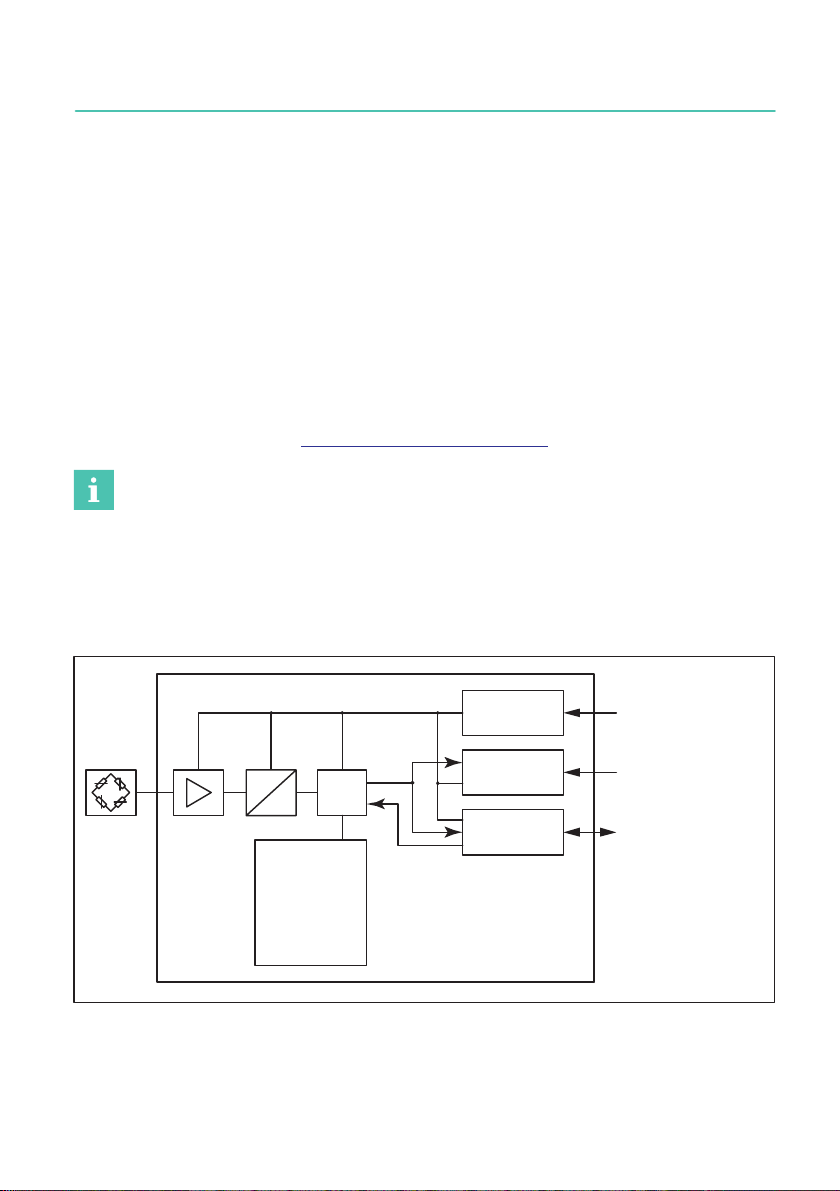

3.1 Structure of the electronics

Voltage

control

Interface

I/Os

Supply voltage

UB/GND

Interface

RS-485/CANopen

IO

Trigger,

Stop Dosing

EEPROM

Linearization

Serial number

Digital filter

Data rate

Sensitivity

Zero value

μP

A

D

PAD

Fig. 3.1 Block diagram

PAD4001A, PAD4003A

STRUCTURE AND MODE OF OPERATION

8

The analog transducer signal is first amplified, then analog filtered, and digitized in the

A/D converter. This signal is processed in the microprocessor and can be transmitted

over the interface. Digital inputs/outputs are available for control. The electronics have

various programs for applications such as filling, dosing, checkweighers or weight grad

ing machines. All the parameters can be stored power failsafe.

3.2 Signal conditioning

FMD

ASF ICR

SZA

SFA

NOV, RSN

LDW, LWT LIC

PVA

IMD

LIV

TAV, TAS Net

meas.

value

Gross

meas

.value

Extreme

values

Trigger/

Stop

Limit

values

Sam

pling

rate

Working

standard

calibration

Filter Tare

A

D

User‐defined

scaling

Lin

earization

Min/

Max

Trigger

Limit

values

RUN

BRK

Coarse Flow

Fine Flow

Ready

Alarm

Dosing control

Fig. 3.2 Signal conditioning

Digitization is followed by filtering, using digital filters adjusted by the software. The com

mand ICR changes the output rate (measured values per second).

In the working standard calibration of the electronics (on delivery), 0 mV/V corresponds

to zero and the maximum capacity is either 1,000,000digits (NOV≠0), or 5,120,000digits

(NOV=0). The two parameters LDW and LWT give you the opportunity to adapt the char

acteristic curve to meet your requirements (scale curve) and you can use the NOV com

mand to standardize the measured values to the required scaling value (e.g. 3000d).

Detailed information can be found in the command documentation and in the Online Help

for the PanelX program.

You also have the opportunity to

Sswitch from gross to net signals,

Sactivate an automatic zero on start up function,

Sactivate an automatic zero tracking function,

Slinearize the input signal with a third order polynomial,

9

PAD4001A, PAD4003A

STRUCTURE AND MODE OF OPERATION

Sactivate various digital filters. Available filters include those with cut-off frequencies

below 1Hz, fast-settling filters for dynamic measurements, notch filters and mean

value filters.

Use MSV? to read out the current measured value. The format of the measured value

(ASCII or binary) is set with the COF command. You can also use the COF command to

activate automatic measurement output. The measured values are transmitted in the

following format, subject to the COF command:

Output format Input signal Output when NOV=0 Output when

NOV>0

Binary, 2 chars. (INT) 0 …maximum

capacity

0 …20,000digits 0 …NOV

Binary, 4 chars. (LONG) 0 …maximum

capacity

0 …5,120,000digits 0 …NOV

ASCII 0 …maximum

capacity

0 …1,000,000digits 0 …NOV

3.3 Adaptive interference suppression

Whatever the mode of operation, you can use the ADF command to activate automatic

interference suppression with adaptive filters. Interference frequencies are automatically

found during measurement and suppressed by comb filters and averaging. The max

imum filter settling time can be limited with the TMA command.

3.4 Inputs and outputs

The two I/Os can be used either as inputs or outputs. You can also set different switching

levels (TTL or PLC) for the inputs. On delivery, both I/Os are set as inputs with a TTL level.

Specify the function of the I/Os as inputs with commands IM1 and IM2, and the function

as outputs with OM1 and OM2.

Notice

The electronics must be operated with a supply voltage of between 12 and 30V. Incorrect

connections between the supply and interface cables or digital inputs/outputs can cause

irreversible damage.

Check the correct assignment of the connections before switching on for the first time.

PAD4001A, PAD4003A

STRUCTURE AND MODE OF OPERATION

10

3.4.1 Trigger function

In Trigger mode (command IMD1), the electronics have four different trigger functions:

SPre-triggering by level

SPre-triggering by external (digital) signal

SPost-triggering by level

SPost-triggering by external (digital) signal

Gross or net values can be used as input values. The filter settling time can be optimized

by the actual electronics (command AST).

3.4.2 Filling and dosing

The electronics include full dosing control (command IMD2). As many as 32 parameter

sets can be stored in the EEPROM for different applications. But you can still change the

dosing parameters yourself during dosing. Digital outputs can be used to control coarse

and fine flow, for example. The PanelX software includes detailed instructions for setting

the different parameters.

3.4.3 Limit value function

In Standard and Trigger modes (command IMD), the electronics allow as many as four

limit values to be monitored (command LIV). Gross or net values, the trigger result, or the

extreme values (Min/Max) are available to you as input signals. Use the measurement

status to read out the status, either simultaneously with the measured values (command

MSV?) or separately (command RIO?).

3.4.4 Extreme value functions

The electronics include a peak value function (Minimum and Maximum, command PVS),

that monitors either the gross or net values, as required. Use command PVA to read out

the values and use command CPV to reset the peak values.

11

PAD4001A, PAD4003A

CONDITIONS ON SITE

4 CONDITIONS ON SITE

The PAD is hermetically encapsulated by laser welding and is made from materials that

do not rust. They are therefore largely impervious to humidity and moisture. The devices

achieve protection classes IP68 (test conditions: 100 hours under 1m water column) and

IP69K (water at high pressure, steam cleaning), as per DIN EN605291). The devices

should nevertheless be protected against the long-term effects of moisture and humidity.

Important

Note that when using a steam cleaner, the conditions stated in EN 60529 under degree of

protection IP69K such as max. pressure, max. temperature, etc., must be met.

Protection against corrosion

The device must be protected against chemicals that could attack the steel of the hous

ing, the plugs or the cables.

Information

Acids and all substances that release ions also attack stainless steels and their seam

welds.

Subsequent corrosion can cause the device to fail. If this is the case, you must provide

appropriate means of protection.

1) With fitted plugs of the same protection class.

PAD4001A, PAD4003A

MECHANICAL INSTALLATION

12

5 MECHANICAL INSTALLATION

5.1 Important precautions during installation

Welding currents must not be allowed to flow over the electronics. If there is a risk that

this might happen, you must provide a suitable low-ohm connection to electrically bypass

the electronics.

Notice

PAD electronics are precision measuring elements, and need to be handled carefully. Drop

ping or knocking them may cause permanent damage. Tighten the plug during installation

with a torque of max. 4Nm.

Important

Before mounting several weighing modules into an installation with a bus system, take the

following into account:

The printed production number (type plate) is required for setting up data communication.

If the type plate can no longer be seen after installation, the numbers of each weighing

module should be noted beforehand. This enables different addresses to be assigned dur

ing the initial start-up.

Alternatively, before connection to the bus system, you can connect each weighing module

individually with a PC, in order to set different addresses (see ADR command in the Online

Help).

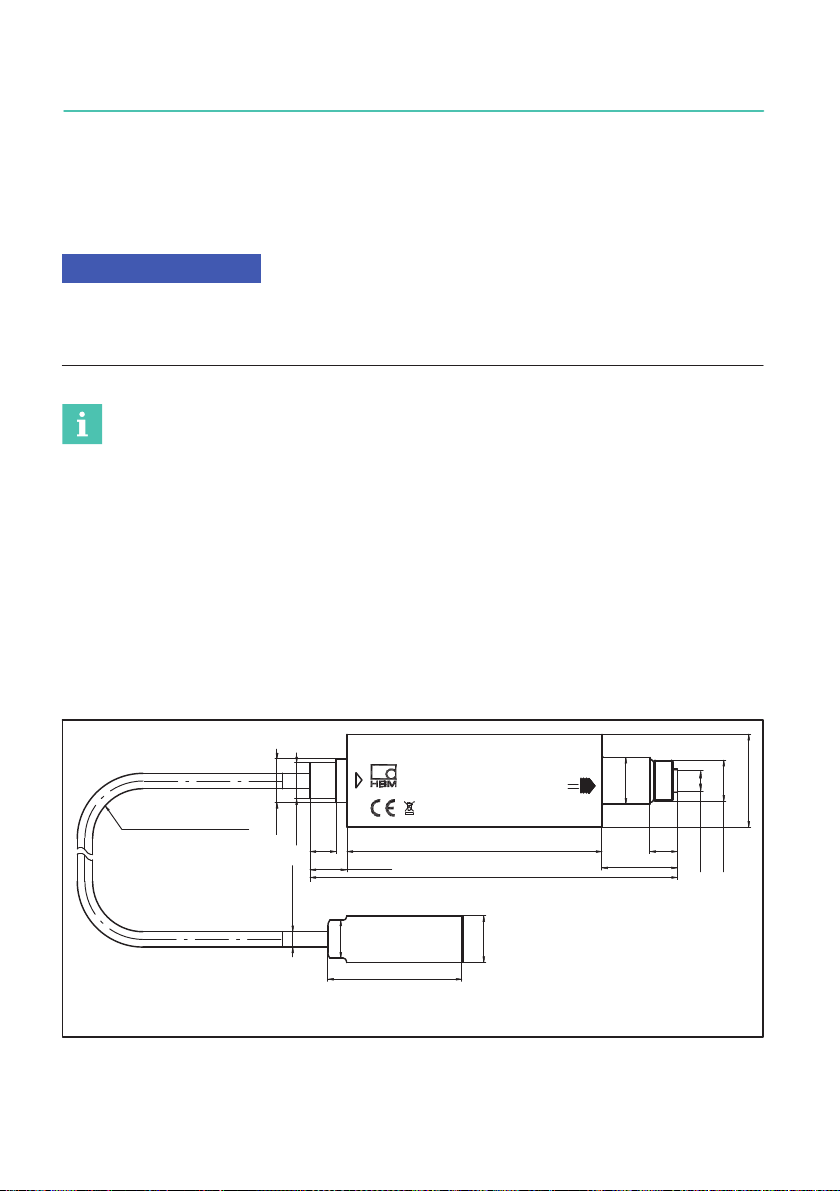

5.2 Dimensions

smallest bending

radius

26 (mobile 52)

126.7+1 26

9.5

16

M14x1

∅32

∅15

∅12.4

12.7+1

13 AF

46

∅161)

∅142)

∅5.3±0.2

9+1 88

M12x1

Serial No.: nnnnnnn

Year: yyyy

Type : PAD4001A-xxx

UB=+12V...+30V

IB, max = 1.1A

1) 4001A: PW15PH, PW25P, PW28PH, PW29P

2) 4003A: PW27AP

Fig. 5.1 Dimensions

13

PAD4001A, PAD4003A

ELECTRICAL CONNECTION

6 ELECTRICAL CONNECTION

Notice

Electronic components are sensitive to electrostatic discharge (ESD). So you must dis

charge your own static electricity before touching the connector plugs.

6.1 Cable laying

Position the connection cable so that any condensation or moisture that may occur at the

cable can drip off (loop). It must not be able to reach the electronics. Also make sure that

it is not possible for humidity or moisture to get into the cables through open ends, thus

preventing damage to the cable sheath.

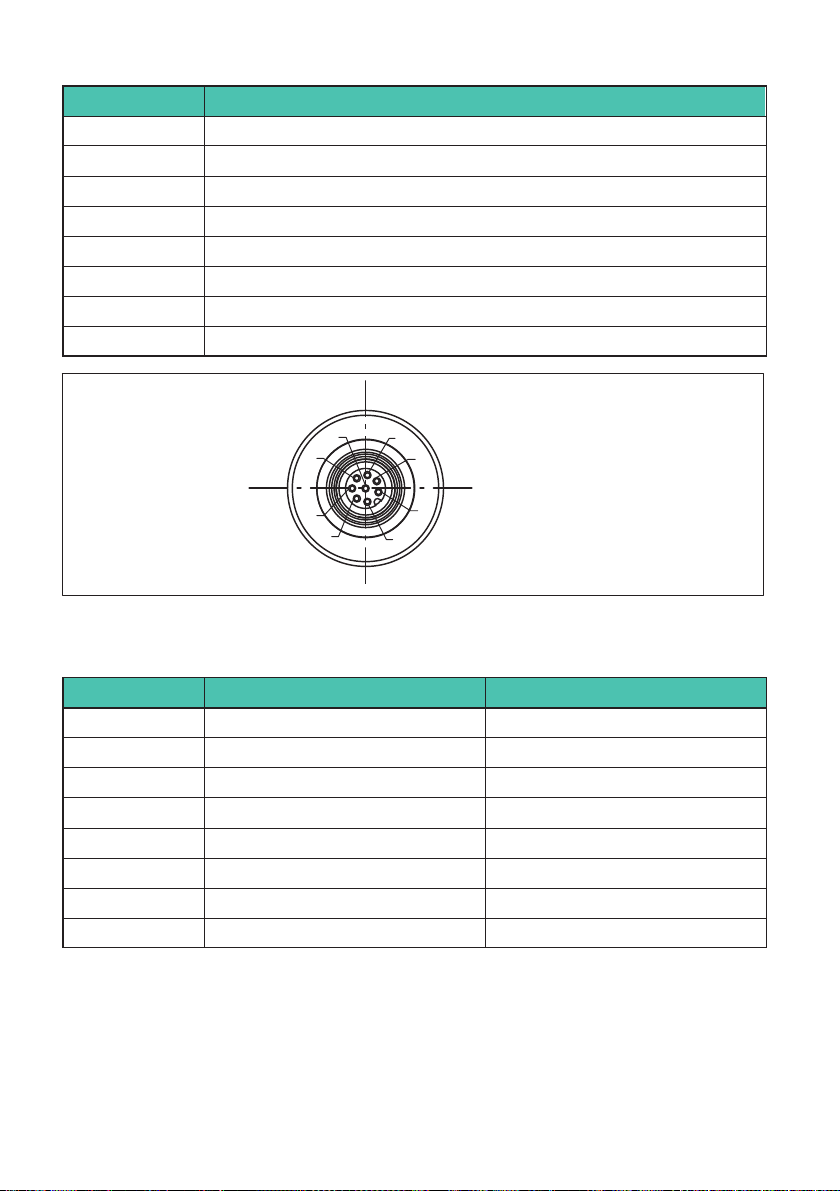

6.2 Pin assignment

Notice

The electronics must be operated with a supply voltage of between 12 and 30V. Incorrect

connections between the supply and interface cables or the digital inputs/outputs can

cause irreversible damage.

So you must check the correct assignment of the connections before switching on for the

first time.

The electronics have an 8‐pin connector plug (M12) for connecting to a transducer

(Fig. 6.1).

1

2

345

6

7

8

Fig. 6.1 M12 connector plug, 8-pin, for transducers

PAD4001A, PAD4003A

ELECTRICAL CONNECTION

14

Pin Transducer connection

1Measurement signal (+)

2Not in use

3Additional excitation voltage line (+)

4Not in use

5Additional excitation voltage line (-)

6Bridge excitation voltage (-)

7Bridge excitation voltage (+)

8Measurement signal (-)

6

8

5

4

32

1

7

Fig. 6.2 Connector socket with M12 internal thread (for 1-KAB165) and M14 external

thread (for 1-KAB173), 8-pin, digital output

Pin RS-485 CANopen

1 GND GND

2I/O 2 I/O 2

3 RA CAN High IN

4I/O 1 I/O 1

5 RB CAN Low IN

6 TB CAN Low OUT

7 TA CAN High OUT

812 …30V 12 …30V

Suitable connection cables and the color code used can be found in the HBM data sheet

"Cables with a plug", B3643.

15

PAD4001A, PAD4003A

ELECTRICAL CONNECTION

Please note:

SWith the CAN interface, you must use a cable with a characteristic impedance of ap

prox. 120Ω. HBM cable 1-KAB173 meets these requirements and also has the same

protection class (IP68/69K) as the PAD housing.

SThe housing of the PAD is connected to the cable shield by the connector socket. To

obtain an EMC-compliant connection (EMC = electromagnetic compatibility), the

shield of this cable must be connected to the housing of the connected electronics or

to ground potential. A direct, low-ohm contact must be made with the shield, by EMC-

compliant plug connections, for example.

SShould it be necessary, a separate cable can be used to establish potential equaliza

tion between the electronics and the (PC/PLC) master (grounding concept). You must

not use the cable shield for this potential equalization.

SUse shielded, low-capacitance cables only for all connections (interface, power supply

and additional devices) - (HBM cables meet these requirements).

SElectrical and magnetic fields often induce interference voltages in the measurement

electronics. Do not route the measurement cables parallel to power lines and control

circuits. If this is not possible, protect the measurement cable (e.g. with a rigid steel

conduit, minimum size M25). A minimum distance of 20mm must be maintained

between the cables to the analog transducers and other transducer cables installed in

parallel.

6.3 Supply voltage

Regulated dc voltage of +12 to +30 V is required to operate the electronics and serial

communication.

Voltage source requirements

SThe supply voltage must be sufficiently smoothed (RMS value minus residual ripple >

12 V).

SThe electronics have a low-loss controller with a power consumption of 3 W during

operation. The current consumption is therefore dependent on the level of the supply

voltage:

3

Voltage in V

W

Power requirement in A =

SWhen switched on, the electronics briefly consume a current of approx. 0.15 A. To

ensure a safe start-up, the power supply must be able to provide this current without a

limit being triggered. This is particularly important when supplying several PADs from

one power supply. In contrast, the sustained loading is calculated from the formula

shown above.

SConnection to a wide-ranging supply network is not permitted as this often causes

interfering voltage peaks to be induced. Instead, a local supply must be provided for

the electronics (even when grouped).

PAD4001A, PAD4003A

ELECTRICAL CONNECTION

16

SThe supply voltage must be insulated from the shield potential. A connection from

GND to the housing is not required, but the max. potential difference must be no more

than 7 V.

SThe supply voltage ground wire (GND) is also used as the reference potential for the

interface signals and the digital inputs/outputs.

SIn layouts with several PADs, the supply can run together with the RS-485 bus lines in

a 6-pin cable (with HBM junction boxes, for example). Ensure that there is sufficient

wire cross-section provided, as some cable sections will conduct the supply current

for all the connected PADs.

17

PAD4001A, PAD4003A

INTERFACES

7 INTERFACES

The electronics interface is referenced to GND. The master interface must also be refer

enced to GND.

Use a shielded cable as the interface cable. The shield should always be connected to the

housing at both ends. The shield of the electronics cable must be electrically connected

to the housing of the electronics.

Important

Before mounting several PADs into an installation with a bus system, take the following

into account:

The printed production number (type plate) is required for setting up data communication.

If the type plate can no longer be seen after installation, the numbers of each PAD should

be noted beforehand. This enables different addresses to be assigned during the initial

start-up.

Alternatively, before connection to the bus system, you can connect each PAD individually

with a PC, in order to set different addresses (see ADR command in the Online Help).

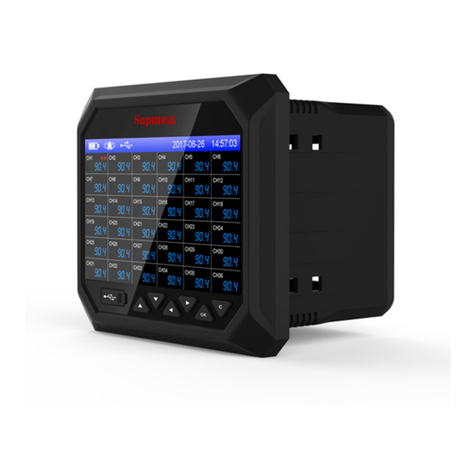

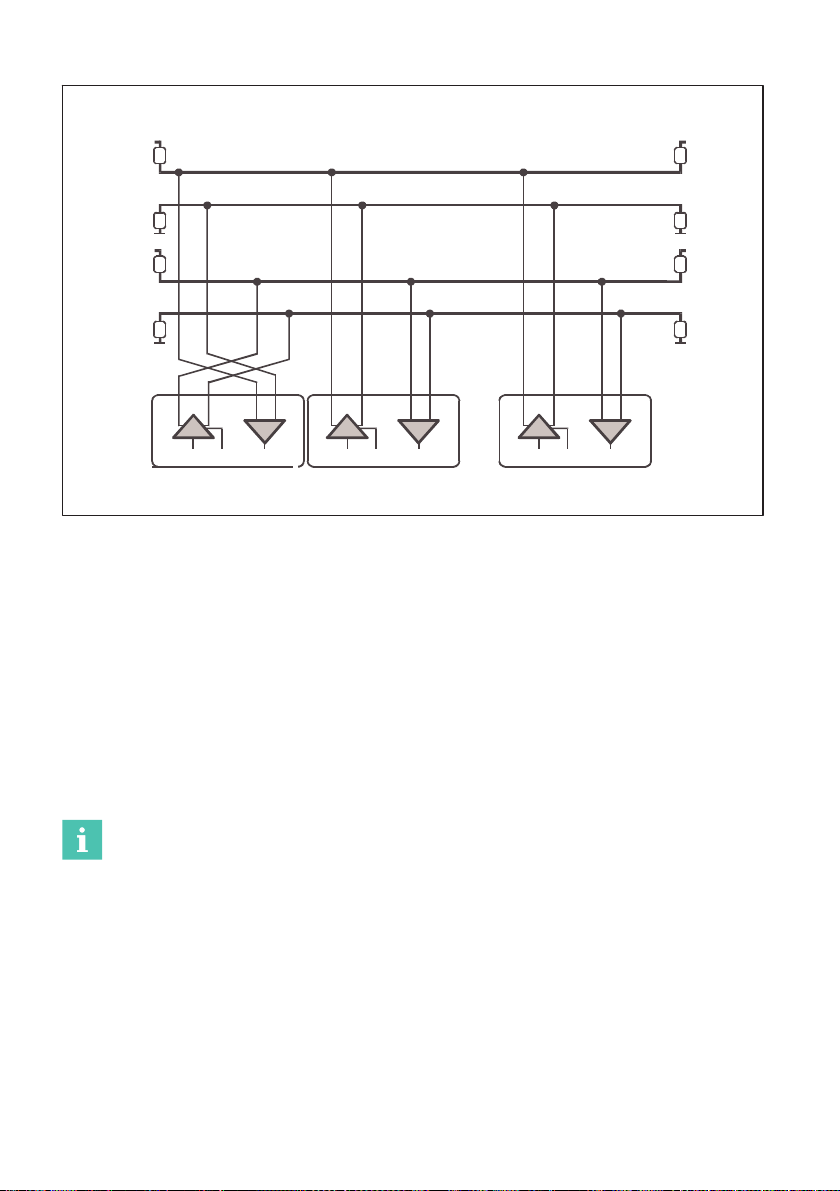

7.1 RS‐485 4‐wire interfaces (UART)

The electronics come supplied with an RS-485 interface. Bit rates of 1200 to 115,200

baud can be set for the interface. The ground reference for all the interface signals is

based on the supply voltage ground (GND).

Either a single PAD can be connected via the RS485 interface, or you can set up a bus

system to connect as many as 90 PADs to an RS485 interface. All the PADs are connec

ted in parallel on a line, the total length of the line can be as much as 500m. The software

uses the different addresses to differentiate between the PADs. If the control computer

only has an RS-232 interface, an interface converter is required (e.g. from HBM, ordering

no.: 1-SC232/422B).

PAD4001A, PAD4003A

INTERFACES

18

Bus termination Bus termination

TB

TA

RB

RA

PC = Master Node 1 Node 90

...

500 Ω

500 Ω

500 Ω

500 Ω

500 Ω

500 Ω

500 Ω

500 Ω

+5 V

+5 V

+5 V

+5 V

TxD on/off RxD

TB TA

TR

RB RA

TxD on/off RxD

TB TA

TR

RB RA

TxD on/off RxD

TB TA

TR

RB RA

Fig. 7.1 Connecting several PADs to a PC via an RS‐485 4‐wire bus

The correct assignment of the transmit and receive lines can be seen in Fig. 7.1 (bus line

Ra to Ta of the converter, etc.). The electronics already include bus termination resistors

(line termination), that can be activated with the software command STR. So no addi

tional bus termination resistors are required for RS-485.

7.2 CANopen interface

The interface design follows the CiA DS301 CANopen standard. The address on delivery

is 63.

The CAN bus is set up as a 2‐wire line (CANH and CANL) (see ISO11898).

Important

You must connect bus termination resistors (each 120W) at the start and at the end of the

bus. The electronics do not contain a bus termination resistor for CANopen.

This manual suits for next models

1

Table of contents

Languages:

Other HBK Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PPS

PPS PPS71 user manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 601A62 Installation and operating manual

ADA INSTRUMENTS

ADA INSTRUMENTS WHEEL 50 DIGITAL operating manual

Stanford Research Systems

Stanford Research Systems SR785 Operating manual and programming reference

Bartec

Bartec Tech200 user guide

YOKOGAWA

YOKOGAWA ST401G user manual