AED9101C-Z2/22

4

A2967−1.0 en/de/frHBM

1 Introduction

Designated use

The AED9101C-Z2 / 22 digital transducer electronics module comprises the

AED9101C basic device and the AD103C amplifier board.

The electronics are a resource that can be used in the potentially explosive

atmospheres of either Zone 2 or Zone 22 −but not in both zones simultan-

eously −for connecting strain gage load cells with a total bridge resist-

ancew80 Wand for connecting a digital processing device with an RS-232,

RS-422 or RS-485 interface. The degree of protection is “nA” per EN

60079-15 or “tD” per EN 61241-1, and is based on the IP65 sealing protec-

tion of the housing.

The device must be protected against mechanical damage.

In the interests of safety, the transducer electronics should only be operated

as described in the Mounting Instructions. It is also essential to comply with

the legal and safety requirements for the application concerned during use.

The same applies to the use of accessories.

If applicable, follow the national legal and safety requirements for using elec-

tronics in potentially explosive atmospheres.

Transducer electronics are not a safety element within the meaning of desig-

nated use. For safe and trouble-free operation, these transducer electronics

must not only be correctly transported and expertly stored, sited and installed

but must also be carefully operated and maintained.

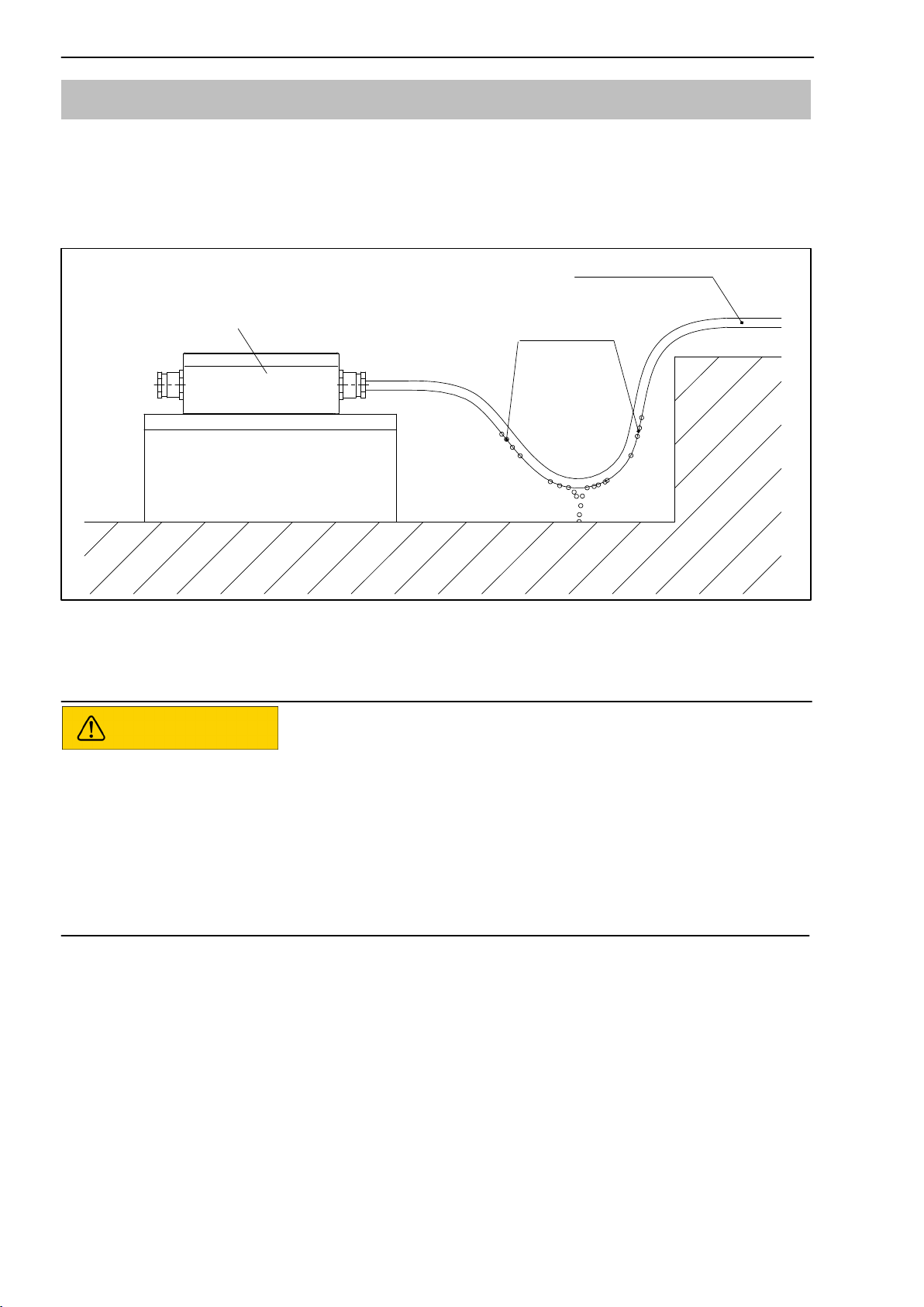

Notes for installation and operation

The amplifier board must only be operated in an enclosed housing. To main-

tain the IP65 degree of protection, all unused cable glands must be sealed

with the plugs provided. The associated swivel nuts must also be tightened, to

prevent moisture and dust penetration.

Use only cables that fall within the 5 mm to 9 mm diameter range stated by

the manufacturer of the M16 x 1.5 screwed cable glands.

The housing should only be opened once it is certain that the atmosphere is

not potentially explosive, or if the electrical equipment inside the housing has

been disconnected from the mains for at least five minutes and is

voltage-free.

Make sure that the rated voltage of the equipment does not exceed 30 V DC,

and that the rated voltage is not exceeded by more than 40% by the effect of

transients. Transducer electronics should be included in local potential equal-

ization.