Safety instructions

6A3592-1.3 HBM: public S2M

The layout of the electronics conditioning the measure

ment signal should be such that measurement signal fail

ure does not cause damage.

General dangers of failing to follow the safety

instructions

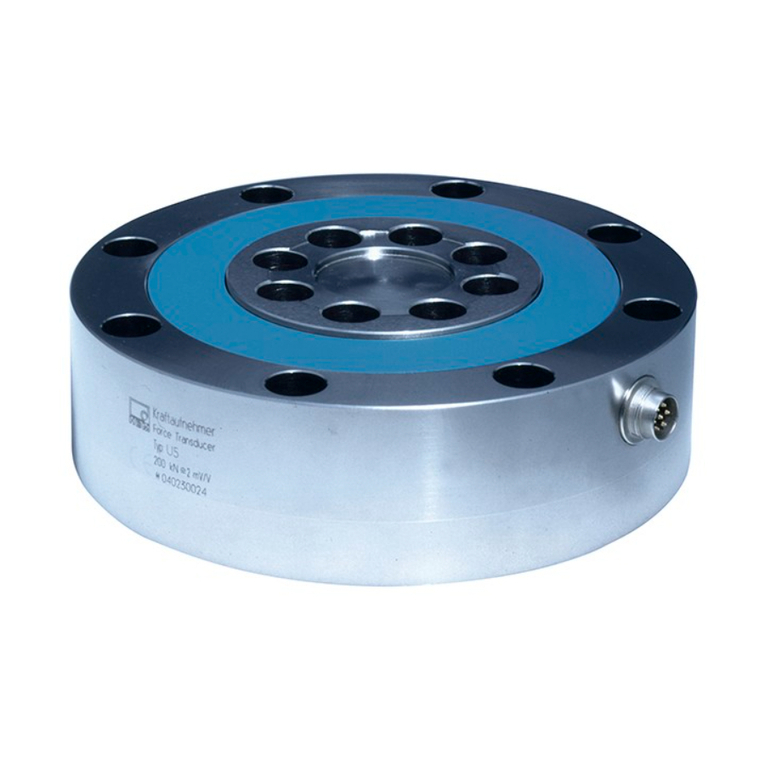

The force transducers are state‐of‐the‐art and reliable.

There may be risks involved if the transducers are moun

ted, sited, installed and operated inappropriately, or by

untrained personnel. Every person involved with siting,

starting‐up, operating or repairing a force transducer

must have read and understood the mounting instruc

tions and in particular the technical safety instructions.

The force transducers can be damaged or destroyed by

non‐designated use of the force transducer or by

non‐compliance with the mounting and operating instruc

tions, these safety instructions or any other applicable

safety regulations (BG safety and accident prevention

regulations) when using the force transducers. Force

transducers can break, particularly in the case of over

loading. The breakage of a force transducer can also

cause damage to property or injury to persons in the

vicinity of the force transducer.

If force transducers are not used according to their desig

nated use, or if the safety instructions or specifications in

the mounting and operating instructions are ignored, it is

also possible that the force transducer may fail or mal

function, with the result that persons or property may be

affected (due to the loads acting on or being monitored

by the force transducer).

The scope of supply and performance of the transducer

covers only a small area of force measurement techno

logy, as measurements with (resistive) strain gauge

sensors presuppose the use of electronic signal condi

tioning. In addition, equipment planners, installers and