Hioki 3227 User manual

Other Hioki Measuring Instrument manuals

Hioki

Hioki BT4560 User manual

Hioki

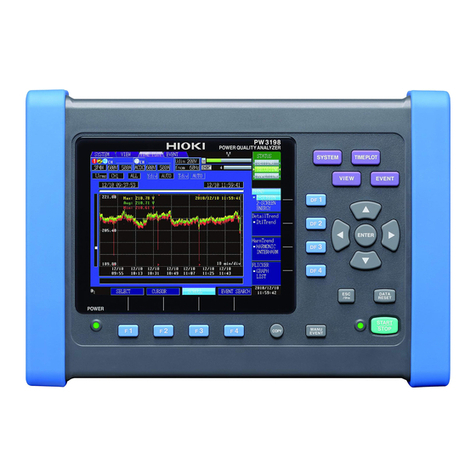

Hioki PW3198 User manual

Hioki

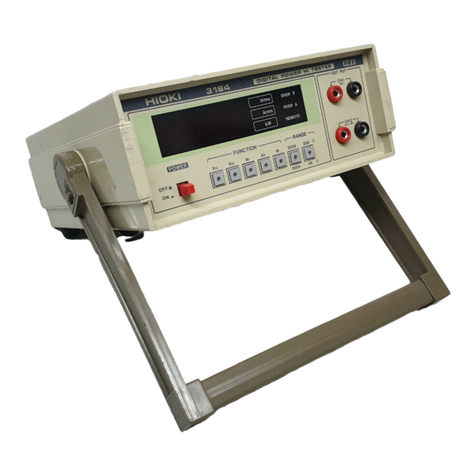

Hioki HITESTER 3184 User manual

Hioki

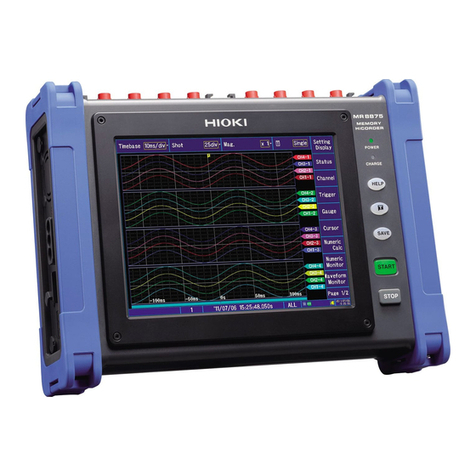

Hioki MR8847A User manual

Hioki

Hioki 3390 User manual

Hioki

Hioki 3506-10 Parts list manual

Hioki

Hioki LCR HiTESTER 3535 Instruction manual

Hioki

Hioki 8715-01 User manual

Hioki

Hioki PQ3198 User manual

Hioki

Hioki SM7420 User manual

Hioki

Hioki 3274 User manual

Hioki

Hioki IM3523A User guide

Hioki

Hioki DT4281 User manual

Hioki

Hioki PQ3100 User manual

Hioki

Hioki 3280-10F User manual

Hioki

Hioki 8715-01 User manual

Hioki

Hioki 3196 User manual

Hioki

Hioki 3143 User manual

Hioki

Hioki 3664 User manual

Hioki

Hioki MEMORY HiCORDER MR8847-01 User manual