i

Introduction........................................................................................1

Verifying Package Contents.............................................................2

Safety Notes.......................................................................................4

Usage Notes.......................................................................................7

1 Overview 15

1.1 Overview and Features.................................................15

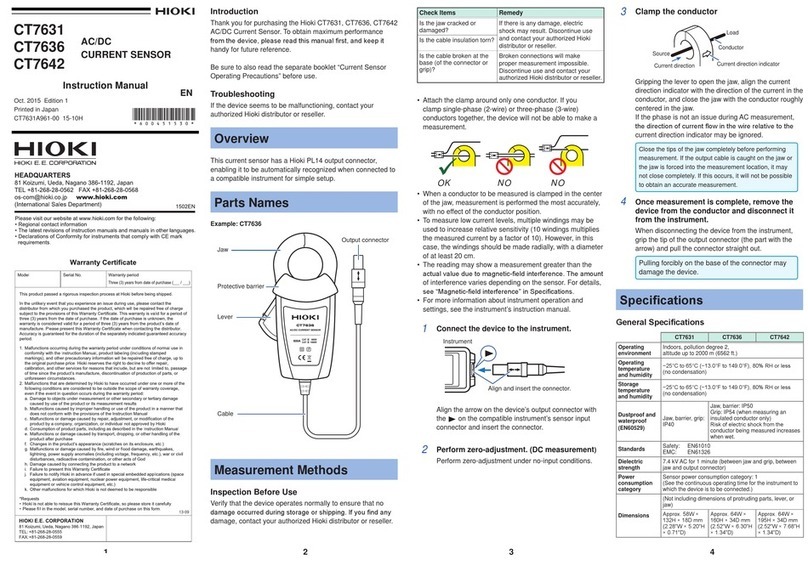

1.2 Component Names and Operation Overview.............16

Power-on settings ....................................................................20

1.3 Flow of Measurement...................................................21

1.4 Screen Layout...............................................................22

1.5 Checking the Measurement Target .............................25

2 Preparing for Measurement 27

2.1 Attaching the Strap.......................................................28

2.2 Loading or Replacing the Batteries ............................29

2.3 Connecting the Test Leads ..........................................30

2.4 Connecting the Z2002 Temperature Sensor

(When Using TC or ΔT).................................................31

2.5 Turning the Power On/Off ............................................32

Turning the power on...............................................................32

Turning the power off...............................................................32

Automatic power off with auto power save (APS)....................33

Disabling auto power save (APS) ............................................33

2.6 Pre-measurement Inspection.......................................34

3 Basic Measurement 35

3.1 Setting the Measurement Range.................................36

3.2 Connecting the Test Leads to the Measurement

Target .............................................................................38

3.3 Reading the Measured Value.......................................39

Switching the display................................................................39

Verifying measurement errors..................................................40

Holding a measured value .......................................................42

Memorizing a measured value.................................................42

Contents

10

9

8

7

6

5

4

3

2

1

Appx. Ind.