7. OPERATING INSTRUCTIONS

7-1 Attention before operation

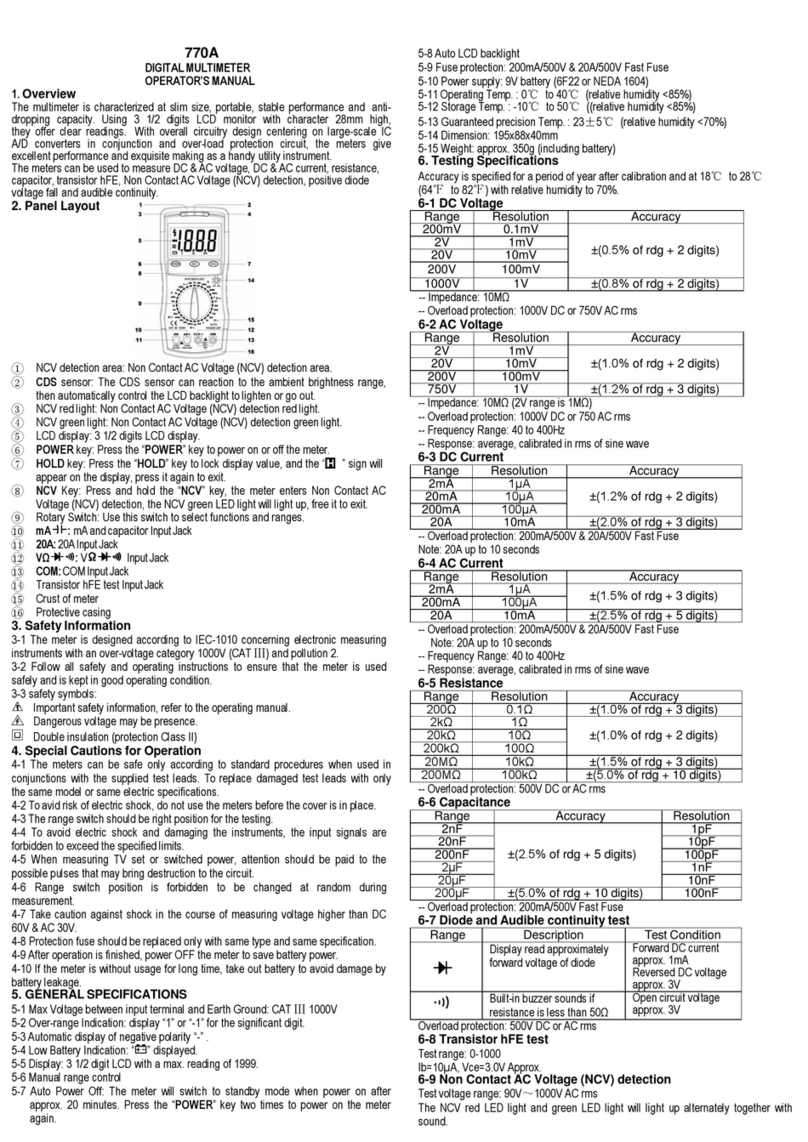

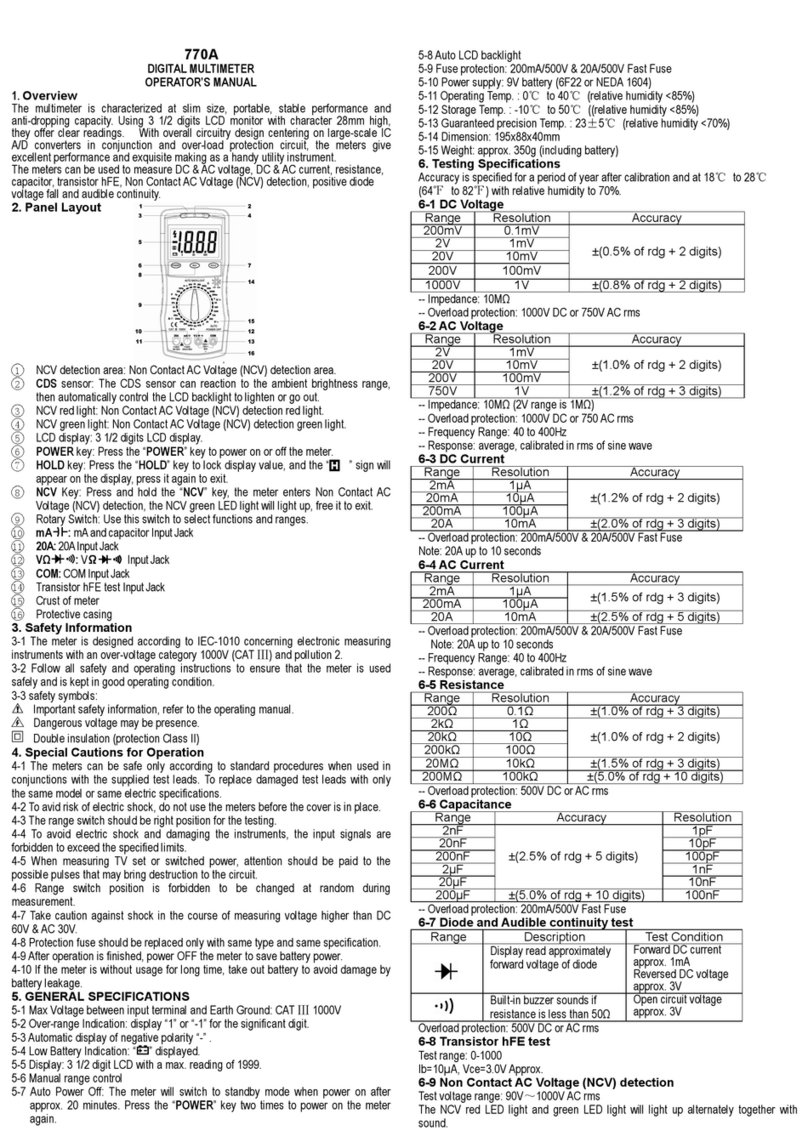

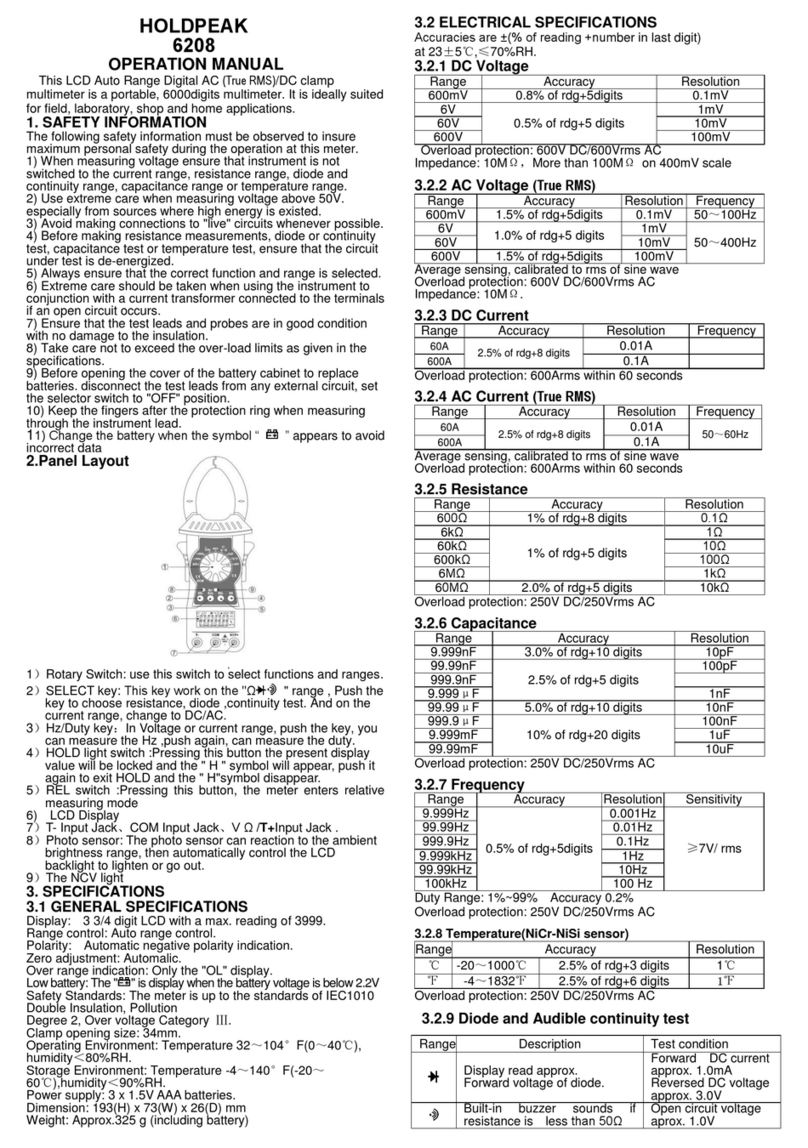

7-1-1 Check battery. When the battery voltage drop below proper operation range,

the “ ” symbol will appear on the LCD display and the battery need to changed.

7-1-2 Pay attention to the “ ” besides the input jack which shows that the input

voltage or current should be within the specified value.

7-1-3 The range switch should be positioned to desired range for measurement

7-2-1 Connect the black test lead to COMT- jack and the red to VΩHz jack.

7-2-2 Set the rotary switch at the desired “V”range position.

7-2-3 Connect test leads across the source or load under measurement.

7-2-4 You can get reading from LCD. The polarity of the red lead connection will be

indicated along with the DC voltage value.

1. When the value scale to be measured is unknown beforehand, set the range selector at

2. When only the figure “1” or “-1” is displayed, it indicates over-range situation and the higher

range has to be selected.

3. “ ” means you can’t input the voltage more than 1000V, it’s possible to show

higher voltage, but it may destroy the inner circuit or pose a shock.

4. Be cautious against shock when measuring high Voltage.

7-3-1 Connect the black test lead to COMT- jack and the red to VΩHz jack.

7-3-2 Set the rotary switch at the desired “V”range position.

7-3-3 Connect test leads across the source or load under measurement.

7-3-4 You can get reading from LCD.

1. When the value scale to be measured is unknown beforehand, set the range selector at

2. When only the figure “1” or “-1” is displayed, it indicates over-range situation and the higher

range has to be selected.

3. “ ” means you can’t input the voltage more than 750V, it’s possible to show

higher voltage, but it may destroy the inner circuit or pose a shock.

4. Be cautious against shock when measuring high Voltage.

7-4-1 Connect the black test lead to COMT- jack and the red to the μAmA jack for a

maximum 200mA current , for a 200mA to 20A current, move the red lead to the 20A

7-4-2 Set the rotary switch at the desired “A”range position.

7-4-3 Connect test leads in series with the load under measurement.

7-4-4 You can get reading from LCD. The polarity of the red lead connection will be

indicated along with the DC current value.

1. When the value scale to be measured is unknown beforehand, set the range

selector at the highest position.

2. When only the figure “1” or “-1” is displayed, it indicates over-range situation and the

higher range has to be selected.

3. “ ” means the socket mA’s maximum current is 200mA and 20A’s maximum

current is 20A, over 200mA or 20A current can be protected by the fast fuse.

4. On the 20A range, the measuring time should be less than 10 seconds to prevent

precision from affecting by circuit heating.

7-5-1 Connect the black test lead to COMT- jack and the red to the μAmA jack for a

maximum 200mA current , for a 200mA to 20A current, move the red lead to the 20A

7-5-2 Set the rotary switch at the desired “A”range position.

7-5-3 Connect test leads in series with the load under measurement.

7-5-4 You can get reading from LCD.

1. When the value scale to be measured is unknown beforehand, set the range

selector at the highest position.

2. When only the figure “1” or “-1” is displayed, it indicates over-range situation and the

higher range has to be selected.

3. “ ” means the socket mA’s maximum current is 200mA and 20A’s maximum

current is 20A, over 200mA or 20A current can be protected by the fast fuse.

4. On the 20A range, the measuring time should be less than 10 seconds to prevent

precision from affecting by circuit heating.

7-6-1 Connect the black test lead to COMT- jack and the red to VΩHz jack.

7-6-2 Set the rotary switch at the desired “Ω” range position.

7-6-3 Connect test leads across the resistance under measurement.

7-6-4 You can get reading from LCD.

NOTE: Max. input overload: 500V rms<10sec

1. When only the figure “1” or “-1” is displayed, it indicates over-range situation and

the higher range has to be selected.

2. For measuring resistance above 10MΩ, the mete may take a few seconds to get

3. When the input is not connected, i.e. at open circuit, the figure “1” or “-1” will be

displayed for the over-range condition.

4. When checking in-circuit resistance, be sure the circuit under test has all power

removed and that all capacitors have been discharged fully.

7-7 Measuring Capacitance

7-7-1 Set the rotary switch at the desired “F”range position.

7-7-2 Insert the capacitance under measurement into the two jacks “Cx+” and

“Cx-/Lx-” on the front panel.

7-7-3 You can get reading from LCD.

1. Capacitors should be discharged before being tested.

2. Do not connect an external voltage or charged capacitor (especially larger

capacitors ) to measuring terminals.

7-8-1 Set the rotary switch at the desired “H”range position.

7-8-2 Insert the inductance under measurement into the two jacks “Lx+” and

“Cx-/Lx-” on the front panel.

7-8-3 You can get reading from LCD.

NOTE: Don’t connect an external voltage to measuring terminals.

7-9 Measuring Temperature

7-9-1 Connect the black banana plug of the sensor to COMT- jack and the

red banana plug to the μAmA jack.

7-9-2 Set the rotary switch at the desired “ ” range position.

7-9-3 Put the sensor probe into the temperature field under measurement.

7-9-4 You can get reading from LCD.

1. The accessory of the meter WRNM-010 type contact thermocouple limit

temperature is 250 (300 shortly), please use special probe for test higher

2. Please don't change the thermocouple at will, otherwise we can't guarantee to

3. Please don’t importing the voltage in the temperature function.

7-10-1 Connect the black test lead to COMT- jack and the red to VΩHz jack.

7-10-2 Set the rotary switch at the desired “200kHz” range position.

7-10-3 Connect the probe across the source or load under measurement.

7-10-4 You can get reading from LCD.

7-11 Diode & Audible continuity Testing

7-11-1 Connect the black test lead to COMT- jack and the red to VΩHz jack.

7-11-2 Set the rotary switch at the “ ” range position.

7-11-3 On diode range, connect the test leads across the diode under measurement,

display shows the approx. forward voltage of this diode.

7-11-4 On Audible continuity range, connect the test leads to two point

of circuit, if the resistance is lower than approx. 50Ω, the buzzer sounds.

NOTE: Make sure the power is cut off and all capacitors need to be discharged

7-12-1 Set the rotary switch at the desired “hFE” position.

7-12-2 Determine whether the transistor is NPN or PNP and locate the Emitter, Base

and Collector leads. Insert the leads into the proper holes in the socket on the front

7-12-3 You can get reading of the approximate hFE value from LCD.

NOTE: Don’t connect an external voltage to measuring terminals.

7-13 Non Contact AC Voltage detection

7-13-1 Set the rotary switch at the desired “NCV” range position, the NCV green LED

7-13-2 Hold the Meter so that the mater’s top is vertically and horizontally centered

and contacting the conductor, when the live voltage ≥ 90V AC rms, the NCV red LED

light and green LED light will light up alternately together with sound.

1. Even without LED indication, the voltage may still exist. Do not rely on non-contact

voltage detector to determine the presence of voltage wire. Detection operation may

be subject to socket design, insulation thickness and different type and other factors.

2. When the meter input terminals presence voltage, due to the influence of presence

voltage, voltage sensing indicator may also be bright.

3. Keep the meter away from electrical noise sources during the tests, i.e., florescent

lights, dimmable lights, motors, etc.. These sources can trigger Non-Contact AC

Voltage detection function and invalidate the test.

8-1 When the battery voltage drop below proper operation range the " " symbol will

appear on the LCD display and the battery need to changed.

8-2 Before changing the battery, power off the meter and remove the test leads from

the terminals. Open the cover of the battery cabinet by a screwdriver.

8-3 Replace the old battery with the same type battery (9V 6F22 or NEDA 1604).

8-4 Close the cover of the battery cabinet and fasten the screw.

9-1 This meter is provided with a 200mA/500V fast fuse to protect the capacitance

test, temperature test and the current measuring circuits which measure up to

200mA, with a 20A/500V fuse to protect the 20A range.

9-2 Ensure the meter is not connected to any external circuit, power off the meter

and remove the test leads from the terminals. Open the cover of the battery cabinet

9-3 Replace the old fuse with the same type and rating: 6×30mm 200mA/500V fast

fuse or 6×30mm 20A/500V fast fuse.

9-4 Close the cover of the battery cabinet and fasten the screw.

10-1 Before attempting to remove the battery door or open the case, be sure that test

leads have been disconnected from measurement circuit top avoid electric shock

10-2 You must replace the test leads if the lead is exposed, and should adopt the

leads with the same specifications as origin.

10-3 Use only moist fabric or small amount of detergent but not chemical solution for

10-4 Do not use the meter before the back cover is properly closed and screw

secured. Upon any abnormality, stop operation immediately and send the meter for

10-5 Please take out the battery when not using for a long time.

[1] Test Leads: electric rating 1000V 20A

[2] Capacitance/Inductance test leads

[3] “K” type thermocouple sensor probe

Above picture and content just for your reference. Please be

subject to the actual products if anything different or updated.

Please pardon for not informing in advance.