Contents 3

Contents

Planning the installation............................................................................................................................5

Safety and regulatory compliance ............................................................................................................................5

Configuration guidelines...........................................................................................................................................5

Determine power and cooling configurations ...........................................................................................................5

Power requirements ......................................................................................................................................5

HPE Apollo Platform Manager.......................................................................................................................5

Hot-plug power supply calculations...............................................................................................................5

Compiling the documentation...................................................................................................................................6

Warnings and cautions.............................................................................................................................................6

Space and airflow requirements...............................................................................................................................7

Temperature requirements.......................................................................................................................................7

Grounding requirements...........................................................................................................................................8

Identifying components and LEDs ............................................................................................................9

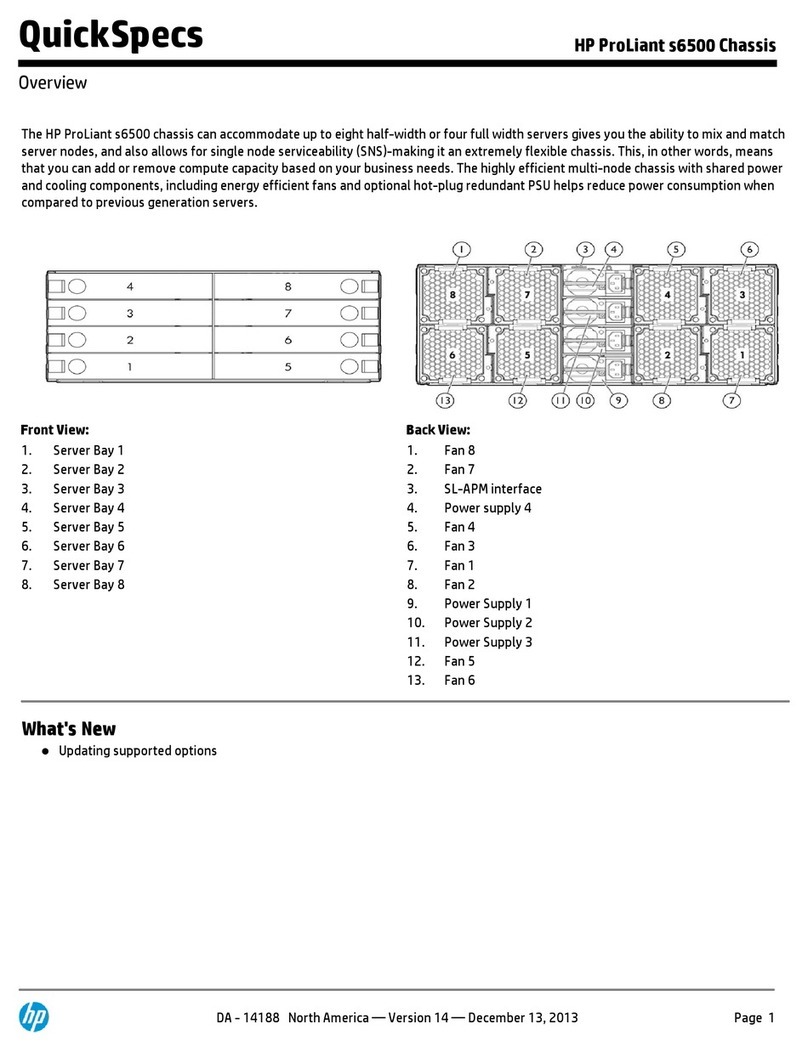

System components.................................................................................................................................................9

Server tray bay numbering .....................................................................................................................................10

Rear panel components .........................................................................................................................................10

Fan assembly bay numbering .....................................................................................................................11

Fan LED ......................................................................................................................................................11

Management module components ..............................................................................................................12

Management module LEDs and buttons .....................................................................................................13

I/O module bay numbering ..........................................................................................................................13

Power shelf rear panel components.......................................................................................................................13

Power supply LEDs ................................................................................................................................................14

Installing the chassis...............................................................................................................................15

Installation overview ...............................................................................................................................................15

Unpacking the system ............................................................................................................................................15

Determining the chassis rack spacing....................................................................................................................15

Installing the rack rails............................................................................................................................................15

Installing the chassis in the rack.............................................................................................................................15

Installing the system components ..........................................................................................................................17

Installing a server tray blank........................................................................................................................17

Installing a server ........................................................................................................................................18

Installing an I/O module...............................................................................................................................19

Installing the fans.........................................................................................................................................20

Installing a power cage................................................................................................................................20

Installing the management module..............................................................................................................22

Installing the power shelf........................................................................................................................................23

Cabling....................................................................................................................................................27

Cabling requirements .............................................................................................................................................27

Cabling the chassis ................................................................................................................................................27

Connecting the chassis to a power shelf.....................................................................................................27

Connecting the chassis to the top-of-rack switch ........................................................................................30

Connecting the optional HPE APM module.................................................................................................31

Connecting power cables and applying power to the chassis.....................................................................32

Configuring the system ...........................................................................................................................33

Power capping........................................................................................................................................................33

Power capping modes.................................................................................................................................33

Configuring a power cap ........................................................................................................................................34

Setting the chassis power cap mode with the PPIC utility...........................................................................34

Setting the chassis power cap mode with APM...........................................................................................34