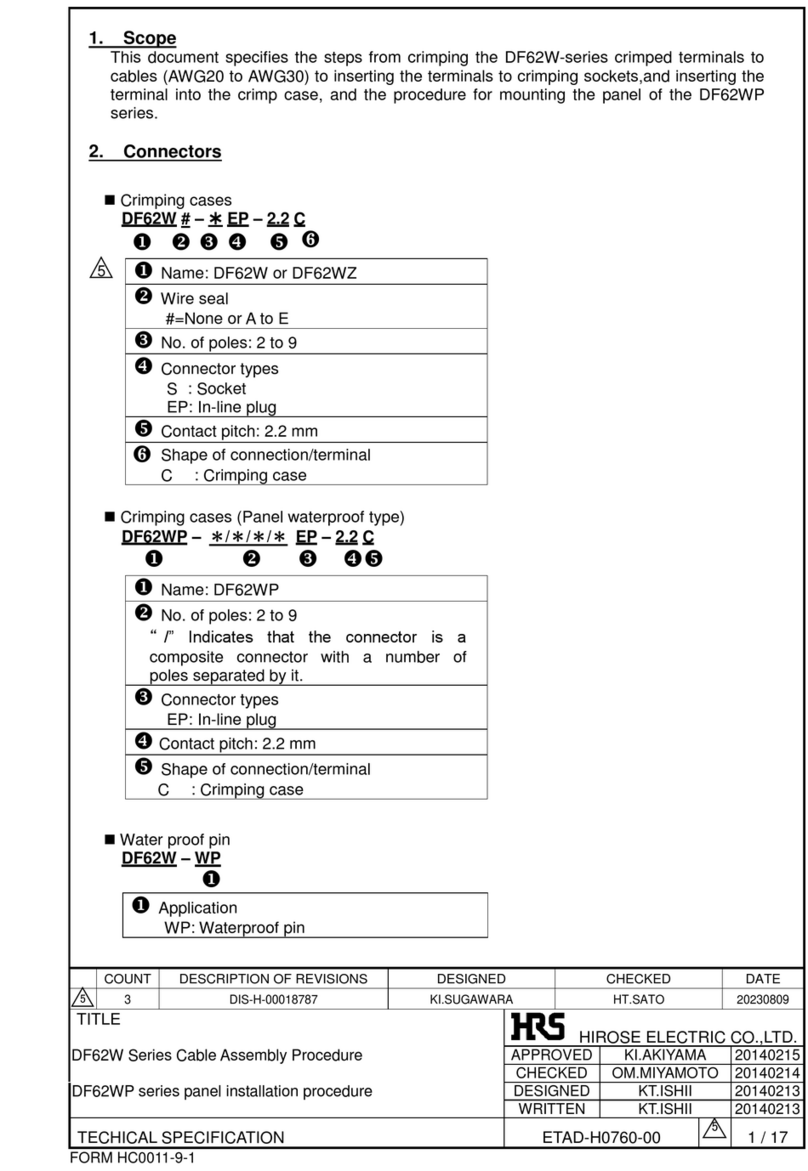

HRS DF62W Series User manual

Other HRS Cables And Connectors manuals

HRS

HRS FH67 Series User manual

HRS

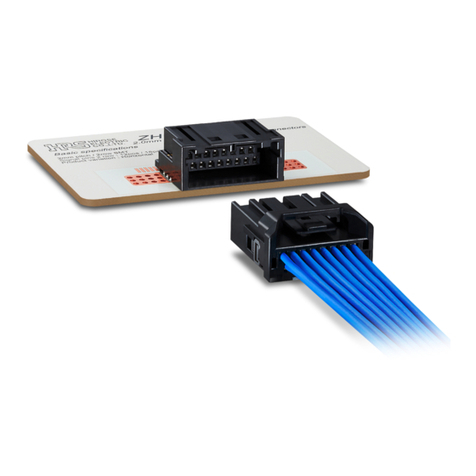

HRS ZH05 Series User manual

HRS

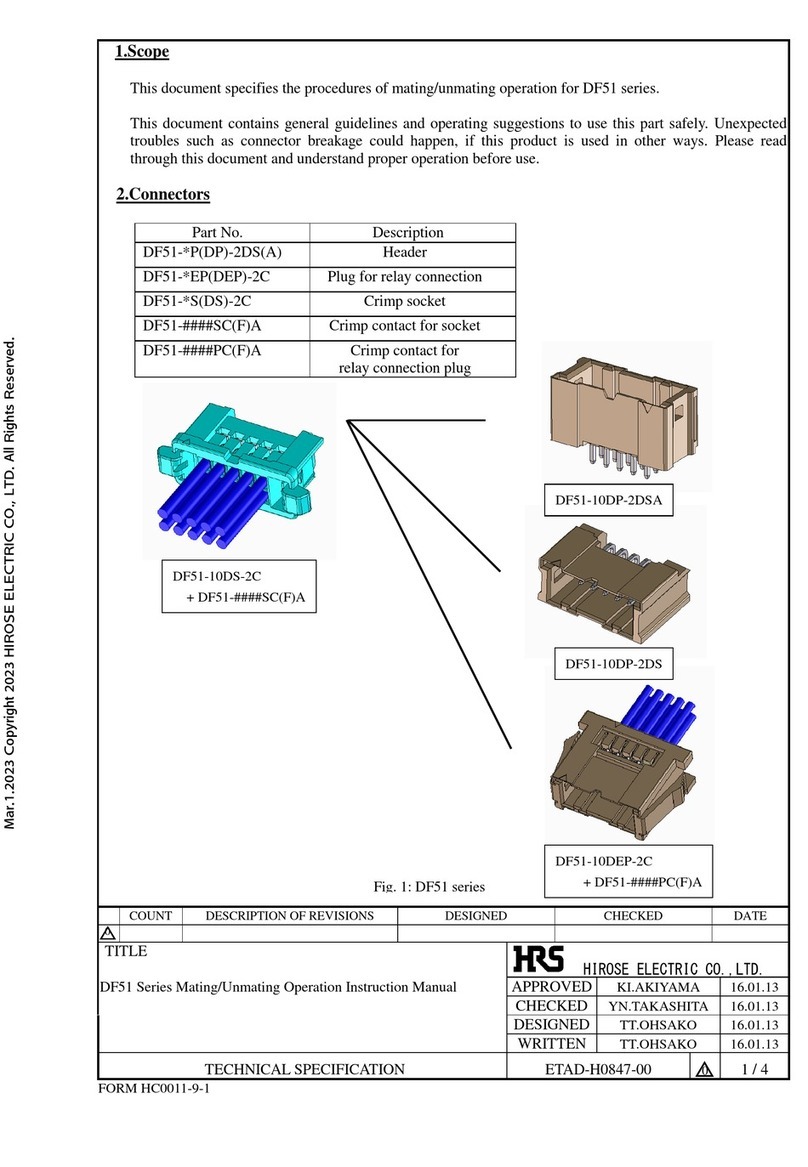

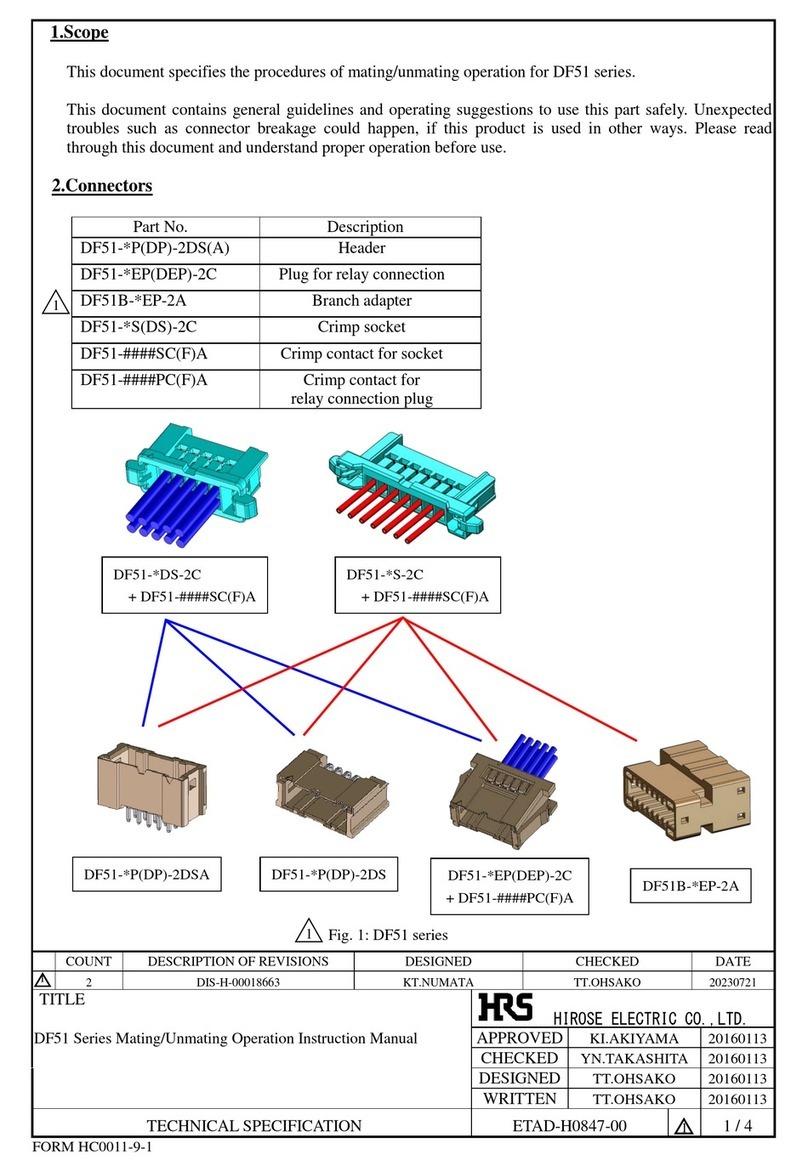

HRS DF51 Series User manual

HRS

HRS DF62W EP 2.2C Series User manual

HRS

HRS GT50 Series Instruction Manual

HRS

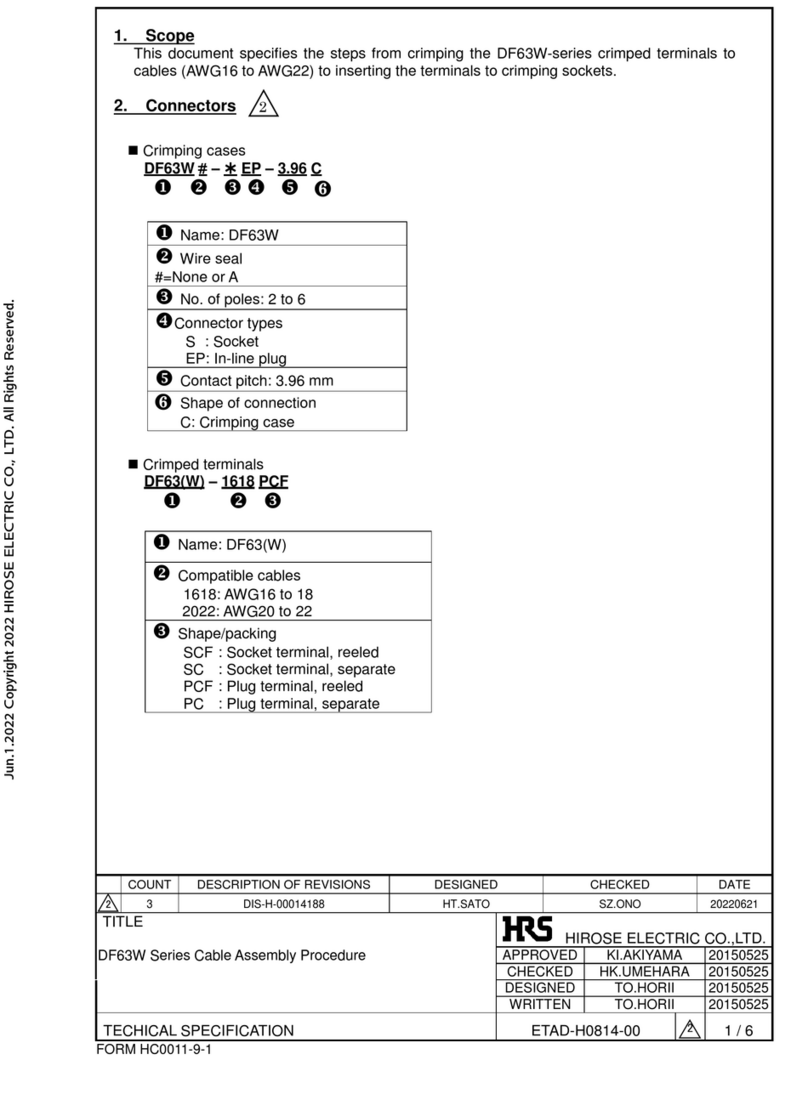

HRS DF63W Series Manual

HRS

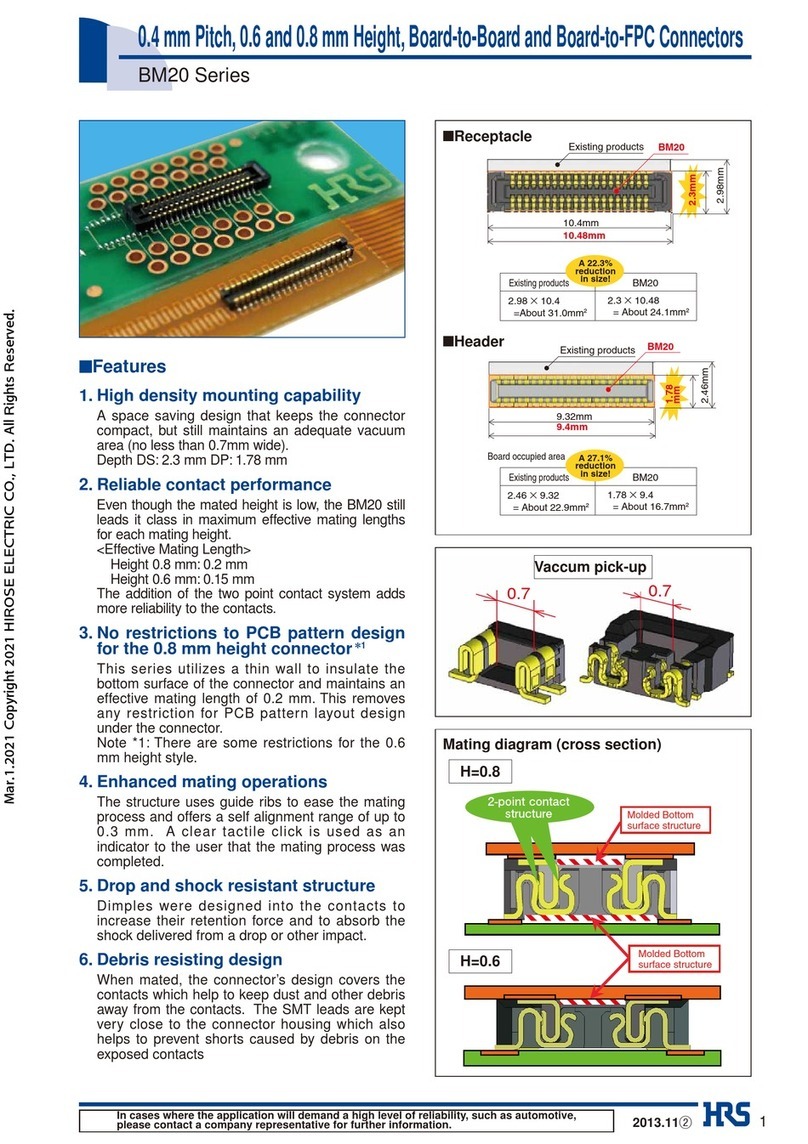

HRS BM20 Series User manual

HRS

HRS GT50 Series User manual

HRS

HRS HELIX User manual

HRS

HRS FH12 Series User manual

HRS

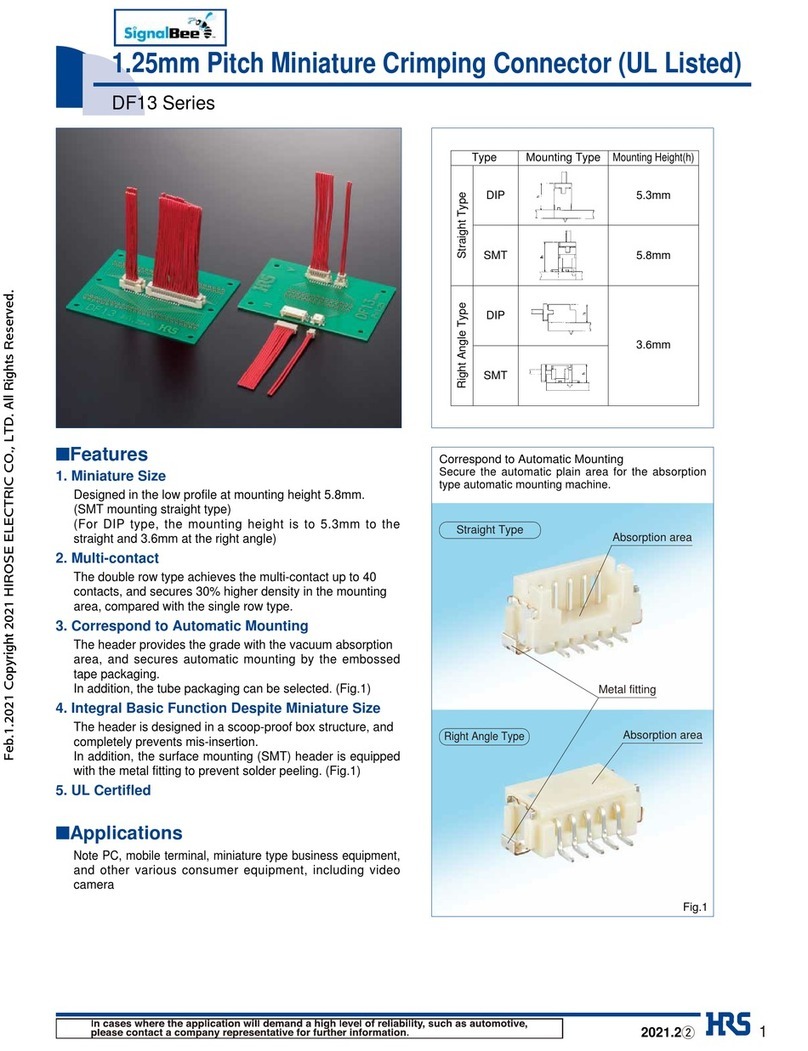

HRS SignalBee DF13 Series User manual

HRS

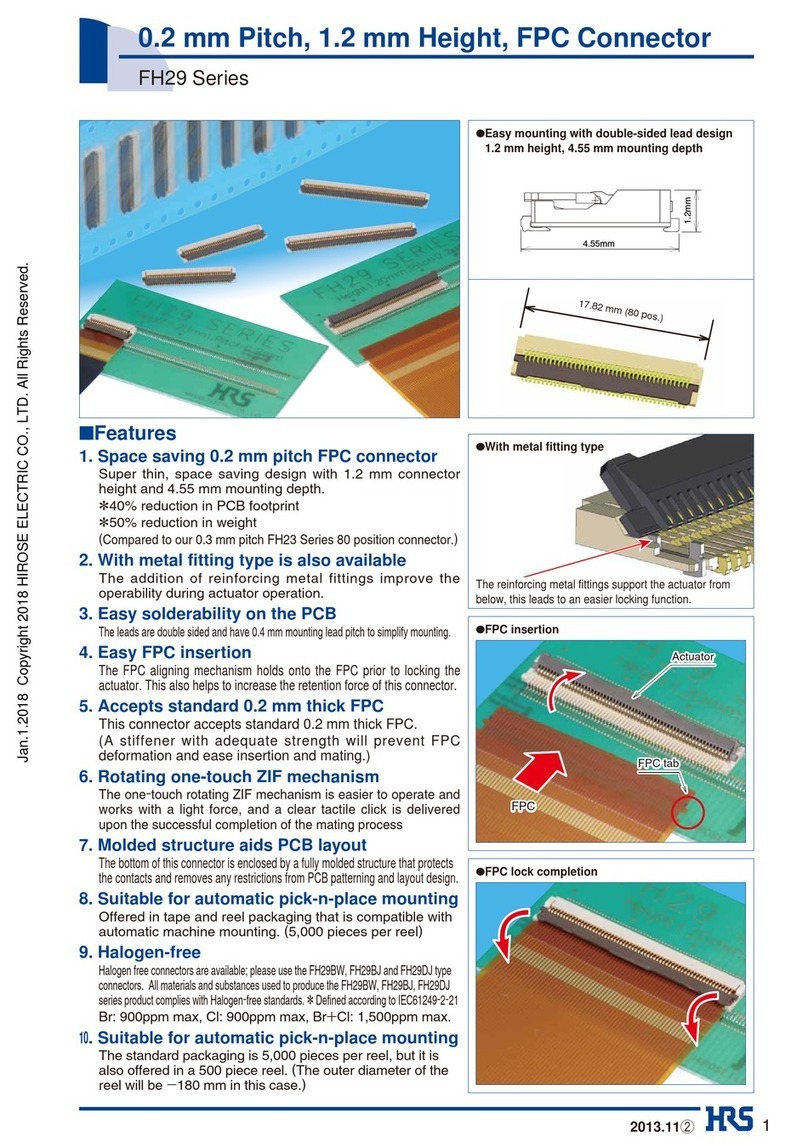

HRS FH29 Series User manual

HRS

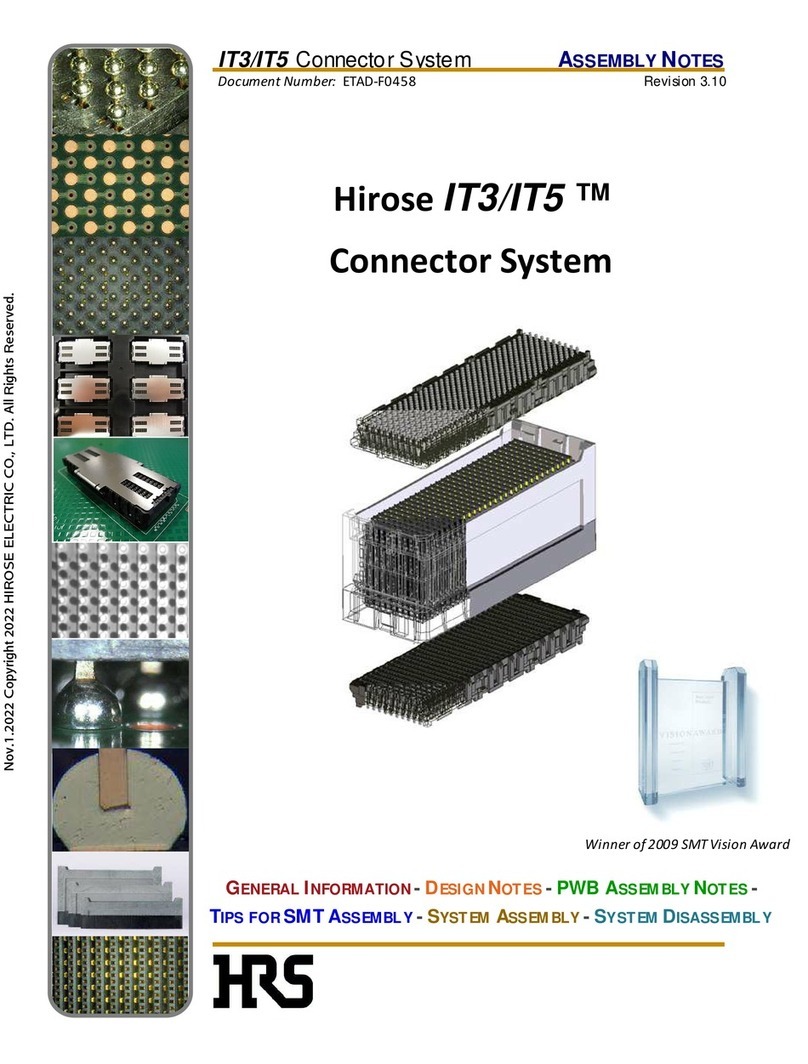

HRS Hirose IT3 Quick start guide

HRS

HRS FH12-20S-0.5SH(54) User manual

HRS

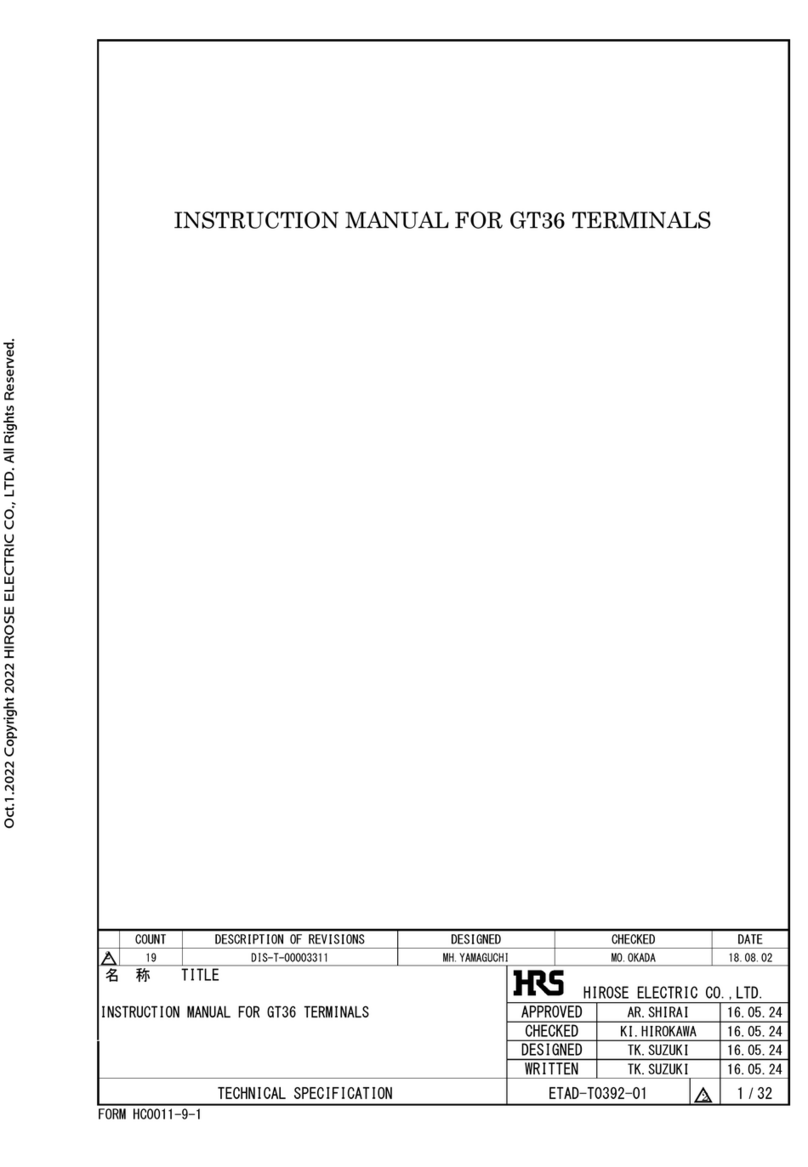

HRS GT36 User manual

HRS

HRS DF51-6EP-2C User manual

HRS

HRS EM30MSD Series User manual

HRS

HRS BM25 Series Instruction Manual

HRS

HRS DF40 Series User manual

HRS

HRS BNC75 Series Manual