FORM HC0011-9-2

4. Precautions for handling

4.1. Packing and storage

To pack or store assemblies, make sure overlapped connectors will not apply extreme load to

the lack section.

If load is applied to the lock section under high temperature and humidity for a long period of

time, the lock section will be deformed which could lead poor fitting.

4.2. Loading to a connector

To pack or store assemblies, make sure overlapped connectors will not apply extreme load to

excessive external force applied to connectors could cause failure or damage. Therefore,

avoid forced insertion or removal, dropping impact, cable wiring (pull, twist) and such.

Note) Breaking strength of lock is approx. 50 N when connector is pulled in straight

direction. Please avoid excessive force is applied to the connector.

Note) Retention force is approx. 27 N / Pin. Please avoid excessive force is applied to

particular cable.

During cable wiring inside the machine, keep sufficient cable length for slack to avoid direct

stress is applied to the connector.

4.3. Rubber seal

If the rubber seal is damaged, the connector is deteriorated water resistant performance.

Therefore, do not use the connector whose rubber seal is damaged.

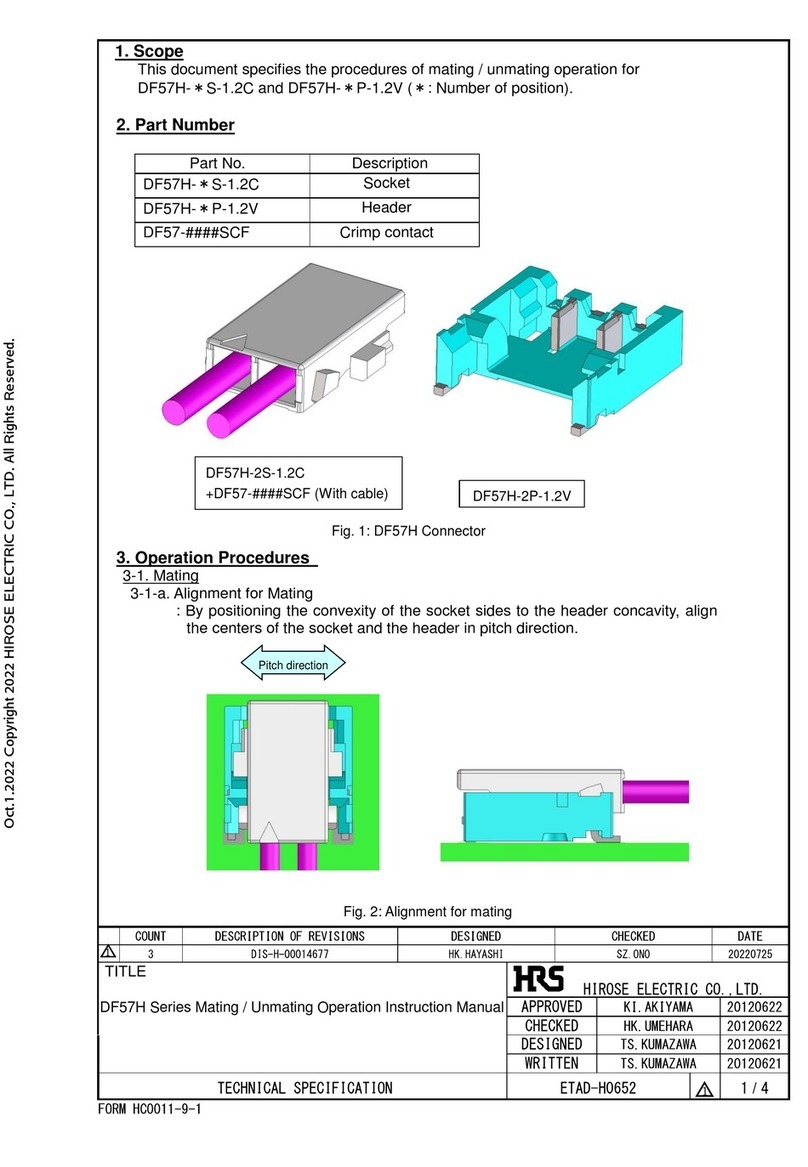

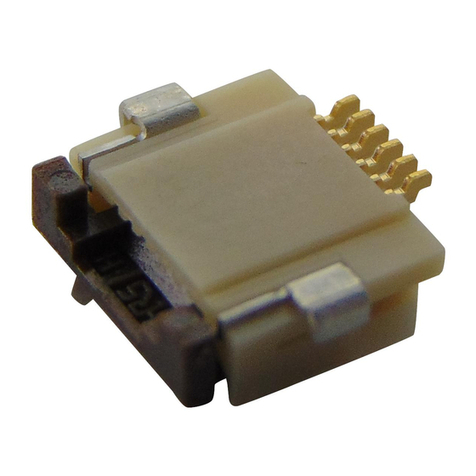

4.4. Wiring cable

When bundling cables, prepare a part that is straight from the end face of the connector as

shown in the figure below.

Do not bind near the end face of the connector because it will put a load on the terminal

contact part and the terminal crimping part and cause contact failure and waterproof

failure.

Keen bending,cable tension should be avoided

No cable tension is applied

Jun.1.2022Copyright2022HIROSEELECTRICCO.,LTD.AllRightsReserved.