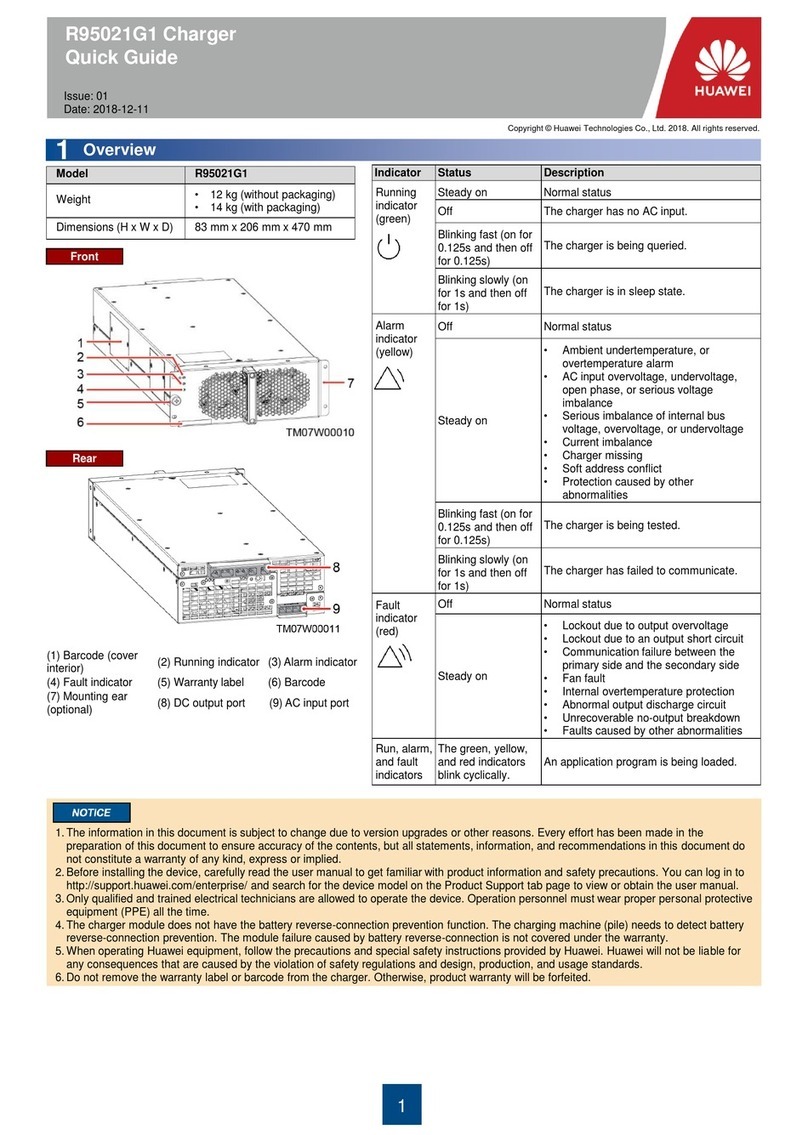

Model R50040G1

Weight •12 kg (without packaging)

•14 kg (with packaging)

Dimensions (H x W x D) 83 mm x 206 mm x 470 mm

•The charging machine (pile) or station should comply with the environment protection requirements in sections 6.3 and 8.3 of NB/T33001-2010 as well as the

environment resistance and protection level requirements in NB/T33008.1-2013. They should provide the protection rating of at least IP54 outdoors or IP30

indoors when used in common environments.

•Avoid using the product in sea environments or outdoor land environments (with simple shielding measures) near pollution sources. If such an environment is

unavoidable, the charging machine (pile) should provide the protection rating of IP65. Otherwise, the product may become faulty, and the resulting product

malfunction or component damage is beyond the warranty scope. Pollution sources refer to the following areas:

–Areas within 3.7 km away from salt water such as the sea

–Areas within 3 km away from serious pollution sources, such as metallurgic plants, coal mines, and heat and power plants

–Areas within 2 km away from medium pollution sources, such as chemical factories, rubber plants, and electroplating factories

–Areas within 1 km away from light pollution sources, such as food factories, tanneries, and heating boilers

Installation Environment and Hole Size Requirements

2.1

Installing the Charger

2.2

Application scope: charging machine (pile) or station

The charger can be installed horizontally, sidewards, or vertically (with the panel at the bottom). If side or vertical installation is adopted, ensure that mechanical

parts are designed to avoid interference. The installation mode can be selected according to the actual situation. Horizontal installation is recommended and vertical

installation is not recommended.

Front

Rear

•Avoid using the product in an environment with corrosive or insulation-damaging materials.

If such an environment is unavoidable, the charging machine (pile) should provide the

protection rating of IP65. Otherwise, the product may become faulty, and the resulting

product malfunction or component damage is beyond the warranty scope.

•It is recommended that the ventilation area for a single charger be 11500 mm2, and the

minimum ventilation area be 9000 mm2. The ventilation area of the system is calculated

based on the number of chargers. (The data is only the area required for heat dissipation of

the charger but not other devices.)

•It is recommended that the air inlet and outlet of the charger be at least 40 mm away from

the cabinet. The specific distance depends on the air channel of the system.

Mounting Hole Sizes (unit: mm)

Copyright © Huawei Technologies Co., Ltd. 2018. All rights reserved.

1. The information in this document is subject to change due to version upgrades or other reasons. Every effort has been made in the preparation of this document to

ensure accuracy of the contents, but all statements, information, and recommendations in this document do not constitute a warranty of any kind, express or implied.

2. Before installing the device, carefully read the user manual to get familiar with product information and safety precautions. You can log in to

http://support.huawei.com/carrier/ and search for the device model on the Product Support tab page to view or obtain the user manual.

3. Only qualified and trained electrical technicians are allowed to operate the device. Operation personnel must wear proper personal protective equipment (PPE) all

the time.

4. Before installing the device, check that the product and accessories are intact and complete. If any damage is found or any component is missing, contact your

supplier.

5. When operating Huawei equipment, follow the precautions and special safety instructions provided by Huawei. Huawei will not be liable for any consequences that

are caused by the violation of safety regulations and design, production, and usage standards.

6. Do not remove the warranty label or barcode from the charger. Otherwise, product warranty will be forfeited.