®

PD1654 (Page 1) Rev. 07/07

English

GENERAL INFORMATION

1. CAUTION:RISK OF ELECTRIC SHOCK. Disconnect power before installation or maintenance.

2. NOTICE: For installation only by a qualified electrician in accordance with national and local

electrical codes and the following instructions.

3. CAUTION: USE COPPER CONDUCT ORS ONLY. Use stranded conductors only .

4. Check that the device’s type and rating are suitable for the application.

5. Select the conductor size from National Electrical Code ® Table 400-5B or Canadian Electrical

Code Table 12A.

Rated for use with Type G, W portable cords or equivalent with COPPER conductors only .

6. The plug is rated Type 3,4, and 4X when connected to an equivalently rated connector or receptacle

when using the locking ring. The receptacle and connector are rated Type 3,4, and 4X when the

cap is in the closed position or connected to an equivalently rated plug when using the locking

ring.

ELECTRICAL RATING: Max. Voltages: 600 VAC, 250 VDC.

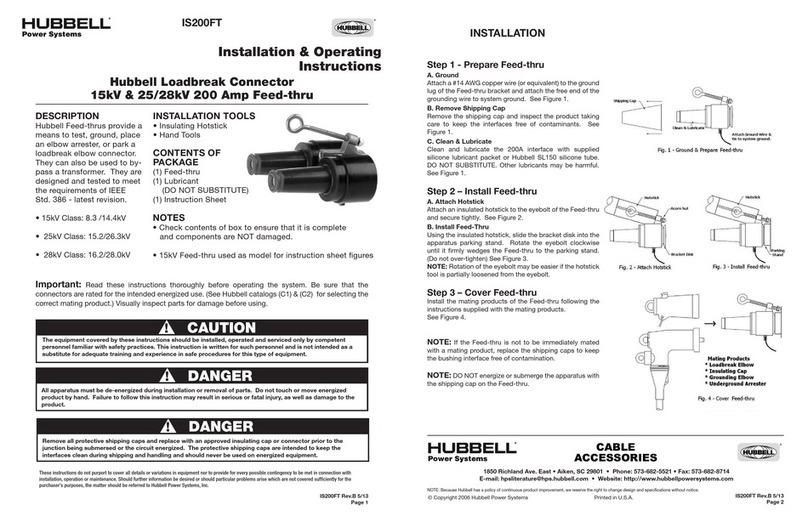

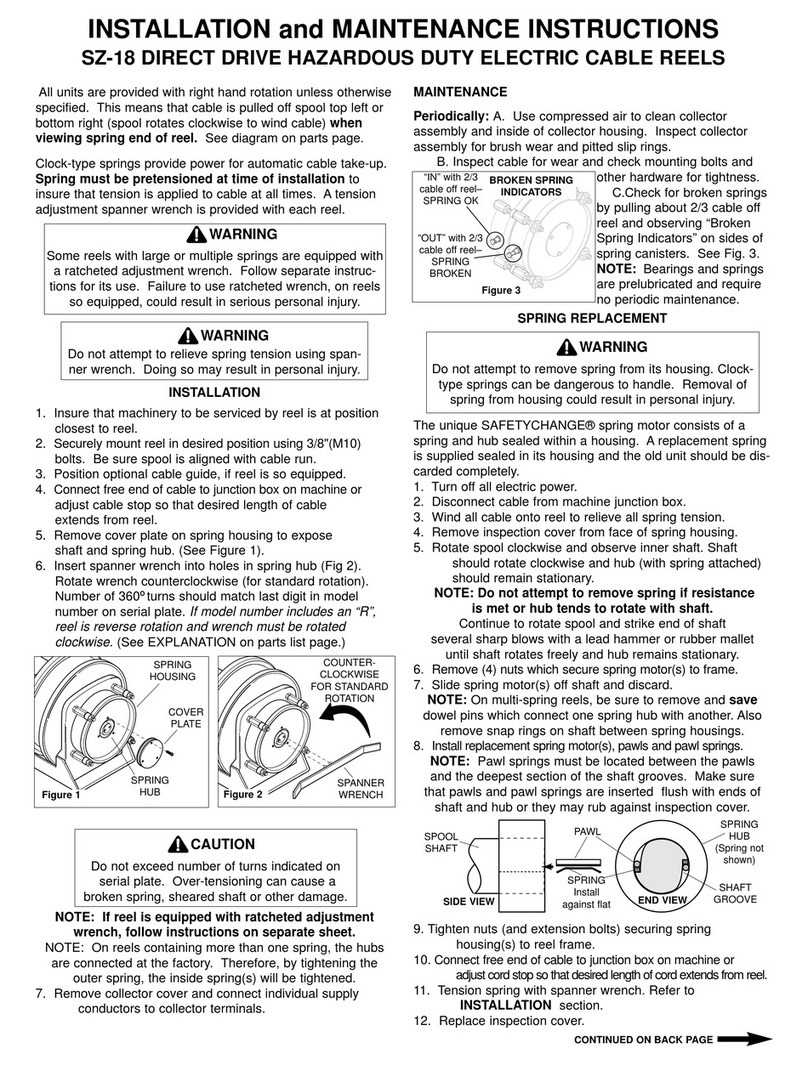

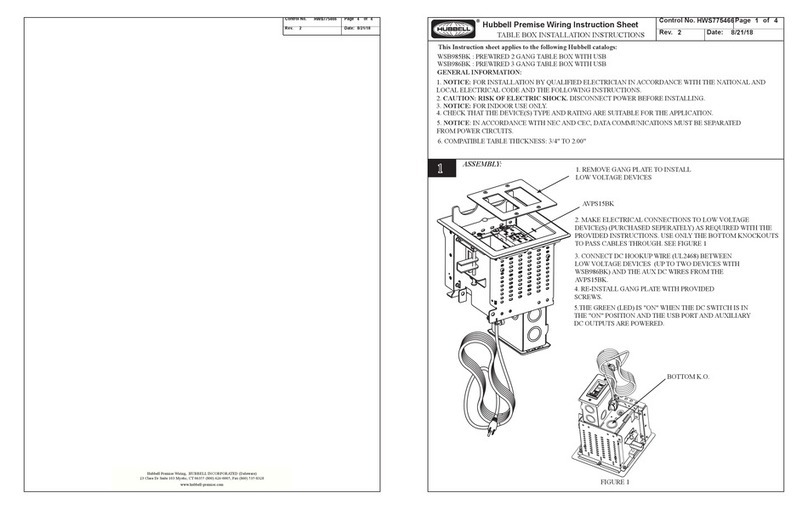

PLUG, CONNECTOR & RECEPTACLE INSTALLATION

1. Check the rating on the label to insure that it is correct

for the installation.

2. Select cable of suitable ampacity and temperature

rating (see Table 1).

3. Select cord end with proper conductor color

orientation that matches terminal location. Shear cord

cleanly. Do not strip away cord jacket or remove

conductor insulation at this time.

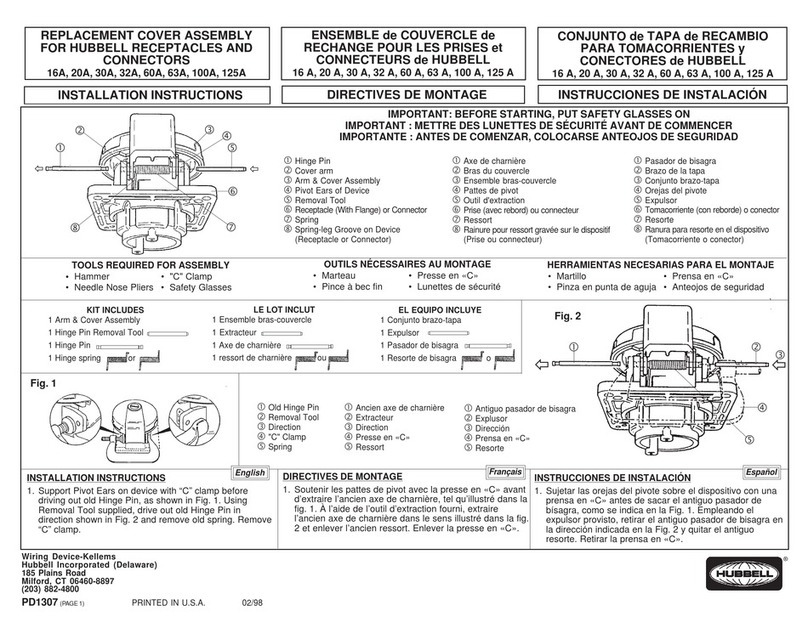

4. To disassemble Plug (see figure 1)

• Remove ground screw (12).

• Remove retaining ring(1) and interior assembly(2)

from plug body(3).

• Loosen clamp guide set screw(4) and turn clamp guide assembly(5) to remove from plug body .

To disassemble Connector (see figure 2)

• Remove adapter set screw(12) and connector adapter(13) from connector nose(17).

• Remove mounting screws(16), ground strap(14), keying ring(15) and interior assembly(2).

• Loosen clamp guide set screw(4) and turn clamp guide assembly(5) to remove from adapter(13).

To disassemble Recept acle (see figure 3)

• Remove mounting screws(16), ground strap(14) w/screw (for S tyle 2), keying ring(15) and

interior assembly(2).

• Slide keying ring(15) over power cable.

Do not disassemble interior assembly .

*For plugs & connectors

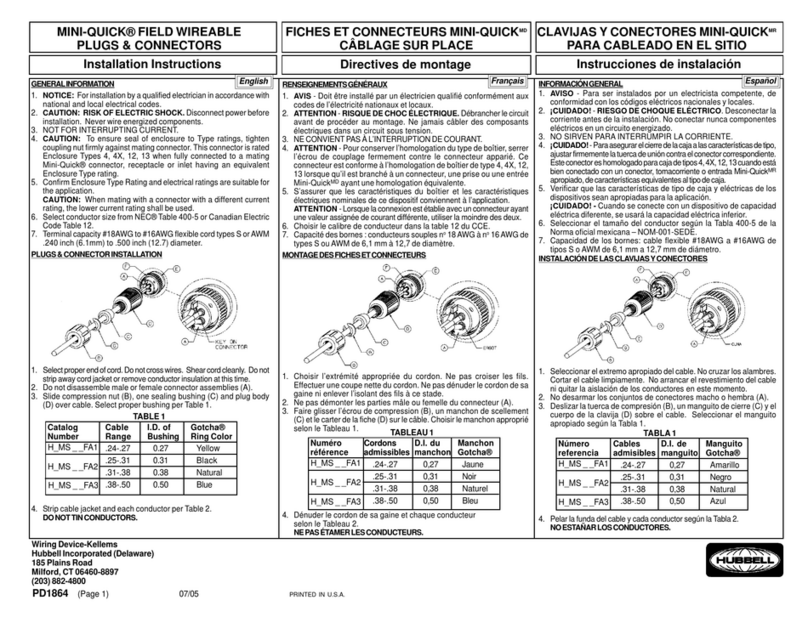

*5. Slide clamp guide(5) with cable clamps(6) (see figure 4 for proper inserts) and one grommet

washer(7) over power cable. (Select proper grommet washer with respect to cable size).

*6. See figure 5 for cable gaging strip to determine how many "inner layers" of the onion skin

grommet(8) are to REMAIN or remove "inner layers" until the grommet slips over power cable.

Remove one layer at a time by pushing through and tearing off.

*7. Place onion skin grommet(8) over power cable. For plugs place plug body(3) with locking

ring(9) and for connectors, place keying ring(15) over power cable.

8. Strip cable jacket 4" and each conductor 1 1/4".

9. Twist wire strands together on each conductor .

DO NOT TIN CONDUCTORS .

10. NOTE: Crossing one ungrounded conductor (Line) over the grounded conductor (Neutral)

may be necessary with five-wire devices.

11. Insert conductors into the proper terminals according to the established wiring pattern. The grounding

terminal (earthing) is indicated by a green marking, a "G" or the earthing symbol. The neutral

terminal (grounded) is to be marked with PERMANENT white coloration by installer in accordance

with National Electrical Code ® Section 200-9. See figure 6 for S tyle 1 and S tyle 2 wiring.

12. Tighten terminal screws to a torque of 17 lb•ft.

13. TAKE CAUTION THAT THERE ARE NO STRAY WIRE STRANDS.

14. To reassemble Plug (see figure 1)

• Slide interior assembly into(2) into plug body(3) aligning the internal plug body key and insulator

key slot. Place retaining ring(1) into the plug body slot.

• Install ground screw (12). Torque to 24 lb.-in.

To reassemble Connector (see figure 2)

• Slide interior assembly(2) into connector nose(17), align keying ring(15) with interior key slot,

and align mounting holes of ring with connector nose.

• Install mounting screws(16) and ground strap(14). Screw adapter(13) onto connector nose(17)

and torque adapter set screw (12) to 15 to 20 lb•in.

To reassemble recept acle (see figure 3)

• Slide interior assembly(2) into receptacle housing. Place and align keying ring(15) with the

key slot in the interior and align mounting holes with receptacle.

• Install mounting screws and ground strap with screw (for S tyle 2).

*For Plugs & Connectors

*15. Slide onion skin grommet(8) down power cable into plug body(3). Place grommet washer in clamp

guide and screw clamp guide onto plug body . Torque clamp guide set screw(4) to 15 to 20 lb•in.

*16. Torque cable clamp screws (1 1) to a minimum of 50 lb•in, alternating sides to prevent binding.

For Receptacle

Mount with gasket(18) using bolts(20) and torque to 30 to 40 lb•in. There must be a tight seal

between housing and back box to assure a weatherproof, oil tight and hosedown water tight fit.

INSULINSUL

INSULINSUL

INSULGRIPGRIP

GRIPGRIP

GRIP®®

®®

® PIN & SLEEVE PIN & SLEEVE

PIN & SLEEVE PIN & SLEEVE

PIN & SLEEVE

PLPL

PLPL

PLUGUG

UGUG

UG,,

,,

, CONNECT CONNECT

CONNECT CONNECT

CONNECTOR & RECEPTOR & RECEPT

OR & RECEPTOR & RECEPT

OR & RECEPT AA

AA

ACLECLE

CLECLE

CLE

200 Amp • Style 1 & 2200 Amp • Style 1 & 2

200 Amp • Style 1 & 2200 Amp • Style 1 & 2

200 Amp • Style 1 & 2

INSTINST

INSTINST

INSTALLAALLA

ALLAALLA

ALLATIONTION

TIONTION

TION

OPERAOPERA

OPERAOPERA

OPERATIONTION

TIONTION

TION

MAINTENMAINTEN

MAINTENMAINTEN

MAINTENANCEANCE

ANCEANCE

ANCE

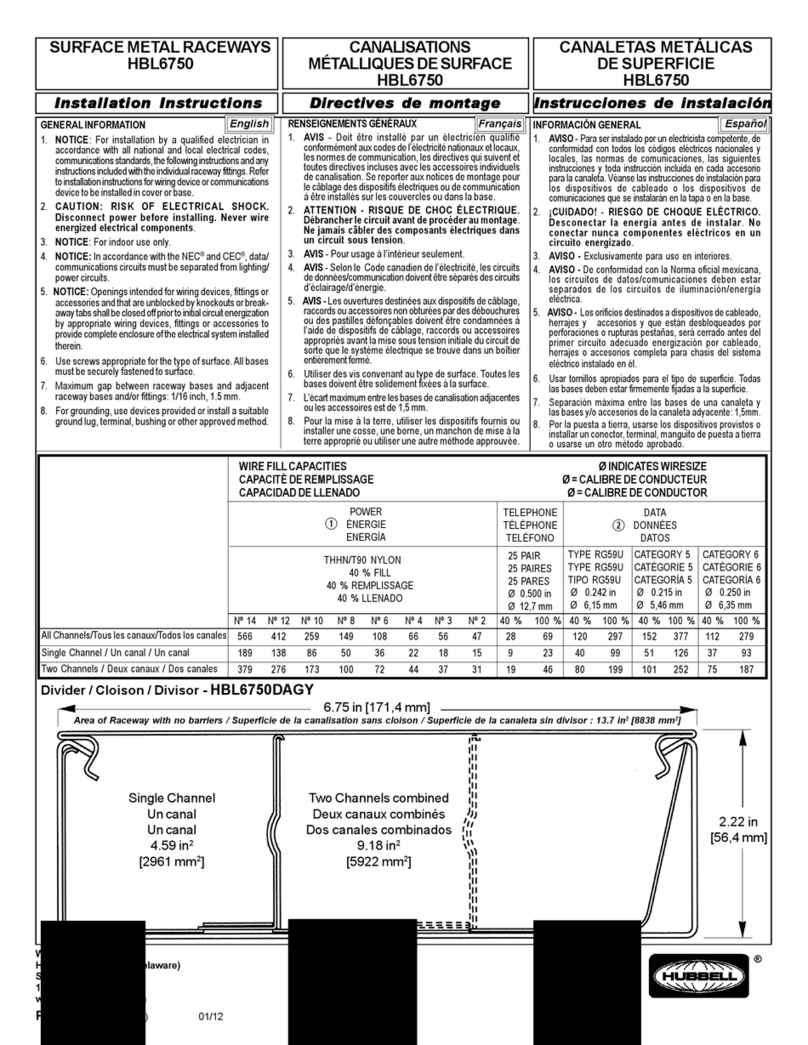

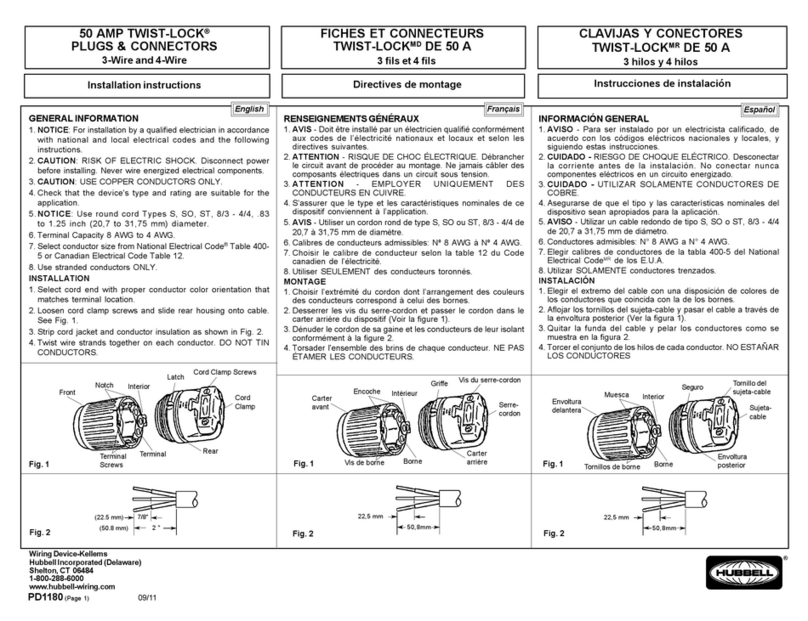

TABLE 1

DEVICE AWG/ CORD O.D.

TYPE COND RANGE (in)

200 Amp 1/3 to 1.00 - 2.50

Style 2:2P+G 250 kcmil/3

200 Amp 1/4 to 1.00 - 2.50

Style 1:3P 250 kcmil/4

Style 2:3P+G

200 Amp 1/5 to 1.00 - 2.50

Style 1:4P 250 kcmil/5

A wire pattern MUST be used so that the same color insulated conductor is put into the same

numbere contact opening in all plugs, receptacles & cable connectors in the system. This

requirement provides correct polarity for the system to avoid causing personal injury and/or

equipment damage.

CAUTION

The equipment grounding path between the receptacle housing and back box must be

established and verified. Star washers are included for use under the mounting bolt

heads to help achieve ground continuity .

CAUTION

DO NOT connect to power before conducting the following Electrical T ests:

• Test continuity of wiring to verify correct phasing and grounding connections.

• Measure insulation resistance to be sure the system does not have any short circuits or

unwanted grounds.

CAUTION