Page 2of 5

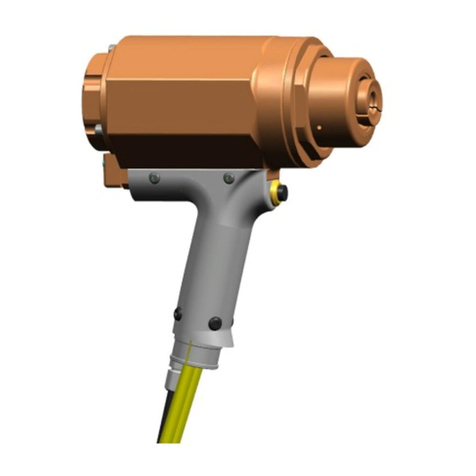

Preparation for use

An air supply of 90-100 psi must be available (6, 3kp/cm2). Every attempt should be made to furnish 90 psi

of clean dry air to the tool. Connect the tool to an air supply equipped with a filter, regulator and lubricator.

If no lubricator is available, pour a small quantity of clean light machine oil into air inlet (43). Press tool

trigger a few times and observe spindle retraction. Attach the nose assembly as shown on the applicable

Nose Assembly Data Sheet.

Operation

Place the pin in the prepared hole and the collar over the pin. Push the tool with attached nose assembly

over the pintail until the tool nose touches the collar. Depress trigger and hold it until the pintail is

separated and release the trigger. The nose will eject automatically. Blind Fasteners may be placed in the

work hole or in the end of the nose assembly. In either case, the tool must be held firmly and at right angle

to the work. Depress the trigger and repeat, if necessary, until the Fastener is installed and the pintail

breaks off.

Maintenance

Regular inspection and immediate repair of minor faults will maintain the tool and nose assembly at its

highest operating efficiency and eliminates unnecessary breakdowns. Daily, before putting the tool into

service, observe the following practice:

Always blow out the airline to clear it of all accumulated dirt or water before connecting air hose to tool. If

the tool is in continuous use, remove the air hose and lubricate the tool with a few drops of light oil every

two or three hours. Nose assemblies should be cleaned periodically. Check completeness according to the

applicable Nose Assembly Data Sheet.

Do not abuse the tool by dropping it, using it as a hammer or otherwise causing unnecessary wear and tear.

Disassembly and assembly

1. Disconnect air hose and remove nose assembly.

2. Unscrew cylinder cap (51) with wrench.

3. Pull out air piston (58) in a straight line with suitable pliers.

4. Remove adapter (4)

5. Unscrew rear gland (21), remove spring (18) and push out pull piston (15).

6. Push out slotted pin (22 & 47) and remove trigger linkage.

7. Unscrew air inlet (41) and remove seat (40) and throttle valve assembly.

8. Push out slotted pin (46), unscrew lock nut (48) with 32mm socket, and separate handle (1) from

cylinder (45).

Before assembling, inspect all parts and replace if necessary. Clean all parts thoroughly with mineral spirits

and lubricate with Lubriplate No. 1300AA (Huck Part Number: 502723).

A good practice to follow is to replace all O-Rings when the tool is disassembled for any reason. Then

assemble, taking care not to damage O-Rings, handle and cylinder housing.