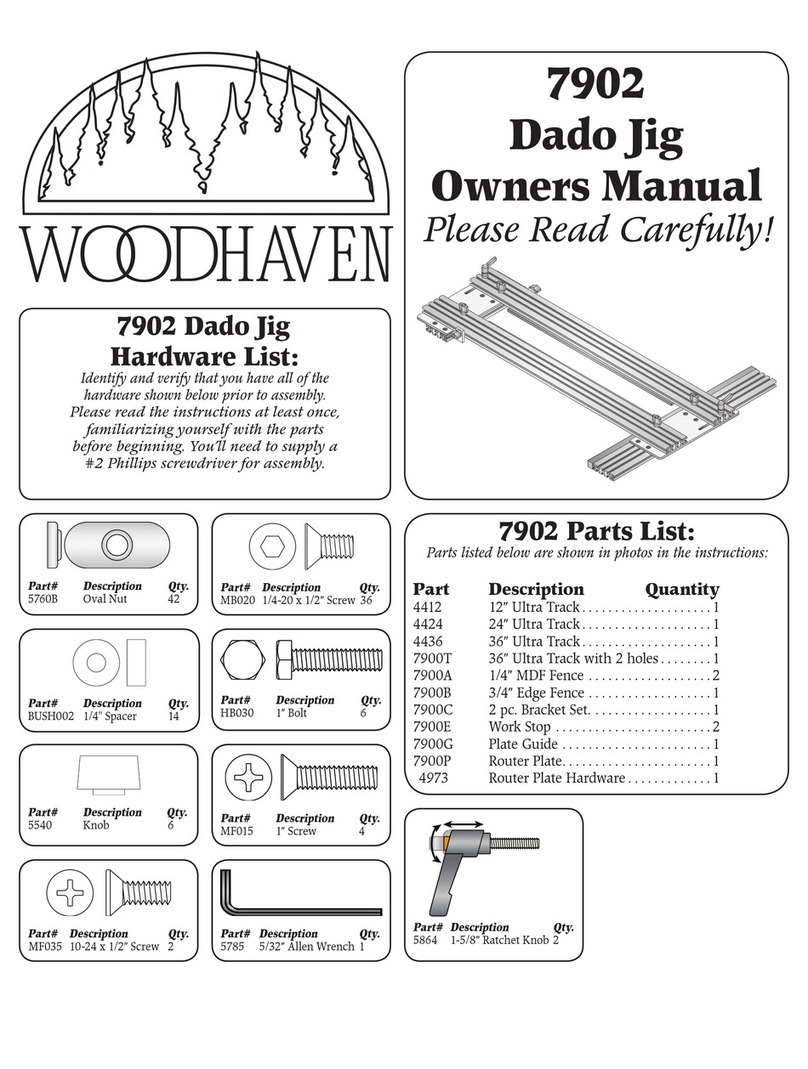

3

BEFORE BEGINNING

Identify and verify that you have all the parts listed. Read

the instructions at least once, familiarizing yourself with the

parts, before beginning assembly.

ASSEMBLY INSTRUCTIONS

Set one of the Side/Arm assemblies upright on a bench

with the 45º scale mark facing you. Align the pointer in the

Arm with the 0º mark on the scale on the top of the Side. Insert

a pin (Ringpin1) through the 0º hole in the Side and into the

hole in the Arm. This will hold the Arm in place for assembly.

Repeat for the other Side/Arm assembly. See fig. 1.

Install a brass washer (WB002), followed by a nylon

washer (WN002) on the ratchet handles with the 1-1/8" stud

(5860-1.5). Slide another nylon washer (WN002) between the

Arm and Side. A credit card will slip between the Arm and

Side to help position the washer. The washer must be aligned

with the curved slot in the Side and the threaded hole in the

Arm. See fig. 2.

Insert the ratchet handle/washers thru the curved slot in the

Side and thread it into the Arm. Make sure there is a nylon

washer between the Arm and Side. Lightly tighten. Repeat for

the other Side/Arm assembly.

Set the router mounting block on a bench so that one of

the grooved ends is facing up with the router block clamping

knob facing away from you and to the bottom.

Insert a 1-1/8" barrel nut (5791B) into hole "A" in the face

of the router block (see part drawing of 1425B). Use a small

screwdriver to align the hole in the barrel nut with the hole in

the router block. See fig. 3, Step 1.

Install a 1/2" spacer (PS001) on the ratchet handle with 1-

5/8" stud (5860-2). Place the Arm of the right hand Side/Arm

assembly in the groove in the router block. Install the ratchet

handle with spacer thru the slot in the Arm and into the barrel

nut in the router block. Lightly tighten. Repeat for the opposite

side. See fig. 3, Step 2.

Set the completed router block/side/arm assembly on the

labeled side (non countersunk side) of the router plate as shown.

See fig. 4. The opening in the router block should be over the

bit opening in the router plate. It is critical to have the angle set

to "0º" and the router block fully lowered on the arms before

proceeding. Tighten all knobs securely before proceeding.

Align the six holes in the router plate with the slotted

holes in the sides. Insert a barrel nut (5793B), with the slot fac-

ing inward, in each of the slotted holes in the sides. Fasten the

router plate to the assembly using the flat head screws

(MF015), inserted thru the router plate and into the barrel nuts.

Get all six screws started before fully tightening them.

See fig. 4.

This is the right

hand Side/Arm

assembly

Step 1: 5791B

Barrel Nut

into hole "A"

Ringpin1

WN002 - Both locations

Attach ratchet handle

thru sides, into arms.

Fig. 1

Fig. 4

Fig. 3

Fig. 2

WB002

5860-2

5860-2

5793B

MF015

PS001

Arm

Side

Step 2: Arm

fits in groove

of the Router

Block