201246 11/04

In the U.S.:1-800-558-5234 and Canada: 1-800-284-8339

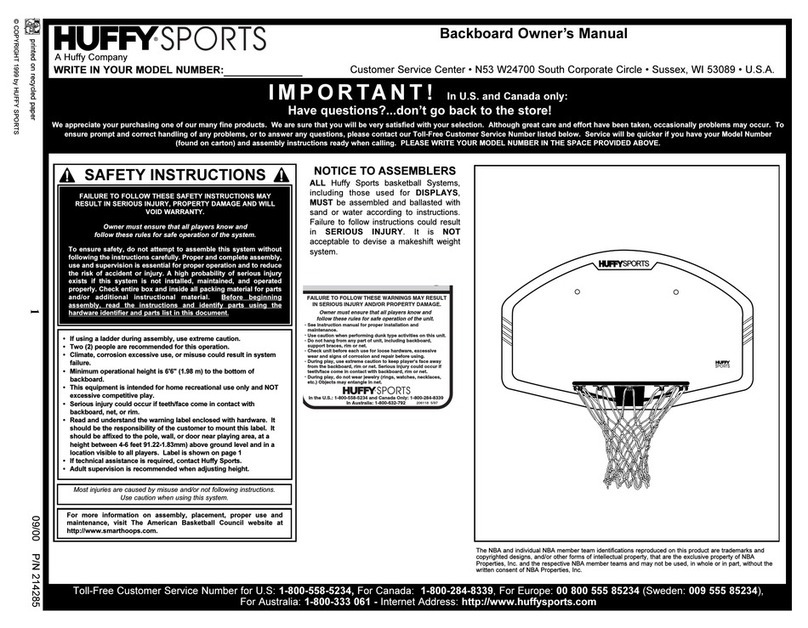

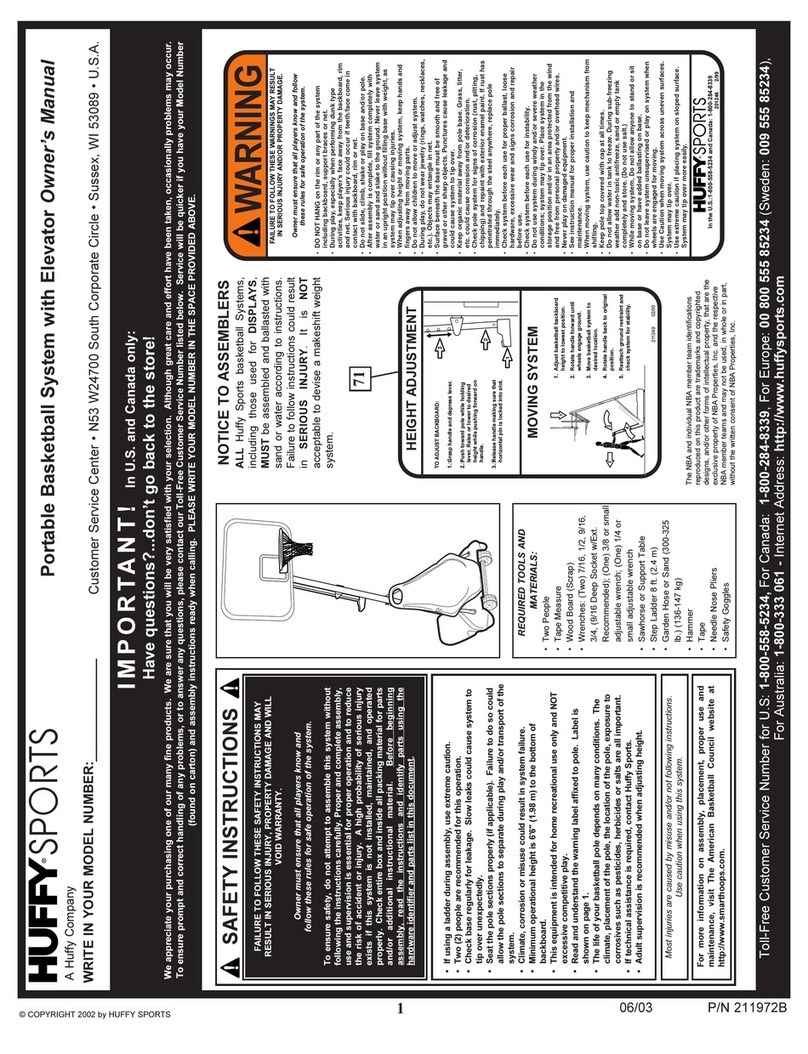

FAILURE TO FOLLOW THESE WARNINGS MAY RESULT IN

SERIOUS INJURY AND/OR PROPERTY DAMAGE.

Owner must ensure that all players know and follow these

rules for safe operation of the system.

WARNING

•

DO NOT HANG on the rim or any part of the system including

backboard, support braces or net.

•

During play, especially when performing dunk type activities,

keep player's face away from the backboard, rim and net.

Serious injury could occur if teeth/face come in contact with

backboard, rim or net.

•

Do not slide, climb, shake or play on base and/or pole.

•

After assembly is complete, fill system completely with water or

sand and stake to the ground. Never leave system in an upright

position without filling base with weight, assystem may tip over

causing injuries.

•

When adjusting height or moving system, keep hands and

fingers away from moving parts.

•

Do not allow children to move or adjust system.

•

During play, do not wear jewelry (rings, watches, necklaces,

etc.). Objects may entangle in net.

•

Surface beneath the base must be smooth and free of gravel or

other sharp objects. Punctures cause leakage and could cause

system to tip over.

•

Keep organic material away from pole base. Grass, litter, etc.

could cause corrosion and/or deterioration.

•

Check pole system for signs of corrosion (rust, pitting,

chipping) and repaint with exterior enamel paint. If rust has

penetrated through the steel anywhere, replace pole

immediately.

•

Check system before each use for proper ballast, loose

hardware, excessive wear and signs corrosion and repair before

use.

•

Check system before each use for instability.

•

Do not use system during windy and/or severe weather

conditions; system may tip over. Place system in the storage

position and/or in an area protected from the wind and free from

personal property and/or overhead wires.

•

Never play on damaged equipment.

•

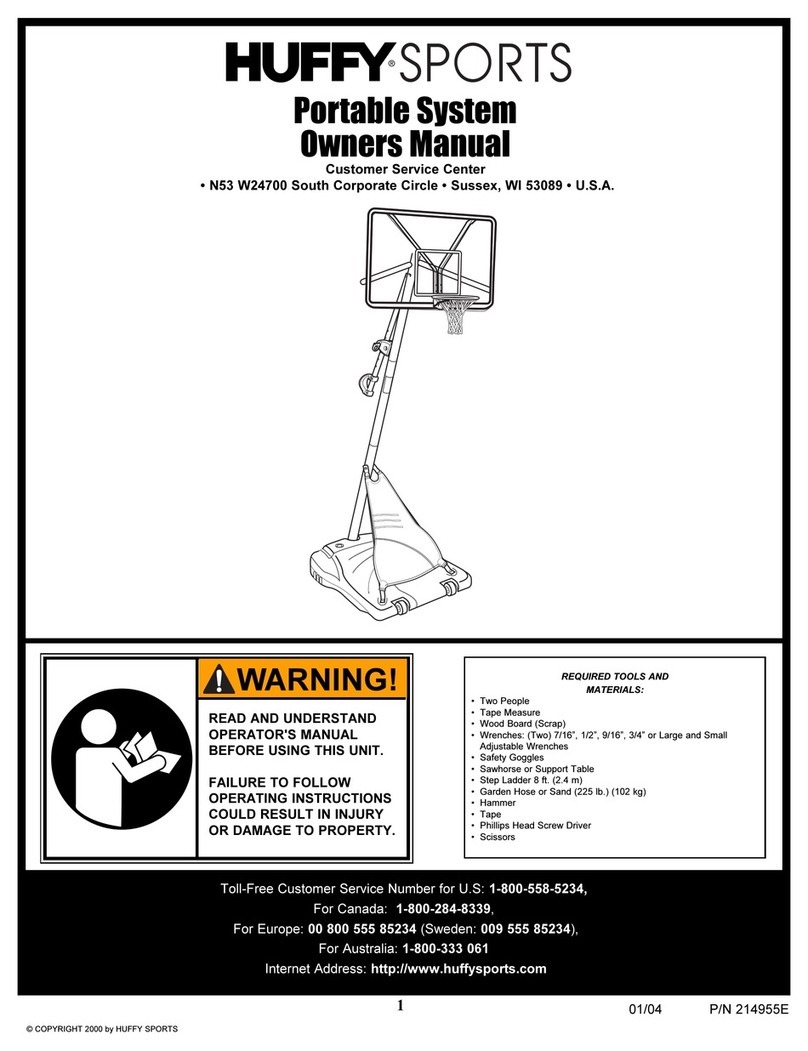

See instruction manual for proper installation and maintenance.

•

When moving system, use caution to keep mechanism from

shifting.

•

Keep pole top covered with cap at all times.

•

Do not allow water in tank to freeze. During sub-freezing

weather add non-toxic antifreeze, sand or empty tank

completely and store. (Do not use salt.)

•

While moving system, do not allow anyone to stand or sit on

base or have added ballasting on base.

•

Do not leave system unsupervised or play on system when

wheels are engaged for moving.

•

Use Caution when moving system across uneven surfaces.

System may tip over.

•

Use extreme caution if placing system on sloped surface.

System may tip over more easily.