04/03 P/N 211953A

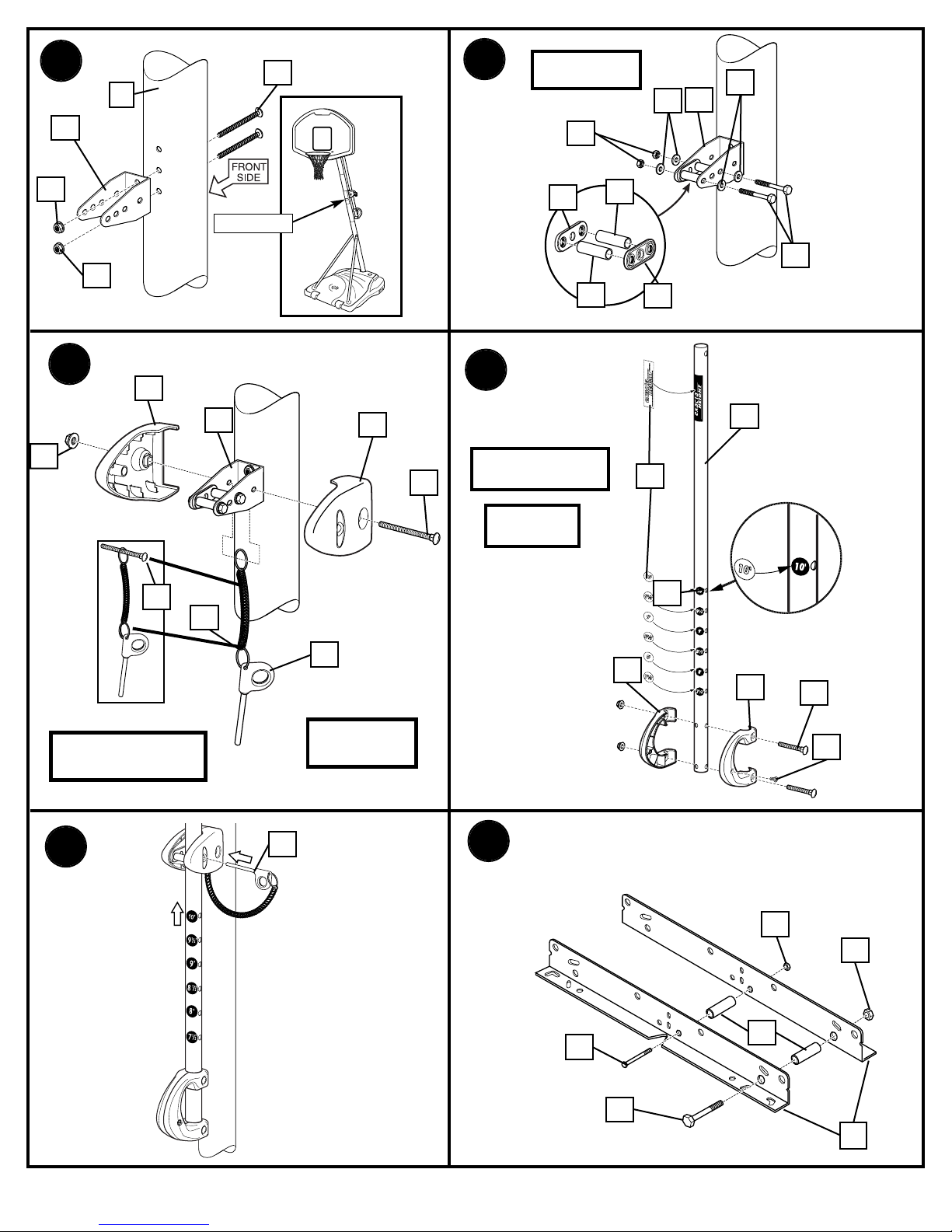

5

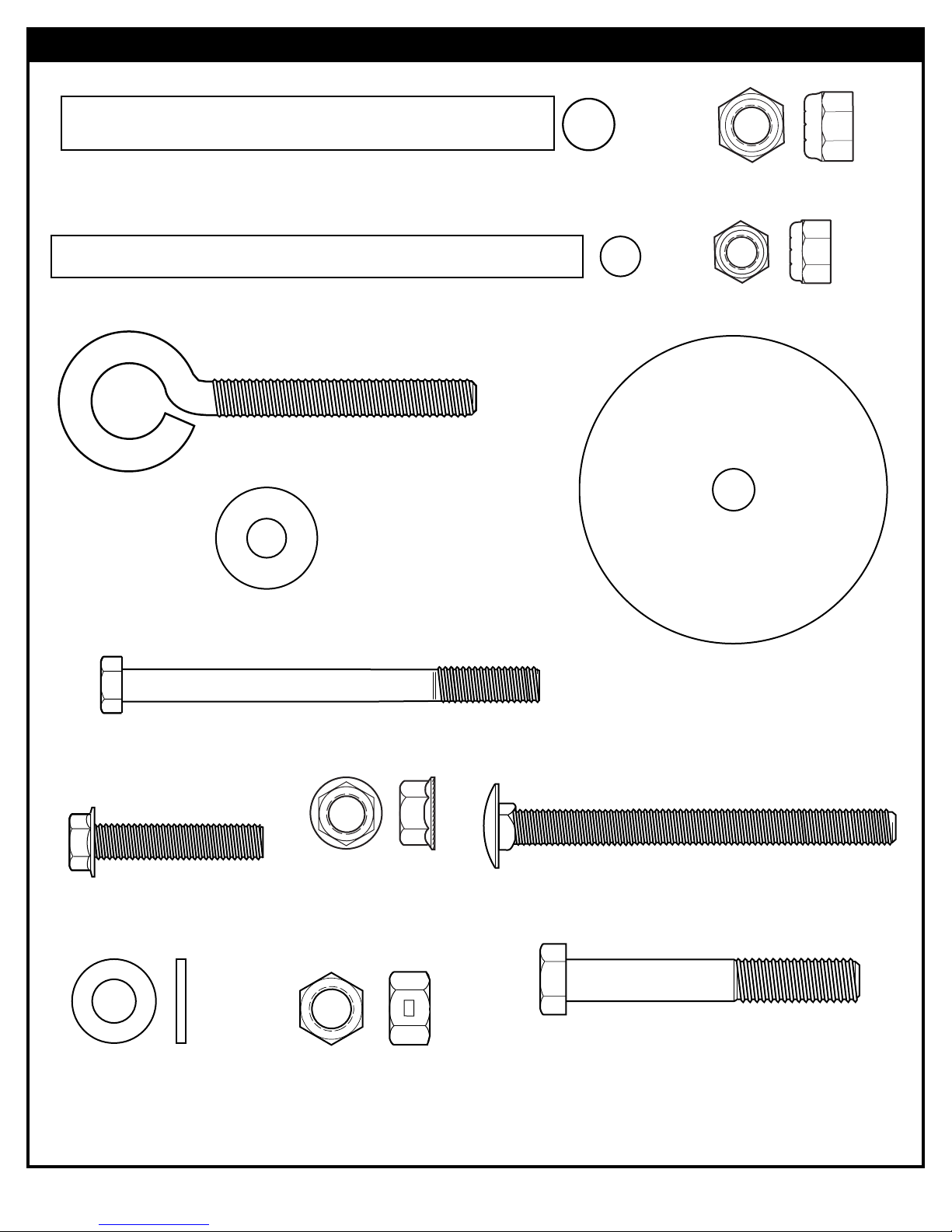

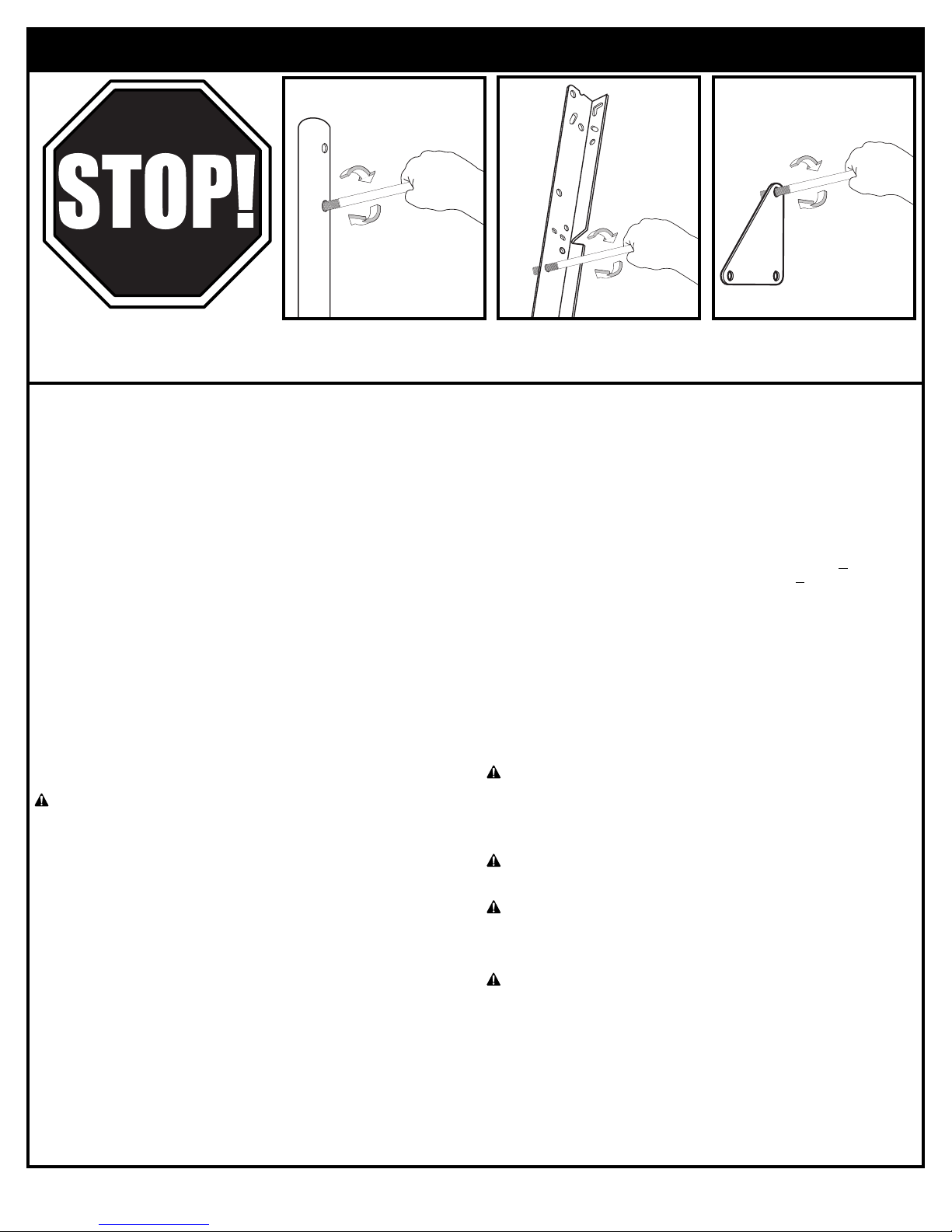

BEFORE YOU START!

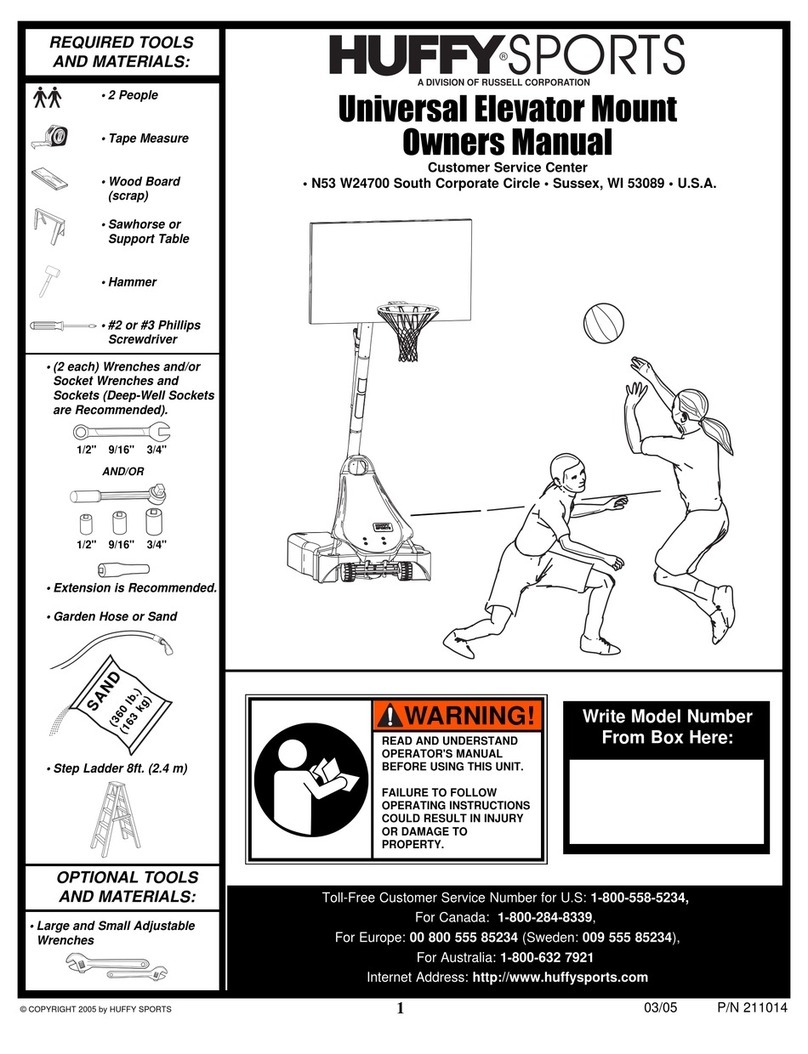

To ensure opt mal playab l ty of backboard system, a close tolerance f t between the elevator components and

hardware s requ red. Test f t large bolts nto large holes of elevator tubes, backboard brackets and tr angle plates.

Carefully rock them n a c rcular mot on to ream out any excess pa nt from holes f necessary.

ENGLISH INSTRUCTIONS

IMPORTANT! WRITE MODEL NUMBER FROM BOX ONTO PAGE 1 OF

THIS OWNERS MANUAL

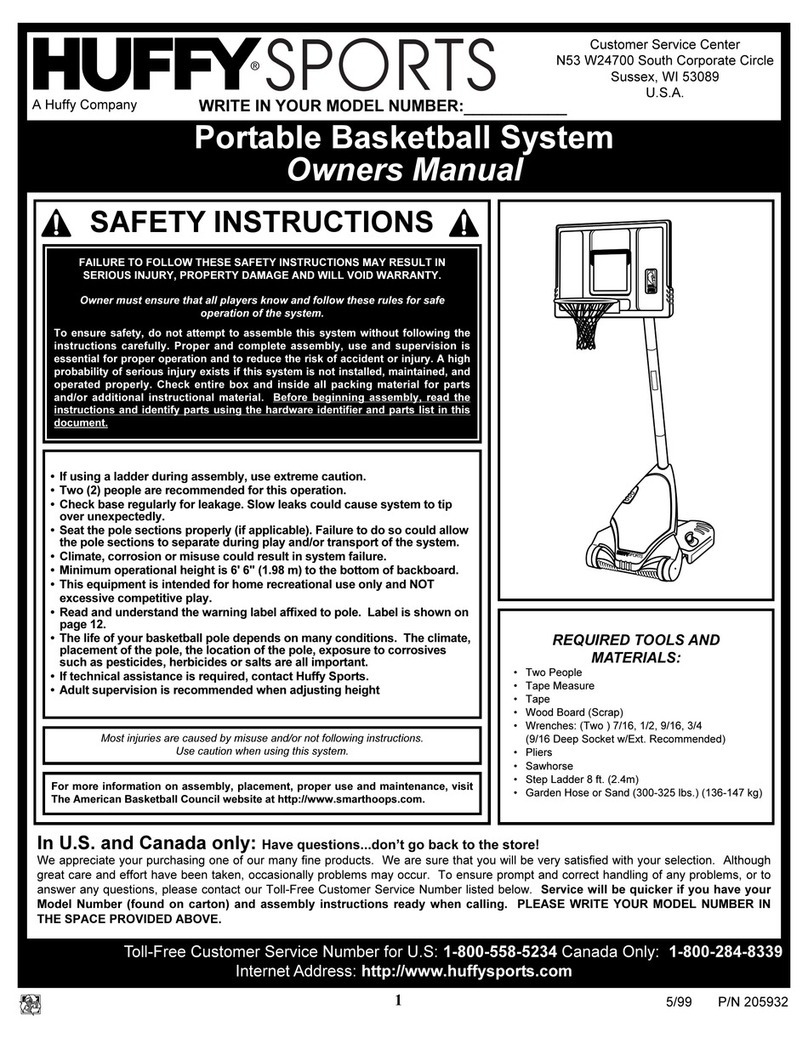

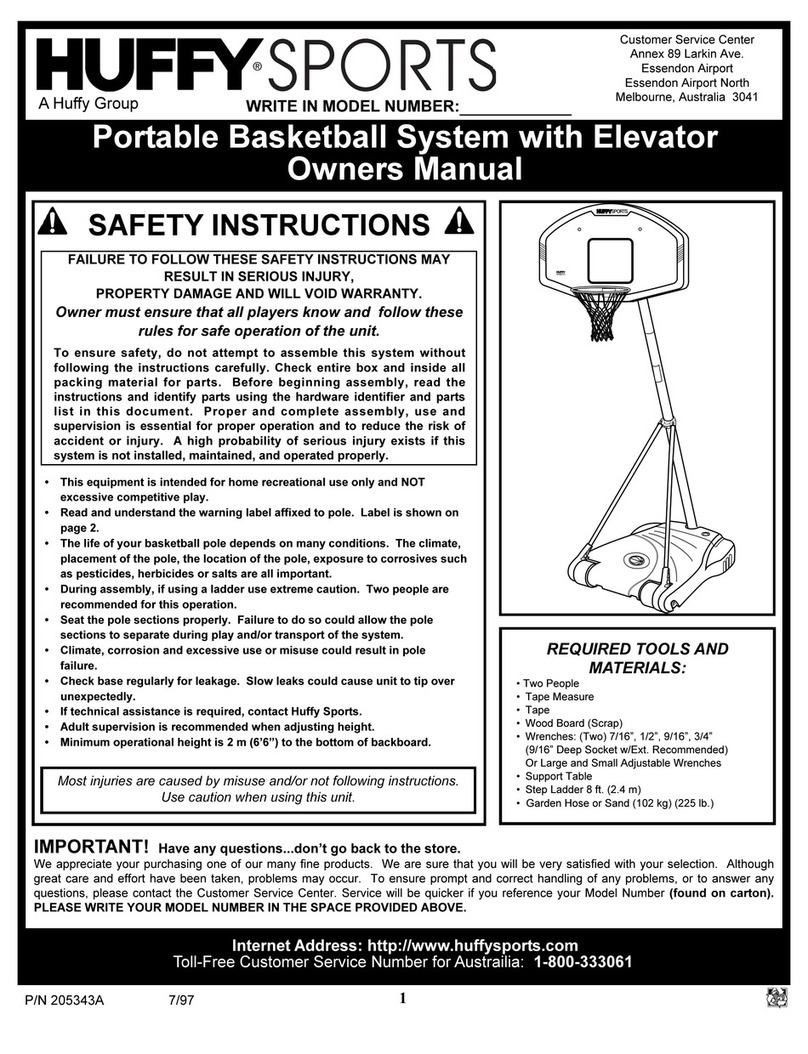

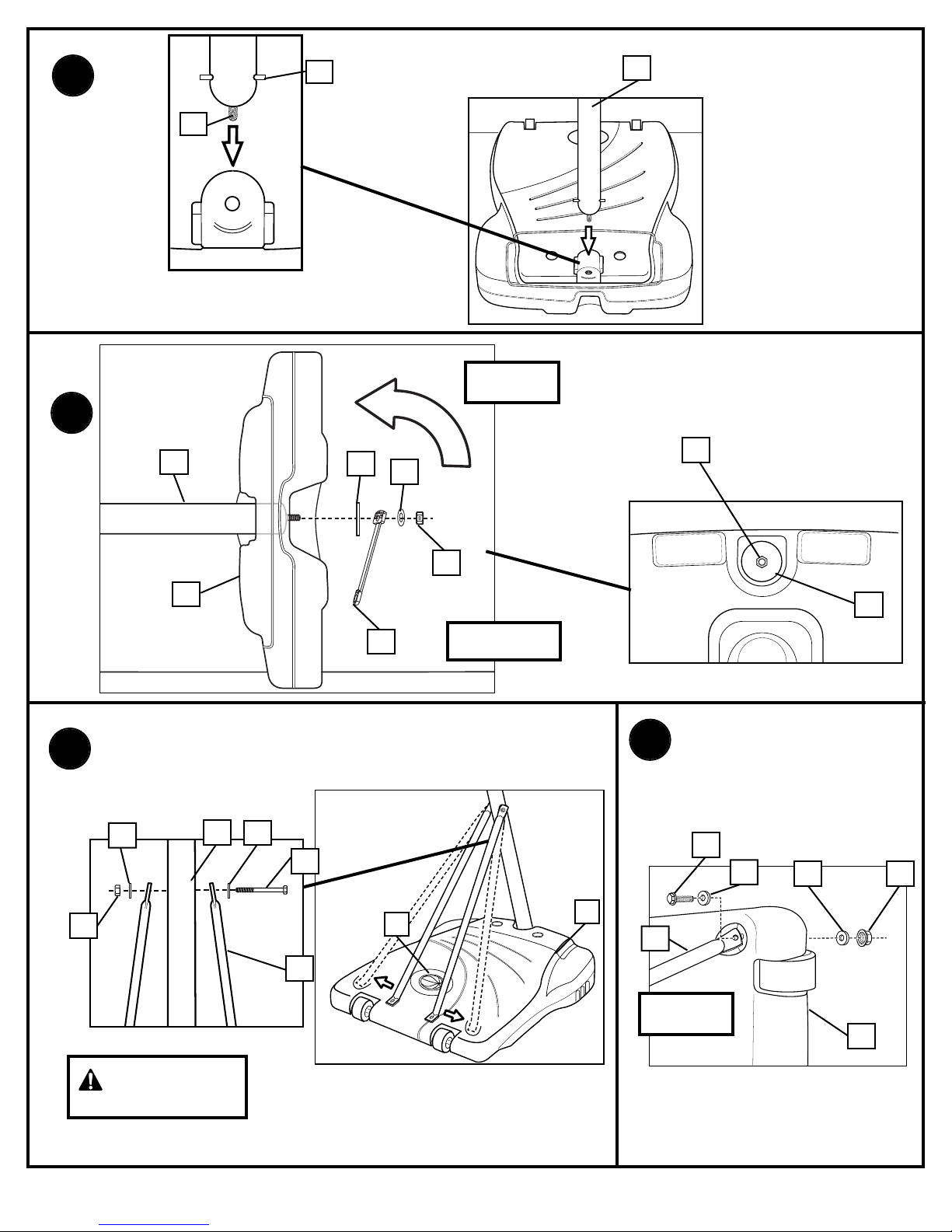

1. Remove all contents from underside of tank Keep tank (1) bottom side

up

2. Insert axle rod (2) through wheel (3), as shown Secure wheel assembly

to tank (1) by tapping wheel downward with hammer, snapping it into

position Repeat for opposite side, then carefully, turn tank (1) over

3. Mark pole sections with tape as shown

4. IMPORTANT! Center al gnment slot of m ddle pole sect on (5) n a

lower hole of top pole sect on (4) as shown. While maintaining

alignment, bounce pole top (4) and middle section (5) together as shown

until they no longer move toward taped reference mark Upright

assembly NOTE: Pole sections should have a

3-1/2” (9 cm) minimum overlap

5. IMPORTANT! Center al gnment slot of lower pole sect on (6) n a

lower hole of m ddle pole sect on (5) as n step 4. While maintaining

alignment, bounce assembly and lower section (6) together as shown

until they no longer move toward taped reference mark NOTE: Pole

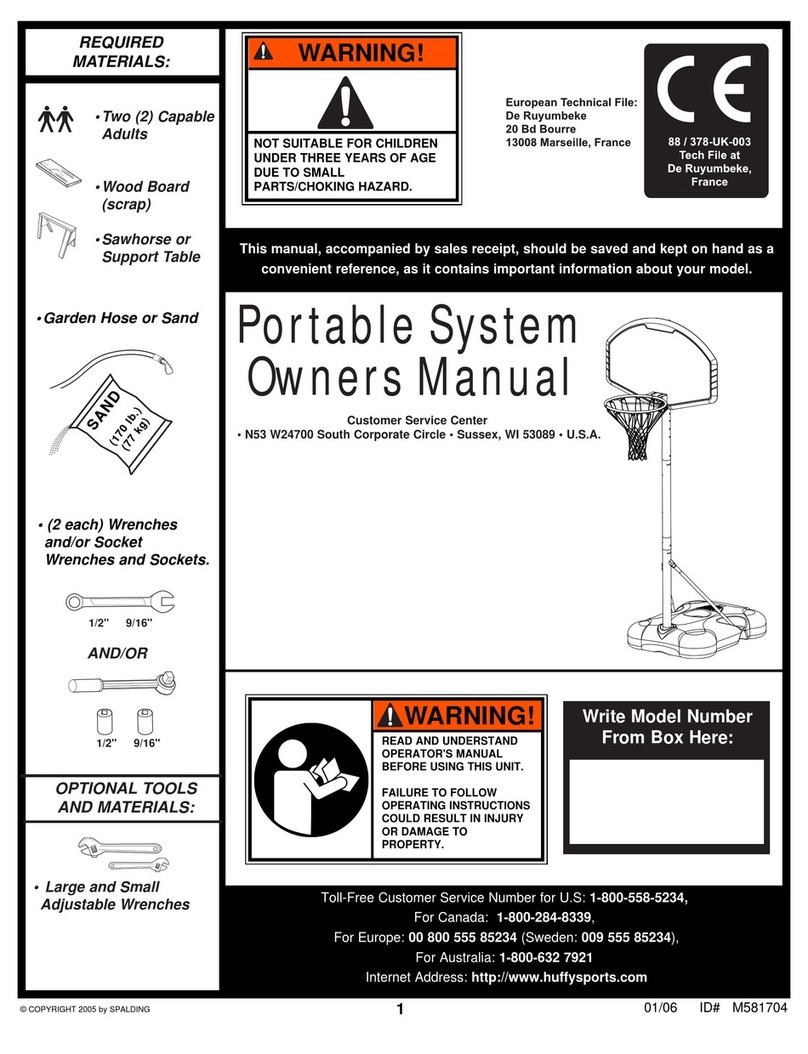

sections should have a 3-1/2” (9 cm) minimum overlap

6. Install rod (7) through holes in bottom pole section (6) and eyebolt (8)

7. Insert pole assembly into tank assembly as shown

8. Carefully place unit on its side Secure pole bottom (6) to tank with

anchor strap (52), washers (9 & 13) and nut (10) as shown Upright unit

NOTE: Keep unnecessary pressure off of the pole assembly when in this

position Two people recommended for this procedure IMPORTANT!

Do not over t ghten, w ll crack tank.

9. Secure strut tubes (11) to bottom pole section (6) as shown

WARNING: TIGHTEN BOLT (14) IN LOCKNUT (12) UNTIL FLUSH

(EVEN) WITH LOCKNUT’S OUTER EDGE.

10. Once again, carefully place unit in the side position and secure strut (11)

to tank (1) as shown Completely tighten Repeat for opposite side

Upright unit NOTE: Keep unnecessary pressure off of the pole assembly

when in this position Two people recommended for this procedure

11. Install pole mount (17) bracket with carriage bolts (18) as shown Tighten

flange nuts (16) completely

12. Attach spacers (22, 23) to pole mount bracket (17) with bolts (21),

washers (19), and nuts (20) as shown IMPORTANT! T ghten unt l

washers (19) no longer move.

13. Attach covers (24) onto pole mount bracket (17) with carriage bolt (25)

and nut (16) as shown

IMPORTANT: Loop end of p n lanyard (27) over carr age bolt (25)

dur ng th s assembly. NOTE: Assemble lanyard (27) to locking pin (26)

as shown

14. Apply logo and height indicator labels (29) to adjustment rod (28) as

shown Attach handle parts (32, 33) to adjustment rod with screw (31),

carriage bolt (30), and flange nut (16) as shown IMPORTANT:

Ind cator labels should be appl ed as close to holes as poss ble to

prevent labels from be ng damaged dur ng he ght adjustment.

NOTE: Holes in adjustment rod allow for either rear access or side

access

15. Insert handle assembly through pole mount assembly as shown Lock

pole assembly in place at the 10’ (3 05 m) mark with pin (26)

16. Install spacers (36) onto backboard brackets (34) with bolts (37, 21) and

lock-nuts (35, 20) as shown

17. Assemble lower elevator tubes (40) as shown

IMPORTANT! It s necessary for all parts to be nstalled for th s

mechan sm to work safely and properly. NOTE: Test fit bolts into

holes of brackets (34) and carefully rock them in a circular motion to

ream out paint from holes if necessary

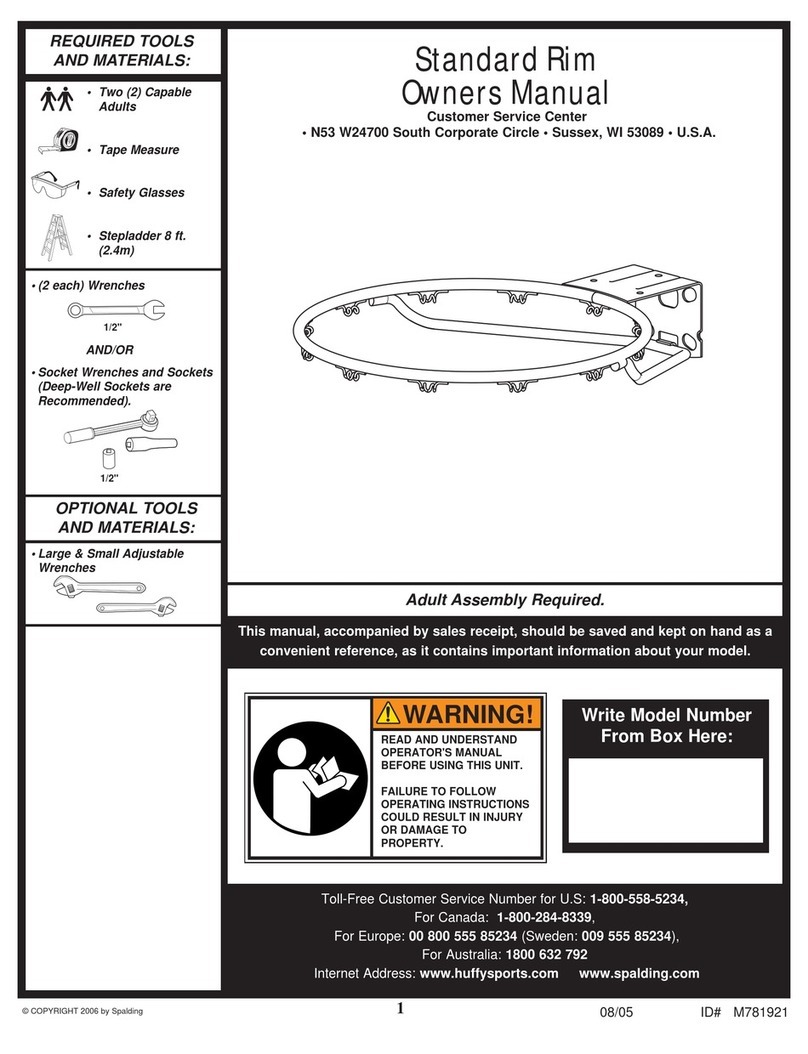

18. Starting with nuts (16) flush against bracket (34), secure rim (42) and

bracket to backboard IMPORTANT! For spr ng loaded r m assembly,

refer to nstruct ons ncluded w th r m hardware. NOTE A: Do not

use washers here on spring return style rim NOTE B: Mounting nuts and

bolts supplied with rim hardware

19. Bend bracket (34) to line up with holes in backboard and secure

20. Assemble upper elevator tubes (43) to backboard brackets (34)

21. Support pole on sawhorse Attach backboard assembly to top pole

section (4) as shown Then install pole cap (46) NOTE: Two people are

recommended for this step Use caution; elevator assembly is heavy

22. Install upper elevator tubes (43) to triangle plates (45) as shown

23. Install handle assembly to lower elevator tubes (40) using bolt (47),

spacers (38, 55), and nut (39) as shown NOTE: Before going on to next

step, set adjustable system assembly to the 10’ (3 05 m) setting

24. Insert bolt (47) through left side upper elevator tube (43), then stretch

spring (41) onto bolt (47) Insert bolt (47) through right side upper

elevator tube (43) and secure with nut (39)

WARNING: USE EYE PROTECTION WHEN INSTALLING SPRINGS.

25. Roll completed assembly to desired playing area Secure assembly to

ground using anchor strap (52) and tie down stake (53) Fill tank with

water (approx 30 gallons (115 Liters)) or sand (approx 255 lbs (113 kg))

and snap cap (49) in place IMPORTANT! Add two gallons (7.6 L ters)

of non-tox c ant freeze n sub-freez ng cl mates.

WARNING: DO NOT LEAVE ASSEMBLY UNATTENDED WHEN

EMPTY, MAY TIP OVER.

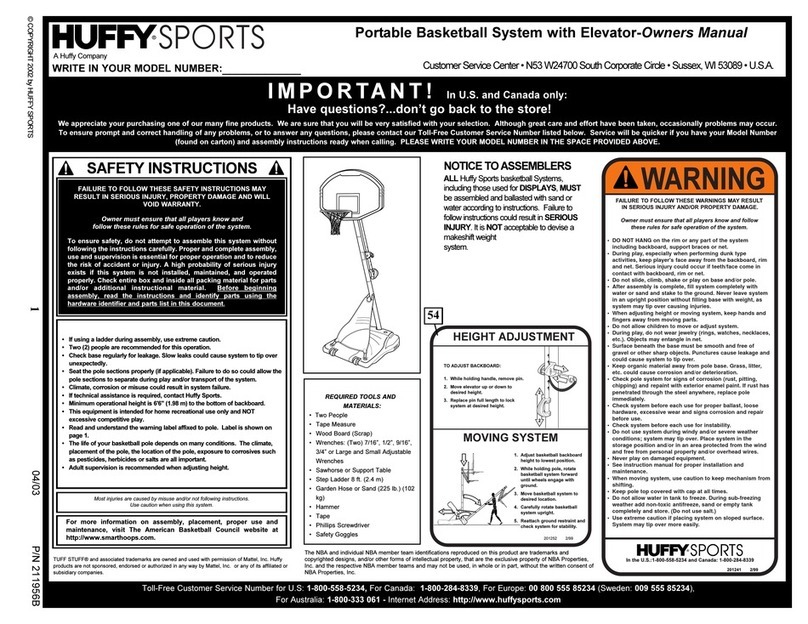

26. While holding handle, remove pin (26)

WARNING: DO NOT ALLOW CHILDREN TO ADJUST HEIGHT.

27. Move elevator up or down to desired height

28. Replace pin (26) full length to lock system at desired height

29. Apply height and transport label (54) to front of pole as shown

Regulation rim height is 10 feet (3 05m)

WARNING: USE OF THIS PRODUCT WITHOUT PROPER

INSTALLATION OF SMART CLIPS, OR WHEN ALL SMART CLIPS

ARE NOT PRESENT COULD RESULT IN BODILY HARM. BE SURE

TO FOLLOW DIRECTIONS CAREFULLY.

30. Install net clips as shown (See illustration)

31. Install net as shown (See illustration)