6

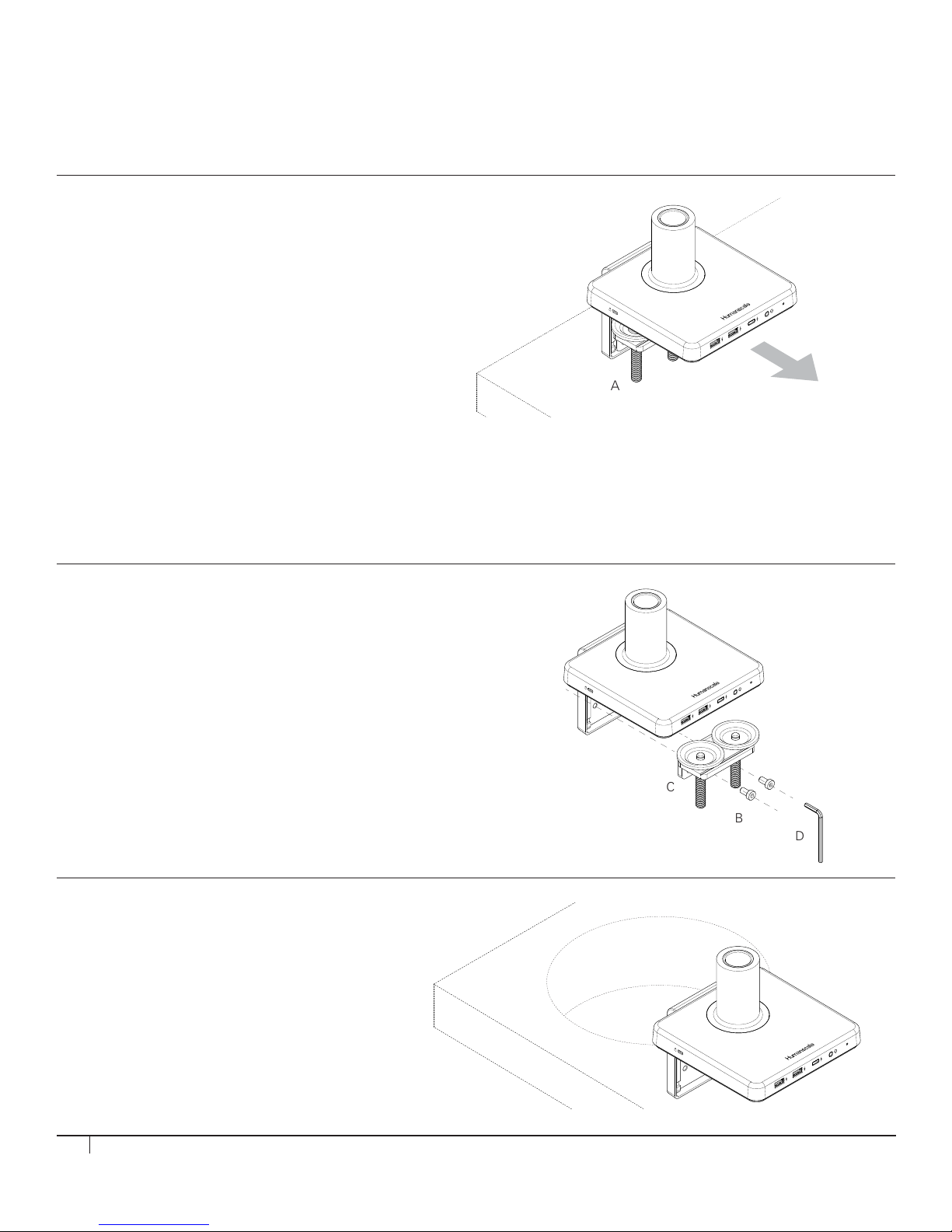

STEP 1

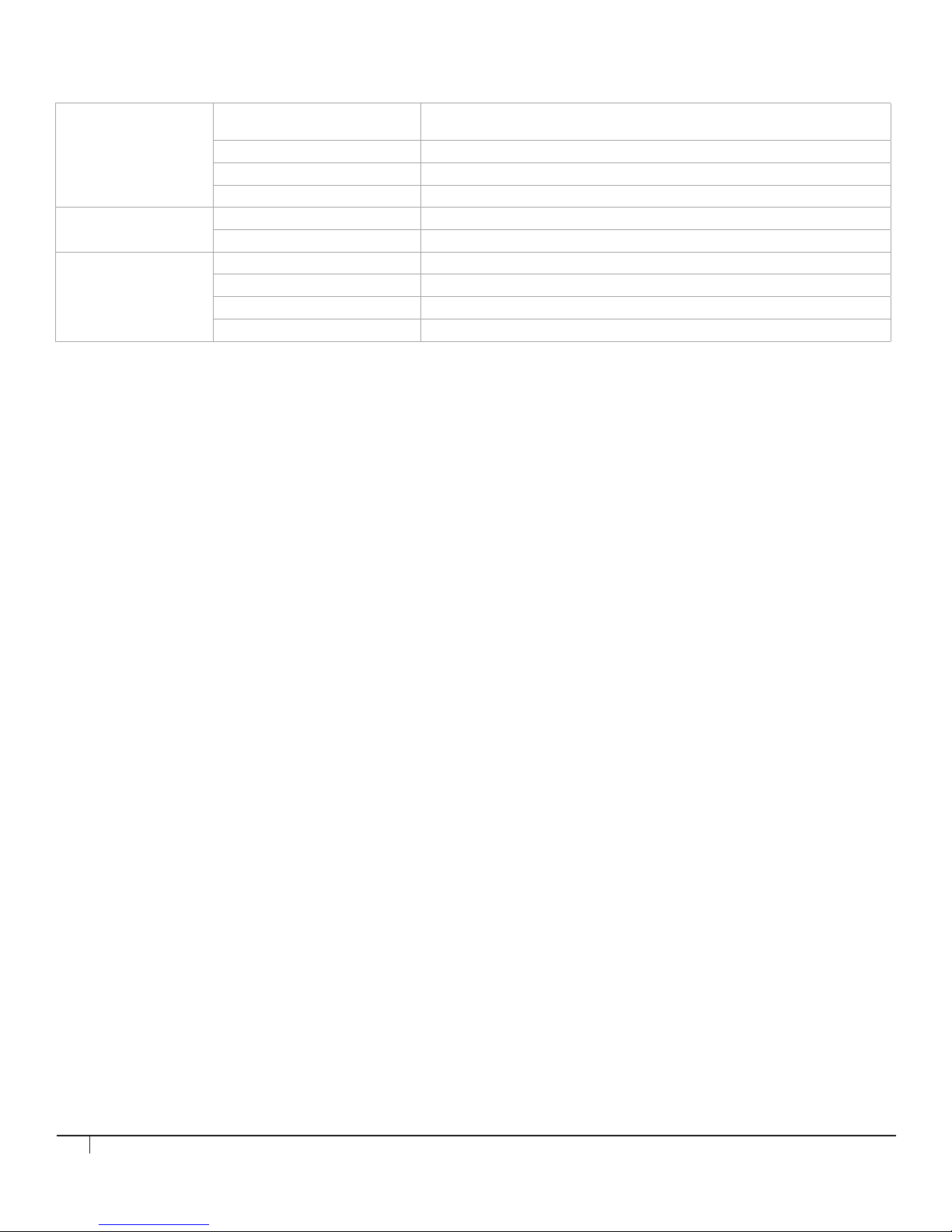

Disassemble Clamp

• Remove the two screws (fig. B) using 4 mm hex key (fig. D) and detach

the smaller clamp bracket (fig. C) from the larger bracket

INSTALLING M/POWER ONTO EDGE OF TABLE

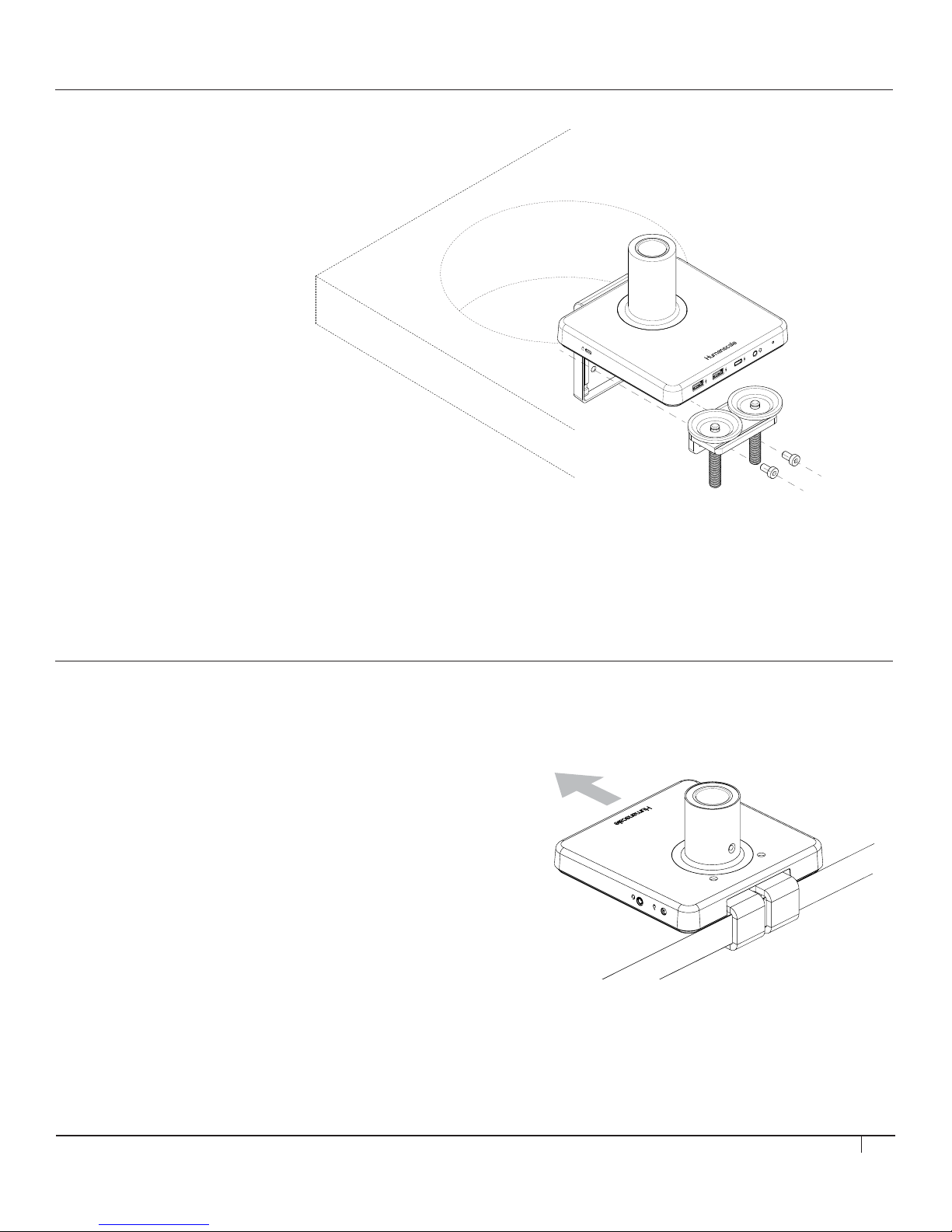

STEP 1

Place M/Power Clamp onto Table

• Slide mount against work surface edge and

fully tighten clamp screw (fig. A)

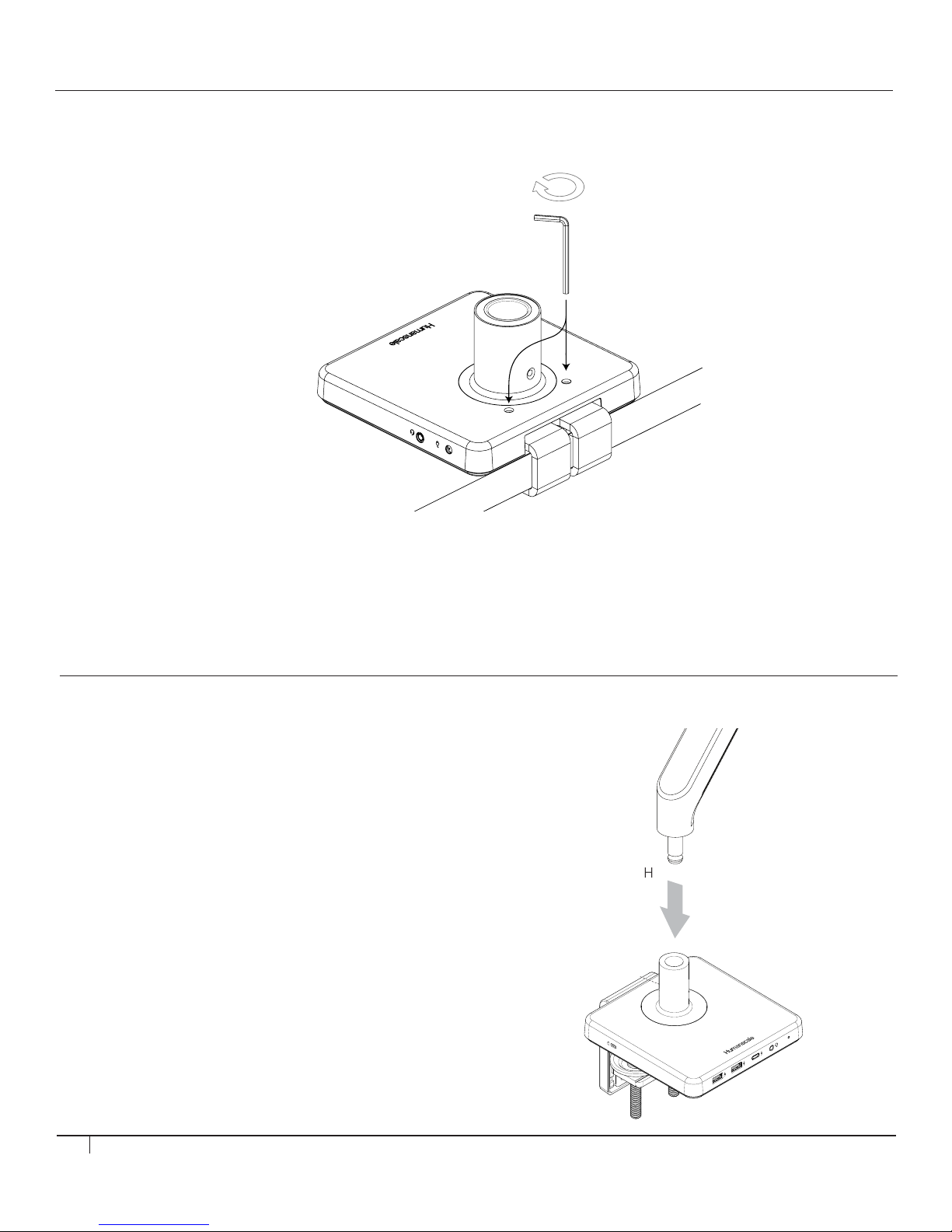

INSTALLING M/POWER THROUGH

A GROMMET HOLE OR SYSTEM FURNITURE

STEP 2

Place into Grommet Hole or System Furniture Gap

• Place the L Bracket of the M/Power through

the grommet hole and to the desired position

Note: Minimum hole diameter is 3" (76 mm)

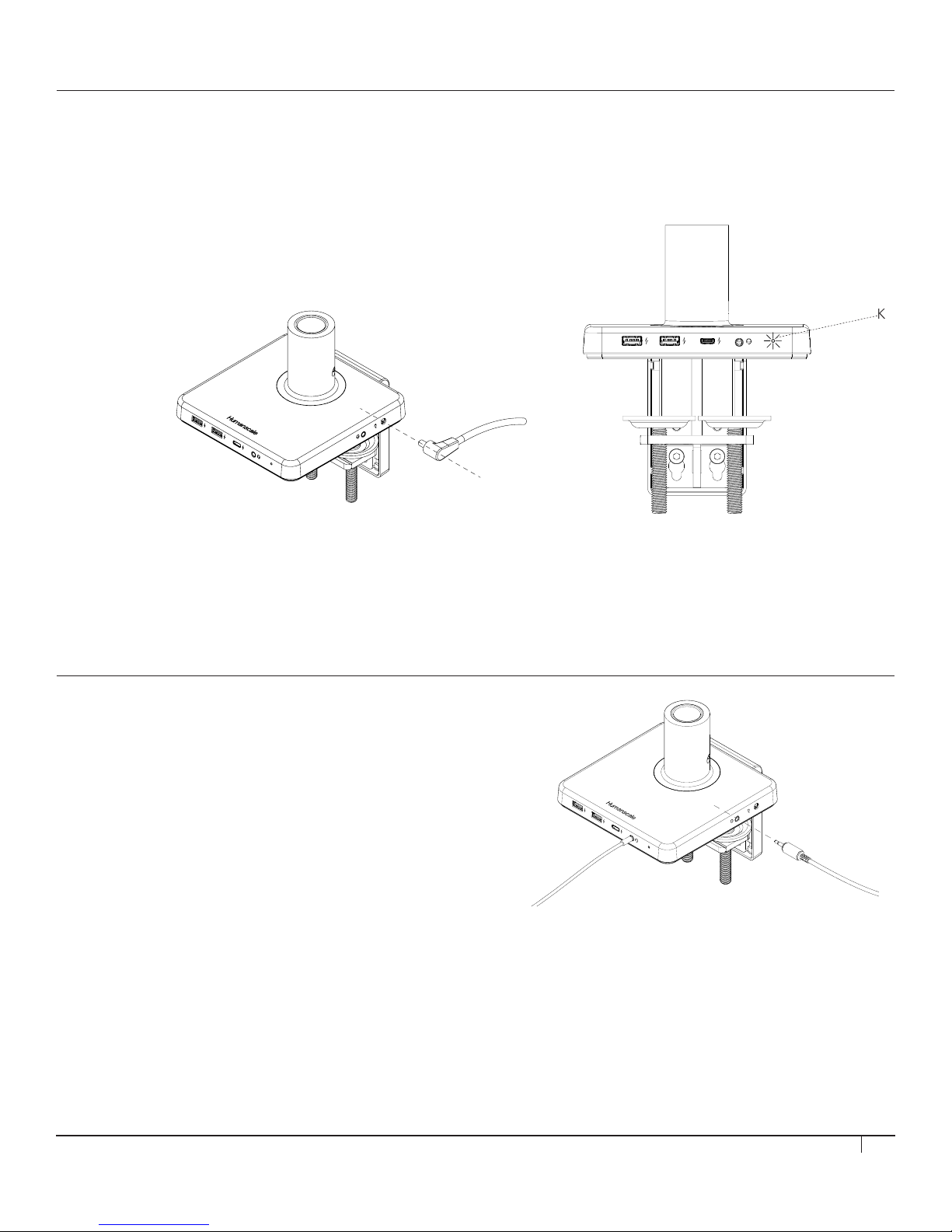

Caution: Maximum weight load of M/Power is as follows: M2.1: 15.5 lbs. M8.1: 28 lbs. M10: 40 lbs. M/Flex: 60 lbs. Total.

M10 is not to be used on M/Flex when mounted to M/Power

Do NOT exceed maximum weight limits.

When used in conjunction with M/Power, M/Flex post must be limited to 24 inches

6

STEP 1

Disassemble Clamp

• Remove the two screws (g. B) using 4mm hex key (g. D) and detach

the smaller clamp bracket (g. C) from the larger bracket

STEP 1

Place M/Power Clamp onto Table

• Slide mount against work surface edge and

fully tighten clamp screw (g. A)

INSTALLING M/POWER ONTO EDGE OF TABLE

INSTALLING M/POWER THROUGH A GROMMET HOLE

OR SYSTEM FURNITURE

STEP 2

Place into Grommet Hole or System Furniture Gap

• Place the L Bracket of the M/Power through

the grommet hole and to the desired position

Note: Minimum hole diameter is 3" (76 mm)

Caution: Maximum weightload of M/Power is as follows: M2: 20 lbs

M8: 40 lbs.

Do NOT exceed maximum weightload limits.

C

B

D

A

6

STEP 1

Disassemble Clamp

• Remove the two screws (g. B) using 4mm hex key (g. D) and detach

the smaller clamp bracket (g. C) from the larger bracket

STEP 1

Place M/Power Clamp onto Table

• Slide mount against work surface edge and

fully tighten clamp screw (g. A)

INSTALLING M/POWER ONTO EDGE OF TABLE

INSTALLING M/POWER THROUGH A GROMMET HOLE

OR SYSTEM FURNITURE

STEP 2

Place into Grommet Hole or System Furniture Gap

• Place the L Bracket of the M/Power through

the grommet hole and to the desired position

Note: Minimum hole diameter is 3" (76 mm)

Caution: Maximum weightload of M/Power is as follows: M2: 20 lbs

M8: 40 lbs.

Do NOT exceed maximum weightload limits.

C

B

D

A

6

STEP 1

Disassemble Clamp

• Remove the two screws (g. B) using 4mm hex key (g. D) and detach

the smaller clamp bracket (g. C) from the larger bracket

STEP 1

Place M/Power Clamp onto Table

• Slide mount against work surface edge and

fully tighten clamp screw (g. A)

INSTALLING M/POWER ONTO EDGE OF TABLE

INSTALLING M/POWER THROUGH A GROMMET HOLE

OR SYSTEM FURNITURE

STEP 2

Place into Grommet Hole or System Furniture Gap

• Place the L Bracket of the M/Power through

the grommet hole and to the desired position

Note: Minimum hole diameter is 3" (76 mm)

Caution: Maximum weightload of M/Power is as follows: M2: 20 lbs

M8: 40 lbs.

Do NOT exceed maximum weightload limits.

C

B

D

A