Version February 2018 EN 3

HÜRNER CNC ECO 630 User’s Manual

HÜRNER Schweisstechnik GmbH

Nieder-Ohmener Str. 26

35325 Mücke,

Germany

Contents

1 Introduction ........................................................................................................ 5

2 Safety Messages .................................................................................................. 5

2.1 The User's Manual............................................................................................... 5

2.2 Explaining Icons .................................................................................................. 5

2.3 Operating the Product Safely............................................................................. 5

2.4 Owner and Operator Obligations...................................................................... 6

2.5 Intended Use ....................................................................................................... 7

2.6 Required Worksite Conditions ........................................................................... 7

2.7 Warranty.............................................................................................................. 7

2.8 Transport and Storage........................................................................................ 7

2.9 Identifying the Product ...................................................................................... 7

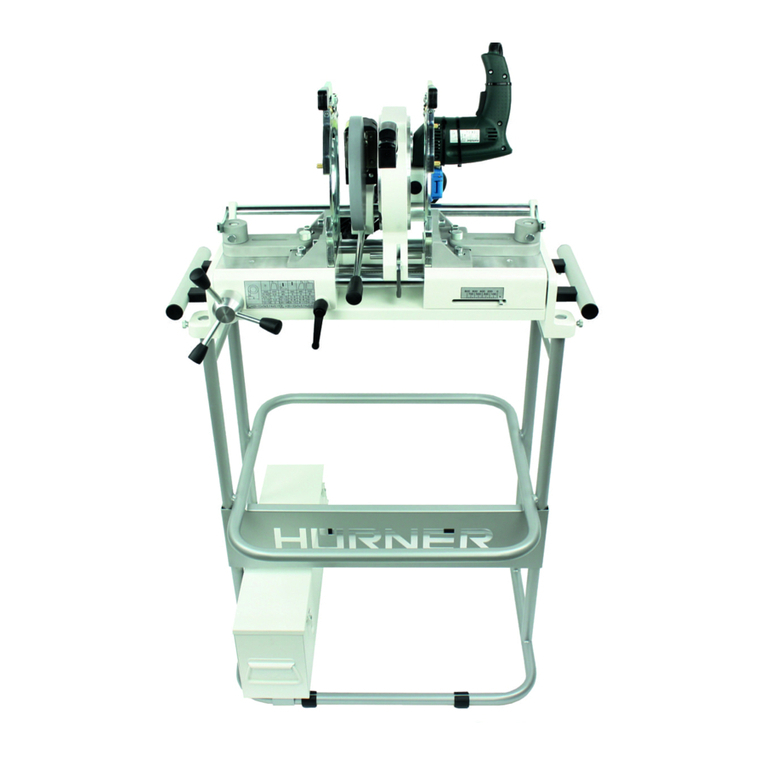

3 Understanding the Machine .............................................................................. 7

3.1 Included Components......................................................................................... 8

3.2 Control Panel....................................................................................................... 8

3.3 Connectors........................................................................................................... 9

3.4 TechnicalSpecications ...................................................................................... 9

3.5 Overview of the Welding Process .................................................................... 10

4 Operation .......................................................................................................... 11

4.1 Start of Operation, Switching the Machine on............................................... 11

4.2 SettingtheDefaultCongurationoftheMachine........................................ 12

4.3 Entering Traceability Data................................................................................ 15

4.4 Entering Pipe or Fitting Parameters ................................................................ 15

4.5 Performing the Welding Process...................................................................... 16

4.5.1 Facing the Pipe Butts ........................................................................................ 16

4.5.2 Checking Pipe Alignment................................................................................. 16

4.5.3 Possibility to Change Welding Parameters...................................................... 17

4.5.4 Inserting and Monitoring the Heating Element ............................................. 17

4.5.5 Bead Build-up Stage ......................................................................................... 17

4.5.6 Heating Stage.................................................................................................... 18

4.5.7 Change-over Stage............................................................................................ 18

4.5.8 Joining and Cooling Stage ............................................................................... 18

4.5.9 End of Welding ................................................................................................. 18

4.5.10 Printing Label Tags............................................................................................ 19

4.6 Displaying Characteristics of the Welding System .......................................... 19

4.7 Using ViewWeld to Manage Logged Welding Reports and Print Tags ......... 19

4.8 Aborted Welding Process ................................................................................. 20

5 Downloading Welding Reports........................................................................ 21

5.1 Selecting the Reports to Download................................................................. 21

5.2 Saving the Reports to a Storage Media........................................................... 21

5.3 Deleting Data in Memory................................................................................. 22

5.4 Keeping Data in Memory ................................................................................. 22

6 Service and Repair............................................................................................. 22

7 Service and Repair Contact............................................................................... 22

8 Accessories/Parts for the Product..................................................................... 23