5.1.1 External Input Specifications................................................................................. 46

5.1.2 External Output Specifications.............................................................................. 47

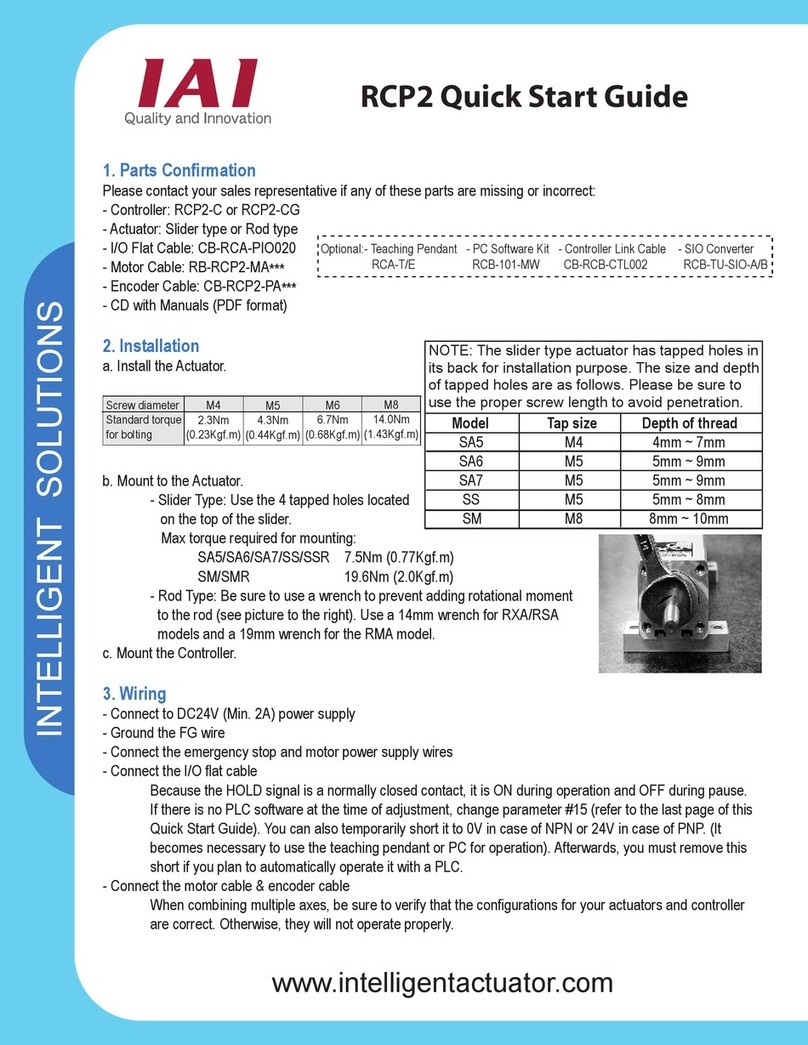

5.2 PIO Patterns and Signal Assignments ...................................................................................... 48

5.2.1 Explanation of Signal Names................................................................................ 49

zPIO pattern = 0 [Positioning mode (Standard type)] ............................................................ 49

zPIO pattern = 1 [Teaching mode (Teaching type)]............................................................... 50

zPIO pattern = 2 [256-point mode (256-point type)] .............................................................. 51

zPIO pattern = 3 [512-point mode (512-point type)] .............................................................. 52

zPIO pattern = 4 [Solenoid valve mode 1 (7-point type)] ....................................................... 53

zPIO pattern = 5 [Solenoid valve mode 2 (3-point type)] ....................................................... 54

5.2.2 Signal Assignment Table for Respective PIO Patterns ......................................... 55

5.3 Details of I/O Signal Functions ..................................................................................................56

5.3.1. Details of Each Input Signal.................................................................................. 56

Operating mode (RMOD) ..................................................................................................... 56

Start (CSTR)......................................................................................................................... 56

Command position number (PC1 to PC256)........................................................................ 57

Pause (*STP)........................................................................................................................ 57

Home return (HOME) ........................................................................................................... 57

Servo ON (SON)................................................................................................................... 57

Alarm reset (RES) ................................................................................................................ 58

Brake release (BKRL) .......................................................................................................... 58

Operation mode (MODE) ..................................................................................................... 58

Current-position write (PWRT) ............................................................................................. 58

Manual operation switching (JISL) ....................................................................................... 58

Jog (JOG+, JOG-) ................................................................................................................59

Direct position command (ST0 to ST6) [Solenoid valve mode 1 (7-point type)] .................. 59

Movement to each position (ST0 to ST2) [Solenoid valve mode 2 (3-point type)]............... 60

5.3.2 Details of Each Output Signal............................................................................... 61

Operating mode status (RMDS) ........................................................................................... 61

Completed position number (PM1 to PM256) ...................................................................... 61

Moving (MOVE)....................................................................................................................61

Position complete (PEND).................................................................................................... 61

Home return completion (HEND) ......................................................................................... 62

Zone (ZONE1, ZONE2)........................................................................................................ 62

Current operation mode (MODES)....................................................................................... 62

Write completion (WEND) .................................................................................................... 62

Movement complete at each position (PE0 to PE6) [Solenoid valve mode 1 (7-point type)]63

Position detection output at each position (LS0 to LS2) [Solenoid valve mode 2 (3-point

type)]..................................................................................................................................... 63

Ready (SV) ........................................................................................................................... 63

Alarm (*ALM) ........................................................................................................................ 63

Torque level status (TRQS).................................................................................................. 63

Emergency stop (*EMGS) .................................................................................................... 64

Output Signal Changes in Each Mode ................................................................................. 64

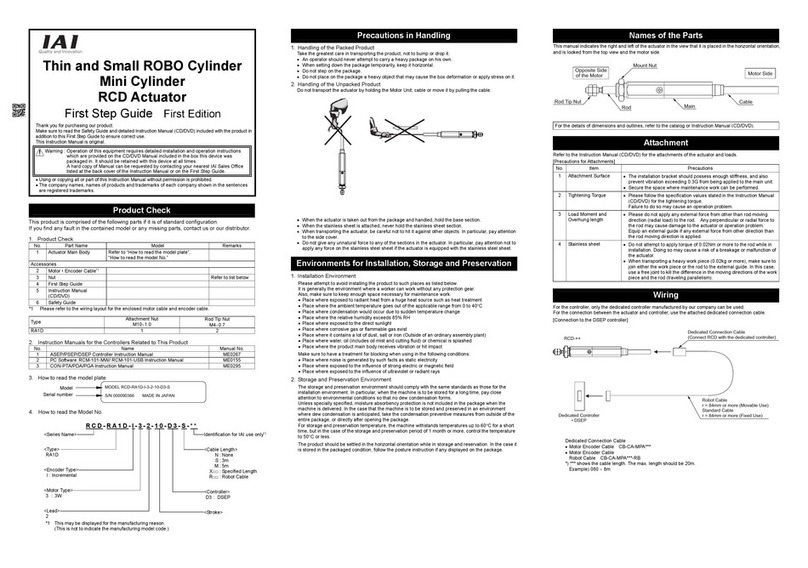

4.4 Connecting the Actuator ............................................................................................................ 43

4.4.1 Wiring the ACON-C/CG and Actuator ................................................................... 43

4.5 Connecting the Communication Cable...................................................................................... 45

5. I/O Signal Control and Signal Functions.................................................................. 46

5.1 Interface Circuit ......................................................................................................................... 46