Table of Contents

Safety Guide ···································································································· 1

Precautions in Operation ···················································································· 8

1. Outline of Extension Motion Control Feature................................................................9

1.1. Supportive Operations...............................................................................................10

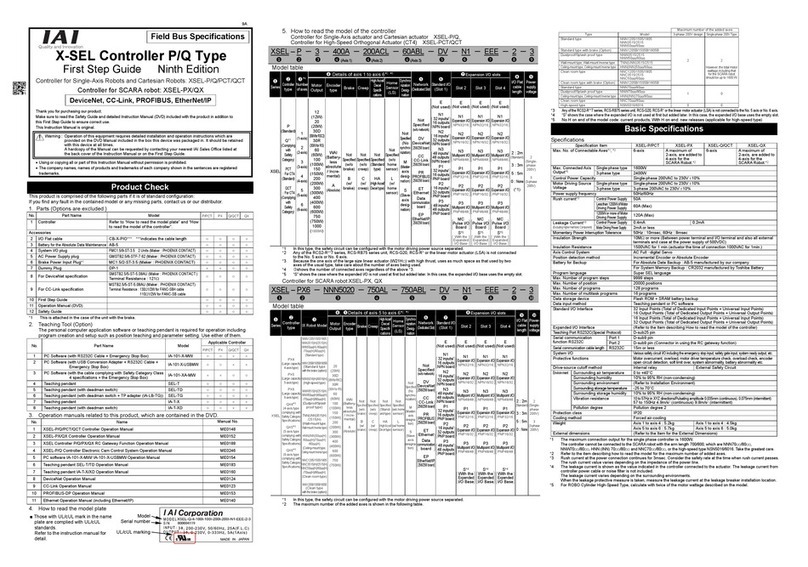

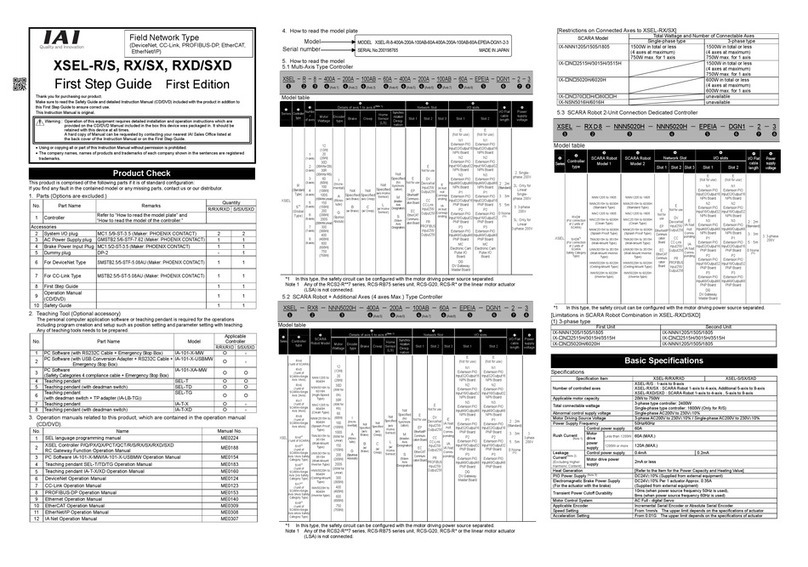

1.2. Basic Specifications...................................................................................................12

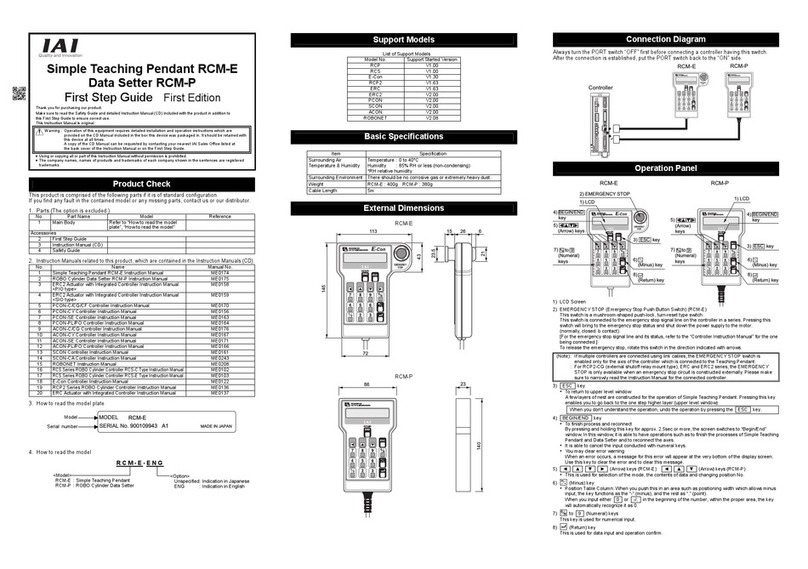

1.3. Teaching Tools and Instruction Manuals....................................................................13

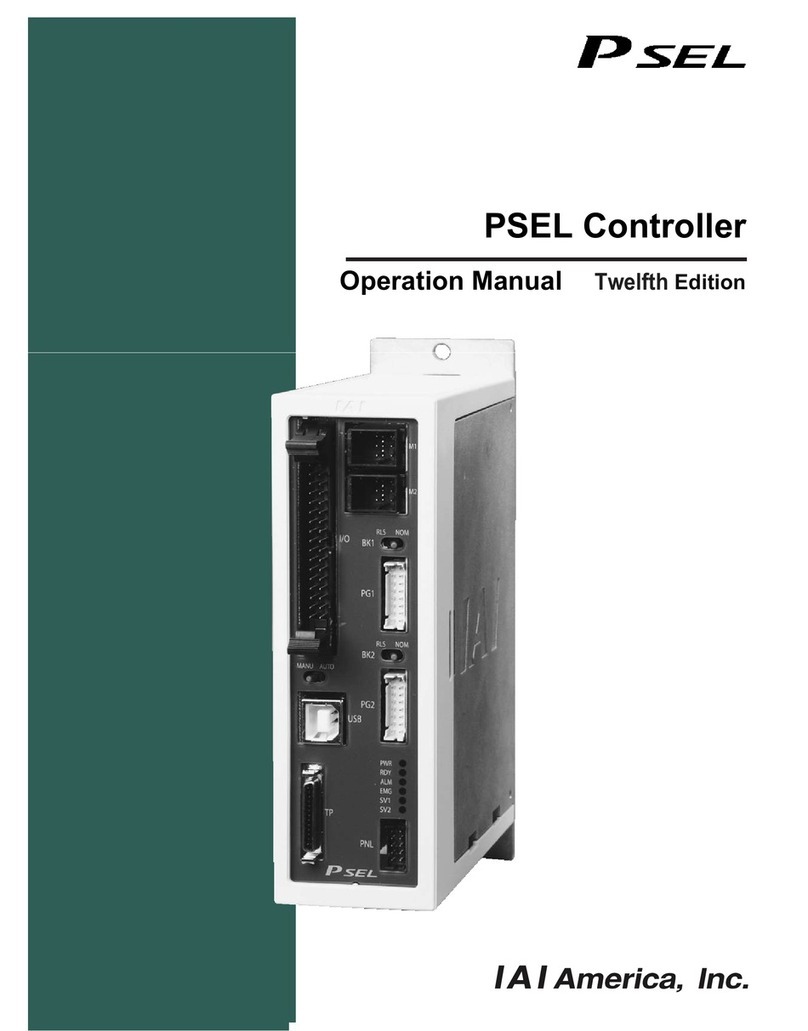

2. Installation and Wiring ................................................................................................15

2.1. Starting Procedures ...................................................................................................15

2.2. Name and Function of Each Part Related to Extension Motion Control Feature .......16

2.3. Example for Emergency Stop System Construction ..................................................17

2.4. Cable Layout .............................................................................................................18

3. Basic Settings.............................................................................................................19

3.1. Check Items before Starting Setup............................................................................19

3.2. How to Set Up ...........................................................................................................22

3.3. RC Controller Settings...............................................................................................23

3.4. Setup of XSEL (Functions in Common).....................................................................24

3.5. Setup of XSEL (for Each Axis)...................................................................................27

3.6. Operation Check .......................................................................................................30

4. Operation Program .....................................................................................................33

4.1. Support Function .......................................................................................................33

4.2. Positioner Function....................................................................................................34

4.2.1. Position Data Count............................................................................................. 34

4.2.2. Editing the Position Data ..................................................................................... 34

4.2.3. Positioning Completion........................................................................................ 36

4.2.4. Actuator Control Commands ............................................................................... 37

4.3. Electronic Shaft .........................................................................................................38

4.4. Electronic CAM..........................................................................................................39

4.4.1. Combination of Master Axes and Slave Axes ..................................................... 41

4.4.2. Synchronized Electronic CAM Operation............................................................ 43

4.4.3. Independent Electronic CAM (virtual master) Operation .................................... 47

4.4.4. Reciprocal Movement and Feed Movement ....................................................... 48

4.4.5. Editing of Electronic CAM Data ........................................................................... 50

4.4.6. CAM Curve Types ............................................................................................... 59

4.5. SEL Commands Used in Extension Motion Control Features ...................................64

4.5.1. List of SEL Commands in Extension Motion Control Features ........................... 64

4.5.2. Relation of Other SEL Commands with Extension Motion Control Features...... 66

4.5.3. Extension Motion Control Axis Position Operation Commands .......................... 68

4.5.4. Extension Motion Control Axis Actuator Control Declaration Command............. 75

4.5.5 Extension Motion Control Axis Actuator Control Command................................ 79

4.5.6. Extension Motion Control Axis Status Acquisition Commands.......................... 104

4.6. Sample Programs....................................................................................................106

4.6.1. Positioning Using Position Data ........................................................................ 106

4.6.2. Electronic Shaft Synchronizing Operation......................................................... 107

4.6.3. Electronic Cam Synchronizing Operation ......................................................... 108

4.7. Sample Programs....................................................................................................109

4.7.1. Pausing.............................................................................................................. 109

4.7.2. Synchronous Movement.................................................................................... 109

4.7.3. Others.................................................................................................................110