Table of Contents

1. Foreword.................................................................................................................................................... 1

2. Before You Begin....................................................................................................................................... 1

3. Safety Precautions ................................................................................................................................... 2

4. Warranty and Scope of Warranty ............................................................................................................... 3

5. Application Environment ............................................................................................................................ 4

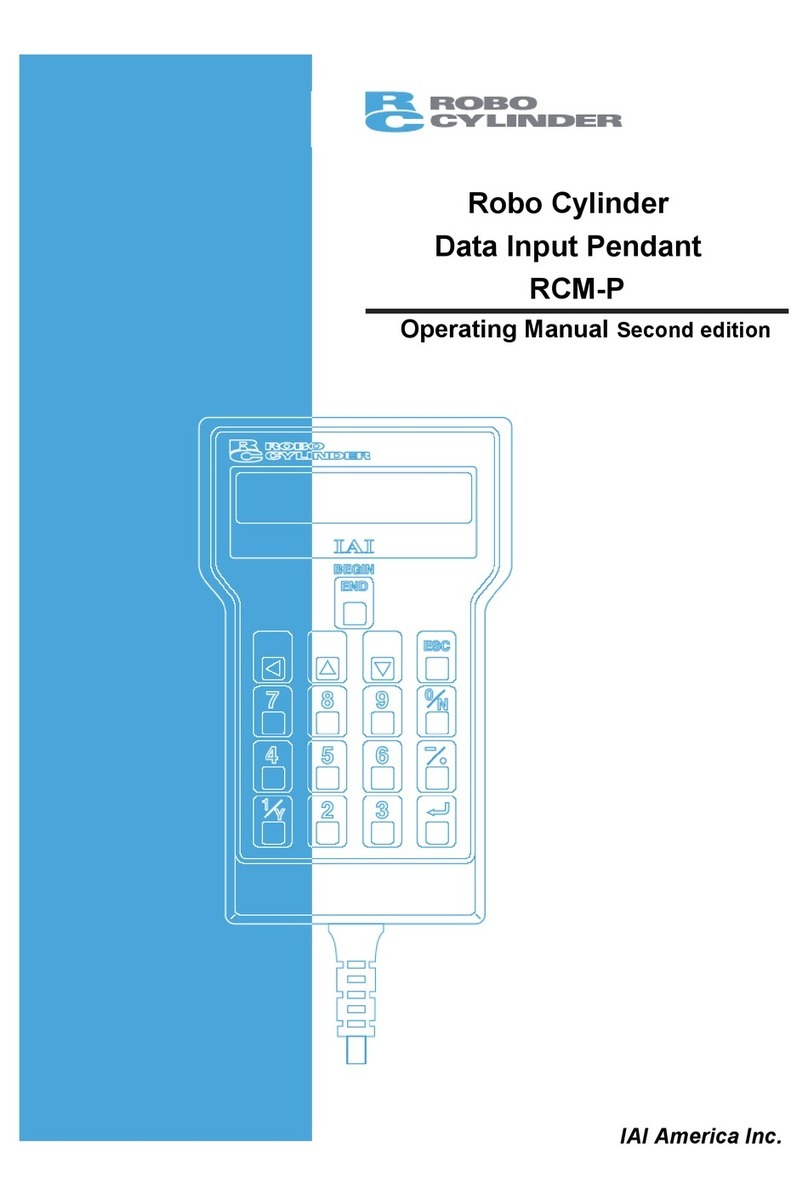

6. Functions and Specifications of Teaching Pendant ................................................................................... 5

6-1 Specifications ................................................................................................................................ 5

6-2 External View ................................................................................................................................ 6

6-3 Description of Each Part................................................................................................................ 7

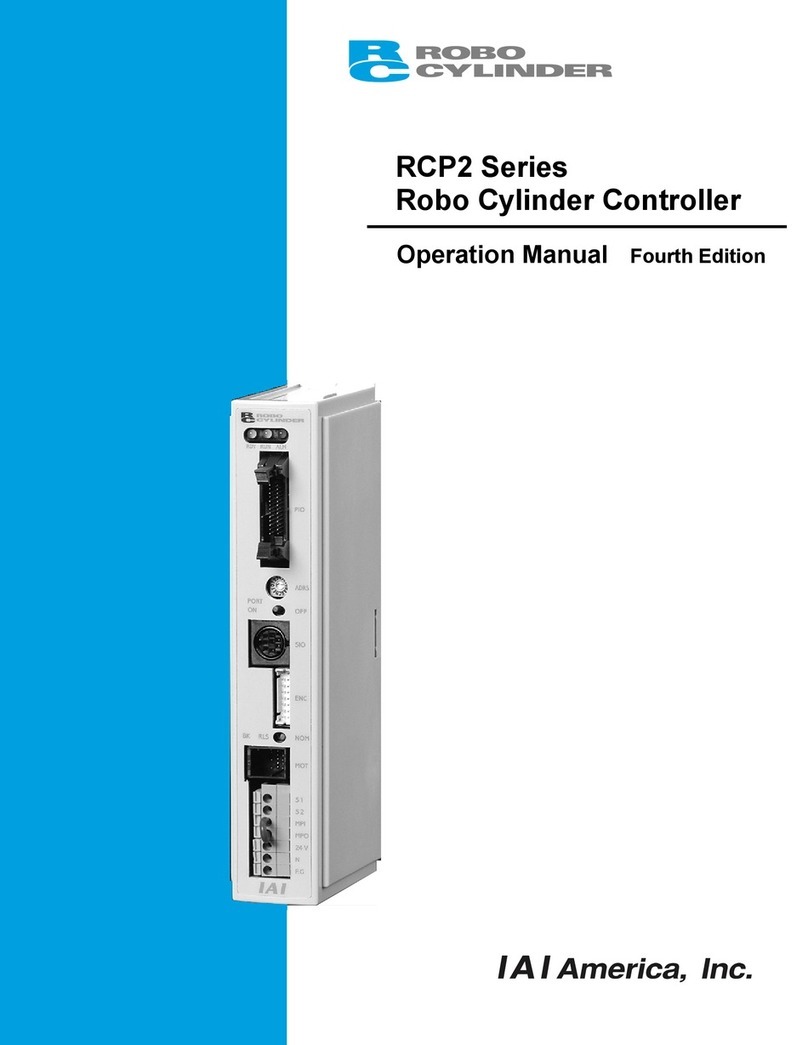

7. Connection With the Controller ................................................................................................................ 11

7-1 Connection with the Teaching Pendant....................................................................................... 11

7-2 How to Disengage the Teaching Pendant ................................................................................... 11

8. Operation: Mode Flow Chart .................................................................................................................... 12

8-1 Initial Screen and TP Operation Mode Screen During Power – UP............................................. 14

8-2 Controller Selection (when using multiple units).......................................................................... 16

8-3 Operation Mode Selection ........................................................................................................... 17

8-3-1 Positioner (PCON-PL/PO, ACON-PL/PO, or SCON: Mode Other than Pulse Train Mode)......... 17

8-3-2 Pulse Train (PCON-PL/PO, ACON-PL/PO, or SCON: Pulse Train Mode) .................................. 18

8-4 Edit/Teaching .............................................................................................................................. 19

8-4-1 PCON, ACON, SCON, or ERC2.................................................................................................. 19

8-4-2 RCP, RCS, E-Con, RCP2, or ERC.............................................................................................. 21

8-5 Position Data Table Contents...................................................................................................... 23

8-5-1 Position Data Table Contents for PCON, ACON, SCON, and ERC2 .......................................... 23

8-5-2 Position Data Table Contents for RCP, RCS, E-Con, RCP2,and ERC ....................................... 29

8-5-3 Data New Input............................................................................................................................ 31

8-5-4 Data Modification......................................................................................................................... 56

8-5-5 Clear • All Clear ........................................................................................................................... 56

8-5-6 Move ........................................................................................................................................... 61

8-5-7 Servo ON/OFF ............................................................................................................................ 68

8-5-8 Pulse Train (PCON-PL/PO, ACON-PL/PO, SCON: Pulse Train Mode) Based Jogging.............. 70

8-6 Monitor ........................................................................................................................................ 72

8-7 Error List...................................................................................................................................... 75