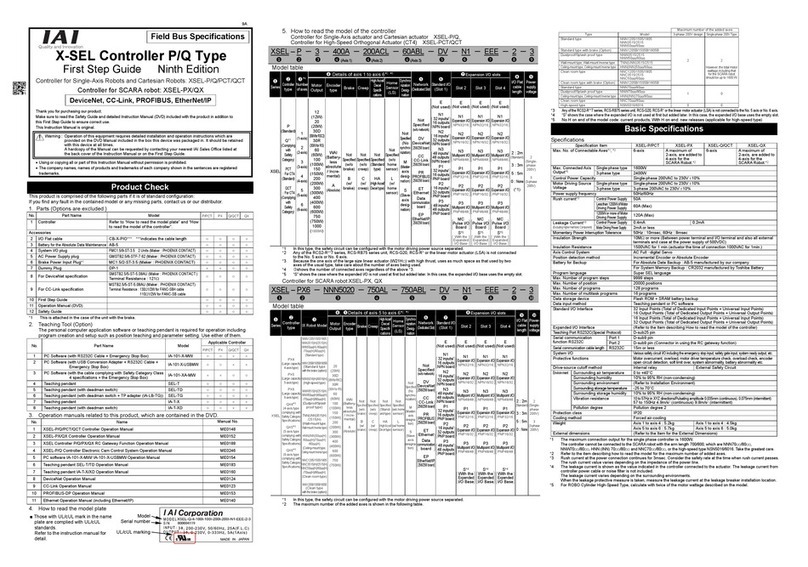

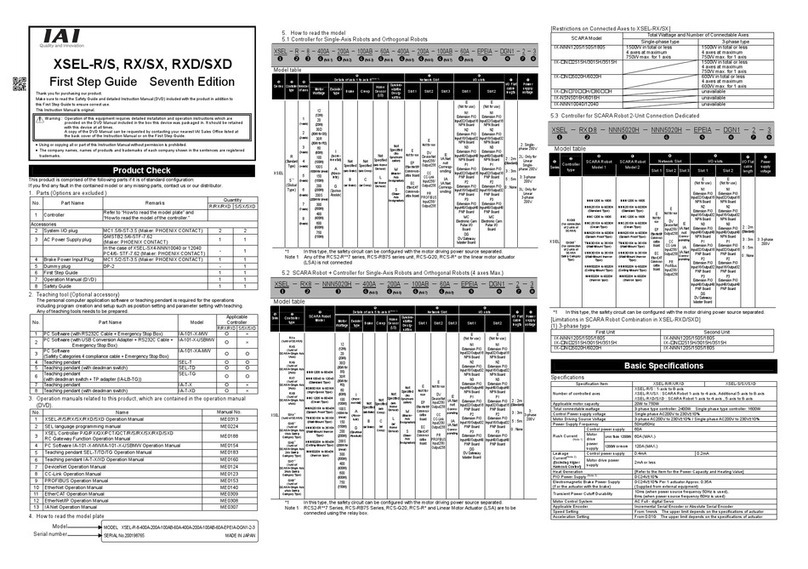

Specification Item XSEL-R/RX/RXD XSEL-S/SX/SXD

Teaching port RS232C: 1CH (X-SEL Serial Communication protocol (Format B))

Baud rate : MAX. 115.2kbps Connector: D-sub 25 pin

Port 1

RS232C: 1CH (X-SEL Serial Communication protocol (Format B))

Baud rate: MAX. 115.2kbps Connector: D-sub 9 pin

Control available with serial communication (Cable length Max.10m)

[General-purpose RS232C]

RS232C: 1CH (X-SEL Serial Communication protocol (Format B))

Baud rate: MAX. 115.2kbps Connector: D-sub 9 pin

Control available with serial communication (Cable length Max.10m)

Serial

Communication

Interface

Port 2 [RC Gateway]

RS485: 1CH (Modbus protocol RTU/ASCII conformance)

Baud rate: MAX. 230.4kbps Connector: D-sub 9 pin

Control available with serial communication (Cable length Max.100m)

PIO Type

PIO Board MAX. 2 pieces

Signal I/O dedicated for 24V DC (Input and output ports, selected from

NPN/PNP) [Refer to 5. How to read controller model code]

External

Interface

Field Network Type

DeviceNet, CC-Link, PROFIBUS, EtherNet/IP, EtherCAT

(For either of DeviceNet, CC-Link or PROFIBUS and either of EtherNet/IP or

EtherCAT, the boards can be inserted at the same time.)

[Refer to each Fieldbus Instruction Manual]

Expanded I/O Unit (option) PIO Board MAX. 4 pieces

Data Setting and Input PC software or teaching pendant

Program Specification Super SEL language

Max. Number of Program Steps 9999 Step

Max. Number of Positions

1-Axis Type: 53332 positions, 5-Axis Type: 22856 positions

2-Axis Type: 40000 positions, 6-Axis Type: 20000 positions

3-Axis Type: 32000 positions, 7-Axis Type: 17776 positions

4-Axis Type: 26666 positions, 8-Axis Type: 16000 positions

Max. Number of Programs 128 programs

Max. Number of Multitask Programs 16 programs

Data Retention Memory Flash ROM + FRAM

Clock Function

Retaining time after power turned OFF: approximately 10 days

Time for battery charge after power is ON after the clock data is lost:

approximately 100 hours

Panel Unit PU-1 (option) Controller status display

System I/O Emergency stop input, safety gate input, system ready output and other safety

circuit inputs and outputs

Drive-source Cutoff Method Internal Relay External Safety Circuit

Emergency-Stop Input B Contact Input

(internal power supply)

B Contact Input (external power supply,

duplication available)

Safety Circuit

Configuration

Enable Input B Contact Input

(internal power supply)

B Contact Input (external power supply,

duplication available)

System Ready Output No-voltage contact (relay) output Max.200mA (24V DC)

Protective Functions

Motor over current, overload, motor driver temperature check, overload check,

encoder open circuit detection, soft limit over, system abnormality, battery

abnormality

Regenerative Resistor Equipped with built-in 1kΩ/20W regenerative resistor

Extension available with connecting an external regenerative resistor

Absolute Battery Actuators except for SCARA Robot: Built in controller (AB-5)

SCARA Robot: Built in main body

Protection Function against Electric Shock Class I In case grounding conducted on ground terminal in addition to basic

insulation for electric shock proof.

Overvoltage Category Category II Voltage durability 2500V at less than 300V AC for input rating

Insulation Resistance 10MΩor more (Between power terminal and I/O terminal and also all external

terminals and case at the power supply of 500V DC)

Insulation strength 1500V AC for 1 min.

Cooling Method Forced Air-Cooling

Surrounding air temperature 0 to +40°C

Surrounding humidity 85% RH or less (non-condensing)

Surrounding environment [Refer to the Item for the Installation Environment]

Surrounding storage

temperature -20 to 70°C (The Absolute Battery is excluded.)

Surrounding storage humidity 85% RH or less (non-condensing)

Maximum Operation Height 1000m

Vibration Resistance

10 to 57Hz in XYZ directions/Pulsating amplitude 0.035mm (continuous),

0.075mm (intermittent) 57 to 150Hz/4.9m/s² (continuous),

9.8m/s² (intermittent)

Protection Class IP20

Environment

Pollution Degree Pollution Degree 2

External Dimensions [Refer to the External dimensions]

With no Absolute Battery Unit Approx. 5.2kg 3-phase type: Approx. 4.7kg

Single-phase type: Approx. 5.2kg

Weight

With the Absolute Battery Unit Approx. 5.8kg 3-phase type: Approx. 5.3kg

Single-phase type: Approx. 5.8kg

Note 1 Rush current at the power connection continues for 3 msec. Note that the value of in-rush current differs

depending on the impedance of the power supply line.

Note 2 Leak current varies depending on the capacity of connected motor, cable length and the surrounding environment.

Measure the leak current at the point where a ground fault circuit interrupter is to be installed when leakage

protection is conducted.

Regarding the leakage breaker, it is necessary to have a clear purpose for selection such as a fire protection or

protection of human body. Use the harmonic type (for inverter) for a leakage breaker.

Note 3 Power supply is not necessary if PIO is not to be used.

Note 4 The converter box is to be used for the connection when connecting an actuator of ABZ (UVW) Parallel Encoder

LSA Series or RCS2-RA7/SRA7 Series.

[Power Capacity and Heating Value]

Rated Power Capacity [VA] = Total Capacity of Motor Power [VA] + Total of the power consumption at the control part [VA]

Heating Value [W] = Total Output Loss [W] + (Total of internal power consumption [VA] × 0.7 (Efficiency) × 0.6 (Power

factor))

•Select the Motor Driving Power [VA] from the Table 1 and 2.

•Figure out the total of the power consumption at the control part [VA] with the total of power of the actually mounted

components • quantity, by selecting the applicable ones from Table 3 Control Power Source (Internal Consumption

and External Consumption).

•To calculate the sum total of output loss [W], refer to the “Output Loss” column in Table 1 below and select the values

corresponding to the output losses of each connected actuator.

•For the inner power demand (VA) for calculating the heating value (W) in the control unit, select the components

which are being placed, from the columns of Control Power Supply (Internal Consumption) and External Power

Supply (Internal Consumption) in Table 3 and calculate it using the formula “Power • Quantity of the Placement

Component”

Table: 1 Motor Volt Amperage of Single-Axis Actuator and Output Loss

Wattage of Actuator Motor [W] Motor Power Capacity [VA] Output loss = Heat Generation [W]

20 26 1.58

30 46 2.07

60 138 3.39

100 234 6.12

150 328 8.30

200 421 9.12

40 796 19.76

600 1164 27.20

750 1521 29.77

100 (Linear Actuator LSAS-N10SS) 379 37

200 (Linear Actuator LSAS-N15SS) 486 37

200 (Linear Actuator LSAS-N15HS) 773 39

Table: 2 Motor Volt Amperage of SCARA Robot and Output Loss

SCARA Robot Wattage [W]

(Rated output)

Motor Power Capacity

[VA]

(Note 1)

Output loss =

Heat Generation

[W]

NN1205, NN1505, NN1805 129.8 216.3 8.13

NN2515H, NN3515H, TNN3015H,

TNN3515H, UNN3015H, UNN3515H 1117.9 1863.1 44.8

NN50H, NN60H,

HNN5020H, HNN6020H,

INN5020H, INN6020H

2218.0 3696.7 69.7

NN70H, NN60H,

HNN7020H, HNN8020H,

INN7020H, INN8020H

3880.6 6467.7 93.2

NSN5016H, NSN6016H 4102.9 6338.1 95.2

Note 1 Calculated with 0.6 for power factor

Table: 3 Motor Driving Power and Output Loss

Control power supply External Power Source

(24VDC)

Internal

Consumption

[VA]

External

Consumptio

[VA]

Internal

Consumption

[VA]

External

Consumption

[VA]

Quantity

Base Unit 31.4 1

Driver Per Board 6.26

Encoder

Section Per axis 2.38 3.57

Fan Unit Per fan 5.71

Axis Sensor Per axis 4.57

Multiply the coefficient

[Refer to Table 4] on the

values on the left for each

number of the connected

axes.

DIO (48 points) N1, N2

P1, P2 5.95 14.52 0 to 2

DIO (96 points) N3, P3 8.33 26.81 0 to 2

I/O Board

Electronic Cam MC 16.7 0 to 2

Number of PCBs

on PIO Board 1

and 2

DeviceNet DV 1.98 3.43 0 to 1

CC-Link CC 5.67 0 to 1

PROFIBUS-DP PR 1.98 0 to 1

Number of PCBs

on Field Network

Board 1

EtherNet/IP EP 1.98 0 to 1

Network

Module

EtherCAT EC 3.93 0 to 1

Number of PCBs

on Field Network

Board 2

IA-T-X/XD 3.57 0 to 1Teaching

pendant SEL-T/TD/TG 6.67 0 to 1

SCARA

Robot

0.28

SCARA

Robot

1.0

Brake Per axis

Added Axis

0.14

2.5

Added Axis

5.8

Total number of brake-

equipped actuators 0 to 8

Connector

terminal Per axis 5.7 0 to 8

Table: 4 Number of Controlled Parts

Number of the connected axes. 1-Axis 2-Axis 3-Axis 4-Axis 5-Axis 6-Axis 7-Axis 8-Axis

Driver 1 1 2 2 3 3 4 4

Encoder Section 1 2 3 4 5 6 7 8

Fan Unit

XSEL-R/RX/RXD : 6 Unit

XSEL-S/SX/SXD (3-phase type) : 5 Unit

XSEL-S (Single-phase type) : 6 Unit

Axis Sensor 1 2 3 4 5 6 7 8

[Selection of Circuit Interrupter]

•3 times of the rated current flows to the controller during the acceleration/deceleration. Select one that does

not trip when the above current passes. When it trips, select the breaker with a rated current one rank

above. (Confirm that Operation Characteristic Curve described in the catalogue of each manufacturer.)

•Select the breaker that does not trip with the rush current.

(Confirm that Operation Characteristic Curve described in the catalogue of each manufacturer.)

•For the rated breaking current, select the current value which can break the current even when a short

circuit occurs.

Rated Breaking Current > Short-circuit Current = Primary Power Supply Capacity / Power Voltage

•Consider margin for the rated current on the circuit breaker.

Rated current of circuit breaker >

rated voltage amperage [VA] / AC input voltage × Margin (1.2 to 1.4 for reference)

[Selection of Leakage Breaker]

•Regarding the leakage breaker, it is necessary to have a clear purpose for selection such as a fire

protection or protection of human body.

•Leak current varies depending on the capacity of connected motor, cable length and the surrounding

environment. Measure the leak current at the point where a ground fault circuit interrupter is to be installed

when leakage protection is conducted.

•Use the applicable to higher harmonics type leakage breaker.

External Dimensions

Controller

Type

R/RX/RXD

S (Single-phase type)

S/SX/SXD

(3-phase type) Side View

Absolute

Battery

Non-

Equipped

Type

Absolute

Battery

Equipped

Type

(80)

125.3

3

Brake Box (Option): RCB-110-RA13-0

Brake Box: A brake release unit dedicated for NS-MZMS, NS-MZMM, NS-LZMS, NS-LZMM, ZR

Brakes for two axes can be controlled with one brake box.

[Specification] [External Dimensions]

Item Specification

Input Power Supply Voltage 24V DC/10%

Input Power Supply Current 1A

Heat Generation 1.2W

Connection Cable Encoder Cables

(Model CB-RCS2-PLA010) 1m

Environment Follows the environmental specifications

of the main body

External Dimensions W162 × H94 × D65.5mm

Weight

0.8kg

[24V Power Supply Connector]

Connector on

Cable Side

(Enclosed in

standard package)

MC1.5/2-STF-3.5 (PHOENIX CONTACT)

Applicable Cable AWG28 to 16

Pin No. Signal Information

1 0V

Power Supply Grounding for

Brake Excitation

Terminal

Assignment

2

24VIN

For Brake Excitation and

24V Power Supply

[Connectors 1 and 2 for external brake release switch connection]

Connected

Equipment Brake Release Switch

Connector on

Cable Side

(

Please prepare

separately

)

XAP-02V-1

(Contact BXA-001T-P0.6)(JST)

Switch Rating 30V DC Minimum Current 1.5mA

Pin No. Signal Information

1

BKMRL

Brake Release Switch Input

Terminal

Assignment 2 COM

Power Supply Output for Brake

Release Switch Input

(Note) Short circuit of pin No. 1 and 2 of this connector releases the brake compulsorily.

Brake release is available in the same manner as the brake release switch equipped on the main

body.

Do not keep the compulsory release condition while in automatic operation.

Regenerative Resistor Unit (Option): REU-1

This is a unit that converts the regenerative current to heat when the motor decelerates.

[Specification] [External Dimensions]

Item Specification

Internal Regenerative Resistor 220Ω/80W

Accessories

*1

Controller link cable

(Model CB-ST-REU010) 1m

Environment Follows the environmental

specifications of the main body

External Dimensions W34 × H195 × D126mm

Weight 0.9kg

[Number of Connectable]

To calculate the total number of necessary units, select the suitable conditions from the table below for the

actuator type connected to XSEL controller and sum up the numbers.

Total Number of Connected Units = Number in 1) + Number in 2) + Number in 3)