Safety precautions

The safety precautions pertaining to this product are listed below.

NO. Task Precautions

1 Model selection zThis product is not planned or designed for uses requiring high degrees of safety.

Accordingly, it cannot be used to sustain or support life and must not be used in the

following applications:

[1] Medical devices relating to maintenance, management, etc., of life or health

[2] Mechanisms or mechanical devices (vehicles, railway facilities, aircraft facilities, etc.)

intended to move or transport people

[3] Important safety parts in mechanical devices (safety devices, etc.)

zDo not use this product in the following environments:

[1] Place subject to flammable gases, ignitable objects, flammables, explosives, etc.

[2] Place that may be exposed to radiation

[3] Place where the surrounding air temperature or relative humidity exceeds the specified

range

[4] Place subject to direct sunlight or radiated heat from large heat sources

[5] Place subject to sudden temperature shift and the formation of moisture.

[6] Place subject to corrosive gases (sulfuric acid, hydrochloric acid, etc.)

[7] Place subject to excessive dust, salt or iron powder

[8] Place where the product receives direct vibration or impact

zDo not use this product outside the specified ranges. Doing so may significantly shorten the

life of the product or result in product failure or facility stoppage.

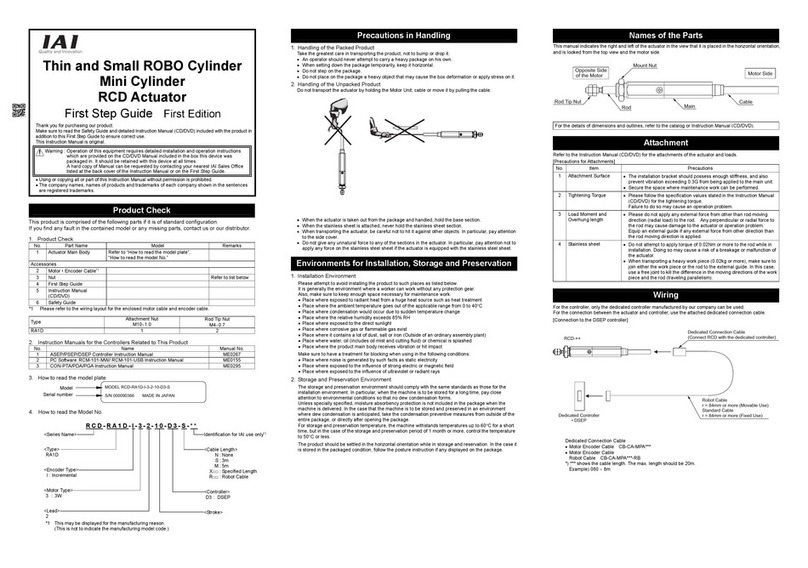

2 Transportation zWhen transporting the product, exercise due caution not to bump or drop the product.

zUse appropriate means for transportation.

zDo not step on the package.

zDo not place on the package any heavy article that may deform the package.

zWhen using a crane capable of 1t or more of weight, have an operator who has

qualifications for crane operation and sling work.

zWhen using a crane or equivalent equipments, make sure not to hang a load that weighs

more than the equipment’s limit.

zUse a hook that suits for the load. Consider the safety factor of the hook in such factors as

shear strength.

zDo not get on the load that is hanged on a crane.

zDo not leave a load hanged up with a crane.

zDo not stand under the load that is hanged up with a crane.

3 Storage and

Preservation zThe storage and preservation environment should conform to the installation environments.

Among others, be careful not to cause the formation of moisture.

(1) Installing the robot, controller, etc.

zBe sure to firmly secure and affix the product (including its loads).

If the product tips over, drops, malfunctions, etc., damage or injury may result.

zDo not step on the product or place any article on top. The product may tip over or the

article may drop, resulting in injury, product damage, loss of/drop in product function,

shorter life, etc.

zIf the product is used in any of the following places, provide sufficient shielding measures:

[1] Place subject to electrical noise

[2] Place subject to a strong electric or magnetic field

[3] Place where power lines or drive lines are wired nearby

[4] Place subject to splashed water, oil or chemicals

4 Installation/startup

(2) Wiring the cables

zUse IAI’s genuine cables to connect the actuator and controller or connect a teaching tool,

etc.

zDo not damage, forcibly bend, pull, loop around an object or pinch the cables or place

heavy articles on top. Current leak or poor electrical continuity may occur, resulting in fire,

electric shock or malfunction.

zWire the product correctly after turning off the power.

zWhen wiring a DC power supply (+24 V), pay attention to the positive and negative

polarities.

Connecting the wires in wrong polarities may result in fire, product failure or malfunction.